Abstract

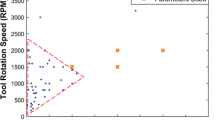

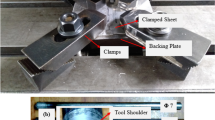

Friction stir tailor-welded blanks are often used in the production of complex-shaped components such as structural and automotive parts for their improved forming limits, uniform strain distribution throughout the component and material savings. Despite having such crucial impact, detailed investigation on the formability of friction stir-welded blanks is limited. This study investigated the impact of different weld parameters upon the mechanical properties and formability of friction stir-welded AA5754 sheets and correlating them with microstructure and texture studies. The tensile and hardness test results were explained based on weld quality at each parameter combination. To assess the formability, limit dome height tests were performed at different strain paths, and it was revealed that the minor strain of the welded specimens was poor in the biaxial region. Texture studies confirmed that the Goss texture component was either weak or completely diminished in the case of the biaxial strain path of deformed welded specimens leading to less minor strain in the biaxial region. The combinations of grain average misorientation, kernel average misorientation, grain orientation spread, and high-angle grain boundary fractions determined from EBSD studies showed the correlation for the effect of different weld parameters on mechanical properties and formability of friction stir-welded AA5754 sheets.

Similar content being viewed by others

References

A. Partnership, Tailor Welded Blank Design and Manufacturing Manual, Southfield, MI, 1995.

M. Simoncini, M. Cabibbo ,and A. Forcellese, Development of Double-Side Friction Stir Welding to Improve Post-Welding Formability of Joints in AA6082 Aluminium Alloy, Proc. Inst. Mech. Eng. Part B J. Eng. Manuf., 2016, 230(5), p 807-817.

T. Gnibl and M. Merklein, Material Flow Control in Tailor Welded Blanks by a Combination of Heat Treatment and Warm Forming, CIRP Ann. Manuf. Technol., 2016, 65, p 305-308.

P. Tayebi, A. Fazli, P. Asadi ,and M. Soltanpour, Formability Analysis of Dissimilar Friction Stir Welded AA 6061 and AA 5083 Blanks by SPIF Process, CIRP J. Manuf. Sci. Technol., 2019, 25, p 50-68.

R. Tylecote, The Solid Phase Welding of Metals, Edwaed Arnold Ltd., New York, 1968.

N.T. Kumbhar, S.K. Sahoo, I. Samajdar, G.K. Dey ,and K. Bhanumurthy, Microstructure and Microtextural Studies of Friction Stir Welded Aluminium Alloy 5052, Mater. Des., 2011, 32(3), p 1657-1666.

M. Pastor, H. Zhao, R.P. Martukanitz ,and T. Debroy, Porosity, Underfill and Magnesium Loss during Continuous Wave Nd: YAG Laser Welding of Thin Plates of Aluminum Alloys 5182 and 5754, Weld. J., 1999, 78, p 207-216.

F. Thompson, Welding of Aluminium and its Alloys, Nature, 1956, 177, p 568-569. https://doi.org/10.1038/177568b0.

R.S. Mishra and Z.Y. Ma, Friction Stir Welding and Processing, Mater. Sci. Eng. R. Rep., 2005, 50(1-2), p 1-78.

G. Buffa, L. Fratini ,and R. Shivpuri, Finite Element Studies on Friction Stir Welding Processes of Tailored Blanks, Comput. Struct., 2008, 86(1-2), p 181-189.

M. Guerra, C. Schmidt, J.C. McClure, L.E. Murr ,and A.C. Nunes, Flow Patterns during Friction Stir Welding, Mater Charact, 2002, 49(2), p 95-101.

E. Lertora, C. Mandolfino ,and C. Gambaro, Effect of Welding Parameters on AA8090 Al-Li Alloy FSW T-Joints, Key Eng. Mater., 2013, 554-557, p 985-995.

T. Hirata, T. Oguri, H. Hagino, T. Tanaka, S.W. Chung, Y. Takigawa ,and K. Higashi, Influence of Friction Stir Welding Parameters on Grain Size and Formability in 5083 Aluminum Alloy, Mater. Sci. Eng. A, 2007, 456(1-2), p 344-349.

M. Simoncini and A. Forcellese, Effect of the Welding Parameters and Tool Configuration on Micro- and Macro-Mechanical Properties of Similar and Dissimilar FSWed Joints in AA5754 and AZ31 Thin Sheets, Mater. Des., 2012, 41, p 50-60.

C. Leitao, R.M. Leal, D.M. Rodrigues, A. Loureiro ,and P. Vilaça, Mechanical Behaviour of Similar and Dissimilar AA5182-H111 and AA6016-T4 Thin Friction Stir Welds, Mater. Des., 2009, 30(1), p 101-108.

M.P. Miles, T.W. Nelson ,and B.J. Decker, Formability and Strength of Friction-Stir-Welded Aluminum Sheets, Metall. Mater. Trans. A, 2004, 35, p 3461-3468.

D. Kim, W. Lee, J. Kim, C. Kim ,and K. Chung, Formability Evaluation of Friction Stir Welded 6111-T4 Sheet with Respect to Joining Material Direction, Int. J. Mech. Sci., 2010, 52(4), p 612-625.

L.E. Murr, G. Liu ,and J.C. McClure, Dynamic Recrystallization in Friction-Stir Welding of Aluminium Alloy 1100, J. Mater. Sci. Lett., 1997, 16, p 1801-1803.

M.M. Attallah, C.L. Davis ,and M. Strangwood, Microstructure-Microhardness Relationships in Friction Stir Welded AA5251, J. Mater. Sci., 2007, 42, p 7299-7306.

D.M. Rodrigues, A. Loureiro, C. Leitao, R.M. Leal, B.M. Chaparro ,and P. Vilaça, Influence of Friction Stir Welding Parameters on the Microstructural and Mechanical Properties of AA 6016-T4 Thin Welds, Mater. Des., 2009, 30(6), p 1913-1921.

U.F.H.R. Suhuddin, S. Mironov, Y.S. Sato ,and H. Kokawa, Grain Structure and Texture Evolution during Friction Stir Welding of Thin 6016 Aluminum Alloy Sheets, Mater. Sci. Eng. A, 2010, 527(7-8), p 1962-1969.

J.H. Cho, W.J. Kim ,and C.G. Lee, Texture and Microstructure Evolution and Mechanical Properties during Friction Stir Welding of Extruded Aluminum Billets, Mater. Sci. Eng. A, 2014, 12(597), p 314-323.

R. Shabadi, S. Suwas, S. Kumar, H.J. Roven ,and E.S. Dwarkadasa, Texture and Formability Studies on AA7020 Al Alloy Sheets, Mater. Sci. Eng. A, 2012, 558, p 439-445.

M. Ghosh, A. Miroux ,and L.A.I. Kestens, Correlating r-Value and through Thickness Texture in Al-Mg-Si Alloy Sheets, J. Alloys Compd., 2015, 619, p 585-591.

S. Sinha, J.A. Szpunar, N.K. Kumar ,and N.P. Gurao, Tensile Deformation of 316L Austenitic Stainless Steel Using In-Situ Electron Backscatter Diffraction and Crystal Plasticity Simulations, Mater. Sci. Eng. A, 2015, 18(637), p 48-55.

J. Rossiter, A. Brahme, K. Inal ,and R. Mishra, Numerical Analyses of Surface Roughness during Bending of FCC Single Crystals and Polycrystals, Int. J. Plast., 2013, 46, p 82-93.

Z.G. Li, N. Li, H.W. Jiang, Y.Y. Xiong ,and L. Liu, Deformation Texture Evolution of Pure Aluminum Sheet under Electromagnetic Bulging, J. Alloy. Compd., 2014, 589, p 164-173.

K.K. Kumar, A. Kumar ,and S. Sundar, Investigation of Microstructure Characteristics and Work Hardening Behaviour of Water-Cooled FSW Dissimilar Aluminium Alloys, Mater. Today Commun., 2023, 35, p 105857.

K. Elangovan and V. Balasubramanian, Influences of Pin Profile and Rotational Speed of the Tool on the Formation of Friction Stir Processing Zone in AA2219 Aluminium Alloy, Mater. Sci. Eng. A, 2007, 459(1-2), p 7-18.

M.M. Ahmed, A.R. Essa, S. Ataya, M.M. El-Sayed Seleman, A.A. El-Aty, B. Alzahrani, K. Touileb, A. Bakkar, J.J. Ponnore ,and A.Y. Mohamed, Friction Stir Welding of AA5754-H24: Impact of Tool Pin Eccentricity and Welding Speed on Grain Structure, Crystallographic Texture,and Mechanical Properties, Materials, 2023, 16(5), p 2031.

L.M. Serio, D. Palumbo, L.A.C. De Filippis, U. Galietti ,and A.D. Ludovico, Effect of Friction Stir Process Parameters on the Mechanical and Thermal Behavior of 5754-H111 Aluminum Plates, Materials, 2016, 9(3), p 122.

P.H. Shah and V.J. Badheka, Friction Stir Welding of Aluminium Alloys: An Overview of Experimental Findings—Process, Variables, Development and Applications, Inst. Mech. Eng., 2019, 223(6), p 1191.

S. Gao, C.S. Wu ,and G.K. Padhy, Material Flow, Microstructure and Mechanical Properties of Friction Stir Welded AA 2024-T3 Enhanced by Ultrasonic Vibrations, J. Manuf. Processes., 2017, 1(30), p 385-395.

P.J. Ramulu, R.G. Narayanan ,and S.V. Kailas, Forming Limit Investigation of Friction Stir Welded Sheets: Influence of Shoulder Diameter and Plunge Depth, Int. J. Adv. Manuf. Technol., 2013, 69, p 2757-2772.

R. Rakshit, A. Sarkar, S.K. Panda ,and S. Mandal, Influence of Out-of-Plane Stretch Forming Induced Different Strain Paths on Micro-Texture Evolution, Slip System Activity and Taylor Factor Distribution in Al-Li Alloy, Mater. Sci. Eng. A, 2022, 830, p 142267.

M. Raturi and A. Bhattacharya, Microstructure and Texture Correlation of Secondary Heating Assisted Dissimilar Friction Stir Welds of Aluminum Alloys, Mater. Sci. Eng. A, 2021, 825, p 141891.

C. Cho, K. Son, J. Lee, S.K. Kim, Y. Yoon ,and S. Hyun, Effect of the Mg Contents on the Annealing Mechanism and Shear Texture of Al-Mg Alloys, Mater. Sci. Eng. A, 2020, 786, p 139471.

A. Kumar and K.K. Mugada, Investigation of Material Flow, Microstructure Evolution,and Texture Development in Dissimilar Friction Stir Welding of Al6061 to Ti6Al4V, Mater. Today Commun., 2022, 1(33), p 104424.

M.M.Z. Ahmed, S. Ataya, M.M.E.S. Seleman, T. Allam, N.A. Alsaleh ,and E. Ahmed, Grain Structure, Crystallographic Texture,and Hardening Behavior of Dissimilar Friction Stir Welded AA5083-O and AA5754-H14, Metals, 2021, 11(2), p 1-17.

M.M. Ahmed, B.P. Wynne, W.M. Rainforth, A. Addison, J.P. Martin ,and P.L. Threadgill, Effect of Tool Geometry and Heat Input on the Hardness, Grain Structure,and Crystallographic Texture of Thick-Section Friction Stir-Welded Aluminium, Metall. Mater. Trans. A, 2019, 50, p 271-284.

B.M. Darras and M.K. Khraisheh, Analytical Modeling of Strain Rate Distribution during Friction Stir Processing, J. Mater. Eng. Perform., 2008, 17, p 168-177.

A. Arora, Z. Zhang, A. De ,and T. DebRoy, Strains and Strain Rates during Friction Stir Welding, Scr. Mater., 2009, 61, p 863-866.

M. Bhargava, S. Chakrabarty, V.K. Barnwal, A. Tewari ,and S.K. Mishra, Effect of Microstructure Evolution during Plastic Deformation on the Formability of Transformation Induced Plasticity and Quenched & Partitioned AHSS, Mater. Des., 2018, 152, p 65-77.

V.K. Barnwal, R. Raghavan, A. Tewari, K. Narasimhan ,and S.K. Mishra, Effect of Microstructure and Texture on Forming Behaviour of AA-6061 Aluminium Alloy Sheet, Mater. Sci. Eng. A, 2017, 679, p 56-65.

R. Jamaati and M.R. Toroghinejad, Effect of Stacking Fault Energy on Deformation Texture Development of Nanostructured Materials Produced by the ARB Process, Mater. Sci. Eng. A, 2014, 598, p 263-276.

R.W. Fonda, J.F. Bingert ,and K.J. Colligan, Development of Grain Structure during Friction Stir Welding, Scr. Mater., 2004, 51, p 243-248.

B. Wang, B.B. Lei, J.X. Zhu, Q. Feng, L. Wang ,and D. Wu, EBSD Study on Microstructure and Texture of Friction Stir Welded AA5052-O and AA6061-T6 Dissimilar Joint, Mater. Des., 2015, 87, p 593-599.

H. Jin and D.J. Lloyd, The Different Effects of Asymmetric Rolling and Surface Friction on Formation of Shear Texture in Aluminium Alloy AA5754, Mater. Sci. Technol., 2010, 26, p 754-760.

S.W. Banovic, M.A. Iadicola and T. Foecke, Textural Development of AA 5754 Sheet Deformed under In-Plane Biaxial Tension, Metall. Mater. Trans. A, 2008, 39, p 2246-2258.

J.H. Han, K.K. Jee ,and K.H. Oh, Orientation Rotation Behavior during In Situ Tensile Deformation of Polycrystalline 1050 Aluminum Alloy, Int. J. Mech. Sci., 2003, 45, p 1613-1623.

S. Panchanadeeswaran and D.P. Field, Texture Evolution during Plane Strain Deformation of Aluminum, Acta Metall. Mater., 1995, 43(4), p 1683-1692.

W.C. Liu, C. Man ,and J.G. Morris, Lattice Rotation of the Cube Orientation to the β Fiber during Cold Rolling of AA 5052 Aluminum Alloy, Scr. Mater., 2001, 45(7), p 807-814.

S. Birosca, The Deformation Behaviour of Hard and Soft Grains in RR1000 Nickel-Based Superalloy, IOP Conf. Ser. Mater. Sci. Eng., 2015, 82, p 012033.

H.W. Yang, I.P. Widiantara and Y.G. Ko, Effect of Deformation Path on Texture and Tension Properties of Submicrocrystalline Al-Mg-Si Alloy Fabricated by Differential Speed Rolling, Mater. Lett., 2018, 213, p 54-57.

Acknowledgment

The authors are delighted to acknowledge Prof. K. Narasimhan, IIT Bombay, for extending the Metal Forming Laboratory facility for this work. The authors are also pleased to acknowledge Prof. Sushil Kumar Mishra, for extending their support to use EBSD at the Microstructural Mechanics and Micro-forming Laboratory at IIT Bombay for this work. The help provided by Dr. V Buchibabu, IIT Palakkad, Dr. M. Gopinath, IIT Hyderabad, and Soumya Ranjan Nayak, IIT Bombay, for conducting the experiments is also deeply acknowledged.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Datta, R., Raja, D. & Bhargava, M. Microstructure and Texture Correlation with Mechanical Properties and Formability of Friction Stir-Welded AA5754 Sheets. J. of Materi Eng and Perform (2023). https://doi.org/10.1007/s11665-023-09043-5

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11665-023-09043-5