Abstract

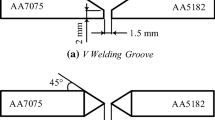

This study explored the heat input effects on automated TIG welded dissimilar AA6061-T6 and AA7075-T6 joints using filler ER5356. Three heat input welded samples, namely HI1 (0.73 kJ/mm), HI2 (1.69 kJ/mm), and HI3 (2.27 kJ/mm), were utilized and their corresponding microstructure and grain boundary features were investigated and correlated with the joint’s mechanical properties. Electron backscattered diffraction (EBSD) results showed that the low-angle grain boundaries (LAGBs) in the base alloys transformed into high-angle grain boundaries (HAGBs) in the fusion zone (FZ) after welding. However, the grain boundary transformations were more pronounced in the high heat input welded sample HI3. Pole figures revealed strong dominance of \({\mathrm{A}}_{1}^{*}\)/\({\mathrm{A}}_{2}^{*}\) and A/\(\stackrel{\mathrm{-}}{\mathrm{A}}\) textures with a small amount of C and B/\(\stackrel{\mathrm{-}}{\mathrm{B}}\) textures at the FZ for all the heat input joints. Orientation distribution functions also exhibited the recrystallization textures P {011} <112> and Goss {110} <001> , plane strain texture S {123} <634> with some deformation texture H {001} <110> at the FZ center. The medium heat input sample HI2 had the highest tensile strength of 182 MPa, elongation of 14.4%, and flexural strength of 202 MPa; while, the welded sample HI1 had the highest microhardness of 81 HV when compared to other welded samples. The HI2 joint fracture surface exhibits fine dimples devoid of porosities, suggesting ductile fracture manner. However, the fracture surface of the HI3 joint displayed both smooth and rough cleavage facets with coarser dimples, resulting in a combination of ductile and brittle fracture modes.

Similar content being viewed by others

References

R.I. Rodriguez, J.B. Jordon, P.G. Allison, T. Rushing and L. Garcia, Microstructure and Mechanical Properties of Dissimilar Friction Stir Welding of 6061-to-7050 Aluminum Alloys, Mater. Des., 2015, 83, p 60–65. https://doi.org/10.1016/j.matdes.2015.05.074

H. Mehdi and R.S. Mishra, Consequence of Reinforced SiC Particles on Microstructural and Mechanical Properties of AA6061 Surface Composites by Multi-pass FSP, J. Adhes. Sci. Technol.Adhes. Sci. Technol., 2022, 36, p 1279–1298. https://doi.org/10.1080/01694243.2021.1964846

R.S. Mishra, Z.Y. Ma and I. Charit, Friction Stir Processing: A Novel Technique for Fabrication of Surface Composite, Mater. Sci. Eng. A, 2003, 341, p 307–310. https://doi.org/10.1016/S0921-5093(02)00199-5

M. Paidar, R. VairaVignesh, A. Moharrami, O.O. Ojo, A. Jafari and S. Sadreddini, Development and Characterization of Dissimilar Joint Between AA2024-T3 and AA6061-T6 by Modified Friction Stir Clinching Process, Vacuum, 2020, 176, p 109298. https://doi.org/10.1016/j.vacuum.2020.109298

S. Memon, M. Paidar, O.O. Ojo, K. Cooke, B. Babaei and M. Masoumnezhad, The Role of Stirring Time on the Metallurgical and Mechanical Properties during Modified Friction Stir Clinching of AA6061-T6 and AA7075-T6 Sheets, Results Phys., 2020 https://doi.org/10.1016/j.rinp.2020.103364

Z. Liu, K. Yang and D. Yan, Refill Friction Stir Spot Welding of Dissimilar 6061/7075 Aluminum Alloy, High Temp. Mater. Processes (London), 2019, 38, p 69–75. https://doi.org/10.1515/htmp-2017-0139

F. Ozturk, A. Sisman, S. Toros, S. Kilic and R.C. Picu, Influence of Aging Treatment on Mechanical Properties of 6061 Aluminum Alloy, Mater. Des., 2010, 31, p 972–975. https://doi.org/10.1016/j.matdes.2009.08.017

M. Temmar, M. Hadji and T. Sahraoui, Effect of Post-weld Aging Treatment on Mechanical Properties of Tungsten Inert Gas welded low Thickness 7075 Aluminium Alloy Joints, Mater. Des., 2011, 32, p 3532–3536. https://doi.org/10.1016/j.matdes.2011.02.011

M. Hakem, S. Lebaili, S. Mathieu, D. Miroud, A. Lebaili and B. Cheniti, Effect of Microstructure and Precipitation Phenomena on the Mechanical Behavior of AA6061-T6 Aluminum Alloy Weld, Int. J. Adv. Manuf. Technol., 2019, 102, p 2907–2918. https://doi.org/10.1007/s00170-019-03401-1

P. Bahemmat, M. Haghpanahi, M.K. Besharati, S. Ahsanizadeh and H. Rezaei, Study on Mechanical, Micro-, and Macrostructural Characteristics of Dissimilar Friction Stir Welding of AA6061-T6 and AA7075-T6, Proc. Inst. Mech. Eng. B J. Eng. Manuf., 2010, 224, p 1854–1865. https://doi.org/10.1243/09544054JEM1959

S. Jain, R.S. Mishra, H. Mehdi, R. Gupta and A.K. Dubey, Optimization of Processing Variables of Friction Stir Welded Dissimilar Composite Joints of AA6061 and AA7075 using Response Surface Methodology, J. Adhes. Sci. Technol.Adhes. Sci. Technol., 2023 https://doi.org/10.1080/01694243.2023.2243682

B.C. Evik and M. Koç, The Effects of Welding Speed on the Microstructure and Mechanical Properties of Marine-grade Aluminium (AA5754) Alloy Joined using MIG Welding, Metallic Materials/Kovové Materiály, 2019, 57, p 307–316.

M. Ishak, N.F. Mohd Noordin and L.H. Ahmad Shah, Feasibility Study on Joining Dissimilar Aluminum Alloys AA6061 and AA7075 by Tungsten Inert Gas (TIG), J. Teknol., 2015 https://doi.org/10.11113/jt.v75.5177

S.S. Kumar and G. Godwin, An Enhancement of Properties on Al7075 and Al6061 Dissimilar Materials Welded by TIG Process, Int. Res. J. Adv. Sci. Hub, 2020, 2, p 115–121. https://doi.org/10.47392/irjash.2020.47

M.S. Bin Reyaz and A.N. Sinha, Analysis of Mechanical Properties and Optimization of Tungsten Inert Gas Welding Parameters on Dissimilar AA6061-T6 and AA7075-T6 by a Response Surface Methodology-Based Desirability Function Approach, Eng. Optim.Optim., 2023 https://doi.org/10.1080/0305215X.2023.2230133

G. İpekoğlu, S. Erim and G. Çam, Investigation into the Influence of Post-Weld Heat Treatment on the Friction Stir Welded AA6061 Al-Alloy Plates with Different Temper Conditions, Metall. and Mater. Trans. A., 2014, 45, p 864–877. https://doi.org/10.1007/s11661-013-2026-y

G. İpekoğlu and G. Çam, Effects of Initial Temper Condition and Postweld Heat Treatment on the Properties of Dissimilar Friction-Stir-Welded Joints between AA7075 and AA6061 Aluminum Alloys, Metall. Mater. Trans. A, 2014, 45, p 3074–3087. https://doi.org/10.1007/s11661-014-2248-7

G. Çam, G. İpekoğlu and S.H. Tarık, Effects of use of Higher Strength Interlayer and External Cooling on Properties of Friction Stir Welded AA6061-T6 Joints, Sci. Technol. Weld. Joining, 2014, 19, p 715–720. https://doi.org/10.1179/1362171814Y.0000000247

G. Çam and G. İpekoğlu, Recent Developments in Joining of Aluminum Alloys, Int. J. Adv. Manuf. Technol., 2017, 91, p 1851–1866. https://doi.org/10.1007/s00170-016-9861-0

N. Kashaev, V. Ventzke and G. Çam, Prospects of Laser Beam Welding and Friction Stir Welding Processes for Aluminum Airframe Structural Applications, J. Manuf. Process., 2018, 36, p 571–600. https://doi.org/10.1016/j.jmapro.2018.10.005

A. Heidarzadeh, S. Mironov, R. Kaibyshev, G. Çam, A. Simar, A. Gerlich et al., Friction Stir Welding/Processing of Metals and Alloys: A Comprehensive Review on Microstructural Evolution, Prog. Mater. Sci. Mater. Sci., 2021, 117, p 100752. https://doi.org/10.1016/j.pmatsci.2020.100752

A. Yürük, B. Çevik and N. Kahraman, Analysis of Mechanical and Microstructural Properties of Gas Metal Arc Welded Dissimilar Aluminum Alloys (AA5754/AA6013), Mater. Chem. Phys., 2021 https://doi.org/10.1016/j.matchemphys.2021.125117

A.O. Al-Roubaiy, S.M. Nabat and A.D.L. Batako, Experimental and Theoretical Analysis of Friction Stir Welding of Al-Cu Joints, Int. J. Adv. Manuf. Technol., 2014, 71, p 1631–1642. https://doi.org/10.1007/s00170-013-5563-z

L. Kaba, M.E. Djeghlal, S. Ouallam and S. Kahla, Dissimilar Welding of Aluminum Alloys 2024 T3 and 7075 T6 by TIG Process with Double Tungsten Electrodes, Int. J. Adv. Manuf. Technol., 2022, 118, p 937–948. https://doi.org/10.1007/s00170-021-07888-5/Published

H. Mehdi and R.S. Mishra, Effect of Friction Stir Processing on Mechanical Properties and Wear Resistance of Tungsten Inert Gas Welded Joint of Dissimilar Aluminum Alloys, J. Mater. Eng. Perform., 2021, 30, p 1926–1937. https://doi.org/10.1007/s11665-021-05549-y

Tanmay and S.S. Panda, Characterisation of Cu–Al Alloy Lap Joint using TIG Welding, CIRP J. Manuf. Sci. Technol., 2021, 35, p 454–459. https://doi.org/10.1016/j.cirpj.2021.07.009

S. Jain and R.S. Mishra, A Review of the Effect of Process Parameters and Temperature Variation on FSWed Dissimilar Aluminium Alloys AA7075 and AA6061, Emerging Trends Mech. Ind. Eng. Select Procee. ICETMIE, 2023 https://doi.org/10.1007/978-981-19-6945-4_64

R. Crushan and V.P. Ashoka, Optimization of Dissimilar AA5052-H32 and AA5083-H111 Aluminium FSW Joints with Scandium Interfacial Layer, Mater. Manuf. Processes, 2023, 38, p 1372–1384. https://doi.org/10.1080/10426914.2023.2165672

M. Raturi, A. Garg and A. Bhattacharya, Joint Strength and Failure Studies of Dissimilar AA6061-AA7075 Friction Stir Welds: Effects of Tool Pin, Process Parameters and Preheating, Eng. Fail. Anal., 2019, 96, p 570–588. https://doi.org/10.1016/j.engfailanal.2018.12.003

A. Garg, M. Raturi, A. Garg and A. Bhattacharya, Microstructure Evolution and Mechanical Properties of Double-sided Friction Stir Welding between AA6061-T6 and AA7075-T651, CIRP J. Manuf. Sci. Technol., 2020, 31, p 431–438. https://doi.org/10.1016/j.cirpj.2020.07.005

C. Chen, G. Sun, W. Du, Y. Li, C. Fan and H. Zhang, Influence of Heat Input on the Appearance, Microstructure and Microhardness of Pulsed Gas Metal Arc Welded Al Alloy Weldment, J. Market. Res., 2022, 21, p 121–130. https://doi.org/10.1016/j.jmrt.2022.09.028

H. Rojas, A. Molina, S. Valdez, B. Campillo, H. Martínez, A. Sedano et al., The Impact of Heat Input on the Microstructures, Fatigue Behaviors, and Stress Lives of TIG-welded 6061–T6 Alloy Joints, Mater. Res. Express, 2020, 7, p 126512. https://doi.org/10.1088/2053-1591/abd136

M. Samiuddin, J. Li, M. Taimoor, M.N. Siddiqui, S.U. Siddiqui and J. Xiong, Investigation on the Process Parameters of TIG-welded Aluminum Alloy Through Mechanical and Microstructural Characterization, Def. Technol., 2021, 17, p 1234–1248. https://doi.org/10.1016/j.dt.2020.06.012

B. Çevik, Gas Tungsten Arc Welding of 7075 Aluminum Alloy: Microstructure Properties, Impact Strength, and Weld Defects, Mater. Res. Express, 2018, 5, p 066540. https://doi.org/10.1088/2053-1591/aacbbc

M.S. Bin Reyaz and A.N. Sinha, An Experimental Investigation on Mechanical Characteristics and Wear Behaviour of TIG Welded Dissimilar Aluminum Alloys, J. Adhes. Sci. Technol.Adhes Sci Technol, 2023 https://doi.org/10.1080/01694243.2023.2251782

N. Çömez and H. Durmuş, Mechanical Properties and Corrosion Behavior of AA5754-AA6061 Dissimilar Aluminum Alloys Welded by Cold Metal Transfer, J. Mater. Eng. Perform., 2019, 28, p 3777–3784. https://doi.org/10.1007/s11665-019-04131-x

H. Ma, G. Qin, P. Geng, Z. Ao and Y. Chen, Effect of Intermetallic Compounds on the Mechanical Property and Corrosion Behaviour of Aluminium Alloy/steel Hybrid Fusion-brazed Welded Structure, J. Manuf. Process., 2022, 75, p 170–180. https://doi.org/10.1016/j.jmapro.2022.01.004

Z. Ye, J. Huang, W. Gao, Y. Zhang, Z. Cheng, S. Chen et al., Microstructure and Mechanical Properties of 5052 Aluminum Alloy/mild Steel butt Joint Achieved by MIG-TIG Double-sided Arc Welding-brazing, Mater. Des., 2017, 123, p 69–79. https://doi.org/10.1016/j.matdes.2017.03.039

Q. Qin, H. Zhao, J. Li, Y. Zhang, B. Zhang and X. Su, Microstructures and Mechanical Properties of TIG Welded Al-Mg2Si Alloy Joints, J. Manuf. Process., 2020, 56, p 941–949. https://doi.org/10.1016/j.jmapro.2020.05.058

Y. Guo, Y. Ma, X. Zhang, X. Qian and J. Li, Study on Residual Stress Distribution of 2024–T3 and 7075–T6 Aluminum Dissimilar Friction Stir Welded Joints, Eng. Fail. Anal., 2020 https://doi.org/10.1016/j.engfailanal.2020.104911

B. Wang, B.B. Lei, J.X. Zhu, Q. Feng, L. Wang and D. Wu, EBSD Study on Microstructure and Texture of Friction Stir Welded AA5052-O and AA6061-T6 Dissimilar Joint, Mater. Des., 2015, 87, p 593–599. https://doi.org/10.1016/j.matdes.2015.08.060

H. Mehdi and R.S. Mishra, Microstructure and Mechanical Characterization of Tungsten Inert Gas-welded Joint of AA6061 and AA7075 by Friction Stir Processing, Procee. Inst. Mech. Eng. Part L J. Mater. Design Appl., 2021, 235, p 2531–2546. https://doi.org/10.1177/14644207211007882

R. Yamada, S. Ishizawa, G. Itoh, A. Kurumada, and M. Nakai. Effects of Environment on Fatigue Crack Growth Behavior of 2000 and 7000 Series Aluminum Alloys. Recent Advances in Structural Integrity Analysis - Proceedings of the International Congress (APCF/SIF-2014), Elsevier; 2014, pp 123–6. https://doi.org/10.1533/9780081002254.123.

C. Rathinasuriyan and V.S.S. Kumar, Mechanical and Metallurgical Properties of GTAW, GMAW and FSW Lap Joints on AA6061-T6 Alloy, Adv. Mater. Processing Technol., 2022, 8, p 3231–3247. https://doi.org/10.1080/2374068X.2021.1946322

G.M.D. Cantin and J.A. Francis, Arc Power and Efficiency in Gas Tungsten Arc Welding of Aluminium, Sci. Technol. Weld. Joining, 2005, 10, p 200–210. https://doi.org/10.1179/174329305X37033

N. Stenbacka, I. Choquet, and K. Hurtig. Review of arc efficiency values for gas tungsten arc welding. IIW Commission IV-XII-SG212, Intermediate Meeting, BAM, Berlin, Germany, 2012, pp 18–20

Y. Koli, N. Yuvaraj, S. Aravindan and Vipin, CMT Joining of AA6061-T6 and AA6082-T6 and Examining Mechanical Properties and Microstructural Characterization, Trans. Indian Inst. Metals, 2021, 74, p 313–329. https://doi.org/10.1007/s12666-020-02134-0

D. Peng, J. Shen, Q. Tang, C.P. Wu and Y.B. Zhou, Effects of Aging Treatment and Heat Input on the Microstructures and Mechanical Properties of TIG-welded 6061–T6 Alloy Joints, Int. J. Miner. Metall. Mater., 2013, 20, p 259–265. https://doi.org/10.1007/s12613-013-0721-8

G. Song, Z. Wang, Z. Liu and L. Liu, Effect of Partial Rolling on the Microstructure and Mechanical Properties of Laser-TIG Hybrid Welded Joints of 7075–T6 Aluminum Alloy, Int. J. Adv. Manuf. Technol., 2022, 121, p 589–599. https://doi.org/10.1007/s00170-022-09287-w

N. Çömez and H. Durmus, Cold Metal Transfer Welding of AA6061 to AA7075: Mechanical Properties and Corrosion, J. Eng. Mater. Technol. Trans. ASME, 2019 https://doi.org/10.1115/1.4042863

I. Sevim, F. Hayat, Y. Kaya, N. Kahraman and S. Şahin, The Study of MIG Weldability of Heat-treated Aluminum Alloys, Int. J. Adv. Manuf. Technol., 2013, 66, p 1825–1834. https://doi.org/10.1007/s00170-012-4462-z

A.H. Eftekhar, S.M. Sadrossadat and M. Reihanian, Effect of Heat Input on Microstructure and Mechanical Properties of TIG-welded Semisolid Cast AXE622 Mg Alloy, Mater CharactCharact., 2022 https://doi.org/10.1016/j.matchar.2021.111692

C. Liu, D.O. Northwood and S.D. Bhole, Tensile Fracture Behavior in CO2 Laser Beam Welds of 7075–T6 Aluminum Alloy, Mater. Des.Des., 2004, 25, p 573–577. https://doi.org/10.1016/j.matdes.2004.02.017

S. Li, H. Dong, X. Wang, Z. Liu, Z. Tan, L. Shangguan et al., Effect of Repair Welding on Microstructure and Mechanical Properties of 7N01 Aluminum Alloy MIG Welded Joint, J. Manuf. Process., 2020, 54, p 80–88. https://doi.org/10.1016/j.jmapro.2020.03.009

H. Zhao, Q. Pan, Q. Qin, Y. Wu and X. Su, Effect of the Processing Parameters of Friction Stir Processing on the Microstructure and Mechanical Properties of 6063 Aluminum Alloy, Mater. Sci. Eng. A, 2019, 751, p 70–79. https://doi.org/10.1016/j.msea.2019.02.064

M. Verma and P. Saha, Effect of Micro-grooves Featured Tool and their Depths on Dissimilar Micro-friction Stir Welding (μFSW) of Aluminum Alloys: A Study of Process Responses and Weld Characteristics, Mater. CharactCharact, 2023, 196, p 112614. https://doi.org/10.1016/j.matchar.2022.112614

H. Zhao, M. Yu, Z. Jiang, L. Zhou and X. Song, Interfacial Microstructure and Mechanical Properties of Al/Ti Dissimilar Joints Fabricated via Friction Stir Welding, J. Alloys Compd., 2019, 789, p 139–149. https://doi.org/10.1016/j.jallcom.2019.03.043

N.S. Biradar and R. Raman, Grain Refinement in Al-Mg-Si Alloy TIG Welds using Transverse Mechanical Arc Oscillation, J. Mater. Eng. Perform., 2012, 21, p 2495–2502. https://doi.org/10.1007/s11665-012-0207-2

R.W. Fonda and J.F. Bingert, Texture Variations in an Aluminum Friction Stir Weld, Scr. Mater., 2007, 57, p 1052–1055. https://doi.org/10.1016/j.scriptamat.2007.06.068

M. Verma and P. Saha, Effect of Micro-grooves Featured Tool and their Depths on Dissimilar Micro-friction Stir Welding (μFSW) of Aluminum Alloys: A Study of Process Responses and Weld Characteristics, Mater CharactCharact., 2023 https://doi.org/10.1016/j.matchar.2022.112614

M. Raturi and A. Bhattacharya, Microstructure and Texture Correlation of Secondary Heating Assisted Dissimilar Friction Stir Welds of Aluminum Alloys, Mater. Sci. Eng. A, 2021 https://doi.org/10.1016/j.msea.2021.141891

J. Li, H. Li, Y. Liang, P. Liu and L. Yang, The Microstructure and Mechanical Properties of Multi-strand, Composite Welding-wire Welded Joints of High Nitrogen Austenitic Stainless Steel, Materials, 2019 https://doi.org/10.3390/ma12182944

O.G. Rivera, P.G. Allison, L.N. Brewer, O.L. Rodriguez, J.B. Jordon, T. Liu et al., Influence of Texture and Grain Refinement on the Mechanical Behavior of AA2219 Fabricated by High Shear Solid State Material Deposition, Mater. Sci. Eng. A, 2018, 724, p 547–558. https://doi.org/10.1016/j.msea.2018.03.088

C.D. Lee, Effect of Grain Size on the Tensile Properties of Magnesium Alloy, Mater. Sci. Eng. A, 2007, 459, p 355–360. https://doi.org/10.1016/j.msea.2007.01.008

M. Tariq, I. Khan, G. Hussain and U. Farooq, Microstructure and Micro-Hardness Analysis of Friction Stir Welded Bi-layered Laminated Aluminum Sheets, Int. J. Lightweight Mater. Manuf., 2019, 2, p 123–130. https://doi.org/10.1016/j.ijlmm.2019.04.010

M.P. Alam and A.N. Sinha, Effect of Heat Assisting Backing Plate in Friction Stir Welding of High Strength Al-Li Alloy, Energy Sour. Part A Recovery Util. Environ. Effects, 2022, 44, p 2851–2862. https://doi.org/10.1080/15567036.2019.1651793

Acknowledgment

The authors acknowledge OIM and Texture Laboratory, the Department of Metallurgical Engineering and Materials Science (MEMS) at Indian Institute of Technology Bombay, Powai, Mumbai, for their assistance in EBSD characterization, which helped complete this study.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

Authors in the present study did not report any conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Reyaz, M.S.B., Sinha, A.N. Effect of Heat Input on Microstructure and Mechanical Properties of Automated Tungsten Inert Gas-Welded Dissimilar AA6061-T6 and AA7075-T6 Joints. J. of Materi Eng and Perform (2023). https://doi.org/10.1007/s11665-023-09026-6

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11665-023-09026-6