Abstract

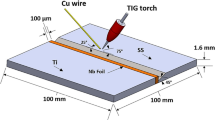

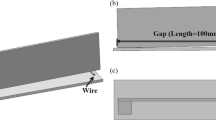

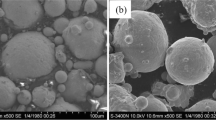

This study aims to analyze the effect of 70-30 Cu-Ni filler metal on mechanical and microstructural properties of Al 2024 and stainless steel 304 hybrid joints fabricated through the gas tungsten arc welding technique. The mechanical properties, i.e., tensile strength and microhardness, of Al-SS joints have been analyzed and evaluated through joint interfacial microstructure analysis. The optimum tensile strength (155.746 MPa) has been obtained at welding current ranges between 75 and 80 A, welding speed of 110–115 mm/min, and gas flow rate of 9.75-10 L/min, whereas maximum microhardness (300 HV) at welding speed of 115-120 mm/min, welding current of 70-75 A, and gas flow rate of 9.5-10 L/min. The fine equiaxed dendrites at the interface of the aluminum weld zone and the thin interfacial layer at the SS304 weld zone interface contributed to the higher tensile strength. Scanning electron microscopy, energy-dispersive spectroscopy, and x-ray diffraction reveal the ductile CuAl, NiAl3, and NiAl phases instead of Fe-Al brittle phase, improving hybrid bonding between Al 2024 and SS 304. The dimples and tear ridges microstructure have been observed for high-strength joint, while cracks and cavities on the fracture surface indicate its brittleness and low strength (102 MPa).

Similar content being viewed by others

References

E. Taban, J.E. Gould, and J.C. Lippold, Dissimilar Friction Welding of 6061-T6 Aluminum and AISI 1018 Steel: Properties and Microstructural Characterization, Mater. Des., 2010, 31(5), p 2305–2311.

S.M. Aceves, F. Espinosa-Loza, J.W. Elmer, and R. Huber, Comparison of Cu, Ti and Ta Interlayer Explosively Fabricated Aluminum to Stainless Steel Transition Joints for Cryogenic Pressurized Hydrogen Storage, Int. J. Hydrogen. Energ., 2015, 40(3), p 1490–1503.

S.A. Hussein and A. Hadzley, Characteristics of Aluminum-to-Steel Joint Made by Friction Stir Welding: A Review, Mater. Today Commun., 2015, 5, p 32–49.

P. Wang, X. Chen, Q. Pan, B. Madigan, and J. Long, Laser Welding Dissimilar Materials of Aluminum to Steel: An Overview, Int. J. Adv. Manuf. Technol., 2016, 87, p 3081–3090.

V.N. Nguyen, V.T. Le, M.T. Nguyen, and T.L.D. Thi, Optimization of the resistance spot welding parameters for aluminum-steel weld joint by using the Taguchi method, proceedings of the international conference on advanced mechanical engineering, automation, and sustainable development 2021 (AMAS2021), 2022, Springer, pp 46-51

J. Song, S. Lin, C.-L. Yang, C. Fan, and G. Ma, Analysis of Intermetallic Layer in Dissimilar TIG Welding-Brazing Butt Joint of Aluminium Alloy to Stainless Steel, Sci. Technol. Weld. Join, 2010, 15(3), p 213–218.

S. Chen, J. Huang, K. Ma, X. Zhao, and A. Vivek, Microstructures and Mechanical Properties of Laser Penetration Welding Joint with/Without Ni-Foil in an Overlap Steel-on-Aluminum Configuration, Metall Mater Trans A, 2014, 45, p 3064–3073.

H. Dong, L. Yang, C. Dong, and S. Kou, Improving Arc Joining of Al to Steel and Al to Stainless Steel, Mater. Sci. Eng. A, 2012, 534, p 424–435.

S. Kotari and E. Punna, Mechanical And Metallurgical Investigation Of Tig Welded-Brazed Aluminum And Stainless Steel Disimilar Joint By Using Copper Filler Rod, J. Univ. Shanghai Sci. Technol., 2021, 23(9), p 187–195.

H. He, S. Lin, C. Yang, C. Fan, and Z. Chen, Combination Effects of Nocolok Flux with Ni Powder on Properties and Microstructures of Aluminum-Stainless Steel TIG Welding-Brazing Joint, J. Mater. Eng. Perform., 2013, 22, p 3315–3323.

X.-L. Cao, W. Gang, X. Chang, C.-W. Tan, and J.-J. Jiang, Effect of Process Parameters on Microstructure and Properties of Laser Welded Joints of Aluminum/Steel With Ni/Cu Interlayer, Trans. Nonferrous Met. Soc. China., 2021, 31(8), p 2277–2286.

L. Shah, Z. Akhtar, and M.J.I.J.O.A. Ishak, Engineering, Investigation of Aluminum-Stainless Steel Dissimilar Weld Quality Using Different Filler Metals, Int. J. Automot. Mech. Eng., 2013, 8, p 1121–1131.

H. He, C. Wu, S. Lin, and C. Yang, Pulsed TIG Welding-Brazing of Aluminum-Stainless Steel with an Al-Cu Twin Hot Wire, J. Mater. Eng. Perform., 2019, 28, p 1180–1189.

J. Song, S. Lin, C. Yang, and C. Fan, Effects of Si Additions on Intermetallic Compound Layer of Aluminum-Steel TIG Welding-Brazing Joint, J. Alloys Compd., 2009, 488(1), p 217–222.

X. Yu, D. Fan, J. Huang, C. Li, and Y. Kang, Arc-Assisted Laser Welding Brazing of Aluminum to Steel, Metals, 2019, 9(4), p 397.

A.T. Assefa, G.M.S. Ahmed, S. Alamri, A. Edacherian, M.G. Jiru, V. Pandey, and N. Hossain, Experimental Investigation and Parametric Optimization of the Tungsten Inert Gas Welding Process parameters of DISSIMILAR Metals, Materials, 2022, 15(13), p 4426.

D. Zhao, D. Ren, K. Zhao, S. Pan, and X. Guo, Effect of Welding Parameters on Tensile Strength of Ultrasonic Spot Welded Joints of Aluminum to Steel-By Experimentation and Artificial Neural Network, J. Manuf. Process., 2017, 30, p 63–74.

H. Azhari-Saray, M. Sarkari-Khorrami, A. Nademi-Babahadi, and S.F. Kashani-Bozorg, Dissimilar Resistance Spot Welding of 6061-T6 Aluminum alloy/St-12 Carbon Steel Using a High Entropy Alloy interlayer, Intermetallics, 2020, 124, p 106876.

J. Bellmann, K. Roder, M. Zimmermann, E. Beyer, L. Kroll, and D. Nestler, Influence of Copper Interlayers on the Magnetic Pulse Welding Process between Aluminum and Steel, Metals, 2021, 11(6), p 868.

T. Watanabe, H. Takayama, and A. Yanagisawa, Joining of Aluminum Alloy to Steel by Friction Stir Welding, J. Mater. Process. Technol., 2006, 178(1–3), p 342–349.

J.H. Han, J.P. Ahn, and M.C. Shin, Effect of Interlayer Thickness on Shear Deformation Behavior of AA5083 Aluminum Alloy/SS41 Steel Plates Manufactured by Explosive Welding, J. Mater. Sci., 2003, 38, p 13–18.

B. Muralimohan Cheepu, N.A. Srinivas, T. Ramachandraiah, D. Sivaji Karna, S.A. Venkateswarlu, and W.S. Che, Dissimilar Joining of Stainless Steel and 5083 Aluminum Alloy Sheets by Gas Tungsten Arc Welding-Brazing Process, IOP Conference Series: Materials Science and Engineering, 2018, 330, p 012048. https://doi.org/10.1088/1757-899X/330/1/012048

G. Padmanaban and V. Balasubramanian, Optimization of Pulsed Current Gas Tungsten Arc Welding Process Parameters to Attain Maximum Tensile Strength in AZ31B Magnesium Alloy, Trans. Nonferrous Met. Soc. China., 2011, 21(3), p 467–476.

M. Jawad, M. Jahanzaib, and M. Ilyas, Evaluation of Welded Joints of Dissimilar Titanium Alloy Ti-5Al-25 Sn and Stainless-Steel 304 at Different Multi-Interlayer Modes, MRX, 2022, 9(10), p 106501.

G. Yu, S. Chen, T. Zou, S. Li, J. Huang, J. Yang, Z. Zhao, W. Huang, and S. Chen, Laser Beam Joining of Al/Steel Dissimilar Metals with Sn-Zn Filler Wire in Overlap Configuration, J. Manuf. Process., 2020, 60, p 481–493.

J. Yang, S. Xue, P. Xue, Z. Lv, W. Long, G. Zhang, Q. Zhang, and P. He, Development of Zn-15Al–xZr Filler Metals for Brazing 6061 Aluminum Alloy to Stainless Steel, Mater. Sci. Eng. A, 2016, 651, p 425–434.

H. Dong, W. Hu, Y. Duan, X. Wang, and C. Dong, Dissimilar Metal Joining of Aluminum Alloy to Galvanized Steel with Al-Si, Al-Cu, Al-Si-Cu and Zn-Al Filler Wires, J. Mater. Process. Technol., 2012, 212(2), p 458–464.

S.C. Ferreira, R. Bruns, H.S. Ferreira, G.D. Matos, J. David, G. Brandão, E.P. da Silva, L. Portugal, P. Dos Reis, and A. Souza, Box-Behnken Design: An Alternative for the Optimization of Analytical Methods, Anal. Chim. Acta, 2007, 597(2), p 179–186.

S.-B. Lin, J.-L. Song, G.-C. Ma, and C.-L. Yang, Dissimilar Metals TIG Welding-Brazing of Aluminum Alloy to Galvanized Steel, Front. Mater. Sci., 2009, 3, p 78–83.

H. Bang, H. Bang, G. Jeon, I. Oh, and C. Ro, Gas Tungsten Arc Welding Assisted Hybrid Friction Stir Welding of Dissimilar Materials Al6061-T6 Aluminum Alloy and STS304 Stainless Steel, Mater. Des., 2012, 37, p 48–55.

J. Kar, S.K. Roy, and G.G.J.M. Roy, Effect of Beam Oscillation on Microstructure and Mechanical Properties of AISI 316L Electron Beam Welds, Metall. Mater. Trans. A, 2017, 48(4), p 1759–1770.

M.A. Ali, M. Jahanzaib, A. Wasim, S. Hussain, and N.A. Anjum, Evaluating the Effects of As-Casted and Aged Overcasting of Al-Al Joints, J. Adv. Manuf. Technol., 2018, 96, p 1377–1392.

A.N. Salah, H. Mehdi, A. Mehmood, A.W. Hashmi, C. Malla, and R. Kumar, Optimization of Process Parameters of Friction Stir Welded Joints of Dissimilar aluminum alloys AA3003 and AA6061 by RSM, Mater. Today: Proc., 2022, 56, p 1675–1683.

M.H. Sarfraz, M. Jahanzaib, W. Ahmed, and S. Hussain, Multi-Response Parametric Optimization of Squeeze Casting Process for Fabricating Al 6061-SiC Composite, Int. J. Adv. Manuf. Technol., 2019, 102(1–4), p 759–773.

M. Jawad, M. Jahanzaib, M.A. Ali, M.U. Farooq, N.A. Mufti, C.I. Pruncu, S. Hussain, and A. Wasim, Revealing the Microstructure and Mechanical Attributes of Pre-Heated Conditions for Gas Tungsten Arc Welded AISI 1045 Steel Joints, Int. J. Press. Vessel., 2021, 192, p 104440.

P. Thakur and A. Chapgaon, A Review on Effects of GTAW Process Parameters on Weld, IJRASET, 2016, 4(1), p 136–140.

V.N. Nguyen, Q.M. Nguyen, and S.-C. Huang, Microstructure and Mechanical Properties of Butt Joints Between Stainless Steel SUS304L and Aluminum Alloy A6061–T6 by TIG Welding, Materials, 2018, 11(7), p 1136.

V. Chaudhary, A. Bharti, S.M. Azam, N. Kumar, and K.K. Saxena, A Re-Investigation: Effect of TIG Welding Parameters on Microstructure, Mechanical, Corrosion Properties of Welded Joints, Mater. Today Proc., 2021, 45, p 4575–4580.

G.S. Saputro and N. Muhayat, Welding Current and Shielding Gas Flow Rate Effect to The Intermetalic Layer Formation of Tungsten Inert Gas (Tig) on Dissimilar Metals Weld Joints Between Galvanized Steel and Aluminium Aa 5052 By Using Al-Si 4043 Filler, Mekanika Majalah Ilmiah Mekanika, 2017 https://doi.org/10.20961/mekanika.v16i1.35052

M. Abd Rahman, N. Zulkipli, M. Kasim, M. Jamli, and E. Budi, Impact of Argon Gas Shielding Flow Rate on the Hardness of Weld Joint, J. Adv. Manuf. Technol., 2022, 16(1), p 29.

W. Chuaiphan and L. Srijaroenpramong, Effect of Welding Speed on Microstructures, Mechanical Properties and Corrosion Behavior of GTA-Welded AISI 201 Stainless Steel Sheets, J. Mater. Process. Technol., 2014, 214(2), p 402–408.

Q. Chang, D. Sun, X. Gu, and H. Li, Microstructures and Mechanical Properties of Metal Inert-Gas Arc Welded Joints of Aluminum Alloy and Ultrahigh Strength Steel Using Al–Mg and Al–Cu Fillers, J. Mater. Res., 2017, 32(3), p 666–676.

R. Karthikeyan and V. Balasubramanian, Predictions of the Optimized Friction Stir Spot Welding Process Parameters for Joining AA2024 Aluminum Alloy Using RSM, Int. J. Adv. Manuf. Technol., 2010, 51, p 173–183.

Z.-F. Li, X.-M. Zhang, J.-M. Chen, X.-Y. Yang, and Z.-P. Zhou, Crack Initiation and Propagation at Al/Steel Interface in Castings Produced by Molten Aluminum and Explosively Welded Cu/Steel Plate, Chin. J. Nonferr. Metals., 2004, 14(2), p 223–227.

X. Yan, F. Wang, H. Chai, L. Ma, X. Tian, C. Du, W.J.O. Wang, and L. Wang, Technology, Improvement of Microstructure and Performance for Steel/Al Welds Produced by Magnetic Field Assisted Laser Welding, Opt. Laser Technol., 2019, 113, p 164–170.

A. Sauraw, A.K. Sharma, D. Fydrych, S. Sirohi, A. Gupta, A. Świerczyńska, C. Pandey, and G. Rogalski, Study on Microstructural Characterization, Mechanical Properties and Residual Stress of Gtaw Dissimilar Joints of p91 and p22 Steels, Materials, 2021, 14(21), p 6591.

Funding

This study has not received any funding.

Author information

Authors and Affiliations

Contributions

Research idea and design by [MJ] and [AA], materials preparation, experimentation by [MJ], and [AA], data analysis and testing [MJ], and [MS], first draft of writing by [MJ], [KI] and [MJ], reviewing process by [KI] and [MJ], guidance and supervision by [MJ].

Corresponding author

Ethics declarations

Conflict of interest

There is no conflict of interest declared by all authors.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Jawad, M., Ali, A., Ishfaq, K. et al. Performance Evaluation of 70-30 Cu-Ni Filler Metal for Improving Dissimilar Al2024-SS304 Joints’ Efficiency: A Mechanical and Microstructural Investigation. J. of Materi Eng and Perform (2023). https://doi.org/10.1007/s11665-023-08659-x

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11665-023-08659-x