Abstract

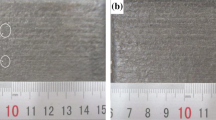

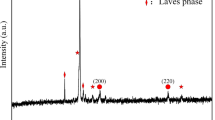

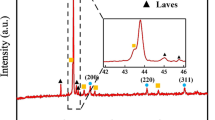

We enhanced the hardness and wear resistance of CoCrFeMnNi high-entropy alloy coatings using laser cladding to produce CoCrFeMnNiNbX (X = 0, 0.3) coatings on Q235 steel plates. The introduction of Nb elements formed Nb-rich Laves phase and solid solution strengthening in the FCC phase, improving mechanical properties. Electron backscatter diffraction (EBSD) revealed significant grain refinement in the CoCrFeMnNiNb0.3 coating, enhancing fine-grain strengthening. The nanohardness increased 1.3 times to approximately 6.29 ± 0.18. Elevated values for HU, H/E, and H3/E2 indicated superior resistance to plastic deformation. The coating demonstrates commendable wear resistance, evident from an average coefficient of friction measuring 0.459 and a specific wear rate of 3.496 × 10-6 mm3/N·m. The wear mechanisms encompass abrasive, oxidative, and adhesive wear.

Similar content being viewed by others

Data Availability

No data was used for the research described in the article.

References

L. Lu, J. Zhang, D. Shen, L. Wu, G. Jiang and L. Li, TEM analysis and wear resistance of the ceramic coatings on Q235 steel prepared by hybrid method of hot-dipping aluminum and plasma electrolytic oxidation, J. Alloy. Compd., 2012, 512(1), p 57–62.

N. Liu, Q. Zhou, M. Xu, M. Niu, P. Zhou and P. Guo, Evolution in microstructure, properties of the laser cladding CoCrFeMoNi coatings at different annealing temperatures, Mater. Sci. Technol., 2023, 39(17), p 2782–2791.

D.C. Wang, C.L. Wu, S. Zhang, C.H. Zhang, D.X. Zhang and X.Y. Sun, Wear and corrosion of CoCrFeNiMnTix high entropy alloy coatings by laser cladding, Mater. Sci. Technol., 2023, 39(17), p 2811–2823.

J. Xu, Z. Hu, S. Wang, W. Tan and J. Zhou, Laser cladding Co-based coating coupled with electromagnetic/ultrasonic compound energy field, Mater. Sci. Technol., 2023, 39(7), p 803–814.

L. Yingpeng, L. Yunlong and F. Hanguang, Improvement properties of laser cladding Ni45-Cr3C2 coatings by adding B4C and V, Mater. Sci. Technol., 2023, 39(4), p 443–453.

S. Yuan, H. Li, C. Han, W. Li, X. Xu, C. Chen, R. Wei, T. Wang, S. Wu and F. Li, FeCoNiCrAl0.6 high-entropy alloy coating on Q235 steel fabricated by laser cladding, Mater. Sci. Technol., 2023, 39(6), p 705–713.

M.H. Nie, S. Zhang, Z.Y. Wang, C.H. Zhang, H.T. Chen and J. Chen, A test method for the normal interface bonding strength of laser cladding, Mater. Sci. Technol., 2022, 38(8), p 453–457.

B. Cantor, I.T.H. Chang, P. Knight and A.J.B. Vincent, Microstructural development in equiatomic multicomponent alloys, Mater. Sci. Eng. A, 2004, 375–377, p 213–218.

Y.-J. Hsu, W.-C. Chiang and J.-K. Wu, Corrosion behavior of FeCoNiCrCux high-entropy alloys in 3.5% sodium chloride solution, Mater. Chem. Phys., 2005, 92(1), p 112–117.

K.P. Yu, S.H. Feng, C. Ding, P. Yu and M.X. Huang, Improving anti-corrosion properties of CoCrFeMnNi high entropy alloy by introducing Si into nonmetallic inclusions, Corros. Sci., 2022, 208, 110616.

Q. Zhao, Z. Pan, X. Wang, H. Luo, Y. Liu and X. Li, Corrosion and passive behavior of AlxCrFeNi3−x (x = 0.6, 0.8, 1.0) eutectic high entropy alloys in chloride environment, Corrosion Sci., 2022, 208, 110666.

J.B. Cheng, X.B. Liang and B.S. Xu, Effect of Nb addition on the structure and mechanical behaviors of CoCrCuFeNi high-entropy alloy coatings, Surf. Coat. Technol., 2014, 240, p 184–190.

C. Liu, Y. Gao, K. Chong, F. Guo, D. Wu and Y. Zou, Effect of Nb content on the microstructure and corrosion resistance of FeCoCrNiNbx high-entropy alloys in chloride ion environment, J. Alloy. Compd., 2023, 935, 168013.

I. Moravcik, N.S. Peighambardoust, A. Motallebzadeh, L. Moravcikova-Gouvea, C. Liu, J.M. Prabhakar, I. Dlouhy and Z. Li, Interstitial nitrogen enhances corrosion resistance of an equiatomic CoCrNi medium-entropy alloy in sulfuric acid solution, Mater Charact, 2021, 172, 110869.

S. Zhang, B. Han, M. Li, Q. Zhang, C. Hu, C. Jia, Y. Li and Y. Wang, Microstructure and high temperature erosion behavior of laser cladded CoCrFeNiSi high entropy alloy coating, Surf. Coat. Technol., 2021, 417, 127218.

Y. Zhang, T.T. Zuo, Z. Tang, M.C. Gao, K.A. Dahmen, P.K. Liaw and Z.P. Lu, Microstructures and properties of high-entropy alloys, Prog. Mater. Sci., 2014, 61, p 1–93.

U.S. Anamu, O.O. Ayodele, E. Olorundaisi, B.J. Babalola, P.I. Odetola, A. Ogunmefun, K. Ukoba, T.C. Jen and P.A. Olubambi, Fundamental design strategies for advancing the development of high entropy alloys for thermo-mechanical application: a critical review, J. Market. Res., 2023, 27, p 4833–4860.

F. He, Z. Wang, P. Cheng, Q. Wang, J. Li, Y. Dang, J. Wang and C.T. Liu, Designing eutectic high entropy alloys of CoCrFeNiNbx, J. Alloy. Compd., 2016, 656, p 284–289.

Y. Zhang, X. Chen, S. Jayalakshmi, R.A. Singh, V.B. Deev and E.S. Prusov, Factors determining solid solution phase formation and stability in CoCrFeNiX0.4 (X=Al, Nb, Ta) high entropy alloys fabricated by powder plasma arc additive manufacturing, J. Alloys Comp., 2021, 857, 157625.

Y. Yu, F. He, Z. Qiao, Z. Wang, W. Liu and J. Yang, Effects of temperature and microstructure on the triblogical properties of CoCrFeNiNbx eutectic high entropy alloys, J. Alloy. Compd., 2019, 775, p 1376–1385.

T.Z. Xu, S. Zhang, L. Wang, Y. Du, C.L. Wu, C.H. Zhang, X.Y. Sun, H.T. Chen and J. Chen, Influence of scanning speed on the microstructure, nanoindentation characteristics and tribological behavior of novel maraging steel coatings by laser cladding, Mater Charact, 2023, 205, 113335.

F. He, Z. Wang, S. Niu, Q. Wu, J. Li, J. Wang, C.T. Liu and Y. Dang, Strengthening the CoCrFeNiNb0.25 high entropy alloy by FCC precipitate, J. Alloys Comp., 2016, 667, p 53–57.

Z. Wang and I. Baker, Interstitial strengthening of a f.c.c. FeNiMnAlCr high entropy alloy, Mater. Lett., 2016, 180, p 153–156.

N.D. Stepanov, D.G. Shaysultanov, R.S. Chernichenko, N.Y. Yurchenko, S.V. Zherebtsov, M.A. Tikhonovsky and G.A. Salishchev, Effect of thermomechanical processing on microstructure and mechanical properties of the carbon-containing CoCrFeNiMn high entropy alloy, J. Alloy. Compd., 2017, 693, p 394–405.

H. Shahmir, T. Mousavi, J. He, Z. Lu, M. Kawasaki and T.G. Langdon, Microstructure and properties of a CoCrFeNiMn high-entropy alloy processed by equal-channel angular pressing, Mater. Sci. Eng. A, 2017, 705, p 411–419.

N.D. Stepanov, D.G. Shaysultanov, M.S. Ozerov, S.V. Zherebtsov and G.A. Salishchev, Second phase formation in the CoCrFeNiMn high entropy alloy after recrystallization annealing, Mater. Lett., 2016, 185, p 1–4.

W. Xu, M. Chen, X. Lu, D.-W. Zhang, H.-P. Singh, Y. Jian-shu, Y. Pan, X.-H. Qu and C.-Z. Liu, Effects of Mo content on corrosion and tribocorrosion behaviours of Ti-Mo orthopaedic alloys fabricated by powder metallurgy, Corros. Sci., 2020, 168, 108557.

Y.F. Juan, J. Li, Y.Q. Jiang, W.L. Jia and Z.J. Lu, Modified criterions for phase prediction in the multi-component laser-clad coatings and investigations into microstructural evolution/wear resistance of FeCrCoNiAlMox laser-clad coatings, Appl. Surf. Sci., 2019, 465, p 700–714.

Y. Guo, L. Liu, Y. Zhang, J. Qi, B. Wang, Z. Zhao, J. Shang and J. Xiang, A superfine eutectic microstructure and the mechanical properties of CoCrFeNiMox high-entropy alloys, J. Mater. Res., 2018, 33(19), p 3258–3265.

X.-G. Chen, G. Qin, X.-F. Gao, R.-R. Chen, Q. Song and H.-Z. Cui, Strengthening CoCrFeNi high-entropy alloy by Laves and boride phases, China Foundry, 2022, 19(6), p 457–463.

F. Shu, B. Zhang, T. Liu, S. Sui, Y. Liu, P. He, B. Liu and B. Xu, Effects of laser power on microstructure and properties of laser cladded CoCrBFeNiSi high-entropy alloy amorphous coatings, Surf. Coat. Technol., 2019, 358, p 667–675.

J. Wang, J. Zou, H. Yang, Z. Liu and S. Ji, High strength and ductility of an additively manufactured CrCoNi medium-entropy alloy achieved by minor Mo doping, Mater. Sci. Eng. A, 2022, 843, 143129.

W. Wang, J. Wang, Z. Sun, J. Li, L. Li, X. Song, X. Wen, L. Xie and X. Yang, Effect of Mo and aging temperature on corrosion behavior of (CoCrFeNi)100-xMox high-entropy alloys, J. Alloy. Compd., 2020, 812, 152139.

C. Dai, H. Luo, J. Li, C. Du, Z. Liu and J. Yao, X-ray photoelectron spectroscopy and electrochemical investigation of the passive behavior of high-entropy FeCoCrNiMox alloys in sulfuric acid, Appl. Surf. Sci., 2020, 499, 143903.

F. Brownlie, T. Hodgkiess, A. Pearson and A.M. Galloway, A study on the erosion-corrosion behaviour of engineering materials used in the geothermal industry, Wear, 2021, 477, 203821.

C. Duan, A. Kostka, X. Li, Z. Peng, P. Kutlesa, R. Pippan and E. Werner, Deformation-induced homogenization of the multi-phase senary high-entropy alloy MoNbTaTiVZr processed by high-pressure torsion, Mater. Sci. Eng. A, 2023, 871, 144923.

N. Gong, R. Karyappa, T.L. Meng, Y. Wang, S.L. Teo, J. Cao, M. Lin, X. Huang, C.K.I. Tan, A. Suwardi and H. Liu, Synthesis and structural characterizations of CrCoFeNiMnx (0 ≤ x ≤ 1) high-entropy-alloy thin films by thermal reduction in hydrogen, J. Mater. Sci., 2023, 58(29), p 12058–12069.

S.Y. Wei, C.M. Wang, W.Y. Peng, R.K. Luo, Y. Chen, Z.Z. Wan and Y. Jin, Effects of process parameters and annealing on microstructure and properties of CoCrFeMnNi high-entropy alloy coating prepared by plasma cladding, China Foundry, 2023, 20(6), p 491–502. https://doi.org/10.1007/s41230-023-3013-6

T.-Y. Liu, Y.-C. Lou, S. Zhang, Z.-H. Zhu, J. Zhao, S.-B. Liu, K. Shi and N. Zhao, A novel Ti-5.55Al-6.70Zr-1.50V-0.70Mo-3.41Nb-0.21Si alloy designed using cluster-plus-glue-atom model for laser additive manufacturing, China Foundry, 2023, 20(5), p 414–422.

T.Z. Xu, S. Zhang, Z.Y. Wang, C.H. Zhang, D.X. Zhang, M. Wang and C.L. Wu, Wear behavior of graphite self-lubricating Babbitt alloy composite coating on 20 steel prepared by laser cladding, Eng. Fail. Anal., 2022, 141, 106698.

D. Song, A. Ma, W. Sun, J. Jiang, J. Jiang, D. Yang and G. Guo, Improved corrosion resistance in simulated concrete pore solution of surface nanocrystallized rebar fabricated by wire-brushing, Corros. Sci., 2014, 82, p 437–441.

H. Jiang, K. Han, D. Qiao, Y. Lu, Z. Cao and T. Li, Effects of Ta addition on the microstructures and mechanical properties of CoCrFeNi high entropy alloy, Mater. Chem. Phys., 2018, 210, p 43–48.

W.H. Liu, T. Yang and C.T. Liu, Precipitation hardening in CoCrFeNi-based high entropy alloys, Mater. Chem. Phys., 2018, 210, p 2–11.

S. Chen, X. Xie, W. Li, R. Feng, B. Chen, J. Qiao, Y. Ren, Y. Zhang, K.A. Dahmen and P.K. Liaw, Temperature effects on the serrated behavior of an Al0.5CoCrCuFeNi high-entropy alloy, Mater. Chem. Phys., 2018, 210, p 20–28.

T.Z. Xu, S. Zhang, Y. Du, C.L. Wu, C.H. Zhang, X.Y. Sun, H.T. Chen and J. Chen, Development and characterization of a novel maraging steel fabricated by laser additive manufacturing, Mater. Sci. Eng. A, 2024, 891, 145975.

Z. Li and D. Raabe, Influence of compositional inhomogeneity on mechanical behavior of an interstitial dual-phase high-entropy alloy, Mater. Chem. Phys., 2018, 210, p 29–36.

Y. Liu, C. Li, P. Chen, M. Li and A. Hu, Effects of electrodeposited Co-W and Co-Fe-W diffusion barrier layers on the evolution of Sn/Cu interface, Mater. Chem. Phys., 2024, 313, 128761.

J.F. Archard, Contact and Rubbing of Flat Surfaces, J. Appl. Phys., 2004, 24(8), p 981–988.

J. Camargo and M. Ferreira, Nonblockers for hereditarily decomposable continua with the property of Kelley, Topol. Appl., 2024, 342, 108782.

M. Sharma and N. Sarma, Multi-objective optimization for energy efficient cooperative communication in energy-constrained overlay Cognitive Radio Networks, Phys. Commun., 2024, 62, 102251.

Z. Tang, T. Yuan, C.-W. Tsai, J.-W. Yeh, C.D. Lundin and P.K. Liaw, Fatigue behavior of a wrought Al0.5CoCrCuFeNi two-phase high-entropy alloy, Acta Mater., 2015, 99, p 247–258.

Acknowledgments

The authors gratefully acknowledge to the financial support for this research from Liaoning Provincial Department of Education (LJKQZ20222302).

Author information

Authors and Affiliations

Contributions

WTZ was involved in investigation, writing—review & editing. CXZ helped in investigation, funding acquisition, data curation. YZ contributed to data curation, supervision.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhou, W.T., Zhao, Y. & Zhu, C.X. Microstructure and Wear Characteristics of Laser-Clad CoCrFeMnNiNb0.3 High-Entropy Alloy Coating. J. of Materi Eng and Perform (2024). https://doi.org/10.1007/s11665-024-09496-2

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11665-024-09496-2