Abstract

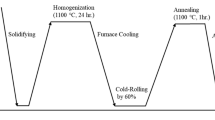

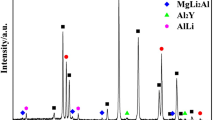

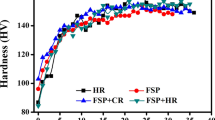

In this paper, the effects of Er element on the microstructure, mechanical properties, texture and deformation properties of 1561 alloy were characterized by optical microscopy, scanning electron microscopy, mechanical properties testing and first-principles calculation. The results reveal that the addition of 0.12%Er reduces the grain size of as-cast alloy by 23% compared with that 295 μm without Er. The tensile strength and yield strength of cold-rolled alloy with 0.12%Er are elevated by 3.8 and 4.0%, respectively. Al3Er can act as heterogeneous nucleation points, and its uniformly distributed within the grain can effectively impede the propagation of movable dislocations during deformation and recrystallization, which can increase the recrystallization temperature and uniformly dispersing deformation. However, the Al3Er phase exhibits brittleness, which will reduce the toughness of the alloy. For the PLC effect, the alloy containing Er has higher stress drop ∆σ and reloading time ∆t. The increase in strain rate can distinctly reduce ∆σ and ∆t. Therefore, conducting an adjustment of the processing rate of Al-Mg alloy appropriately in production is beneficial to the uniform deformation of the workpiece.

Similar content being viewed by others

References

D.S. Zhou, X.Z. Zhang, H. Wang et al., Influence of Mg on Tensile Deformation Behavior of High Mg-Content Al-Mg Alloys, Int. J. Plasticity, 2022, 157, p 103405.

W. Xu, Y.C. Xin, B. Zhang et al., Stress Corrosion Cracking Resistant Nanostructured Al-Mg Alloy with Low Angle Grain Boundaries, Acta Mater., 2022, 225, p 117607.

M.J. Li, S. Liu, X.D. Wang et al., Improved Intergranular Corrosion Resistance of Al-Mg-Mn Alloys with Sc and Zr Additions, Micron, 2022, 154, 103202.

K. Son, M.E. Kassner, T. Lee et al., Mg Effect on the Cryogenic Temperature Toughness of Al-Mg Alloys, Mater. Design, 2022, 224, p 111336.

X.Y. Li, W.J. Xia, J.H. Chen et al., Dynamic Recrystallization Texture and Mechanical Properties of High Mg Content Al-Mg Alloy Deformed by High Strain Rate Rolling, T. Nonferr. Metal SOC, 2021, 31, p 2885–2898.

M. Zha, Y. Li, R.H. Mathiesen et al., Microstructure Evolution and Mechanical Behavior of a Binary Al-7Mg Alloy Processed by Equal-Channel Angular Pressing, Acta Mater., 2015, 84, p 42–54.

M. Zha, H.M. Zhang, Z.Y. Yu et al., Bimodal Microstructure - A Feasible Strategy for High-Strength and Ductile Metallic Materials, J. Mater. Sci. Technol., 2018, 34, p 257–264.

A. Syl, B. Ct, B. Jih et al., Macroscopic and Microscopic Characterizations of Portevin-LeChatelier Effect in Austenitic Stainless Steel Using High-Temperature Digital Image Correlation Analysis, Acta Mater., 2020, 205, p 116560.

H.J. Pan, M.H. Cai, H. Ding et al., Microstructure Evolution and Enhanced Performance of a Novel Nb-Mo microalloyed Medium Mn Alloy Fabricated by Low-Temperature Rolling and Warm Stamping, Mater. Des., 2017, 134, p 352–360.

X.G. Wang, L. Wang, and M.X. Huang, Kinematic and Thermal Characteristics of Lüders and Portevin-Le Châtelier Bands in a Medium Mn Transformation-Induced Plasticity Steel, Acta Mater., 2017, 124, p 17–29.

F. Shehata, M.J. Painter, and R. Pearce, Warm Forming of Aluminium/Magnesium Alloy Sheet, J. Mech. Work. Technol., 1978, 2, p 279–290.

L. Zhang, C.Y. Liu, B. Zhang et al., Mechanical Properties of Al-Mg Alloys with Equiaxed Grain Structure Produced by Friction Stir Processing, Mater. Chem. Phys., 2023, 294, p 127010.

E. Aldalur, A. Suárez, and F. Veiga, Metal Transfer Modes for Wire Arc Additive Manufacturing Al-Mg Alloys: Influence of Heat Input in Microstructure and Porosity, J. Mater. Process. Tech., 2021, 297, 117271.

T.L. Liu, H.R. Li, Y.L. Ma et al., Investigation of Anisotropy And Structure Variation Of Spray-Formed 2195 Al-Li Alloy Via Final Temperature-Controlled Rolling and Cold Rolling, J. Alloy. Compd., 2023, 937, p 168414.

X.X. Chen, G.Q. Zhao, X. Xu et al., Effects of Heat Treatment on the Microstructure, Texture and Mechanical Property Anisotropy of Extruded 2196 Al-Cu-Li Alloy, J. Alloy. Compd., 2021, 862, p 158102.

B.D. Zanchetta, V.K.D. Silva, V.L. Sordi, J.B. Rubert et al., Effect of Asymmetric Rolling Under High Friction Coefficient on Recrystallization Texture and Plastic Anisotropy of AA1050 alloy, T. Nonferr. Metal. Soc., 2019, 29, p 2262–2272.

E. Nes, N. Ryum, and O.J. Hunderi, On the Zener Drag, Acta Metall., 1985, 33(1), p 11–22.

Q.A. Li, X.F. Li, Q. Zhang et al., Effect of Rare-Earth Element Sm on the Corrosion Behavior of Mg-6Al-1.2Y-0.9Nd Alloy, Rare Met., 2010, 29, p 557–560.

H. Yan, X.C. Song, and X. Huang, Preparation of Al-La Master Alloy by Ultrasonic Method and Modification on Al Alloy, Rare Met., 2015, 34, p 457–462.

X. Zhang, Z.H. Wang, Z.H. Zhou et al., Effects of Magnetic Field and Rare Earth Addition on Corrosion Behavior of Al-3.0 wt% Mg Alloy, J. Alloy. Compd., 2017, 698, p 241–249.

X.X. Yu, J. Sun, Z.T. Li et al., Solidification Behavior and Elimination of Undissolved Al2CuMg Phase During Homogenization in Ce-modified Al-Zn-Mg-Cu Alloy, Rare Met., 2020, 39, p 1279–1287.

G. Kresse and J. Hafner, Ab Initio Molecular Dynamics for Liquid Metals, Phys. Rev. B, 1993, 47(1), p 558–561.

J.P. Perdew, K. Burke, and M. Ernzerhof, Generalized Gradient Approximation Made Simple, Phys. Rev. Lett., 1996, 77(18), p 3865–3868.

X. Sauvage, N. Enikeev, R. Valiev et al., Atomic-Scale Analysis of the Segregation and Precipitation Mechanisms in a Severely Deformed Al-Mg alloy, Acta Mater., 2014, 72, p 125–136.

L. Zhao, S.Z. Liu, C. Zhang, L. Jin, and Q.X. Yang, Ultrasonic Nonlinear Parameter Based on Hollomon Hardening Model, Vacuum, 2022, 197, p 110841.

Y. Deng, Z.M. Yin, and F.G. Cong, Intermetallic Phase Evolution of 7050 Aluminum Alloy During Homogenization, Intermetallics, 2012, 26, p 114–121.

Q. Li, G. Huang, Y. Cao, Z. Jia, J. He, Z. Liang, and Q. Liu, Enhancement in dispersoid precipitation and dispersion strengthening by prior deformation in an Al-Mg-Mn alloy, Mater. Sci. Eng. A, 2023, 869, p 144808.

Q. Cai, C.L. Mendis, I.T. Chang, and Z. Fan, Effect of Short T6 Heat Treatment on the Microstructure and the Mechanical Properties of Newly Developed Die-Cast Al-Si-Mg-Mn Alloys, Mater. Sci. Eng. A, 2020, 788, p 139610.

B.L. Bramfitt, The Effect of Carbide and Nitride Additions on the Heterogeneous Nucleation Behavior of Liquid Iron, Metall. Trans., 1970, 1, p 1987–1995.

S.X. Deng, J.F. Li, H. Ning et al., Effect of Zr Addition on the Microstructure Evolution and Mechanical Properties of Extruded Al-Cu-Li-Mn Alloys, Mater Charact, 2023, 202, p 113011.

Y.Z. Liu, Y.H. Jiang, J. Feng et al., Elasticity, Electronic Properties and Hardness of MoC Investigated by First Principles Calculations, Physica B, 2013, 419, p 45–50.

J. Feng, B. Xiao, J. Chen et al., Stability, Thermal and Mechanical Properties of PtxAly Compounds, Mater. Des., 2011, 32(6), p 3231–3239.

S.F. Pugh, Relations Between The Elastic Moduli and The Plastic Properties of Polycrystalline Pure Metals, Lond. Edinb. Dublin. Philos. Mag. J. Sci., 1954, 45, p 823.

P.W. Kao, Texture and Earing Behaviour of Cold-Rolled Aluminium Alloy 3004, Mater. Sci. Eng., 1985, 74(2), p 147–157.

T.L. Johnston and C.E. Feltner, Grain Size Effects in the Strain Hardening of Polycrystals, Metall. Mater. Trans. B, 1970, 1, p 1161–1167.

K. Lücke, The Orientation Dependence of Grain Boundary Motion and the Formation of Recrystallization Textures, Can. Metall. Quart., 2013, 13, p 261–274.

H.W. Heller, J.H. Van Dorp, G. Wolff, and C.A. Verbraak, Recrystallization Behaviour of {110} <112> Aluminium Single Crystals After Rolling and Plane-Strain Deformation, Metal Sci., 1981, 15(8), p 333–341.

I. Choi, S. Jin, and S. Kang, Effects of Microstructure and Alloy Contents on the Lüders Line Formation in Al-Mg Alloys, Scr. Mater., 1998, 38, p 887–892.

X.J. Nie, H. Zhang, H.H. Zhu et al., On the role of Zr content into Portevin-Le Chatelier (PLC) effect of selective laser melted high strength Al-Cu-Mg-Mn alloy, Mater. Lett., 2019, 248, p 5–7.

C.H. Cho, H.W. Son, J.C. Lee, K.T. Son, J.W. Lee, and S.K. Hyun, Effects of High Mg Content and Processing Parameters on Portevin-Le Chatelier and Negative Strain Rate Sensitivity Effects in Al Mg Alloys, Mater. Sci. Eng. A, 2020, 779, p 139151.

Y.L. Cai, S.L. Yang, Y.H. Wang, S.H. Fu, and Q.C. Zhang, Characterization of the Deformation Behaviors Associated with the Serrated Flow of a 5456 Al-Based Alloy Using Two Orthogonal Digital Image Correlation Systems, Mater. Sci. Eng. A, 2016, 664, p 155–164.

P.G. Mccormick, The Portevin-Le Chatelier Effect in an Al-Mg-Si Alloy, Acta Metall., 1971, 19, p 463–471.

Acknowledgments

The authors would like to thank the National Key R&D Program of China (2022YFB3504401), the National Natural Science Foundation of China (52271094, U1708251) and the Key Research and Development Program of Liaoning, China (2020JH2/10700003).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, X., Song, Z., Yu, F. et al. Evolution of Microstructure, Mechanical Properties, and Deformation Behavior of 1561 Alloy with Trace Er. J. of Materi Eng and Perform (2023). https://doi.org/10.1007/s11665-023-08978-z

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11665-023-08978-z