Abstract

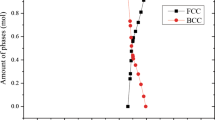

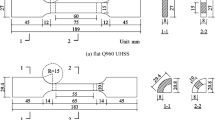

To investigate the post-fire change of the microstructure and properties of a vehicle body made of DP590 structural steel, this study simulated the post-fire process of a vehicle by considering heating processes with different heat treatment methods. The results reveal that, when the temperature was 200–700 °C, the strength decreased to varying degrees as the temperature increased, and the microstructure consisted of ferrites and martensites. With heating to 800 °C and air-cooling, the microstructure consisted of ferrites, bainites, and pearlites, and the strength and elongation were lower compared with the ordinal material. After water-cooling, the microstructure consisted of ferrites and martensites, and the strength was much higher compared with the original base material, but the elongation decreased. With heating to 900–1000 °C, the microstructure consisted of ferrites, bainites, and pearlites after air-cooling, and the strength and elongation decreased. After water-cooling, the microstructure transformed into bainites and martensites, with high strength but low elongation. Moreover, the high-temperature mechanical properties of DP590 steel were measured. When the temperature was lower than 400 °C, the strength increased and the elongation decreased. When the temperature was higher than 400 °C, the strength decreased sharply and the elongation increased.

Similar content being viewed by others

References

C. Jianhong, L. Kai, and Y. Shan, Electric Vehicle Fire Risk Assessment Based on WBS-RBS and Fuzzy BN Coupling, J. Math., 2022, 10(20), p 3799–3799.

P. Jiankun and Z. Wei, Electric Vehicle Fire Trace Recognition Based on Multi-Task Semantic Segmentation, J. Electron., 2022, 11(11), p 1738–1738.

D.L. Zhang, L.Y. Xiao, Y. Wang, and G.Z. Huang, Study on Vehicle Fire Safety: Statistic, Investigation Methods and Experimental Analysis, J. Safety Sci., 2019, 117, p 194–204.

B. Zhang, Z. Lu, Z. Liu, G. Liang, and Y. Chen, Investigation of a Vehicle Fire Caused by Manufacturing Defect, J. Eng. Fail. Anal., 2018, 91, p 28–34.

X. Huang, L. Chang, H. Zhao, and Z. Cai, Study on Craniocerebral Dynamics Response and Helmet Protective Performance Under the Blast Waves, J. Mater. Des., 2022, 224, p 111408.

H. Li, W. Peng, X. Yang, H. Chen, J. Sun, and Q. Wang, Full-Scale Experimental Study on the Combustion Behavior of Lithium Ion Battery Pack Used for Electric Vehicle, J. Fire Technol., 2020, 56(6), p 2545–2564.

L. Meng, Research and Analysis of Electric Vehicle Fire Accidents and Review of Lithium-Ion Battery Thermal Runaway Mechanism, J. Int. J New Develop. Eng. Soc., 2022, 6(2), p 6–14.

M.Z.M. Tohir, M. Spearpoint, and C. Fleischmann, Prediction of Time to Ignition in Multiple Vehicle Fire Spread Experiments, J. Fire Mater., 2018, 42(1), p 69–80.

M. Hideki, I. Shinichiro, M. Kazuo, and O. Takeo, Temperature Characteristics of a Hybrid Electric Vehicle Fire, J. SAE Int. J. Alternat. Powertra., 2012, 1(1), p 195–207.

Z.H. Fu, B.J. Yang, M.L. Shan, T. Li, Z.Y. Zhu, C.P. Ma, X. Zhang, G.Q. Gou, Z.R. Wang, and W. Gao, Hydrogen Embrittlement Behavior of SUS301L-MT Stainless Steel Laser-Arc Hybrid Welded Joint Localized Zones, J. Corros. Sci., 2020, 164, p 108337.

K. Yang, H. Yu, X. Cao, J. Guan, S. Cai, Z. Yang, W. Huang, B. Wang, N. Qin, Z. Wu, W. Tian, S. Zhang, and R.O. Ritchie, The Critical Role of Corrugated Lamellae Morphology on the Tough Mechanical Performance of Natural Syncerus Caffer Horn Sheath, J. Cell Rep. Phys. Sci., 2023, 4(9), p 101576.

G. Azuma and W.H. Hansen, Effect of Hardness of Martensite and Ferrite on Void Formation in Dual Phase Steel, J. Mater. Sci. Technol., 2012, 28(9–10), p 1092–1100.

J. Oliver Fourlaris, Dual Phase Versus TRIP Strip Steels: Comparison of Dynamic Properties for Automotive Crash Performance, J. Mater. Sci. Technol., 2007, 23(4), p 423–431.

W. Wurong, L. Meng, H. Changwei, W. Xicheng, W. Dazhi, and D. Hanbin, Experimental Study on High Strain rate Behavior of High Strength 600–1000MPa Dual Phase Steels and 1200MPa Fully Martensitic Steels, J. Mater. Des., 2012, 47, p 510–521.

Y. Li, R. Song, L. Jiang, and Z. Zhao, Strength Response of 1200 MPa Grade Martensite-Ferrite Dual-Phase Steel Under High Strain Rates, J. Scripta Mater., 2019, 164, p 21–24.

H. Niloufar, R. Ali, S. Veera, and P. Ulrich, Failure Predictions of DP600 Steel Sheets Using Various Uncoupled Fracture Criteria, J. Eng. Fract. Mechan., 2018, 190, p 367–381.

C.C. Tasan, M. Diehl, D. Yan, M. Bechtold, F. Roters, L. Schemmann, C. Zheng, N. Peranio, D. Ponge, M. Koyama, K. Tsuzaki, and D. Raabe, An Overview of Dual-Phase Steels: Advances in Microstructure-Oriented Processing and Micromechanically Guided Design, J. Ann. Rev. Mater. Res., 2015, 45(1), p 391–431.

A.R. Salehi, S. Serajzadeh, and A.K. Taheri, A Study on the Microstructural Changes in Hot Rolling of Dual-Phase Steels, J. Mater. Sci., 2006, 41(7), p 1917–1925.

A. Ramazani, K. Mukherjee, H. Quade, U. Prahl, and W. Bleck, Correlation Between 2D and 3D Flow Curve Modeling of DP Steels Using a Microstructure-Based RVE Approach, J. Mater. Sci. Eng. A, 2013, 560, p 129–139.

D.K. Matlock and J.G. Speer, Processing Opportunities for New Advanced High-Strength Sheet Steels, J. Mater. Manuf. Process., 2010, 25(1–3), p 7–13.

M. Adhikary, A. Chakraborty, A. Das, T. Venugopalan, and B.R. Kumar, Influence of Annealing Texture on Dynamic Tensile Deformation Characteristics of Dual Phase Steel, J. Mater. Sci. Eng. A, 2018, 736, p 209–218.

G. Ali, B. Vinzenz, K. Alexander, and S.S. Javad, A Comparative Study on Mechanical Behavior and Damage Scenario of DP600 and DP980 Steels, J. Mechan. Mater., 2020, 143, p 103339.

L. Wenqi, L. Junhe, A. Nikolaos, and M. Sebastian, A Strategy for Synthetic Microstructure Generation and Crystal Plasticity Parameter Calibration of Fine-Grain-Structured Dual-Phase Steel, J. Int. J. Plast., 2020, 126, p 102614.

A. Kalhor, M. Soleimani, H. Mirzadeh, and V. Uthaisangsuk, A Review of Recent Progress in Mechanical and Corrosion Properties of Dual Phase Steels, J. Arch. Civ. Mechan. Eng., 2020, 20(3), p 85.

G. Xueyun, W. Haiyan, X. Lei, M. Cainv, L. Yiming, S. Gang, and R. Huiping, The Synergistic Effects of Ultrafine Grains and Nano-Size Cu-Rich Precipitates on the Mechanical Properties of DP Steels, J. Mater. Sci. Eng. A, 2020, 805, p 140547.

X. Hao, X. Zhao, B. Huang, H. Chen, J. Ma, C. Wang, and Y. Yang, Influence of Intercritical Quenching Temperature on Microstructure, Mechanical Properties and Corrosion Resistance of Dual-Phase Steel, J. Mater. Eng. Perform., 2020, 29(7), p 4446–4456.

Z. Jingbin, S. Yinrui, J. Zhijie, L. Haiwen, and L. Feng, Improved Mechanical Properties of V-Microalloyed Dual Phase Steel by Enhancing Martensite Deformability, J. Mater. Sci. Technol., 2021, 75, p 139–153.

Y. Wu, J. Chen, L. Zhang, J. Ji, Q. Wang, and S. Zhang, Effect of Boron on the Structural Stability, Mechanical Properties, and Electronic Structures of γ′-Ni3Al in TLP Joints of Nickel-Based Single-Crystal Alloys, J. Mater. Today Commun., 2022, 31, p 103375.

J. Wang, Z. Pan, Y. Wang, L. Wang, L. Su, D. Cuiuri, Y. Zhao, and H. Li, Evolution of Crystallographic Orientation, Precipitation, Phase Transformation and Mechanical Properties Realized by Enhancing Deposition Current for Dual-Wire Arc Additive Manufactured Ni-rich NiTi Alloy, J. Addit. Manuf., 2020, 34, p 101240.

M. Calcagnotto, D. Ponge, and D. Raabe, Effect of Grain Refinement to 1μm on Strength and Toughness of Dual-Phase Steels, J. Mater. Sci. Eng. A, 2010, 527(29–30), p 7832–7840.

M. Papa Rao, V. SubramanyaSarma, and S. Sankaran, Processing of Bimodal Grain-Sized Ultrafine-Grained Dual Phase Microalloyed V-Nb Steel with 1370 MPa Strength and 16 pct Uniform Elongation Through Warm Rolling and Intercritical Annealing, J. Metall. Mater. Trans. A, 2014, 45(12), p 5313–5317.

H. Mirzadeh, M. Alibeyki, and M. Najafi, Unraveling the Initial Microstructure Effects on Mechanical Properties and Work-Hardening Capacity of Dual-Phase Steel, J. Metall. Mater. Trans. A, 2017, 48(10), p 4565–4573.

N. Nakada, Y. Arakawa, K.-S. Park, T. Tsuchiyama, and S. Takaki, Dual Phase Structure Formed by Partial Reversion of Cold-Deformed Martensite, J. Mater. Sci. Eng. A, 2012, 553, p 128–133.

H. Ashrafi, M. Shamanian, R. Emadi, and N. Saeidi, A Novel and Simple Technique for Development of Dual Phase Steels with Excellent Ductility, J. Mater. Sci. Eng. A, 2017, 680, p 197–202.

H. Azizi-Alizamini, M. Militzer, and W.J. Poole, Formation of Ultrafine Grained Dual Phase Steels through Rapid Heating, J. ISIJ Int., 2011, 51(6), p 958–964.

E. Erişir and O.G. Bilir, Effect of Intercritical Annealing Temperature on Phase Transformations in Medium Carbon Dual Phase Steels, J. Mater. Eng. Perform., 2013, 23(3), p 1055–1061.

A. Ghaheri, A. Shafyei, and M. Honarmand, Effects of Inter-Critical Temperatures on Martensite Morphology, Volume Fraction and Mechanical Properties of Dual-Phase Steels Obtained from Direct and Continuous Annealing Cycles, J. Mater. Des., 2014, 62, p 305–319.

S.S.G. Banadkouki, and E. Fereiduni, Effect of Prior Austenite Carbon Partitioning on Martensite Hardening Variation in a Low Alloy Ferrite–Martensite Dual Phase Steel, J. Mater. Sci. Eng. A, 2014, 619, p 129–136.

G. Marcel, S. Darko, A. Mansur, K. Hagen, R. Hans, C. Ezio, and W. Konrad, Analysis of Two Parameter Identification Methods for Original and Modified Johnson-Cook Fracture Strains, Including Numerical Comparison and Validation of a New Blue-Brittle Dependent Fracture Model for Free-Cutting Steel 50SiB8, J. Theoret. Appl. Fract. Mechan., 2021, 112, p 102905.

Z.Y. Zhu, Y.L. Liu, G.Q. Gou, W. Gao, and J. Chen, Effect of Heat Input on Interfacial Characterization of the Butter Joint of Hot-Rolling CP-Ti/Q235 Bimetallic Sheets by Laser + CMT, J. Sci. Rep., 2021, 11(1), p 10020.

Y. Chen, S. Sun, T. Zhang, X. Zhou, and S. Li, Effects of Post-Weld Heat Treatment on the Microstructure and Mechanical Properties of Laser-Welded NiTi/304SS Joint with Ni Filler, J. Mater. Sci. Eng. A, 2020, 771, p 138545.

W. Weimin, Q. Haiquan, D. Zhongzhong, L. Wentong, W. Yu, G. Chuncheng, L. Anqi, and H. Xiangnan, J. Trans. Mater. Heat Treat., 2024, 45(1), p 138–147 (in Chinese)

L. Hua, Y. Liu, D. Qian, L. Xie, F. Wang, and M. Wu, Mechanism of Void Healing in Cold Rolled Aeroengine M50 Bearing Steel Under Electroshocking Treatment: A Combined Experimental and Simulation Study, J. Mater. Charact., 2022, 185, p 111736.

Y. Ding, F. Yuan, Z. Cao, J. Ren, Y. Li, Y. Xin, and G. Ran, In-situ Study on Factors Impeding Dislocation Motion in Fe9Cr1.5W0.4Si F/M Steel During High Temperature Heating, J. Mater. Sci. Eng. A, 2024, 891, p 145964.

M. Mingtu and W. Baorong, Physical and Mechanical Metallurgy of Dual Phase Steel M, Metallurgical Industry Press, Beijing, 2009 (in Chinese)

Acknowledgments

The authors are grateful for the financial Supported by Guangxi Science and Technology Major Project (Nos. AA22067079)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, W., Qi, H., Da, Z. et al. Evolution of Microstructure and Mechanical Properties of DP590 Structural Steel of Vehicle in Heat-Treatment Post-Fire Simulation. J. of Materi Eng and Perform (2024). https://doi.org/10.1007/s11665-024-09376-9

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11665-024-09376-9