Abstract

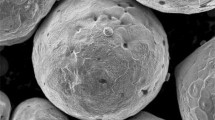

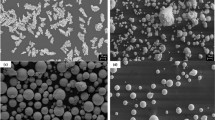

Compared with other thermal spray technologies, cold spray relies on high-speed impact of solid particles. Generally, cold spray cannot deposit on surfaces that are positioned in low incident angle, so it is critical to understand the impact of incident angle to improve the properties of the coating in uneven or curved surfaces. In this work, pure Cu coatings were obliquely deposited on Cr-Zr-Cu substrates using high-pressure cold spray (CS) system. The influence of particle incident angle from 60° to 90° on the surface characteristics, mechanical properties and thermal conductivity of coating was studied. Results showed that increasing the incident angle of Cu particles resulted in a more compact coating. As the incident angle changed from 60° to 90°, the thickness of Cu coatings increased by 42.7%. The high micro-hardness exceeding 120 HV was maintained due to the low porosity and pure Cu particles deformation strengthening, which is close to that of 145 HV of Cr-Zr-Cu substrate. The thermal conductivity tests revealed that the superior thermal conductivity was obtained at incident angle of 90°. The results could be discussed in terms of the deformation modes of pure Cu particles and interface properties of the coatings.

Similar content being viewed by others

Data availability

Data openly available in a public repository.

References

S. Zhou, B. Zhao, Z. Zhen et al., Application of Lanthanum in High Strength and High Conductivity Copper Alloys, J. Rare Earths, 2006, 24(1), p 385–388.

I. Yasar, A. Ca Nakci and F. Arslan, The Effect of Brush Spring Pressure on the Wear Behaviour of Copper–Graphite Brushes with Electrical Current, Tribol. Int., 2007, 40(9), p 1381–1386.

A.P. Alkhimov, A.N. Papyrin, V.F. Kosarev, et al. Gas-Dynamic Spraying Method for Applying a Coating: US, US5302414 A[P]. (1997)

A.N. Papyrin, V.F. Kosarev, S.V. Klinkov, et al. On the Interaction of High Speed Particles with a Substrate under the Cold Spraying. (2002)

H. Assadi, Klassen, et al., Cold Spraying—A Materials Perspective, Acta Mater., 2016, 116, p 382–407.

S. Yin, P. Ca Valiere, B. Aldwell et al., Cold Spray Additive Manufacturing and Repair: Fundamentals and Applications, Addit. Manuf., 2018, 21, p 628–650.

W. Li, K. Yang, S. Yin et al., Solid-State Additive Manufacturing and Repairing by Cold Spraying: A Review, J. Mater. Sci. Technol., 2018, 34(3), p 440–457.

W. Li, C. Cao and S. Yin, Solid-State Cold Spraying of Ti and its Alloys: A Literature Review, Progress Mater. Sci., 2020, 110(11), p 100633.1-100633.53.

W. Li, H. Assadi, F. Gaertner et al., A Review of Advanced Composite and Nanostructured Coatings by Solid-State Cold Spraying Process, Crit. Rev. Solid State Mater. Sci., 2019, 44(2), p 109–156.

F. Raletz et al., Critical Particle Velocity under Cold Spray Conditions, Surface Coat. Technol., 2006, 201(5), p 1942–1947.

T. Schmidt, F. Gartner, H. Assadi et al., Development of a Generalized Parameter Window for Cold Spray Deposition, Acta Mater., 2006, 54(3), p 729–742.

M. Grujicic, C.L. Zhao, W.S. Derosset et al., Adiabatic Shear Instability Based Mechanism for Particles/Substrate Bonding in the Cold-Gas Dynamic-Spray Process, Mater. Des., 2004, 25(8), p 681–688.

H. Koivuluoto, A. Coleman, K. Murray et al., High Pressure Cold Sprayed (HPCS) and Low Pressure Cold Sprayed (LPCS) Coatings Prepared from OFHC Cu Feedstock: Overview from Powder Characteristics to Coating Properties, J. Therm. Spray Technol., 2012, 21(5), p 1065–1075.

M.R. Rokni, C.A. Widener and V.R. Champagne, Microstructural Evolution of 6061 Aluminum Gas-Atomized Powder and High-Pressure Cold-Sprayed Deposition, J. Therm. Spray Technol., 2014, 23(3), p 514–524.

G. Jeandin, et al. Influence of spray angle on cold spray with Al for the repair of aircraft components. Dvs Berichte (2014)

Z. Zhang, D. Leng, M. Lin et al., Cold Spray Deposition of Inconel 718 in Comparison with Atmospheric Plasma Spray Deposition, Appl. Surface Sci., 2020, 535, p 147704.

R. Singh, K.H. Rauwald, E. Wessel et al., Effects of Substrate Roughness and Spray-Angle on Deposition Behavior of Cold-Sprayed Inconel 718, Surf. Coat. Technol., 2017, 319, p 249–259.

E. Lin, Q. Chen, O.C. Ozdemir et al., Effects of Interface Bonding on the Residual Stresses in Cold-Sprayed Al-6061: A Numerical Investigation, J. Therm. Spray Technol., 2019, 28, p 472–483.

W. Wong, A. Rezaeian, E. Irissou et al., Cold Spray Characteristics of Commercially Pure Ti and Ti-6Al-4V, Adv. Mater. Res., 2010, 89–91, p 639–644.

S. Yin, X. Suo, J. Su et al., Effects of Substrate Hardness and Spray Angle on the Deposition Behavior of Cold-Sprayed Ti Particles, J. Therm. Spray Technol., 2014, 23(1), p 76–83.

L.I. Wenya, L.I. Changjiu, W. Yuyue et al., Effect of Parameters of Cold Sprayed Cu Particles on its Impacting Behavior, Acta Metall. Sin., 2005, 41(3), p 282–286. ((in Chinese))

C.H. Ng, S. Yin, R. Lupoi et al., Mechanical Reliability Modification of Metal Matrix Composite Coatings by Adding Al Particles via Cold Spray Technology, Surfaces Interfaces, 2020, 20, p 100515.

A. Xtl, G.A. Yi, B. Yx et al., Dynamic Evolution of Oxide Scale on the Surfaces of Feed Stock Particles from Cracking and Segmenting to Peel-Off While Cold Spraying Copper Powder Having a High Oxygen Content, J. Mater. Sci. Technol., 2021, 67, p 105–115.

V. Munagala, R. Chakrabarty, J. Song et al., Effect of Metal Powder Properties on the Deposition Characteristics of Cold-Sprayed Ti6Al4V-TiC Coatings: An Experimental and Finite Element Study, Surfaces Interfaces, 2021, 25, p 101208.

Y. Xie, C. Chen, M.P. Planche et al., Effect of Spray Angle on Ni Particle Deposition Behaviour in Cold Spray, Surface Eng., 2017, 34(5), p 352–360.

B.V. Padmini, D.G. Bhosale and H.B. Niranjan, A Study of T11 Boiler Steel Protection by Cold Sprayed Inconel 738 Coating Against High Temperature Erosion, Surfaces Interfaces, 2021, 23, p 101002.

Z. Zhang, H.L.D. Seng, M. Lin, S.L. Teo, T.L. Meng, J.J.C. Lee, Z.-Q. Zhang, T. Ba, J. Guo, K. Sundaravadivelu, P.K. Aw and J. Pan, Cold Spray Deposition of Inconel 718 in Comparison with Atmospheric Plasma Spray Deposition, Appl. Surf. Sci., 2021, 535, p 147704.

R. Ghelichi, S. Bagherifard, D. Macdonald et al., Experimental and Numerical Study of Residual Stress Evolution in Cold Spray Coating, Appl. Surface Sci., 2014, 288(JAN. 1), p 26–33.

J.Y. Lek, A. Bhowmik, A.W.-Y. Tan, W. Sun, X. Song, W. Zhai, P.J. Buenconsejo, F. Li, E. Liu, Y.M. Lam and C.B. Boothroyd, Understanding the Microstructural Evolution of Cold Sprayed Ti-6Al-4V Coatings on Ti-6Al-4V Substrates, Appl. Surf. Sci., 2018, 459, p 492–504.

X.T. Luo, Y.K. Wei, Y. Wang et al., Microstructure and Mechanical Property of Ti and Ti6Al4V Prepared by an In-Situ Shot Peening Assisted Cold Spraying, Mater. Des., 2015, 85(Nov. 15), p 527–533.

F. Sevillano, P. Poza, C.J. Mu’nez, S. Vezzu, S. Rech and A. Trentin, Cold-Sprayed Ni-Al2O3 Coatings for Applications in Power Generation Industry, J. Therm. Spray Technol., 2013, 22, p 772–782.

K. Cao, M. Yu, C.M. Liang and H. Chen, Study on Thermal Conductivity of Cold Sprayed Cu Coating, Surf. Eng., 2020, 36(10), p 1058–1066.

Acknowledgments

The authors gratefully acknowledge the financial support from National Natural Science Foundation of China (Nos.12075071 and 11875119) and Heilongjiang Touyan Innovation Team Program (HITTY-20190013).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there is no conflict of interests; we do not have any possible conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhou, C., Gong, C., Wang, Z. et al. Effect of Particle Incident Angle on the Hardness and Thermal Conductivity of Cu Coating Applied to a Cr-Zr-Cu Substrate using High-Pressure Cold Spray. J. of Materi Eng and Perform (2024). https://doi.org/10.1007/s11665-024-09189-w

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11665-024-09189-w