Abstract

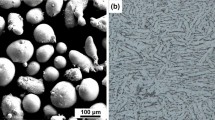

In this paper, two kinds of coatings (iron-based and cobalt-based) were successfully prepared on the surface of AISI 304 stainless steel using laser cladding technology as substitute materials with excellent wear resistance and corrosion resistance, respectively. Subsequently, the phase composition, microstructure, crystallographic texture, microhardness distribution, wear behavior and corrosion behaviour of the two coatings were investigated. The results showed that the iron-based coating mainly composed of α-Fe and Cr23C6 phases, while the cobalt-based coating mainly composed of γ-Co and Cr23C6. There was no obvious texture in the two coatings, and the grain orientation showed a random characteristic. The grain size of iron-based coatings is greatly smaller than that of cobalt-based coatings. The average microhardness of the iron-based and cobalt-based coatings is 704 HV and 502 HV. The simultaneous effect of fine grain strengthening and second phase strengthening ensures high wear resistance of the iron-based coating. The combination of Cr-rich passive film and fine dispersed carbides ensures high corrosion resistance of the cobalt-based coating.

Similar content being viewed by others

References

A. Pardo, M.C. Merino, A.E. Coy, F. Viejo, R. Arrabal, and E. Matykina, Effect of Mo and Mn Additions on the Corrosion Behaviour of AISI 304 and 316 Stainless Steels in H2SO4, Corros. Sci., 2008, 50(3), p 780–794

C. Hu, S. Xia, H. Li, T. Liu, B. Zhou, W. Chen, and N. Wang, Improving the Intergranular Corrosion Resistance of 304 Stainless Steel by Grain Boundary Network Control, Corros. Sci., 2011, 53(5), p 1880–1886

Y.A. Albrimi, A.A. Addi, J. Douch, R.M. Souto, and M. Hamdani, Inhibition of the Pitting Corrosion of 304 Stainless Steel in 0.5 M Hydrochloric Acid Solution by Heptamolybdate Ions, Corros. Sci., 2015, 90, p 522–528

M. Abdallah, Corrosion Behaviour of 304 Stainless Steel in Sulphuric Acid Solutions and its Inhibition by Some Substituted Pyrazolones, Mater. Chem. Phys., 2003, 82, p 786–792

Y. Liu, Y. Ding, L. Yang, R. Sun, T. Zhang, and X. Yang, Research and Progress of Laser Cladding on Engineering Alloys: A Review, J. Manuf. Process., 2021, 66, p 341–363

T. Zhao, S. Zhang, F.Q. Zhou, H.F. Zhang, C.H. Zhang, and J. Chen, Microstructure Evolution and Properties of in-situ TiC Reinforced Titanium Matrix Composites Coating by Plasma Transferred Arc Welding (PTAW), Surf. Coat. Tech., 2021, 424, p 127637

M. Li, B. Han, L. Song, and Q. He, Enhanced Surface Layers by Laser Cladding and Ion Sulfurization Processing towards Improved Wear-Resistance and Self-Lubrication Performances, Appl. Surf. Sci., 2020, 503, p 144226

C. Zhou, S.R. Wang, G.Q.J.P. Zhang, and W.L. Liu, Investigation on the Microstructure, Wear and Corrosion Resistance of FeCoNiCrMox High-Entropy Alloy Coatings Deposited on 40Cr by Laser Cladding, J. Mater. Sci., 2022, 57(39), p 18615–18639

T.Y. Yin, S. Zhang, F.Q. Zhou, R.J. Huo, C.H. Zhang, and J. Chen, Effects of Heat Treatment on Microstructure and Wear Behavior of Modified Aluminum Bronze Coatings Fabricated by Laser Cladding, J. Mater. Eng. Perform., 2022, 31, p 4294–4304

C. Wang, S. Zhang, C.H. Zhang, C.L. Wu, J.B. Zhang, and A.O. Abdullah, Phase Evolution and Wear Resistance of in situ Synthesized V8C7 Particles Reinforced Fe-Based Coating by Laser Cladding, Opt. Laser Technol., 2018, 105, p 58–65

L. Ding, S. Hu, X. Quan, and J. Shen, Effect of VN Alloy Addition on the Microstructure and Wear Resistance of Co-Based Alloy Coatings, J. Alloy. Compd., 2016, 659, p 8–14

L. Ding, S. Hu, X. Quan, and J. Shen, Effect of Aging Treatment on Microstructure and Properties of VN Alloy Reinforced Co-Based Composite Coatings by Laser Cladding, Mater Charact, 2017, 129, p 80–87

H. Zhu, Y. Li, B. Li, Z. Zhang, and C. Qiu, Effects of Low-Temperature Tempering on Microstructure and Properties of the Laser-Cladded AISI 420 Martensitic Stainless Steel Coating, Coatings, 2018, 8(12), p 451

H.F. Lu, K.N. Xue, X. Xu, K.Y. Luo, F. Xing, J.H. Yao, and J.Z. Lu, Effects of Laser Shock Peening on Microstructural Evolution and Wear Property of Laser Hybrid Remanufactured Ni25/Fe104 Coating on H13 Tool Steel, J. Mater. Process. Tech., 2021, 291, p 117016

W.R. Wang, W. Qi, X.L. Zhang, X. Yang, L. Xie, D.Y. Li, and Y.H. Xiang, Superior Corrosion Resistance-Dependent Laser Energy Density in (CoCrFeNi)95Nb5 High Entropy Alloy Coating Fabricated by Laser Cladding, Int. J. Min. Met. Mater., 2021, 28(5), p 888–897

H. Wu, S. Zhang, Z. Wang, C.H. Zhang, H.T. Chen, and J. Chen, New Studies on Wear and Corrosion Behavior of Laser Cladding FeNiCoCrMox High Entropy Alloy Coating: The Role of Mo, Int. J. Refract. Met. H., 2022, 102, p 105721

X. Wang, C.H. Zhang, X. Cui, S. Zhang, J. Chen, and J.B. Zhang, Microstructure and Mechanical Behavior of Additive Manufactured Cr-Ni-V Low Alloy Steel in Different Heat Treatment, Vacuum, 2020, 175, p 109216

X.D. Liang, S. Zhang, Z.Y. Wang, C.H. Zhang, D.X. Zhang, and C.L. Wu, Characterisation of Heat-Treated Gradient Alloy Steel Fabricated by Laser Melting Deposition, Mater. Sci. Technol., 2023, 39(5), p 567–581

H.F. Zhang, C.H. Zhang, Z.Y. Wang, X. Cui, S. Zhang, and H.T. Chen, Microstructure and Corrosion Behaviour of WC/NiCrBSi Coatings by Vacuum Cladding, Mater. Sci. Tech., 2022, 38(1), p 19–29

H. Song, J. Lei, J. Xie, S. Wu, L. Wang, and W. Shou, Laser Melting Deposition of K403 Superalloy: The Influence of Processing Parameters on the Microstructure and Wear Performance, J. Alloy. Compd., 2019, 805, p 551–564

A. Gholipour, M. Shamanian, and F. Ashrafizadeh, Microstructure and Wear Behavior of Stellite 6 Cladding on 17–4 PH Stainless Steel, J. Alloy. Compd., 2011, 509(14), p 4905–4909

X. Wang, M. Zhang, and S. Qu, Development and Characterization of (Ti, Mo) C Carbides Reinforced Fe-Based Surface Composite Coating Produced by Laser Cladding, Opt. Laser Eng., 2010, 48(9), p 893–898

X.Y. Yang, X. Peng, J. Chen, and F. Wang, Effect of a Small Increase in the Ni Content on the Properties of a Laser Surface Clad Fe-Based Alloy, Appl. Surf. Sci., 2007, 253(9), p 4420–4426

Q. Ma, Y. Li, J. Wang, and K. Liu, Investigation on Cored-Eutectic Structure in Ni60/WC Composite Coatings Fabricated by Wide-Band Laser Cladding, J. Alloy. Compd., 2015, 645, p 151–157

X. Cui, S. Zhang, C. Wang, C. Zhang, J. Chen, and J.B. Zhang, Effects of Stress-Relief Heat Treatment on the Microstructure and Fatigue Property of a Laser Additive Manufactured 12CrNi2 Low alloy Steel, Mater. Sci. Eng. A, 2020, 791, p 139738

X. He, R.G. Song, and D.J. Kong, Microstructure and Corrosion Behaviour of Laser-Cladding Al-Ni-TiC-CeO2 Composite Coatings on S355 Offshore Steel, J. Alloy. Compd., 2019, 770, p 771–783

J.Z. Lu, K.N. Xue, H.F. Lu, F. Xing, and K.Y. Luo, Laser Shock Wave-Induced Wear Property Improvement and Formation Mechanism of Laser Cladding Ni25 Coating on H13 Tool Steel, J. Mater. Process. Tech., 2021, 296, p 117202

P.F. Jiang, C.H. Zhang, S. Zhang, J.B. Zhang, J. Chen, and Y. Liu, Microstructure Evolution, Wear Behavior, and Corrosion Performance of Alloy Steel Gradient Material Fabricated by Direct Laser Deposition, J. Mater. Res. Technol., 2020, 9(5), p 11702–11716

X. Wang, C.H. Zhang, X. Cui, S. Zhang, J. Chen, and J.B. Zhang, Novel Gradient Alloy Steel with Quasi-Continuous Ratios Fabricated by SLM: Material Microstructure and Wear Mechanism, Mater Charact, 2021, 174, p 111020

J.Z. Lu, J. Cao, H.F. Lu, L.Y. Zhang, and K.Y. Luo, Wear Properties and Microstructural Analyses of Fe-Based Coatings with Various WC Contents on H13 Die Steel by Laser Cladding, Surf. Coat. Tech., 2019, 369, p 228–237

Z. Wang, Z. Liu, C. Gao, K. Wong, S. Ye, and Z. Xiao, Modified Wear Behavior of Selective Laser Melted Ti6Al4V Alloy by Direct Current Assisted Ultrasonic Surface Rolling Process, Surf. Coat. Tech., 2020, 381, p 125122

G.F. Sun, Z.P. Tong, X.Y. Fang, X.J. Liu, Z.H. Ni, and W. Zhang, Effect of Scanning Speeds on Microstructure and Wear Behavior of Laser-Processed NiCr-Cr3C2-MoS2-CeO2 on 38CrMoAl Steel, Opt. Laser Technol., 2016, 77, p 80–90

Z. Tong, X. Pan, W. Zhou, Y. Yang, Y. Ye, D. Qian, and X. Ren, Achieving Excellent Wear and Corrosion Properties in Laser Additive Manufactured CrMnFeCoNi High-Entropy Alloy by Laser Shock Peening, Surf. Coat. Tech., 2021, 422, p 127504

Y. Zhou, S. Chen, X. Chen, T. Cui, J. Liang, and C. Liu, The Evolution of Bainite and Mechanical Properties of Direct Laser Deposition 12CrNi2 Alloy Steel at Different Laser Power, Mater. Sci. Eng. A, 2019, 742, p 150–161

J. Archard, Contact and Rubbing of Flat Surfaces, J. Appl. Phys., 1953, 24(8), p 981–988

M. Ziętala, T. Durejko, M. Polański, I. Kunce, T. Płociński, W. Zieliński, M. Łazińska, W. Stępniowski, T. Czujko, and K.J. Kurzydłowski, The Microstructure, Mechanical Properties and Corrosion Resistance of 316 L Stainless Steel Fabricated using Laser Engineered Net Shaping, Mater. Sci. Eng. A, 2016, 677, p 1–10

X. Wang, C.H. Zhang, F.Q. Zhou, S. Zhang, J. Chen, and J.B. Zhang, Novel Gradient Alloy Steel with Quasi-Continuous Ratios Fabricated by Selective Laser Melting: Microstructure and Corrosion Behavior, Steel Res. Int., 2021, 92(11), p 2100232

T. Ge, L. Chen, P. Gu, X. Ren, and X. Chen, Microstructure and Corrosion Resistance of TiC/Inconel 625 Composite Coatings by Extreme High Speed Laser Cladding, Opt. Laser Technol., 2022, 150, p 107919

M.H. Nie, S. Zhang, Z.Y. Wang, T.Y. Yin, C.H. Zhang, C.L. Wu, and D.X. Zhang, Laser Cladding of 17–4 PH Stainless Steel Coatings: Microstructure, Texture Characterization, and Corrosion Resistance, J. Mater. Eng. Perform., 2023, 32(12), p 5545–5553

C. Liao, J. Yang, Y. He, and X.Z. Ming, Electrochemical Corrosion Behavior of the Carburized Porous TiAl Alloy, J. Alloy. Compd., 2015, 619, p 221–227

M. Cao, L. Liu, Z. Yu, L. Fan, Y. Li, and F. Wang, Electrochemical Corrosion Behavior of 2A02 Al Alloy under an Accelerated Simulation Marine Atmospheric Environment, J. Mater. Sci. Technol., 2019, 35(4), p 651–659

X. Xu, H.F. Lu, K.Y. Luo, J.H. Yao, L.Z. Xu, J.Z. Lu, and Y.F. Lu, Mechanical Properties and Electrochemical Corrosion Resistance of Multilayer Laser Cladded Fe-Based Composite Coatings on 4Cr5MoSiV1 Steel, J. Mater. Process. Tech., 2020, 284, p 116736

Y. Gan, W. Wang, Z. Guan, and Z. Cui, Multi-Layer Laser Solid Forming of Zr65Al7.5Ni10Cu17.5 Amorphous Coating: Microstructure and Corrosion Resistance, Opt. Laser Technol., 2015, 69, p 17–22

X. Xu, H.F. Lu, Y.Y. Su, M.X. Peng, F. Xing, K.Y. Luo, and J.Z. Lu, Comparing Corrosion Behavior of Additively Manufactured Cr-rich Stainless Steel Coating between Conventional and Extreme High-Speed Laser Metal Deposition, Corros. Sci., 2022, 195, p 109976

Acknowledgments

The authors gratefully acknowledge to the financial support for this research from National Key Research and Development Program of China (No. 2016YFB1100204), Key Research Project from Science and Shenyang Science and Technology Funded Project (No.22-101-0-16, 19-109-1-03).

Author information

Authors and Affiliations

Contributions

FJ: Investigation, Writing—review & editing. SZ: Review & editing, Funding acquisition, Data curation. CLW: Review & editing, Funding acquisition, Data curation. CHZ: Funding acquisition, Data curation. XYS: Data curation. XLB: Data curation.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Jin, F., Zhang, S., Wu, C.L. et al. Comparative Study on the Microstructure, Wear Behavior, and Corrosion Performance of Iron-Based and Cobalt-Based Coatings Fabricated by Laser Cladding. J. of Materi Eng and Perform (2023). https://doi.org/10.1007/s11665-023-08821-5

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11665-023-08821-5