Abstract

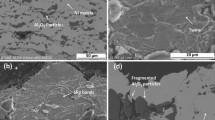

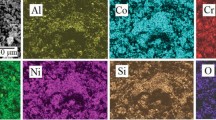

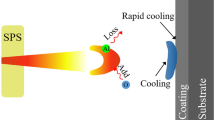

Nanostructural Al2O3 coatings were formed on a steel substrate surface using a multichamber detonation sprayer. The Al2O3 coatings were characterized by a dense microstructure with porosity below 1% and hardness of 1300 ± 25 HV0.3. The transition layer between the coating and substrate was up to 15 μm thick, containing Fe-Al-type intermetallic compounds (FeAl3, Fe2Al5). Postdeposition heat treatment of the samples at 850 °C for 3 h was carried out in air and argon environments. The effect of heat treatment on the microstructure and microhardness of the Al2O3 coatings was investigated by optical microscopy, scanning and transmission electron microscopy, scanning probe microscopy, x-ray phase analysis, and Vickers hardness testing. A positive impact of postcoating heat treatment on the coating microstructure and microhardness was observed. Heat treatment resulted in an increase in the coating hardness from 1300, to 1350 ± 25 HV0.3 and 1600 ± 25 HV0.3 after annealing in air and argon, respectively. Heat treatment in argon led to a more significant increase in the α-Al2O3 phase from 47 to 81%.

Similar content being viewed by others

References

R.B. Heimann, Applications of Plasma-Sprayed Ceramic Coatings, Key Eng. Mater., 2006, 122-124, p 399-442

L. Pawlowski, Strategic Oxides for Thermal Spraying: Problems of Availability and Evolution of Prices, Surf. Coat. Technol., 2013, 220, p 14-19

D.H. Trinh, K. Back, G. Pozina, H. Blomqvist, T. Selinder, M. Collin, I. Reineck, L. Hultman, and H. Högberg, Phase Transformation in Kappa- and Gamma-Al2O3 Coatings on Cutting Tool Inserts, Surf. Coat. Technol., 2009, 203, p 1682-1688

C.-J. Li and A. Ohmori, Relationship Between the Structure and Properties of Thermally Sprayed Coatings, J. Therm. Spray Technol., 2002, 11(3), p 365-374

C.-J. Li, A. Ohmori, and R. McPherson, The Relationship Between Microstructure and Young’s Modulus of Thermally Sprayed Ceramic Coatings, J. Mater. Sci., 1997, 32, p 997-1004

A. Ohmori and C.-J. Li, Quantitative Characterization of the Structure of Plasma Sprayed Al2O3 Coating by Using Copper Electroplating, Thin Solid Films, 1991, 201, p 241-252

C.-J. Li and W.-Z. Wang, Quantitative Characterization of Lamellar Microstructure of Plasma-Sprayed Ceramic Coatings through Visualization of Void Distribution, Mater. Sci. Eng. A, 2004, 386(1-2), p 10-19

L. Pawlowski, Quality Improvement of Coating by a Prespray and Postspray Process, J. Therm. Spray Technol., 1998, 7, p 3-6

L. Pawlowski, The Science and Engineering of Thermal Spray Coatings, Wiley, New York, 1995, p 193-203

V.S. Thompson and O.J. Whittemore, Structural Changes on Reheating Plasma-Sprayed Alumina, Ceram. Bull., 1968, 47, p 637-641

P.K. Ghosh, Ram, and Neki, Characteristics of Heat Treated Tungsten Carbide Embedded Nickel Base Hard Surfacing on Structural Steel Produced by Gas Thermal Spray Process, Int. J. Joining Mater., 1997, 9(3), p 114-121

K.A. Khor and N.L. Loh, Hot Isostatic Pressing of Plasma Sprayed Ni-Base Alloys, J. Therm. Spray Technol., 1994, 3(1), p 57-62

G. Sridhar, S. Ghosh Chowdhury, and N.G. Goswami, Materials Characterization Techniques–Principles and Applications, 1999, p 163-176

Standard Methods of Preparing Metallographic Specimens, E-3-86, Annual Book of ASTM Standards, American Society for Metals, Vol 03.01, 1986, 12 p

N. Vasilik, N. Tyurin, and O. Kolisnichenko, Gas-Dynamic Detonation Method of Acceleration of Powders and Device for Its Implementation, Application for RU Patent 2,012,129,061, 2012

M. Kovaleva, Yu Tyurin, O. Kolisnichenko, M. Prozorova, and M. Arseenko, Properties of Detonation Nanostructured Titanium-Based Coatings, J. Therm. Spray Technol., 2013, 22(4), p 518-524

M. Arseenko, M. Kovaleva, Yu. Tyurin, M. Prozorova, and I. Pavlenko, Influence of Heat Treatment on the Microstructure and Phase Compositions of Detonation Nanostructured Alumina Coatings, NANOCON 2013 (Brno, Czech Republic), October 16-18, 2013, www.nanocon.eu

J. Chipman, Thermodynamics and Phase Diagram of the Fe-C System, Metall. Trans., 1972, 3(1), p 55-64

A. Kostov, B. Friedrich, and D. Živković, Thermodynamic Calculations in Alloys Ti-Al, Ti-Fe, Al-Fe and Ti-Al-Fe, J. Min. Metall. Sect. B, 2008, 44(1), p 49-61

G.J. Moskal, The Porosity Assessment of Thermal Barrier Coatings Obtained by APS Method, Achieve. Mater. Manuf. Eng., 2007, 20(1-2), p 483-486

C. Li and W. Li, Deposition Characteristics of Titanium Coating in Cold Spraying, Surf. Coat. Technol., 2003, 167, p 278-283

Y. Gao, Y. Kang, An. Kang, and Ch. Dalian, Compound Coatings of MCrAlY and Alumina Prepared by Detonation Thermal Spraying,Thermal Spray Connects: Explore Its Surfacing Potential! ITSC 2005, E. Lugscheider, Ed., May 2-4, 2005, (Basel), ASM International, 2005, p 1403-1405

M. Kovaleva, Yu Tyurin, N. Vasilik, O. Kolisnichenko, M. Prozorova, and M. Arseenko, Deposition and Characterization of Al2O3 Coatings by Multi-Chamber Gas-Dynamic Accelerator, Surf. Coat. Technol., 2013, 232, p 719-725

H.-T. Wang, C.-J. Li, G.-J. Yang, and C.-X. Li, Effect of Heat Treatment on the Microstructure and Property of Cold-Sprayed Nanostructured FeAl/Al2O3 Intermetallic Composite Coating, Vacuum, 2009, 83, p 146-152

S.W. Wang, L.D. Chen, T. Hirai, and J. Guo, Formation of Al2O3 Grains with Different Sizes and Morphologies During the Pulse Electric Current Sintering Process, J. Mater. Res., 2001, 16(12), p 3514-3517

C.C. Stahr, S. Saaro, L.-M. Berger, J. Dubsky et al., Dependence of the Stabilization of α-Alumina on the Spray Process, J. Therm. Spray Technol., 2007, 16(5-6), p 822-830

N.N. Ault, Characteristics of Refractory Oxide Coatings Produced by Flame-Spraying, J. Am. Ceram. Soc., 1957, 40, p 69-74

H. Herman, Plasma-Sprayed Coatings, Sci. Am., 1988, 259(3), p 112-117

P. Chraska, J. Dubsky, B. Kolman, J. Ilavsky, and J. Forman, Study of Phase Changes in Plasma-Sprayed Deposits, J. Therm. Spray Technol., 1992, 1(4), p 301-306

L.A. Fisher, Variables Influencing the Characteristics of Plasma-Sprayed Coatings, Int. Met. Rev., 1972, 17, p 117-129

J. Ilavsky, C.C. Berndt, H. Herman, P. Chraska, and J. Dubsky, Alumina-Base Plasma-Sprayed Materials—Part II: Phase Transformations in Aluminas, J. Therm. Spray Technol., 1997, 6(4), p 439-444

G.D. Chukin, Cтpoeниe Oкcидa Aлюминия и Кaтaлизaтopoв Гидpooбeccepивaния. Mexaнизмы Peaкций (The Structure of Alumina and Hydrodesulfurization Catalyst. The Mechanisms of Reactions), Paladin, 2010, 288 p. (in Russian)

O. Sarikaya, Effect of the Substrate Temperature on Properties of Plasma Sprayed Al2O3 Coatings, Mater. Des., 2005, 26, p 53-57

T.C. Chou, T.G. Nieh, S.D. McAdams, and G.M. Pharr, Microstructures and Mechanical Properties of Thin Films of Aluminum Oxide, Scripta Met., 1991, 25(10), p 2203-2208

Acknowledgments

This study was supported by Grant No. MK-215.2013.8. The authors are grateful to the staff of the Joint Research Center “Diagnostics of structure and properties of nanomaterials,” Belgorod State National Research University, for their assistance with instrumental analysis.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kovaleva, M., Tyurin, Y., Vasilik, N. et al. Effect of Heat Treatment on the Microstructure and Microhardness of Nanostructural Al2O3 Coatings. J Therm Spray Tech 23, 1199–1209 (2014). https://doi.org/10.1007/s11666-014-0126-x

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-014-0126-x