Abstract

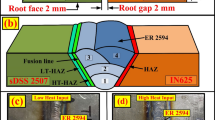

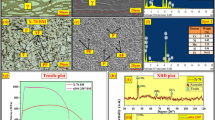

SS316L steel is known as a marine-grade material, which is frequently used in shipbuilding structures and marine industries. In the present study, a shielded metal arc welding (SMAW) process was used for welding of SS316L steel plate by using electrode E316L-16 and E308L-16, welding currents of 70, 80 and 90 A and constant voltages of 24 V. The effect of process parameters on the microstructure and mechanical properties of the welded specimens in the fusion zone (FZ), heat-affected zone (HAZ) and at base has been analysed using scanning electron microscopy (SEM) and microhardness test. The results show that the mechanical properties of the SMAW welded sample are influenced by both electrode properties and applied current. The fusion zone hardness increases compared to the base material. The welded sample processed by using electrode E316L-16 and 80 A current exhibits the higher hardness i.e., 223 HV due to a combination of lower heat input, higher welding speed, and the presence of a fine grain structure compared to other welded sample. A tensile result shows that the Ultimate tensile strength (UTS) of the SMAW welded sample varies from 190 to 262 N/mm2 compared to a base material, i.e., 565 N/mm2. This drop in tensile strength in the welded joints is attributed to HAZ softening stemming from the formation of coarse-grained microstructures. Furthermore, thermal analysis utilizing ANSYS software was employed to assess the influence of heat input at different welding arc times and to map temperature distribution across various plate regions. The results indicate that reducing welding time leads to lower temperatures in the electrode samples, consistent with simulation outcomes. Additionally, variations in microstructure were evident across distinct plate regions. The impact of heat input on microstructural behaviour was further comprehensively examined.

Similar content being viewed by others

References

S.K. Sharma, A.K. Singh, R.K. Mishra, A. K. Shukla, and C. Sharma, Processing Techniques, Microstructural and Mechanical Properties of Additive Manufactured 316L Stainless Steel: Review, J. Inst. Eng. Ser. D, 2023.

S. Basak, S.K. Sharma, M. Mondal, K.K. Sahu, S. Gollapudi, J. Dutta-Majumdar and S.T. Hong, Electron Beam Surface Treatment of 316L Austenitic Stainless Steel: Improvements in Hardness, Wear, and Corrosion Resistance, Met. Mater. Int., 2021, 27(5), p 953–961.

M.F. McGuire, “Stainless Steels for Design Engineers,” Stainless Steels for Design Engineers, 2008.

A.K. Shukla, D. Gond, M. Bharadwaj and D. Puri, High Temperature Oxidation and Hot Corrosion Behaviour of 9Cr 1Mo Ferritic Cold Rolled Steel in Air at 900°C under Cyclic Condition, J. Miner. Mater. Charact. Eng., 2011, 10(11), p 1061–1075.

A.K. Shukla, D. Gond, and D. Puri, “Effect of Cold Working on Hot Corrosion Behavior of 9 Cr–1 Mo Ferritic Steel in 75 Wt% Na2SO4 + 25 Wt% K2SO4 Molten Salt Environment at 900 °C. Trans. Indian Inst. Metals, 2016, p 1049–1057.

I.S. Asibeluo and E. Emifoniye, Effect of Arc Welding Current on the Mechanical Properties of A36 Carbon Steel Weld Joints, Int. J. Mech. Eng., 2015, 2(9), p 32–40.

S. Gupta, D. Singh, A. Yadav, S. Jain and B. Pratap, A Comparative Study of 5083 Aluminium Alloy and 316L Stainless Steel for Shipbuilding Material, Mater. Today Proc., 2020, 28, p 2358–2363. https://doi.org/10.1016/j.matpr.2020.04.641

R. Unnikrishnan, K.S.N.S. Idury, T.P. Ismail, A. Bhadauria, S.K. Shekhawat, R.K. Khatirkar and S.G. Sapate, Effect of Heat Input on the Microstructure, Residual Stresses and Corrosion Resistance of 304l Austenitic Stainless Steel Weldments, Mater CharactCharact., 2014, 93, p 10–23. https://doi.org/10.1016/j.matchar.2014.03.013

M.M. Mahapatra, G.L. Datta and B. Pradhan, Three-Dimensional Finite Element Analysis to Predict the Effects of Shielded Metal Arc Welding Process Parameters on Temperature Distributions and Weldment Zones in Butt and One-Sided Fillet Welds, Proc. Inst. Mech. Eng., 2006, 220(6), p 837–845.

M. Sohel, M. Panwala, S.A. Channiwala and K.N. Srinivasan, Numerical Simulation of Transient Temperature in SMAW, Am. Soc. Mech. Eng., 2010, 6, p 449–456.

Tanmay, M. Chandra, S. Sharma and S.S. Panda, Study of Mechanical and Metallurgical Properties of Cold and Hot Reciprocating Wire TIG Welding on AISI 1035 Carbon Steel, J. Inst. Eng. Ser D, 2021, 102(1), p 159–166.

S. Basak, K.K. Sahu, S.K. Sharma and J.D. Majumdar, Studies on Electron Beam Surface Melting of AISI 316 Stainless Steel and AISI 347 Stainless Steel, Proc. Manuf., 2017, 7, p 647–653.

S. Basak, S.K. Sharma, K.K. Sahu, S. Gollapudi, and J.D. Majumdar, Surface Modification of Structural Material for Nuclear Applications by Electron Beam Melting: Enhancement of Microstructural and Corrosion Properties of Inconel 617, SN Appl. Sci., 2019, 1(7).

I. AghaAli, M. Farzam, M.A. Golozar and I. Danaee, The Effect of Repeated Repair Welding on Mechanical and Corrosion Properties of Stainless Steel 316L, Mater. Des., 2014, 54, p 331–341. https://doi.org/10.1016/j.matdes.2013.08.052

A.S. Abdel-Wanees, T.S. Mahmoud and I.M. Ibrahim, Effect of Electrode Material on Microstructural and Mechanical Characteristics of AISI 304 Stainless Steels Plates Joined Using Shielded Metal Arc Welding, Eng. Res. J., 2020, 1(44), p 1–4.

Y. Nakasone and S. Yoshimoto, “Engineering Analysis with ANSYS Software. Elsevier Butterworth-Heinemann, 2006.

L.O. Osoba, W.A. Ayoola, Q.A. Adegbuji and O.A. Ajibade, Influence of Heat Inputs on Weld Profiles and Mechanical Properties of Carbon and Stainless Steel, Niger. J. Technol. Dev., 2021, 18(2), p 135–143.

H. Arora, R. Singh and G.S. Brar, Prediction of Temperature Distribution and Displacement of Carbon Steel Plates by FEM, Mater. Today Proc., 2019, 18, p 3380–3386. https://doi.org/10.1016/j.matpr.2019.07.264

J. Kar, S.K. Roy and G.G. Roy, Effect of Beam Oscillation on Electron Beam Welding of Copper with AISI-304 Stainless Steel, J. Mater. Process. Technol., 2016, 233, p 174–185.

S. Miftin, H. Mohammed and A. Nassar, Measurement and Prediction of Residual Stresses in Low Carbon Steel Pipes Welded Shielded Metal Arc Welding, Basrah J. Eng. Sci., 2020, 20(2), p 60–65.

A. Saxena, A. Kumaraswamy, G. Madhusudhan Reddy and V. Madhu, Influence of Welding Consumables on Tensile and Impact Properties of Multi-Pass SMAW Armox 500T Steel Joints Vis-a-Vis Base Metal, Def. Technol., 2018, 14(3), p 188–195.

Y. Kchaou, N. Haddar, G. Hénaff, V. Pelosin and K. Elleuch, Microstructural, Compositional and Mechanical Investigation of Shielded Metal Arc Welding (SMAW) Welded Superaustenitic UNS N08028 (Alloy 28) Stainless Steel, Mater. Des., 2014, 63, p 278–285. https://doi.org/10.1016/j.matdes.2014.06.014

H. Vemanaboina, S. Akella, A.C. Uma-Maheshwer-Rao, E. Gundabattini and R.K. Buddu, Analysis of Thermal Stresses and Its Effect in the Multipass Welding Process of SS316L, Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng., 2021, 235(2), p 384–391.

V. Gohel, J. Makwana and R. Ranjan, Thermo-Mechanical Analysis in TIG Welding of SS 304, Int. J. Eng. Dev. Res., 2016, 4(2), p 1704–1710.

Funding

This research received no specific grant from any funding agency.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kumar, A.S., Sharma, S.K. & Shukla, A.K. Microstructural, Mechanical, and Thermal Analysis of SS316L Weldment for Marine Engineering Application. J. of Materi Eng and Perform (2023). https://doi.org/10.1007/s11665-023-08906-1

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11665-023-08906-1