Abstract

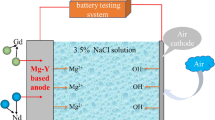

In this study, the impact of extrusion ratio (ER: 10, 16, and 25) on the electrochemical behaviors and discharge performances of Mg-3Al-2.8Y-0.7Mn (wt.%) alloys was investigated. The results indicate that an increase in extrusion ratio contributes to the homogeneous distribution of second phases and improves corrosion resistance. Notably, a higher extrusion ratio (ER25) enables the alloy anode to have the highest proportion of prismatic-oriented grains, leading to improved discharge activity and enhanced shedding of discharge products. Consequently, this alloy exhibits the highest and most stable voltage. At a current density of 20 mA cm−2, the ER25 anode demonstrates a cell voltage of 1.32 V, discharge capacity of 1170.37 mAh g−1, and anode efficiency of 53.60%. These findings underscore the influence of the extrusion ratio on microstructural features and electrochemical performance, highlighting the potential for optimizing magnesium-air battery anodes through controlled processing methods.

Similar content being viewed by others

References

H.F. Wang and Q. Xu, Materials Design for Rechargeable Metal-Air Batteries, Matter, 2019, 1(3), p 565–595.

H. Liu, Y. Yan, X. Wu, H. Fang et al., Effects of Al and Sn on Microstructure, Corrosion Behavior and Electrochemical Performance of Mg–Al-Based Anodes for Magnesium-Air Batteries, J. Alloys Compd., 2021, 859, p 157755.

F.E. Shangguan, W.L. Cheng, Y.H. Chen, H. Yu, L.F. Wang, H. Li, and J.H. Wang, Elucidating the Dependence Of Electrochemical Behavior and Discharge Performance on the Grain Structure of lean Mg-03 Bi-03 Ag-03 In Anodes in Primary Mg-Air Battery, J. Power. Sources, 2023, 564, p 232856.

M. Yuasa, X. Huang, K. Suzuki et al., Discharge Properties of Mg-Al-Mn-Ca and Mg-Al-Mn Alloys as Anode Materials for Primary Magnesium-Air Batteries, J. Power. Sources, 2015, 297, p 449–456.

M. Deng, D. Höche, S.V. Lamaka et al., Mg-Ca Binary Alloys as Anodes for Primary Mg-Air Batteries, J. Power. Sources, 2018, 396, p 109–118.

N. Wang, R. Wang, Y. Feng et al., Discharge and Corrosion Behaviour of Mg-Li-Al-Ce-Y-Zn Alloy as the Anode for Mg-Air Battery, Corros. Sci., 2016, 112, p 13–24.

S. Cheng, W. Cheng, X. Gu et al., Discharge Properties of Low-Alloyed Mg-Bi-Ca Alloys as Anode Materials for Mg-Air Batteries: Influence of Ca Alloying, J. Alloys Compd., 2020, 823, p 153779.

N. Wang, R. Wang, C. Peng et al., Discharge Behaviour of Mg-Al-Pb and Mg-Al-Pb-In Alloys as Anodes for Mg-Air Battery, Electrochim. Acta, 2014, 149, p 193–205.

J. Sha, M. Qiao, J. Bao et al., Improving the Electrochemical Behaviors and Discharge Performance of As-Rolled Mg-4Li Alloys through Multicomponent Alloying, J. Alloys Compd., 2022, 895, p 162536.

W. Huang, Z. Jiang, P. Wu et al., Tailoring the Electrochemical Behavior and Discharge Performance of Mg-Al-Ca-Mn Anodes for Mg-Air Batteries by Different Extrusion Ratios, J. Mater. Res. Technol., 2024, 28, p 3494–3506.

Y. Feng, G. Lei, Y. He et al., Discharge Performance of Mg-Al-Pb-La Anode for Mg-Air Battery, Trans. Nonferrous Met. Soc. China, 2018, 28(11), p 2274–2286.

Y. Liu, W. Cheng, X. Gu et al., Tailoring the Microstructural Characteristic and Improving the Corrosion Resistance of Extruded Dilute Mg–0.5Bi–0.5 Sn Alloy by Microalloying with Mn, J. Magnes. Alloy, 2021, 9(5), p 1656–1668.

Y. He, C. Peng, Y. Feng et al., Effects of Alloying Elements on the Microstructure and Corrosion Behavior of Mg-Li-Al-Y Alloys, J. Alloys Compd., 2020, 834, p 154344.

L.A. Oliveira, R.M.P. Silva, A.C.D. Rodas et al., Surface Chemistry, Film Morphology, Local Electrochemical Behavior and Cytotoxic Response of Anodized AZ31B Magnesium Alloy, J. Mater. Res. Technol., 2020, 9(6), p 14754–14770.

D. Huang, T. Bu, G.L. Song et al., High Anodic-Efficiency and Energy-Density Magnesium-Air Battery with Modified AZ31 Anode, J. Alloys Compd., 2023, 960, p 170592.

X. Chen, Q. Zou, Q. Le et al., The Quasicrystal of Mg-Zn-Y on Discharge and Electrochemical Behaviors as the Anode for Mg-Air Battery, J. Power. Sources, 2020, 451, p 227807.

H. Lu, L. Ren, L. Fan et al., Effect of Yttrium and Calcium Additions on Electrochemical Behaviors and Discharge Performance of AZ80 Anodes for Mg-Air Battery, T Nonferr. Metal Soc., 2022, 32(8), p 2510–2526.

S.M. Baek, S.Y. Lee, J.C. Kim et al., Role of Trace Additions of Mn and Y in Improving the Corrosion Resistance of Mg-3Al-1Zn Alloy, Corros. Sci., 2021, 178, p 108998.

A.E. Coy, F. Viejo, P. Skeldon et al., Susceptibility of Rare-Earth-Magnesium Alloys to Micro-Galvanic Corrosion, Corros. Sci., 2010, 52(12), p 3896–3906.

Y. Shi, C. Peng, Y. Feng et al., Microstructure and Electrochemical Corrosion Behavior of Extruded Mg-Al-Pb-La Alloy as Anode for Seawater-Activated Battery, Mater. Des., 2017, 124, p 24–33.

J. Liu, H. Hu, T. Wu et al., Tailoring the Microstructure of Mg-Al-Sn-RE Alloy Via Friction Stir Processing and the Impact on Its Electrochemical Discharge Behaviour as the Anode for Mg-Air Battery, J. Magnes. Alloy, 2022 https://doi.org/10.1016/j.jma.2022.07.016

H. Yang, B. Lei, L. Wu, B. Jiang, W. Liu, Q. Yang, and F. Pan, Effects of Texture and Discharge Products on the Discharge Performance of Mg Anodes for Mg Air Batteries, J. Electrochem. Soc., 2020, 167(13), p 130528.

N. Wang, Y. Mu, W. Xong et al., Effect of Crystallographic Orientation on the Discharge and Corrosion Behaviour of AP65 Magnesium Alloy Anodes, Corros. Sci., 2018, 144, p 107–126.

Y.S. Jeong and W.J. Kim, Enhancement of Mechanical Properties and Corrosion Resistance of Mg–Ca Alloys through Microstructural Refinement by Indirect Extrusion, Corros. Sci., 2014, 82, p 392–403.

Y. Sun, R. Wang, C. Peng et al., Effects of Sn and Y on the Microstructure, Texture, and Mechanical Properties of As-Extruded Mg-5Li-3Al-2Zn Alloy, Mater. Sci. Eng. A, 2018, 733, p 429–439.

H.W. Chang, D. Qiu, J.A. Taylor et al., The Role of Al2Y in Grain Refinement in Mg–Al–Y Alloy System, J. Magnes. Alloy., 2013, 1(2), p 115–121.

H. Lv, L. Li, Z. Wen et al., Effects of Extrusion Ratio and Temperature on the Microstructure and Mechanical Properties of Mg-Zn-Yb-Zr Extrusion Alloys, Mater. Sci. Eng. A, 2022, 833, p 142521.

Q. Lin, J. Liu, X. An et al., Cryogenic-Deformation-Induced Phase Transformation in an FeCoCrNi High-Entropy Alloy, Mater. Res. Lett., 2018, 6(4), p 236–243.

L.G. Bland, K. Gusieva, and J.R. Scully, Effect of Crystallographic Orientation on the Corrosion of Magnesium: Comparison of Film Forming and Bare Crystal Facets Using Electrochemical Impedance and Raman Spectroscopy, Electrochim. Acta, 2017, 227, p 136–151.

A. Salandari-Rabori, A. Zarei-Hanzaki, S. Asqardoust et al., Novel RE-Texture Component and Bimodal Microstructure Formation during Post-Annealing of an Accumulative Back Extruded WE43 Alloy, Mater. Lett., 2023, 337, p 134006.

X. Chen, Q. Liao, Q. Le et al., The Influence of Samarium (Sm) on the Discharge and Electrochemical Behaviors of the Magnesium Alloy AZ80 as an Anode for the Mg-Air Battery, Electrochim. Acta, 2020, 348, p 136315.

X. Liu, J. Xue, and D. Zhang, Electrochemical Behaviors and Discharge Performance of the As-Extruded Mg-1.5 wt% Ca Alloys as Anode for Mg-Air Battery, J. Alloys Compd., 2019, 790, p 822–828.

S. Li, H. Li, C. Zhao et al., Effects of Ca Addition on Microstructure, Electrochemical Behavior and Magnesium-Air Battery Performance of Mg-2Zn-xCa Alloys, J. Electroanal. Chem., 2022, 904, p 115944.

Y. Yang, S. Cao, T. Ying et al., The Effects of a Corrosion Product Film on the Corrosion Behavior of Mg-Al Alloy with Micro-Alloying of Yttrium in a Chloride Solution, Corr. Commun., 2023, 11, p 12–22.

Y. Zhang, L. Fan, Y. Guo et al., Discharge Performance of Mg-Y Binary Alloys as Anodes for Mg-Air Batteries, Electrochim. Acta, 2023, 460, p 142594.

Q. Zou, Q. Le, X. Chen et al., The Influence of Ga Alloying on Mg-Al-Zn Alloys as Anode Material for Mg-Air Primary Batteries, Electrochim. Acta, 2022, 401, p 139372.

W. Cheng, Y. Chen, X. Gu et al., Revealing the Influence of Crystallographic Orientation on the Electrochemical and Discharge Behaviors of Extruded Diluted Mg-Sn-Zn-Ca Alloy as Anode for Mg-Air Battery, J. Power. Sources, 2022, 520, p 230802.

X. Gu, W. Cheng, S. Cheng et al., Tailoring the Microstructure and Improving the Discharge Properties of Dilute Mg-Sn-Mn-Ca Alloy as Anode for Mg-Air Battery through Homogenization Prior to Extrusion, J. Mater. Sci. Technol., 2021, 60, p 77–89.

B. Xiao, G.L. Song, D. Zheng et al., A Corrosion Resistant Die-Cast Mg-9Al-1Zn Anode with Superior Discharge Performance for Mg-Air Battery, Mater. Des., 2020, 194, p 108931.

J. Bao, J. Sha, L. Li et al., Electrochemical Properties and Discharge Performance of Mg-3Sn-xCa Alloy as a Novel Anode for Mg-Air Battery, J. Alloys Compd., 2023, 934, p 167849.

G.L. Song, R. Mishra, and Z.Q. Xu, Crystallographic Orientation and Electrochemical Activity of AZ31 Mg Alloy, Electrochem. Commun., 2010, 12(8), p 1009–1012.

H. Yang, L. Wu, B. Jiang et al., Clarifying the Roles of Grain Boundary and Grain Orientation on the Corrosion and Discharge Processes of α-Mg Based Mg-Li Alloys for Primary Mg-Air Batteries, J. Mater. Sci. Technol., 2021, 62, p 128–138.

X. Liu, J. Xue, P. Zhang et al., Effects of the Combinative Ca, Sm and La Additions on the Electrochemical Behaviors and Discharge Performance of the As-Extruded AZ91 Anodes for Mg-Air Batteries, J. Power. Sources, 2019, 414, p 174–182.

G.L. Song and Z. Xu, Crystal Orientation and Electrochemical Corrosion of Polycrystalline Mg, Corros. Sci., 2012, 63, p 100–112.

Acknowledgment

The financial support from the Natural Science Foundation of China [Grant No. 52105140] and Young Science and Technology Talent in Hunan Province [Grant No. 2022RC1065] are acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Huang, W., Liu, G., Wu, P. et al. The Effect of Extrusion Ratio on the Discharge and Corrosion Behavior of Mg-3Al-2.8Y-0.7Mn Alloy. J. of Materi Eng and Perform (2024). https://doi.org/10.1007/s11665-024-09532-1

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11665-024-09532-1