Abstract

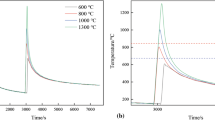

The single-pass welding thermal simulation test of V-N micro-alloyed steel was carried out by MMS-300 thermal simulation testing machine, and combined with an optical microscope (OM), electron backscattering diffraction, impact test, and other technologies, to study the organization, toughness, and its change rule of critical reheating coarse-grained heat-affected zone under different welding conditions. The results show that the microstructure of single-pass simulated CGHAZ is composed of polygonal ferrite, acicular ferrite, bainite beam, and a small amount of lath martensite at low and medium linear energies. The precipitates in the heat-affected zone of coarse grain in single-pass welding are mainly VN or V(C, N). The microhardness and high-angle grain boundary fraction (> 15°) of CGHAZ decrease with the increase in welding heat input. When t8/5 is 10 s, the microstructure is dominated by fine lath bainite, and a large number of high-angle grain boundaries exist between the lath strands in different microstructure, which can effectively hinder crack propagation. With the increase in t8/5, that is, the increase in welding line energy, the lamellar structure decreases obviously, and the proportion of low-angle grain boundary is higher. Meanwhile, the M/A island hard phase inside the granular bainite reduces the free slip path of the plastic ferrite phase during deformation, which is difficult to prevent crack extension and deteriorates the toughness, and the weld thermal cycling process destroys the strength and toughness equilibrium of the V-N micro-alloyed high-strength candidate steel.

Similar content being viewed by others

References

C. Capdevila, C. Garcia-Mateo, J. Chao, and F.G. Caballero, Advanced Vanadium Alloyed Steel for Heavy Product Applications, Mater. Sci. Technol., 2009, 25, p 1383–1386.

K.F.A. Hajeri, C.I. Garcia, M. Hua, and A.J. DeArdo, Refinement of Ferrite Grain Size Through Particle Stimulated Nucleation (PSN) Mechanism in Heavy Steel Sections, Mater. Sci. Technol., 2005, 2, p 51–62.

J.H. Shim, Y.J. Oh, J.Y. Suh, Y.W. Cho, J.D. Shim, J.S. Byun, and D.N. Lee, Ferrite Nucleation Potency of Non-metallic Inclusions in Medium Carbon Steels, Acta Mater., 2001, 49, p 2115–2122.

C. Capdevila, C. Garcia-Mateo, J. Cornide, J. Chao, and F.G. Caballero, Effect of V Precipitation on Continuously Cooled Sulfur-Lean Vanadium-Alloyed Steels for Long Products Applications, Metall. Mater. Trans. A, 2011, 42A, p 3743–3751.

K. He and D.V. Edmonds, Formation of Acicular Ferrite and Influence of Vanadium Alloying, Mater. Sci. Technol., 2002, 18, p 289–296.

J.Y. Tian, G. Xu, M.X. Zhou, and H.J. Hu, Refined Bainite Microstructure and Mechanical Properties of a High-Strength Low-Carbon Bainitic Steel Treated by Austempering Below and Above MS, Steel Res. Int., 2018, 89(4), p1700469.

D.S. Liu, B.G. Cheng, and M. Luo, Microstructure and Impact Fracture Behaviour of HAZ of F460 Heavy Ship Plate with High Strength and Toughness, Acta Metall. Sin., 2011, 47, p 1233–1240.

W.Y. Liu, W. Lai, J.B. Liu, Y.Y. Zhang, P.H. Li, and G.L. Yuan, Microstructures and Properties in Simulated Heat-Affected Zones of 685 MPa Grade Copper Bearing Steel, J. Iron. Steel Res. Int., 2007, 14(5), p 220–226.

C. Thaulow, A.J. Paauw, and K. Guttormsen, Heat-Affected Zone Toughness of Low-Carbon Micro-Alloyed Steels, Weld. J., 1987, 66(9), p 266–279.

L. Zhu and J.H. Chen, Strength and Deformation in HAZ Softened Welding Joints, Transat. China Weld. Inst., 2004, 25(04), p 61–65.

I. Toda-Caraballo, P.D. Bristowe, and C. Capdevila, A Molecular Dynamics Study of Grain Boundary Free Energies, Migration Mechanisms and Mobilities in a bcc Fe-20Cr Alloy, Acta Mater., 2012, 60, p 1116–1128.

A. Lambert-Perlade, A.F. Gourgues, J. Besson, T. Sturel, and A. Pineau, Mechanisms and Modeling of Cleavage Fracture in Simulated Heat-Affected Zone Microstructures of a High-Strength Low Alloy Steel, Metall. Mater. Trans. A, 2004, 35A, p 1039–1053.

H. Kitahara, R. Ueji, N. Tsuji, and Y. Minamino, Crystallographic Features of Lath Martensite in Low-Carbon Steel, Acta Mater., 2006, 54, p 1279–1288.

J. Hu, X.Y. Li, Q.W. Meng, L.Y. Wang, and Y.Z. Li, Tailoring Retained Austenite and Mechanical Property Improvement in Al-Si-V Containing Medium Mn Steel Via Direct Intercritical Rolling, Mater. Sci. Eng. A, 2022, 855(10), p143904.

R. Ikawa, H. Oshige, and T. Tanoue, Effect of Martensite-Austenite Constituent on HAZ Toughness of a High Strength Steel, Transact. Jpn Weld. Soc., 1980, 11(2), p 3–12.

F. Njock Bayock, P. Kah, P. Layus, and V. Karkhin, Numerical and Experimental Investigation of the Heat Input Effect on the Mechanical Properties and Microstructure of Dissimilar Weld Joints of 690-MPa QT and TMCP Steel, Metals, 2019, 9(3), p 355.

Y.H. Lou, H.J. Xiao, Y. Peng et al., Study on Microstructure and Properties of Welded Joints of a 690 MPa Grade HSLA Steel, Mater. Sci. Technol., 2012, 20(2), p 101–107.

L. Zhao, X.D. Zhang, and W.Z. Chen, Research on 800 MPa Grade Low-Alloyed Steel Weld HAZ Toughness, Acta Metall. Sin., 2005, 41(4), p 392–396.

Acknowledgments

This work is supported by the Talent Project of Tangshan Human Resources and Social Security Bureau (A202202008) and funded by S&P Program of Hebei (Grant No. 479 22281802Z).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Liu, Y., Zheng, XM., Li, QM. et al. Microstructure and Properties of Coarse Grain Zone in Single-Pass Welding of V-N Microalloyed Steel. J. of Materi Eng and Perform (2024). https://doi.org/10.1007/s11665-024-09365-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11665-024-09365-y