Abstract

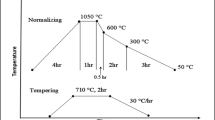

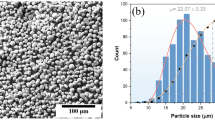

In this paper, the influence of induction quenching and tempering temperatures on the evolution of mechanical properties and microstructure of 45 steel for linear guides were investigated based on the tensile, impact, hardness tests and fracture morphology. The results indicate that the hardness of untempered and 200 °C tempered samples are higher and the difference is not significant, while the hardness of 300 and 400 °C tempered samples decrease as tempering temperature increases. Lower tensile strengths are observed in untempered and 200 °C tempered samples, which increase significantly after being tempered at 300 °C and then decrease slightly after being tempered at 400 °C. As the tempering temperature remains constant, the impact toughness value steadily declines as the quenching temperature rises, whereas when the quenching temperature remains constant, the impact toughness increases as the tempering temperature rises. The optimum induction quenching temperature was finally determined to be 850-900 °C, and the optimum tempering temperature was 300 °C. The findings of this study can be used to develop technical guidelines for the design of induction hardening and tempering process parameters for linear guides.

Similar content being viewed by others

Data Availability

The raw/processed data required to reproduce these findings cannot be shared at this time as the data also forms part of an ongoing study.

References

J. Li, Y. Ran, H.W. Wang, G.Q. Huang, Z.Y. Mu, and G.B. Zhang, Dynamic Performance Reliability Analysis of Rolling Linear Guide under Parameter Uncertainty, J. Mech. Sci. Technol., 2020, 34(11), p 4525–4536.

W. Sun, X.X. Kong, B. Wang, and X.Z. Li, Statics Modeling and Analysis of Linear Rolling Guideway Considering Rolling Balls Contact, Proc. Inst. Mech. Eng. Part C-J. Eng. Mech. Eng. Sci., 2015, 229(1), p 168–179.

X.Y. Wang, H.T. Feng, C.G. Zhou, and K.Q. Ye, A Thermal Model for Real-Time Temperature Forecast of Rolling Linear Guide considering Loading Working Conditions, Int. J. Adv. Manuf. Technol., 2020, 109, p 2249–2271.

X.Y. Wang, C.G. Zhou, and Y. Ou, Experimental Analysis of the Wear Coefficient for the Rolling Linear Guide, Adv. Mech. Eng., 2019, 11(1), p 1687814018821744.

C.Y. Li, M.T. Xu, G.K. He, H.Z. Zhang, Z.D. Liu, D. He, and Y.M. Zhang, Time-Dependent Nonlinear Dynamic Model for Linear Guideway with Crowning, Tribol. Int., 2020, 151, p 106413.

C.G. Zhou, S.H. Ren, H.T. Feng, J.W. Shen, Y.S. Zhang, and Z.T. Chen, A New Model for the Preload Degradation of Linear Rolling Guide, Wear, 2021, 482, p 203963.

Y.Q. Wang, B.T. Liu, and Z.C. Guo, Wear Resistance of Machine Tools’ Bionic Linear Rolling Guides by Laser Cladding, Opt. Laser Technol., 2017, 91, p 55–62.

C. Lorenzo-Martin and O.O. Ajayi, Rapid Surface Hardening and Enhanced Tribological Performance of 4140 Steel by Friction Stir Processing, Wear, 2015, 332, p 962–970.

H. Purwanto, M. Dzulfikar, M. Tauviqirrahman, R. Ismail, and A. Jumain, The Effect of Austenization Temperature in Surface Hardening Process on Steel Plate as Ballistic Plate, J. Phys. Conf. Ser., 2021, 1908(1), p 012030.

J.K. Choi, K.S. Park, and S.S. Lee, Prediction of High-Frequency Induction Hardening Depth of an AISI 1045 Specimen by Finite Element Analysis and Experiments, Int. J. Precis. Eng. Manuf., 2018, 19(12), p 1821–1827.

H. Li, H. Zhou, P. Zhang, T. Zhou, W. Su, S.Y. Wang, and H.F. Zhang, Influence of Laser Energy Density on Acquisition and Wear Resistance of Bionic Semisolid unit of 40Cr Steel, J. Mater. Eng. Perform., 2020, 29(4), p 2283–2295.

J. Liu, C. Wang, J. Zhong, Y. Wu, S.Y. Mo, and C.X. Gu, Microstructure and Properties of 45 Steel After Laser transformation Hardening and Induction Heating Surface Hardening, Trans. Mater. Heat Treat., 2018, 39(11), p 58–66.

D.C. Feng, J.X. Cui, X.X. Sun, and X.F. Wu, Effects of Induction and Traditional Tempering at Low Temperature on Microstructure and Properties of 45 Steel Tubes, Hot Work. Technol., 2019, 48(2), p 171–174.

J. Li, Z.X. Cao, L. Liu, X.D. Liu, and J. Peng, Effect of Microstructure on Hardness and Wear Properties of 45 Steel After Induction Hardening, Steel Res. Int., 2021, 92(4), p 2000540.

K. Kurek and D.M. Dolega, Numerical Simulation of Superficial Induction Hardening Process, Int. J. Mater. Prod. Technol., 2007, 29(1–4), p 84–102.

H.P. Li, L.F. He, K. Gai, R. Jiang, C.Z. Zhang, and M.S. Li, Numerical Simulation and Experimental Investigation on the Induction Hardening of a Ball Screw, Mater. Des., 2015, 87, p 863–876.

J. Grum, A Review of the Influence of Grinding Conditions on Resulting Residual Stresses After Induction Surface Hardening and Grinding, J. Mater. Process. Technol., 2001, 114(3), p 212–226.

V. Rudnev, Induction Hardening of Gears and Critical Components, Gear. Technol., 2008, p 58–63.

R.M. Horn and R.O. Ritchie, Mechanisms of Tempered Martensite Embrittlement in Low Alloy Steels, Metall. Trans. A, 1978, 9, p 1039–1053.

A. Salemi and A. Abdollah-zadeh, The Effect of Tempering Temperature on the Mechanical Properties and Fracture Morphology of a NiCrMoV Steel, Mater. Charact, 2008, 59(4), p 484–487.

F.G. Liu, X. Lin, M.H. Song, H.O. Yang, K. Song, P.F. Guo, and W.D. Huang, Effect of Tempering Temperature on Microstructure and Mechanical Properties of Laser Solid Formed 300M Steel, J. Alloys Compd., 2016, 689, p 225–232.

S. Maropoulos, S. Karagiannis, and N. Ridley, The Effect of Austenitising Temperature on Prior Austenite Grain Size in a Low-Alloy Steel, Mater. Sci. Eng. A, 2008, 483, p 735–739.

J.M. Han, S.H. Cui, W.J. Li, and X.Y. Ma, Dual Phase Heat Treatment of Low-Alloy Steel, J. Iron. Steel Res. Int., 2005, 12(5), p 47–51.

J. Wang, Z.N. Xu, and X.F. Lu, Effect of the Quenching and Tempering Temperatures on the Microstructure and Mechanical Properties of H13 Steel, J. Mater. Eng. Perform., 2020, 29(3), p 1849–1859.

W. Cheng, X.L. Zhang, J.Z. Lu, F.Z. Dai, and K.Y. Luo, Effect of Laser Oscillating Welding on Microstructure and Mechanical Properties of 40Cr steel/45 Steel Fillet Welded Joints, Optik, 2021, 231, p 166458.

G. Krauss, Deformation and Fracture in Martensitic Carbon Steels Tempered at Low Temperatures, Metall. Mater. Trans. B, 2001, 32, p 205–221.

X.D. Liang, J.W. Lü, H. Yan, Z.J. Zhao, X.Y. Wang, J.M. Meng, and X. Wang, Effect of Tempering Temperature on Microstructure and Mechanical Properties of C61 Gear Steel, Trans. Mater. Heat Treat., 2022, 43(1), p 84–91.

C. Sun, P.X. Fu, H.W. Liu, H.H. Liu, and N.Y. Du, Effect of Tempering Temperature on the Low Temperature Impact Toughness of 42CrMo4-V Steel, Metals, 2018, 8(4), p 232.

P. Yan, Z.D. Liu, H.S. Bao, Y.Q. Weng, and W. Liu, Effect of Tempering Temperature on the Toughness of 9Cr-3W-3Co Martensitic Heat Resistant Steel, Mater. Des., 2014, 54, p 874–879.

Acknowledgments

This research was funded by the National Natural Science Foundation of China (52175342), The Natural Science Foundation of Shandong (ZR2021ME129), the National Natural Science Foundation of China (52005304), Science and Technology Plan for Youth Innovation Team in Colleges and Universities of Shandong Province (2022KJ219).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sun, Y., He, L., Gao, Y. et al. Effect of Induction Quenching and Tempering Temperature on the Mechanical Properties and Microstructure Evolution of 45 Steel for Linear Guide. J. of Materi Eng and Perform (2023). https://doi.org/10.1007/s11665-023-08839-9

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11665-023-08839-9