Abstract

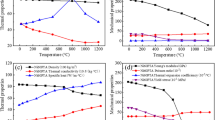

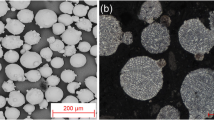

To improve the cladding quality of Ni-based powder on gray cast iron by high-speed laser cladding, ANSYS was used to construct the cladding model. The effects of laser power P, scanning rate v, and spot diameter r on the cladding quality were explored in terms of substrate surface temperature, temperature gradient G/solidification rate R, and heat-affected zone (HAZ) by the three-factor and three-level orthogonal test. The parameters that significantly affect the factors v and r were determined. Based on simulation tests, the effect of P on the microstructure, hardness and wear resistance of the molten layer was investigated by using scanning electron microscopy (SEM), hardness tester, friction wear machine and ultra-depth of field. The results showed that the microstructure of the cladding layer became sparse and coarse with increasing P, and the cross-sectional hardness and surface hardness didn’t change much. Compared to 2000 W, the wear quality loss of 1600 and 2400 W is improved by 24.8, 40.4%. The best wear resistance was achieved for 2000 W. The wear resistance and bond strength of Ni-based coating are optimal when v = 3 mm, r = 30 mm/s, and P = 2000 W.

Similar content being viewed by others

Data Availability

The datasets generated during and/or analyzed during the current study are available from the corresponding authors upon reasonable request.

References

A. Adedayo, Characterization of Graphite Flakes in gray Iron Microstructure, Arab. J. Sci. Eng., 2012, 37, p 1645–1652. (in English)

G. Wang, Z. Liu, Y. Li, and X. Chen, Different Thermal Fatigue Behaviors Between Gray Cast Iron and Vermicular Graphite Cast Iron, China Foundry, 2022, 19, p 245–252. (in English)

S. Fischer, S. Muschna, A. Buhrig-Polaczek, and M. Bunck, In-Situ Surface Hardening of Cast Iron by Surface Layer Metallurgy, Mat. Sci. Eng. A-Struct., 2014, 615, p 61–69. (in English)

A. Sadeghi, A. Moloodi, M. Golestanipour, and M. Shahri, An Investigation of Abrasive Wear and Corrosion Behavior of Surface Repair of Gray Cast Iron by SMAW, J. Mater. Res. Technol, 2017, 6, p 90–95. (in English)

H. Li, L. Feng, H. Zhou, P. Zhang, T. Zhou, Q. Sui, and L. Ren, Influence of Varying Forms of Bionic Units on Repairing Remaining Quenching Surface of Gray Cast Iron, J. Iron. Steel Res. Int., 2021, 28, p 201–210. (in English)

A. Siddiqui and A. Dubey, Recent Trends in Laser Cladding and Surface Alloying, Opt. Laser Technol., 2021, 134, p 106619. (in English)

L. Zhu, P. Xue, Q. Lan, G. Meng, Y. Ren, Z. Yang, P. Xu, and Z. Liu, Recent Research and Development Status of Laser Cladding: A Review, Opt. Laser Technol., 2021, 138, p 1006915. (in English)

L. Zhu, Y. Liu, Z. Li, L. Zhou, Y. Li, and A. Xiong, Microstructure and Properties of Cu-Ti-Ni Composite Coatings on Gray Cast Iron Fabricated by Laser Cladding, Opt. Laser Technol., 2020, 122, p 105879. (in English)

J. Ding, Y. Liu, L. Zhu, L. Zhou, and Y. Li, Microstructure and Properties of a Titanium Carbide Reinforced Coating on gray Iron Applied with Laser Cladding, Mater. Tehnol., 2019, 53(3), p 377–381. (in English)

M. Kiehl, A. Scheid, K. Graf, B. Ernst, and U. Tetzlaff, Coaxial Laser Cladding of Cobalt-Base Alloy StelliteTM 6 on Gray Cast Iron/Investigations on Friction, Wear Versus Commercial Brake Pad, and Corrosion Characteristics, P. I. Mech. Eng. D-J. Aut., 2023, 237, p 3285–3303. (in English)

T. Yu, L. Yang, Y. Zhao, J. Sun, and B. Li, Experimental Research and Multi-Response Multi-Parameter Optimization of Laser Cladding Fe313, Opt. Laser Technol., 2018, 108, p 321–332. (in English)

J. Kim and Y. Peng, Melt Pool Shape and Dilution of Laser Cladding with Wire Feeding, J. Mater. Process Tech., 2000, 104, p 284–293. (in English)

H. Tian, X. Chen, Z. Yan, X. Zhi, Q. Yang, and Z. Yuan, Finite-Element Simulation of Melt Pool Geometry and Dilution Ratio During Laser Cladding, Appl. Phys. A-Mate., 2019, 125, p 1–9. (in English)

P. Yi, X. Zhan, Q. He, Y. Liu, P. Xu, P. Xiao, and D. Jia, Influence of Laser Parameters on Graphite Morphology in the Bonding Zone and Process Optimization in Gray Cast Iron Laser Cladding, Opt. Laser Technol., 2019, 109, p 480–487. (in English)

F. Huang, Z. Jiang, X. Liu, J. Lian, and L. Chen, Effects of Process Parameters on Microstructure and Hardness of Layers by Laser Cladding, ISIJ int., 2011, 51, p 441–447. (in English)

D. Goodarzi, J. Pekkarinen, and A. Salminen, Effect of Process Parameters in Laser Cladding on Substrate Melted Areas and the Substrate Melted Shape, J. Laser Appl., 2015 https://doi.org/10.2351/1.4906376. (in English)

P. Nie, O. Ojo, and Z. Li, Modeling Analysis of Laser Cladding of a Nickel-Based Superalloy, Surf. Coat. Tech., 2014, 258, p 1048–1059. (in English)

P. Ma, Y. Wu, P. Zhang, and J. Chen, Solidification Prediction of Laser Cladding 316L by the Finite Element Simulation, Int. J. Adv. Manuf. Tech., 2019, 103, p 957–969. (in English)

H. Liu, M. Li, X. Qin, S. Huang, and F. Hong, Numerical Simulation and Experimental Analysis of Wide-Beam Laser Cladding, Int. J. Adv. Manuf. Tech., 2019, 100, p 237–249. (in English)

Q. Bai, C. Ouyang, C. Zhao, B. Han, and Y. Liu, Microstructure and Wear Resistance of Laser Cladding of Fe-Based Alloy Coatings in Different Areas of Cladding Layer, Materials, 2021, 14, p 2839. (in English)

Y. Javid and M. Ghoreishi, Thermo-Mechanical Analysis in Pulsed Laser Cladding of WC Powder on INCONEL 718, Int. J. Adv. Manuf. Tech., 2017, 92, p 69–79. (in English)

J. Yin, H. Zhu, L. Ke, P. Hu, C. He, H. Zhang, and X. Zeng, A Finite Element Model of Thermal Evolution in Laser Micro Sintering, Int. J. Adv. Manuf. Tech., 2016, 83, p 1847–1859. (in English)

R. Wei, C. Ouyang, R. Wang, C. Zhao, H. Li, and R. Deng, Research Status of the Transition Layer on Laser Cladding, Metall. Res. Technol., 2023, 120, p 318. (in English)

Y. Cheng, C. Cao, X. Yang, J. Zhou, J. Yang, X. Liang, and X. Li, Effects of Laser Energy Density and Path on Residual Stress of Remanufactured Key Components for Shield Tunneling Machine, Mater. Chem. Phys., 2022, 290, p 126617. (in English)

S. Liu, H. Zhu, G. Peng, J. Yin and, X. Zeng, Microstructure Prediction of Selective Laser Melting alsi10 mg Using Finite Element Analysis, Mater. Design, 2018, 142, p 319–328. (in English)

Y. Shi, X. Zhou, X. Wang, X. Feng, and L. Peng, Effects of Electromagnetic Fields on the Microstructure of Laser Cladding, Materials, 2022, 15, p 4198. (in English)

Y. Liu, X. Zhan, P. Yi, T. Liu, B. Liu, and Q. Wu, Research on the Transformation Mechanism of Graphite Phase and Microstructure in the Heated Region of Gray Cast Iron by Laser Cladding, Opt. Laser Technol., 2018, 100, p 79–86. (in English)

H. Liu, J. Hao, Z. Han, G. Yu, X. He, and H. Yang, Microstructural Evolution and Bonding Characteristic in Multi-Layer Laser Cladding of Nicocr Alloy on Compacted Graphite Cast Iron, J. Mater. Process. Tech., 2016, 232, p 153–164. (in English)

W. Xi, B. Song, Y. Zhao, T. Yu, and J. Wang, Geometry and Dilution Rate Analysis and Prediction of Laser Cladding, Int. J. Adv. Manuf. Tech., 2019, 103, p 4695–4702. (in English)

J. Yang, B. Bai, H. Ke, Z. Cui, Z. Liu, Z. Zhou, H. Xu, J. Xiao, Q. Liu, and H. Li, Effect of Metallurgical Behavior on Microstructure and Properties of FeCrMoMn Coatings Prepared by High-Speed Laser Cladding, Opt. Laser Technol., 2021, 144, p 107431. (in English)

D. Wang, Q. Hu, Y. Zheng, Y. Xie, and X. Zeng, Study on Deposition Rate and Laser Energy Efficiency of Laser-Induction Hybrid Cladding, Opt. Laser Technol., 2016, 77, p 16–22. (in English)

R. Wang, C. Ouyang, Q. Li, Q. Bai, C. Zhao, and Y. Liu, Microstructure and Corrosion Properties of a Ni-Based Alloy Coating Deposited onto the Surface of Ductile Cast Iron Using High-Speed Laser Cladding, Materials, 2022, 15, p 1643. (in English)

J. Zhang, C. Zhao, Q. Bai, Q. Li, C. Chen, and J. Liang, Effect of Ultrasonic High-Frequency Percussion on the Microstructure and Corrosion Resistance of Fe-Based Alloy Coatings by High-Speed Laser Cladding, Mater. Lett., 2023, 335, p 133769. (in English)

R. Wei, C. Ouyang, R. Wang, C. Zhao, R. Deng, and H. Li, Effect of Chromic Acid Anodization on the Corrosion Resistance of Fe-Based Alloy Coatings by High-Speed Laser Cladding, Mater. Lett., 2023, 350, p 134887. (in English)

J. Pekkarinen, A. Salminen, and V. Kujanpaa, Laser Cladding with Scanning Optics: Effect of Scanning Frequency and Laser Beam Power Density on Cladding Process, J. Laser Appl., 2014, 26, p 032002. (in English)

M. Fesharaki, R. Shoja-Razavi, H. Mansouri, and H. Jamali, Microstructure Investigation of Inconel 625 Coating Obtained by Laser Cladding and TIG Cladding Methods, Surf. Coat. Tech., 2018, 353, p 25–31. (in English)

H. Lv, X. Li, Z. Li, W. Wang, K. Yang, F. Li, and H. Xie, Investigation on the Columnar-to-Equiaxed Transition During Laser Cladding of IN718 alloy, J. Manuf. Process., 2021, 67, p 63–76. (in English)

A. Khorram, Microstructural Evolution of Laser Clad Stellite 31 Powder on Inconel 713 LC superalloy, Surf. Coat. Tech., 2021, 423, p 127633. (in English)

Y. Zhao, T. Yu, C. Guan, J. Sun, and X. Tan, Microstructure and Friction Coefficient of Ceramic (TiC, TiN and B4C) Reinforced Ni-Based Coating by Laser Cladding, Ceram. Int., 2019, 45, p 20824–20836. (in English)

S. Qian, Y. Dai, Y. Guo, and Y. Zhang, Microstructure and Wear Resistance of Multi-Layer Ni-Based Alloy Cladding Coating on 316L SS Under Different Laser Power, Materials, 2021, 14, p 781. (in English)

W. Li and D. Kong, Effects of TiO2 Mass Fraction on Friction Reduction and Wear Resistance of Laser-Cladded CrNi, J. Mater. Eng. Perform., 2021, 30, p 2280–2290. (in English)

J. Pereiram, J. Zambrano, M. Licausi, M. Tobar, and V. Amigo, Tribology and High Temperature Friction Wear Behavior of MCrAlY Laser Cladding Coatings on Stainless Steel, Wear, 2015, 330, p 280–287. (in English)

Funding

This research was supported financially by the National Natural Science Foundation of China (No. 52275358) and University Doctoral Research Initiation Grant (No. 2023085).

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection and analysis were performed by RW, MM, CO, RW and CZ. The first draft of the manuscript was written by HL and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Li, H., Mao, M., Wang, R. et al. Numerical Optimization and Performance Study of Ni-Based Coatings on Gray Cast Iron Surface by High-Speed Laser Cladding Based on Orthogonal Test. J. of Materi Eng and Perform (2024). https://doi.org/10.1007/s11665-024-09487-3

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11665-024-09487-3