Abstract

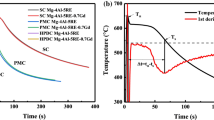

The effect of cooling rate on the microstructure and mechanical properties of the Al86Cu6Co2Y6 (at.%) alloy is studied in copper mold casting and melt spinning processes. The micro-hardness values of the copper-mold rods (248.4 ± 10.7 HV) are more than 3 times that of the conventional casting. Moreover, yield strength at room temperature has increased significantly by 67% (301 ± 13 MPa). The plastic strain increased from 4 to 7% during copper mold casting due to the microstructure refinement, extended solid solubility of elements, homogeneously distributed of the fine eutectic and intermetallic phases (Al3Y, AlCu, AlCu3, Al3Y5) along with the matrix. However, a further increase in the cooling rate up to about 6.9 × 106 Ks−1 obtained by the Lin and Johnson method during melt spinning can even inhibit the crystallization process. The amorphous ribbons exhibit a remarkable micro-hardness and tensile strength of 265.5 ± 12.6 HV and 701 ± 19 MPa, respectively. Non-crystalline structure with a lack of dislocations and grain boundaries results in such a high level of strength.

Graphical Abstract

Similar content being viewed by others

References

S. Jin, A. Wang, K. Wang, W. Li, B. Wan, and T. Zhai, Significant Strengthening Effect in Ultra-Fine Grained Al Alloy Made by Fast Solidification and Hot Extrusion Processes, J. Mater. Res. Technol., 2022, 16, p 1761–1769.

S. Liu, X. Wang, Q. Zu, B. Han, X. Han, and C. Cui, Significantly Improved Particle Strengthening of Al-Sc Alloy by High Sc Composition Design and Rapid Solidification, Mater. Sci. Eng. A, 2021, 800, p 140304.

M.T. P´erez-Prado, A. Martin, D.F. Shi, S. Milenkovic, and C.M. Cepeda-Jim´enez, An Al-5Fe-6Cr Alloy with Outstanding High Temperature Mechanical Behavior by Laser Powder Bed Fusion, Addit. Manuf., 2022, 55, p 102828.

H.R. Ammar, M. Baig, A.H. Seikh, and J.A. Mohammed, Effect of Alloying Elements on Thermal Stability of Nanocrystalline Al Alloys, Trans. Nonferrous Met. Soc. China, 2021, 31, p 11–23.

T. Kozieł, K. Pajor, and Ł. Gondek, Cooling Rate Evaluation during Solidification in the Suction Casting Process, J. Mater. Res. Technol., 2020, 9(6), p 13502–13508.

H. Teng, X. Zhang, Z. Zhang, T. Li, and S. Cockcroft, Research on Microstructures of Sub-rapidly Solidified AZ61 Magnesium Alloy, Mater Charact, 2009, 60, p 482–486.

K. Saksl, D. Vojtech, and J. Durisin, In situ XRD Studies on Al-Ni and Al-Ni-Sr Alloys, J. Alloys Compd., 2008, 464, p 95–100.

Y. Liu, M. Gao, S. Meng, Y. Fu, W. Li, C. Li, and R. Guan, Solidification Behavior and Enhanced Properties of Semi-Solid Ale8Sie0.5Fe Alloys Fabricated by Rheo-diecasting, J. Mater. Res. Technol., 2022, 19, p 3160–3171.

A.G. Odeshi, A.A. Tiamiyu, D. Das, N. Katwal, I.N.A. Oguocha, and A.K. Khan, High Strain-Rate Deformation of T8-tempered, Cryo-rolled and Ultrafine Grained AA 2099 Aluminum Alloy, Mater. Sci. Eng. A, 2019, 754, p 602–612.

Y.H. Kim, K. Hiraga, A. Inoue, T. Masumoto, and H.H. Jo, Crystallization and High Mechanical Strength of Al-based Amorphous Alloys, Mater. Trans. JIM, 1994, 35, p 293–302.

E. Pershina, D. Matveev, G. Abrosimova, and A. Aronin, Formation of Nanocrystals in an Amorphous Al90Y10 Alloy, Mater Charact, 2017, 133, p 87–93.

F.G. Cuevas, S. Lozano-Perez, R.M. Aranda, and E.S. Caballero, Crystallization of Amorphous Al-Sm-Ni-(Cu) Alloys, Intermetallics, 2008, 112, p 106537.

B. Rusanov, V. Sidorov, P. Svec, P. Svec Sr., D. Janickovic, A. Moroz, L. Son, and O. Ushakova, Electric Properties and Crystallization Behavior of Al-TM-REM Amorphous Alloys, J. Alloys Compd., 2019, 787, p 448–451.

A. Sahu, R.S. Maurya, and T. Laha, Non-isothermal Crystallization Behavior of Al86Ni8Y6 and Al86Ni6Y4.5Co2La15 Melt-Spun Ribbons, Milled Ribbon Particles and Bulk Samples Consolidated by Spark Plasma Sintering, Thermochim. Acta, 2020, 684, p 178486.

M. Kubota, P. Cizek, and W.M. Rainforth, Properties of Mechanically Milled and Spark Plasma Sintered Al-15 at.% MgB2 Composite Materials, Compos. Sci. Technol., 2008, 68, p 888–895.

Y. Shen and J.H. Perepezko, Al-based Amorphous Alloys: Glass-Forming Ability, Crystallization Behavior and Effects of Minor Alloying Additions, J. Alloys Compd., 2017, 707, p 3–11.

J.I. Hyun, C.I. Kim, S.W. Nam, W.T. Kim, and D.H. Kim, Nanoscale Phase Separation and Microstructure Evolution during Crystallization in Al-Si-Ni Amorphous Alloy, Mater. Des., 2020, 192, p 108719.

K.G. Prashanth, S. Scudino, B.S. Murty, and J. Eckert, Crystallization Kinetics and Consolidation of Mechanically Alloyed Al70Y16Ni10Co4 Glassy Powders, J. Alloys Compd., 2009, 477, p 171–177.

Z.H. Huang, J.F. Li, Q.L. Rao, and Y.H. Zhou, Effects of La Content on the Glass Transition and Crystallization Process of Al-Ni-La Amorphous Alloys, Intermetallics, 2007, 15, p 1139–1146.

S. Scudino, K.B. Surreddi, S. Sager, M. Sakaliyska, J.S. Kim, W. Löser, and J. Eckert, Production and Mechanical Properties of Metallic Glass-Reinforced Al-based Metal Matrix Composites, J. Mater. Sci., 2008, 43, p 4518–4526.

S.F. Chen, C.Y. Chen, and C.H. Lin, Insight on the Glass-Forming Ability of Al-Y-Ni-Ce bulk Metallic Glass, J. Alloys Compd., 2015, 637, p 418–425.

Z. Wang, S. Scudino, J. Eckert, and K.G. Prashanth, Selective Laser Melting of Nanostructured Al-Y-Ni-Co Alloy, Manuf. Lett., 2020, 25, p 21–25.

X. Shi, C. Wang, Z.T. Liu, X. Liu, J. Jiang, Z.M. Hua, Y.T. Mo, N. Jiang, M. Zha, and H.Y. Wang, Revealing the Underlying Mechanism of Abnormal Grain Growth in Sub-rapid Solidified Al-Mg-Si-Fe Alloy, Mater Charact, 2021, 174, p 110987.

S.Y. Zhang, X. Wang, X. Liu, Y.T. Mo, C. Wang, T. Cheng, O. Ivasishin, and H.Y. Wang, High Strength-Ductility Synergy Induced by Sub-rapid Solidification in Twin-Roll Cast Al-Mg-Si Alloys, J. Mater. Res. Technol., 2022, 16, p 922–933.

Z. Gong, J. Wang, Y. Sun, S. Zhu, L. Wang, and S. Guan, Microstructure and Mechanical Properties of the Sub-rapidly Solidified Mg-Zn-Y-Nd Alloy Prepared by Step-Copper Mold Casting, Mater. Today Commun., 2021, 27, p 102308.

Z.T. Liu, C. Wang, Q. Luo, J. You, X.L. Zhou, J. Xu, Y.T. Mo, J.W. Song, M. Zha, and H.Y. Wang, Effects of Mg Contents on the Microstructure Evolution and Fe-bearing phase selection of Al-Mg-Si-Fe Alloys under Sub-rapid Solidification, Materialia, 2020, 13, p 100850.

Y. Qu, K. Yang, Y. Zhou, Y. Mao, W. Zhang, and S. Xu, Phase Selection in Sub-rapidly Solidified Au-20Sn Alloys, Mater. Sci. Forum, 2015, 817, p 325–330.

S. Scudino, M. Sakaliyska, K.B. Surreddi, F. Ali, and J. Eckert, Structure and Mechanical Properties of Al-Mg Alloys Produced by Copper Mold Casting, J. Alloys Compd., 2010, 504S, p S483–S486.

T. Kozieł, Estimation of Cooling Rates in Suction Casting and Copper-Mold Casting Process, Arch. Metall. Mater., 2015, 60, p 2.

W.J. Botta, C. Triveno Rios, R.D. Sa Lisboa, A.R. de Andrade, M.F. de Oliveira, C. Bolfarini, and C.S. Kiminami, Crystallization Behaviors of Al-based Metallic Glasses: Compositional and Topological Aspects, J. Alloys Compd., 2009, 483, p 89–93.

A.P. Kumar, V.M.S. Muthaiah, and S. Mula, Effect of Nb, Y and Zr on Thermal Stability of Nanocrystalline Al-45 wt.% Cu Alloy Prepared by Mechanical Alloying, J. Alloys Compd., 2017, 722, p 617–627.

Y. Li, T. Jiang, B. Wei, B. Xu, G. Xu, and Z. Wang, Microcharacterization and Mechanical Performance of an Al-50Si Alloy Prepared Using the Sub-rapid Solidification Technique, Mater. Lett., 2020, 263, p 127287.

N. Unlu, A. Genc, and M.L. Ovecoglu, Characterization Investigation Meltspun Ternary Al−xSi−3.3Fe (x = 10, 20 wt.%) Alloys, J. Alloys Compd., 2001, 322, p 249–256.

S. Guo and Y. Liu, Estimation of Critical Cooling Rates for Formation of Amorphous Alloys from Critical Sizes, J. Noncryst. Solids, 2012, 358, p 2753–2758.

J.P. Liao, B.J. Yang, Y. Zhang, W.Y. Lu, X.J. Gu, and J.Q. Wang, Evaluation of Glass Formation and Critical Casting Diameter in Al-based Metallic Glasses, Mater. Des., 2015, 88, p 222–226.

C.T. Rios, S. Suriñach, M.D. Baró, C. Bolfarini, W.J. Botta, and C.S. Kiminami, Glass Forming Ability of the Al-Ce-Ni System, J. Noncryst. Solids, 2008, 354, p 4874–4877.

A. Inoue, Stabilization of Metallic Supercooled Liquid and Bulk Amorphous Alloys, Acta Mater., 2000, 48, p 279–306.

P.J. Squire and I.T.H. Chang, Development of Rapidly Solidified Al-Y-Ni-Based Alloys, Mater. Sci. Eng. A, 2007, 449–451, p 1009–1012.

M. Salehi and S.G. Shabestari, Nanostructure Evolution, Thermal Stability and Hardness of Amorphous Al-Cu-Y (Co, La) (at.%) Alloys, J. Noncryst. Solids, 2022, 589, p 121663.

S.V. Kontomaris and A. Malamou, Hertz Model or Oliver & Pharr Analysis? Tutorial Regarding AFM Nanoindentation Experiments on Biological Samples, Mater. Res. Express, 2020, 7, p 033001.

W.H. Jiang, F.E. Pinkerton, and M. Atzmon, Mechanical Behavior of Shear Bands and the Effect of Their Relaxation in a Rolled Amorphous Al-based Alloy, Acta Mater., 2005, 53, p 3469–3477.

Funding

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest with regard to the submitted manuscript.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Shabestari, M.G., Salehi, M. Investigation of the Effect of Sub-rapid Solidification Processes on the Microstructure and Mechanical Properties of Al86Cu6Co2Y6 (at.%) Alloy. J. of Materi Eng and Perform (2023). https://doi.org/10.1007/s11665-023-09051-5

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11665-023-09051-5