Abstract

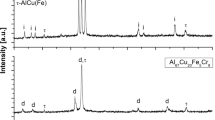

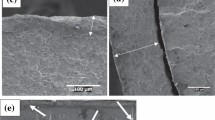

In this study, Cr3C2/10%NiCr layer was deposited on the AISI 2205 duplex stainless steel by the HVOF technique. Microstructural, tribological and corrosion behaviors of the coated and uncoated samples were investigated. The characterization studies were carried out by scanning electron microscopy, energy dispersive spectroscopy and optical microscopy. Moreover, dry sliding wear tests, corrosion tests and hardness measurements were performed to reveal the influence of Cr3C2-10%NiCr on the properties of AISI 2205 duplex stainless steel. Microstructural analysis revealed that proper bonding was achieved at the substrate-coating interface. On the other hand, it was observed that the coating structure consisted of chromium carbides and nickel-chromium binders. According to the corrosion test results, it was observed that the coating protected its structure and delayed the corrosion damage of the AISI 2205 alloy. The wear rate of the AISI 2205 alloy was reduced from 73.32 ± 5.28 × 10−5 mm3·(Nmm)−1 to 6.97 ± 0.61 × 10−5 mm3·(Nmm)−1 with Cr3C2-10%NiCr coating, as a result of the wear tests. In conclusion, test results showed that the Cr3C2-NiCr layer improved the corrosion and wear behavior of the AISI 2205 duplex stainless steel.

Similar content being viewed by others

References

R. Badji, M. Bouabdallah, B. Bacroix, C. Kahloun, K. Bettahar, and N. Kherrouba, Effect of Solution Treatment Temperature on the Precipitation Kinetic of σ-Phase in 2205 Duplex Stainless Steel Welds, Mater. Sci. Eng. A, 2008, 496(1-2), p 447–454. https://doi.org/10.1016/j.msea.2008.06.024

R. Francis and G. Byrne, Duplex Stainless Steels—Alloys for the 21st Century, Metals, 2021, 11(5), p 836. https://doi.org/10.3390/met11050836

S.K. Ghosh and S. Mondal, High Temperature Ageing Behaviour of a Duplex Stainless Steel, Mater Charact, 2008, 59(12), p 1776–1783. https://doi.org/10.1016/j.matchar.2008.04.008

A. Kisasoz, S. Gurel, and A. Karaaslan, Effect of Annealing Time and Cooling Rate on Precipitation Processes in a Duplex Corrosion-Resistant Steel, Met. Sci. Heat Treat., 2016, 57(9-10), p 544–547. https://doi.org/10.1007/s11041-016-9919-5

V.A. Hosseini, L. Karlsson, S. Wessman, and N. Fuertes, Effect of Sigma Phase Morphology on the Degradation of Properties in a Super Duplex Stainless Steel, Materials, 2018, 11(6), p 933. https://doi.org/10.3390/ma11060933

E.A. Melo and R. Magnabosco, Influence of the Heterogeneous Nucleation Sites on the Kinetics of Intermetallic Phase Formation in Aged Duplex Stainless Steel, Metall. Mater. Trans. A Phys. Metall. Mater. Sci., 2017, 48(11), p 5273–5284. https://doi.org/10.1007/s11661-017-4299-z

E.M. Cojocaru et al., Influence of Ageing Treatment on Microstructural and Mechanical Properties of a Solution Treated UNS S32750/EN 1.4410/F53 Super Duplex Stainless Steel (SDSS) Alloy, J. Market. Res., 2020, 9(4), p 8592–8605. https://doi.org/10.1016/j.jmrt.2020.05.127

A. Kisasoz, A. Karaaslan, and Y. Bayrak, Effect of Etching Methods in Metallographic Studies of Duplex Stainless Steel 2205, Met. Sci. Heat Treatm., 2017, 58(11-12), p 704–706. https://doi.org/10.1007/s11041-017-0081-5

R.O. Sousa, P. Lacerda, P.J. Ferreira, and L.M.M. Ribeiro, On the Precipitation of Sigma and Chi Phases in a Cast Super Duplex Stainless Steel, Metall. Mater. Trans. A Phys. Metall. Mater. Sci., 2019, 50(10), p 4758–4778. https://doi.org/10.1007/s11661-019-05396-6

R. Wang, Precipitation of Sigma Phase in Duplex Stainless Steel and Recent Development on its Detection by Electrochemical Potentiokinetic Reactivation: A Review, Corros. Commun., 2021, 2, p 41–54. https://doi.org/10.1016/j.corcom.2021.08.001

Y. Xiao et al., Corrosion Behavior of 2205 Duplex Stainless Steel in NaCl Solutions Containing Sulfide İons, Corros. Sci., 2022, 200, p 110240. https://doi.org/10.1016/j.corsci.2022.110240

Y. Zhou and D.L. Engelberg, Fast Testing of Ambient Temperature Pitting Corrosion in Type 2205 Duplex Stainless Steel by Bipolar Electrochemistry Experiments, Electrochem. Commun., 2020, 117, p 106779. https://doi.org/10.1016/j.elecom.2020.106779

C. Örnek, K. Davut, M. Kocabaş, A. Bayatlı, and M. Ürgen, Understanding Corrosion Morphology of Duplex Stainless Steel Wire in Chloride Electrolyte, Corros. Mater. Degrad., 2021, 2, p 397–411. https://doi.org/10.3390/cmd2030021

D.D.S. Silva, T.A. Simões, D.A. Macedo, A.H.S. Bueno, S.M. Torres, and R.M. Gomes, Microstructural İnfluence of Sigma Phase on Pitting Corrosion Behavior of Duplex Stainless Steel/NaCl Electrolyte Couple, Mater. Chem. Phys., 2021, 259, p 124056. https://doi.org/10.1016/j.matchemphys.2020.124056

Y. Guo, J. Hu, J. Li, L. Jiang, T. Liu, and Y. Wu, Effect of Annealing Temperature on the Mechanical and Corrosion Behavior of a Newly Developed Novel Lean Duplex Stainless Steel, Materials, 2014, 6(9), p 6604–6619. https://doi.org/10.3390/ma7096604

H. Hwang and Y. Park, Effects of Heat Treatment on the Phase Ratio and Corrosion Resistance of Duplex Stainless Steel, Mater. Trans., 2009, 50(6), p 1548–1552. https://doi.org/10.2320/matertrans.MER2008168

F. Marques, W.M. Da Silva, J.M. Pardal, S.S.M. Tavares, and C. Scandian, Influence of Heat Treatments on the Micro-abrasion Wear Resistance of a Superduplex Stainless Steel, Wear, 2011, 271(9-10), p 1288–1294. https://doi.org/10.1016/j.wear.2010.12.087

M.B. Davanegeri, S. Narendranath, and R. Kadoli, Influence of Heat Treatment on Microstructure, Hardness and Wear Behaviour of super Duplex Stainless Steel AISI 2507, Am. J. Mater. Sci., 2015, 5, p 48–52. https://doi.org/10.5923/c.materials.201502.10

J.L. del Abra-Arzola, M.A. Garcia-Renteria, V.I. Cruz-HErnandez, J. Garcia-Guerra, V.H. Martinez-Landeros, L.A. Falcon-Franco, and F.F. Curiel-Lopez, Study of the Effect of sigma Phase Precipitation on the Sliding Wear and Corrosion Behaviour of Duplex Stainless Steel AISI 2205, Wear, 2018, 400-401, p 43–51. https://doi.org/10.1016/j.wear.2017.12.019

J.K. Sahu, U. Krupp, R.N. Ghosj, and H.J. Christ, Effect of 475 °C Embrittlement on the Mechanical Properties of Duplex Stainless Steel, Mater. Sci. Eng. A, 2009, 508, p 1–14. https://doi.org/10.1016/j.msea.2009.01.039

M. Pohl and O. Storz, Sigma-Phase in Duplex-Stainless Steels, Z. Met., 2004, 95(7), p 631–638.

H. Sieurin and R. Sandström, Sigma Phase Precipitation in Duplex Stainless Steel 2205, Mater. Sci. Eng. A, 2007, 444, p 271–276. https://doi.org/10.1016/j.msea.2006.08.107

L.K. de Paula Inácio, W. Wolf, B.C.B. de Leucas, G.C. Stumpf, and D.B. Santos, Microtexture Evolution of Sigma Phase in an Aged Fine-Grained 2205 Duplex Stainless Steel, Mater Charact, 2021, 171, p 110802. https://doi.org/10.1016/j.matchar.2020.110802

R. Subbiah, V. Vinod Kumar, and G. Lakshmi Prasanna, Wear Analysis of Treated Duplex Stainless Steel Material by Carburizing Process—A Review, Mater. Today: Proc., 2019, 26, p 2946–2952. https://doi.org/10.1016/j.matpr.2020.02.608

O. Palma Calabokis, Y. Núñez de la Rosa, C.M. Lepienski, R. Perito Cardoso, and P.C. Borges, Crevice and Pitting Corrosion of Low Temperature Plasma Nitrided UNS S32750 Super Duplex Stainless Steel, Surf. Coat. Technol., 2021, 413, p 127095. https://doi.org/10.1016/j.surfcoat.2021.127095

J.O.P. Neto et al., Wear and Corrosion Study of Plasma Nitriding F53 Super Duplex Stainless Steel, Mater. Res., 2016, 19(6), p 1241–1252. https://doi.org/10.1590/1980-5373-MR-2015-0656

R. Goyal, B.S. Sidhu, and V. Chawla, Hot Corrosion Performance of Plasma-Sprayed Multiwalled Carbon Nanotube-Al2O3 Composite Coatings in a coal-Fired Boiler at 900 °C, J. Mater. Eng. Perform., 2020, 29, p 5738–5749. https://doi.org/10.1007/s11665-020-05070-8

R. Goyal, B. Sidhu, and V. Chawla, Characterization of Plasma-Sprayed Carbon Nanotube (CNT)-Reinforced Alumina Coatings on ASME-SA213-T11 Boiler Tube Steel, Int. J. Adv. Manuf. Technol., 2017, 92(9-12), p 3225–3235. https://doi.org/10.1007/s00170-017-0405-z

G. Singh, N. Bala, V. Chawla, and Y.K. Singla, Hot Corrosion Behavior of HVOF-Sprayed Carbide based Composite Coatings for Boiler Steel in Na2SO4-60% V2O5 Environment at 900° C under Cyclic Conditions, Corros. Sci., 2021, 190, p 109666. https://doi.org/10.1016/j.corsci.2021.109666

S. Yin, J. Cizek, X. Suo, W. Li, and H. Liao, Thermal Spray Technology, Adv. Mater. Sci. Eng., 2019, 2019, p 8654764. https://doi.org/10.1155/2019/8654764

G.C.M. Patel, N.B. Pradeep, L. Girisha, H.M. Harsha, and A.K. Shettigar, Experimental Analysis and Optimization of Plasma Spray Parameters on Microhardness and Wear Loss of Mo-Ni-Cr Coated Super Duplex Stainless Steel, Aust. J. Mech. Eng., 2022, 20(5), p 1426–1438. https://doi.org/10.1080/14484846.2020.1808760

K. Singh, K. Goyal, and R. Goyal, Hot Corrosion Behaviour of Different Cr3C2-NiCr Coatings on Boiler Tube Steel at Elevated Temperature, World J. Eng., 2019, 16(4), p 452–459. https://doi.org/10.1108/WJE-02-2019-0049

A. Singh, K. Goyal, and R. Goyal, An Investigation on Hot Corrosion Behaviour of Cermet Coatings in Simulated Boiler Environment, J. Bio- Tribo-Corros., 2019, 5, p 86. https://doi.org/10.1007/s40735-019-0278-9

V.P.S. Sidhu, K. Goyal, and R. Goyal, Corrosion Behaviour of HVOF Sprayed Coatings on ASME SA213 T22 Boiler Steel in an Actual Boiler Environment, Adv. Eng. Forum, 2017, 20, p 1–9. https://doi.org/10.4028/www.scientific.net/AEF.20.1

S. Hong et al., Microstructure and Cavitation-Silt Erosion Behavior of High-Velocity Oxygen-Fuel (HVOF) Sprayed Cr3C2-NiCr Coating, Surf. Coat. Technol., 2013, 225, p 85–91. https://doi.org/10.1016/j.surfcoat.2013.03.020

Z. Zhang, X. Lu, and J. Luo, Tribological Properties of Rare Earth Oxide Added Cr3C2-NiCr Coatings, Appl. Surf. Sci., 2007, 253(9), p 4377–4385. https://doi.org/10.1016/j.apsusc.2006.09.040

V.Y. Ulianitsky, I.S. Batraev, D.K. Rybin, D.V. Dudina, A.A. Shtertser, and A.V. Ukhina, Detonation Spraying of Cr3C2-NiCr Coatings and their Properties, J. Therm. Spray Technol., 2022, 31(3), p 598–608. https://doi.org/10.1007/s11666-021-01301-z

J.M. Guilemany, J. Fernandez, J. Delgado, A.V. Benedetti, and F. Climent, Effects of thickness coating on the electrochemical behaviour of thermal spray Cr3C2-NiCr coatings, Surf. Coat. Technol., 2002, 153, p 107–113.

G.C. Ji, C.J. Li, Y.Y. Wang, and W.Y. Li, Microstructural Characterization and Abrasive Wear Performance of HVOF Sprayed Cr3C2-NiCr Coating, Surf. Coat. Technol., 2006, 200(24), p 6749–6757. https://doi.org/10.1016/j.surfcoat.2005.10.005

P.S. Kevin, A. Tiwari, S. Seman, S.A.B. Mohamed, and R. Jayaganthan, Erosion-Corrosion Protection due to Cr3C2-NiCr Cermet Coating on Stainless Steel, Coatings, 2020, 10(11), p 1–17. https://doi.org/10.3390/coatings10111042

B.B. Mishra and H. Nautiyal, Frictional and Wear Behavior of Cr3C2-NiCr Coating on AISI-304 Stainless Steel, Adv. Mater. Process. Technol., 2022, 8(4), p 4007–4017. https://doi.org/10.1080/2374068X.2022.2036508

M. Majunatha, R.S. Kulkarni, and M. Krishna, Investigation of HVOF Thermal Sprayed Cr3C2-NiCr Cermet Carbide Coatings on Erosive Performance of AISI 316 Molybdenum Steel, Procedia Mater. Sci., 2014, 5, p 622–629. https://doi.org/10.1016/j.mspro.2014.07.308

A.S. Hajare and C.L. Gogte, Comparative Study of Wear Behaviour of Thermal Spray HVOF Coating on 304 SS, Mater. Today Proc., 2018, 5, p 6924–6933. https://doi.org/10.1016/j.matpr.2017.11.354

D.H. Bhosale, W.S. Rathod, M. Nogaraj, and M. Nagaraj, High-Temperature Erosion and Sliding Wear of Thermal Sprayed WC-Cr3C2-Ni Coatings, Mater. High Temp., 2021, 38, p 464–474. https://doi.org/10.1080/09603409.2021.1979734

N.V. Abhijith, D. Kumar, and D. Kalyansundaram, Development of Single-Stage TiNbMoMnFe High-Entropy Alloy Coating on 304L Stainless Steel using HVOF Thermal Spray, J. Therm. Spray Technol., 2022, 31, p 1032–1044. https://doi.org/10.1007/s11666-021-01294-9

N. Abu-warda, A.J. Lopez, M.D. Lopez, and M.V. Utrilla, Ni20Cr Coating on T24 Steel Pipes by HVOF Thermal Spray for High Temperature Protection, Surf. Coat. Technol., 2020, 381, p 125133. https://doi.org/10.1016/j.surfcoat.2019.125133

S. Singh and M. Kaur, Mechanical and Microstructural Properties of NiCrFeSiBC/Cr3C2 Composite Coatings—Part I, Surf. Eng., 2016, 32, p 464–474. https://doi.org/10.1179/1743294414Y.0000000416

J.O. Park, S. Matsch, and H. Böhni, Effects of Temperature and Chloride Concentration on Pit Initiation and Early Pit Growth of Stainless Steel, J. Electrochem. Soc., 2002, 149(2), p B34. https://doi.org/10.1149/1.1430415

J.M. Guilemany, J. Nutting, and N. Llorca-Isern, Characterisation of Cr3C2-NiCr Cermet Powder for High Velocity Oxyfuel Spraying, Powder Metall., 1994, 37, p 289–292. https://doi.org/10.1179/pom.1994.37.4.289

Q. Feng, C. Jiang, Z. Xu, L. Xie, and V. Ji, Effect of Shot Peening on the Residual Stress and Microstructure of Duplex Stainless Steel, Surf. Coat. Technol., 2013, 226, p 140–144. https://doi.org/10.1016/j.surfcoat.2013.03.047

J.M. Guilemany, N. Espallargas, P.H. Suegama, and A.V. Benedetti, Comparative Study of Cr3C2-NiCr Coatings Obtained by HVOF and Hard Chromium Coatings, Corros. Sci., 2006, 48(10), p 2998–3013. https://doi.org/10.1016/j.corsci.2005.10.016

S.S. Chatha, H.S. Sidhu, and B.S. Sidhu, High Temperature Hot Corrosion Behaviour of NiCr and Cr3C2-NiCr Coatings on T91 Boiler Steel in an Aggressive Environment at 750 °C, Surf. Coat. Technol., 2012, 206(19-20), p 3839–3850. https://doi.org/10.1016/j.surfcoat.2012.01.060

W. Zhou, K. Zhou, Y. Li, C. Deng, and K. Zeng, High Temperature Wear Performance of HVOF-Sprayed Cr3C2-WC-NiCoCrMo and Cr3C2-NiCr hardmetal coatings, Appl. Surf. Sci., 2017, 416, p 33–44. https://doi.org/10.1016/j.apsusc.2017.04.132

A. Babu, D. Dzhurinskiy, S. Dautov, and P. Shorkinov, Structure and Electrochemical Behavior of Atmospheric Plasma Sprayed Cr3C2-NiCr Cermet Composite Coatings, Int. J. Refract Metal Hard Mater., 2023, 111, p 106105. https://doi.org/10.1016/j.ijrmhm.2023.106105

J. Du, F. Li, Y. Li, L. Wang, H. Lu, X. Ran, and X. Zhang, Influences of Plasma Arc Remelting on Microstructure and Service Performance of Cr3C2-NiCr/NiCrAl Composite Coating, Surf. Coat. Technol., 2019, 369, p 16–30. https://doi.org/10.1016/j.surfcoat.2019.04.037

R.S. Dutta, R. Purandare, A. Lobo, S.K. Kulkarni, and G.K. Dey, Microstructural Aspects of the Corrosion of Alloy 800, Corros. Sci., 2004, 46(12), p 2937–2953. https://doi.org/10.1016/j.corsci.2004.04.005

A. Szewczyk-Nykiel and J. Kazior, Effect of Aging Temperature on Corrosion Behavior of Sintered 17-4 PH Stainless Steel in Dilute Sulfuric Acid Solution, J. Mater. Eng. Perform., 2017, 26(7), p 3450–3456. https://doi.org/10.1007/s11665-017-2778-4

J. Pi, Y. Pan, J. Wu, and X. He, Influence of Minor Addition of in on Corrosion Resistance of Cu-based Bulk Metallic Glasses in 3.5% NaCl Solution, Xiyou Jinshu Cailiao Yu Gongcheng/Rare Metal Mater. Eng., 2014, 43(1), p 32–35. https://doi.org/10.1016/s1875-5372(14)60047-3

Č Donik, A. Kocijan, D. Mandrino, I. Paulin, M. Jenko, and B. Pihlar, Initial Oxidation of Duplex Stainless Steel, Appl. Surf. Sci., 2009, 255(15), p 7056–7061. https://doi.org/10.1016/j.apsusc.2009.03.041

G. Özer, Investigation of Inhibitory Effects of Chitosan on Pitting and Electrochemical Corrosion Behavior Caused by Sigma Phase in Duplex Stainless Steels (DSS), Prot. Met. Phys. Chem. Surf., 2022, 58(1), p 176–189. https://doi.org/10.1134/S2070205122010154

T. Suter, E.G. Webb, H. Böhni, and R.C. Alkire, Pit Initiation on Stainless Steels in 1 M NaCl With and Without Mechanical Stress, J. Electrochem. Soc., 2001, 148(5), p B174. https://doi.org/10.1149/1.1360204

Z. Wei, D. Cui, Z. Wei, and S. Hong, HVOF spray of Cr3C2-NiCr Coating for Enhancing the Corrosion Resistance of Nickel Aluminium Bronze in 3.5% NaCI Solution with Different Sulphide Concentrations, J. Market. Res., 2023, 23, p 869–881. https://doi.org/10.1016/j.jmrt.2023.01.050

M. Hoseinpoor, M. Momeni, M.H. Moayed, and A. Davoodi, EIS Assessment of Critical Pitting Temperature of 2205 Duplex Stainless Steel in Acidified Ferric Chloride Solution, Corros. Sci., 2014, 80, p 197–204. https://doi.org/10.1016/j.corsci.2013.11.023

K. Bobzin, L. Zhao, M. Öte, T. Königstein, and M. Steeger, Impact Wear of an HVOF-Sprayed Cr3C2-NiCr Coating, Int. J. Refract. Metals Hard Mater., 2018, 70, p 191–196. https://doi.org/10.1016/j.ijrmhm.2017.10.011

G. Özer et al., Effect of Heat Treatments on the Microstructure and Wear Behaviour of a Selective Laser Melted Maraging Steel, Proc. Inst. Mech. Eng. Part E: J. Process Mech. Eng., 2022, 236(6), p 2526–2535. https://doi.org/10.1177/09544089221093994

H.M. Khan, M.S. Yilmaz, S.S. Karabeyoğlu, A. Kisasoz, and G. Özer, Dry Sliding Wear Behavior of 316 L Stainless Steel Produced by Laser Powder Bed Fusion: A Comparative Study on Test Temperature, Mater. Today Commun., 2023, 34, p 105155. https://doi.org/10.1016/j.mtcomm.2022.105155

Acknowledgments

The authors would like to thank Çimtaş Hassas İşleme Sanayi ve Ticaret Ltd. Şti. for the support provided to establish this work.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Işık, R.G., Özbay Kısasöz, B., Tarakçı, G. et al. Influence of High-Velocity Oxy-fuel Sprayed Cr3C2-NiCr Coating on Corrosion and Wear Properties of AISI 2205. J. of Materi Eng and Perform (2024). https://doi.org/10.1007/s11665-024-09324-7

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11665-024-09324-7