Abstract

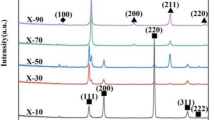

To explore wear-resistant and high-strength materials, Fe50Mn25Co10Cr10Ti5 high entropy alloy with non-equal atomic ratio was designed and prepared. The influence of annealing temperature on wear and mechanical properties was researched. The results show that the as-cast Fe50Mn25Co10Cr10Ti5 alloy presents hypereutectic microstructure which is composed of primary Laves phases and eutectic structure with FCC plus Laves phases. The main wear mechanism is contained fatigue wear, oxidation wear and abrasive wear. The microstructure and wear mechanism of the alloy have not changed significantly after annealing. With the increasing annealing temperature, the hardness and volume wear loss of the alloy present a tendency of going up first and then going down. The friction coefficient has not changed significantly after annealing 900 and 950 °C, while the alloy has increased significantly after annealing 1000 °C. In addition, the mechanical properties of Fe50Mn25Co10Cr10Ti5 alloy have not significantly improved after annealing 900 and 950 °C, while the compression rate and fracture strength have increased from 8.3 to 11.2% and 1493.2 to 1710.2 MPa, respectively, after annealing 1000 °C. The research results could provide experimental references to modify the wear and mechanical performance by using the annealing process.

Similar content being viewed by others

References

Q.F. Wu, Z.J. Wang, T. Zheng, D. Chen, Z.S. Yang, J.J. Li, J.J. Kai, and J.C. Wang, A Casting Eutectic High Entropy Alloy with Superior Strength-Ductility Combination, Mater. Lett., 2019, 253, p 268–271. https://doi.org/10.1016/j.matlet.2019.06.067

J.W. Yeh, S.K. Chen, S.J. Lin, J.Y. Gan, T.S. Chin, T.T. Shun, C.H. Tsau, and S.Y. Chang, Nanostructured High Entropy Alloys with Multiple Principal Elements: Novel Alloy Design Concepts and Outcomes, Adv. Eng. Mater., 2004, 6(5), p 299–303. https://doi.org/10.1002/adem.200300567

D.B. Miracle and O.N. Senkov, A Critical Review of High Entropy Alloys and Related Concepts, Acta Mater., 2017, 122, p 448–511. https://doi.org/10.1016/j.actamat.2016.08.081

X. Yang and Y. Zhang, Prediction of High Entropy Stabilized Solid-Solution in Multi-component Alloys, Mater. Chem. Phys., 2012, 132(2–3), p 233–238. https://doi.org/10.1016/j.matchemphys.2011.11.021

S. Guo, Q. Hu, C. Ng, and C.T. Liu, More than Entropy in High Entropy Alloys: Forming Solid Solutions or Amorphous Phase, Intermetallics, 2013, 41, p 96–103. https://doi.org/10.1016/j.intermet.2013.05.002

J.Y. Aguilar-Hurtado, A. Vargas-Uscategui, K. Paredes-Gil, R. Palma-Hillerns, M.J. Tobar, and J.M. Amado, Boron Addition in a Non-Equiatomic Fe50Mn30Co10Cr10 alloy Manufactured by Laser Cladding: Microstructure and Wear Abrasive Resistance, Appl. Surf. Sci., 2020, 515, p 146084. https://doi.org/10.1016/j.apsusc.2020.146084

Y.Y. Chen, T. Duval, U.D. Hung, J.W. Yeh, and H.C. Shih, Microstructure and Electrochemical Properties of High Entropy Alloys—A Comparison with Type-304 Stainless Steel, Corros. Sci., 2005, 47(9), p 2257–2279. https://doi.org/10.1016/j.corsci.2004.11.008

C.J. Tong, M.R. Chen, J.W. Yeh, S.J. Lin, S.K. Chen, T.T. Shun, and S.Y. Chang, Mechanical Performance of the AlxCoCrCuFeNi High-Entropy Alloy System with Multiprincipal Elements, Metall. Mater. Trans. A, 2005, 36(5), p 1263–1271. https://doi.org/10.1007/s11661-005-0218-9

Z. Wu, H. Bei, F. Otto, G.M. Pharr, and E.P. George, Recovery, Recrystallization, Grain Growth and Phase Stability of a Family of FCC-Structured Multi-Component Equiatomic Solid Solution Alloys, Intermetallics, 2014, 46, p 131–140. https://doi.org/10.1016/j.intermet.2013.10.024

R. Tewari, B. Vishwanadh, and V.K. Vasudevan, Formation of the Laves Phase in Nb-Ti-Cr-Si-X-Based Alloys, Trans. Indian Inst. Met., 2022, 75, p 931–939. https://doi.org/10.1007/s12666-022-02530-8

Y.J. Zhou, Y. Zhang, Y.L. Wang, and G.L. Chen, Solid Solution Alloys of AlCoCrFeNiTix with Excellent Room-Temperature Mechanical Properties, Appl. Phys. Lett., 2007, 90, p 181904. https://doi.org/10.1063/1.2734517

X.F. Wang, Y. Zhang, Y. Qiao, and G.L. Chen, Novel Microstructure and Properties of Multicomponent CoCrCuFeNiTix Alloys, Intermetallics, 2007, 15, p 357–362. https://doi.org/10.1016/j.intermet.2006.08.005

P. Cui, Y.M. Ma, L.J. Zhang, M.D. Zhang, J.T. Fan, W.Q. Dong, P.F. Yu, G. Li, and R.P. Liu, Effect of Ti on Microstructures and Mechanical properties of High Entropy Alloys based on CoFeMnNi System, Mater. Sci. Eng. A, 2018, 737, p 198–204. https://doi.org/10.1016/j.msea.2018.09.050

M.Y. Wu, R.C. Setiawan, and D.Y. Li, Benefits of Passive Element Ti to the Resistance of AlCrFeCoNi High-Entropy Alloy to Corrosion and Corrosive Wear, Wear, 2022, 492, p 204231. https://doi.org/10.1016/j.wear.2021.204231

S.S. Nene, K. Liu, M. Frank, R.S. Mishra, R.E. Brennan, K.C. Cho, Z. Li, and D. Raabe, Enhanced Strength and Ductility in a Wear Stir Processing Engineered Dual Phase High Entropy Alloy, Sci. Rep., 2017, 7, p 16167. https://doi.org/10.1038/s41598-017-16509-9

L.A. Chen, Y.S. Lu, Y.T. Lin, and Y.L. Lee, Preparation and Characterization of Cerium-Based Conversion Coating on a Fe50Mn30Co10Cr10 Dual-Phase High-Entropy Alloy, Appl. Surf. Sci., 2004, 2021(562), p 150200. https://doi.org/10.1016/j.apsusc.2021.150200

Y. Liu, J. Tu, L. Deng, C.H. Wang, and J.R. Luo, Characteristics of Thermal- and Strain-Induced ε-Martensite in Fe50Mn30Co10Cr10 Multi-component Alloy: Effect of Grain Size, Mater. Charact., 2021, 171, p 110817. https://doi.org/10.1016/j.matchar.2020.110817

D. Kong, J. Guo, R.W. Liu, X.H. Zhang, Y.P. Song, Z.X. Li, F.J. Guo, X.F. Xing, Y. Xu, and W. Wang, Effect of Remelting and Annealing on the Wear Resistance of AlCoCrFeNiTi0.5 High Entropy Alloys, Intermetallics, 2019, 114, p 106560. https://doi.org/10.1016/j.intermet.2019.106560

Z. Li, K.G. Pradeep, Y. Deng, D. Raabe, and C.C. Tasan, Metastable High-Entropy Dual-Phase Alloys Overcome the Strength-Ductility Trade-off, Nature, 2016, 534(7606), p 227–230. https://doi.org/10.1038/nature17981

J. Wang, J.L. Chai, H.P. Zhang, P.F. Tai, C. Liu, L.J. Niu, W.H. He, W.Y. Huang, R. Shu, L.H. Luo, W.P. Li, Y.B. Zhu, C.F. Yao, and P.F. Gao, Microstructure Investigations of Fe50Mn30Co10Cr10 Dual-Phase High–Entropy Alloy under Fe Ions Irradiation, J. Nucl. Mater., 2021, 552, p 153006. https://doi.org/10.1016/j.jnucmat.2021.153006

W.N. Jiao, H. Jiang, D.X. Qiao, J.Y. He, H.L. Zhao, Y.P. Lu, and T.J. Li, Effects of Mo on Microstructure and Mechanical Properties of Fe2Ni2CrMox Eutectic High Entropy Alloys, Mater. Chem. Phys., 2021, 260, p 124175. https://doi.org/10.1016/j.matchemphys.2020.124175

A. Shafiei, Design of Eutectic High Entropy Alloys in Al–Co–Cr–Fe–Ni system, Met. Mater. Int., 2021, 27(1), p 127–138. https://doi.org/10.1007/s12540-020-00655-3

Y.S. Na, K.R. Lim, H.J. Chang, and J. Kim, Effect of Trace Additions of Ti on the Microstructure of AlCoCrFeNi-Based High Entropy Alloy, Sci. Adv. Mater., 2016, 8(10), p 1984–1988. https://doi.org/10.1166/sam.2016.2793

W.Y. Huo, H. Zhou, F. Fang, Z.H. Xie, and J.Q. Jiang, Microstructure and Mechanical Properties of CoCrFeNiZrx Eutectic High-Entropy Alloys, Mater. Des., 2017, 134, p 226–233. https://doi.org/10.1016/j.matdes.2017.08.030

N.D. Stepanov, N.Y. Yurchenko, D.G. Shaysultanov, G.A. Salishchev, and M.A. Tikhonovsky, Effect of Al on Structure and Mechanical Properties of AlxNbTiVZr (x= 0, 05, 1, 15) High Entropy Alloys, Mater. Sci. Technol., 2015, 31(10), p 1184–1193. https://doi.org/10.1179/1743284715Y.0000000032

N.D. Stepanov, N.Y. Yurchenko, V.S. Sokolovsky, M.A. Tikhonovsky, and G.A. Salishchev, An AlNbTiVZr0.5 High-Entropy Alloy Combining High Specific Strength and Good Ductility, Mater. Lett., 2015, 161, p 136–139. https://doi.org/10.1016/j.matlet.2015.08.099

V. Rigaud, D. Daloz, and G. Lesoult, Influence of Ti and Zr Additions on Solidification of Fe Base Intermetallics Precipitating Laves Phase, Int. J. Cast Met. Res., 2009, 22(1–4), p 47–50. https://doi.org/10.1179/136404609X367948

K.B. Zhang and Z.Y. Fu, Effects of Annealing Treatment on Phase Composition and Microstructure of CoCrFeNiTiAlx High-Entropy Alloys, Intermetallics, 2012, 22, p 24–32. https://doi.org/10.1016/j.intermet.2011.10.010

X.Y. Liu, S.Q. Zhou, and Y. Xu, Microstructure and Tribological Performance of Fe50Mn30Co10Cr10 High-Entropy Alloy Based Self-Lubricating Composites, Mater. Lett., 2018, 233, p 142–145. https://doi.org/10.1016/j.matlet.2018.08.100

J. Jiang, R. Li, T. Yuan, P. Niu, C. Chen, and K. Zhou, Microstructural Evolution and Wear Performance of the High-Entropy FeMnCoCr Alloy/TiC/CaF2 Self-Lubricating Composite Coatings on Copper Prepared by Laser Cladding for Continuous Casting Mold, J. Mater. Res., 2019, 34(10), p 1714–1725. https://doi.org/10.1557/jmr.2019.57

P. Shi, R. Li, Y. Li, Y. Wen, Y. Zhong, W. Ren, Z. Shen, T. Zheng, J.C. Peng, and Y.D. Wang, Hierarchical Crack Buffering Triples Ductility in Eutectic Herringbone High-Entropy Alloys, Science, 2021, 373(6557), p 912–918.

C.D. Rabadia, Y.J. Liu, L.Y. Chen, S.F. Jawed, L.Q. Wang, H. Sun, and L.C. Zhang, Deformation and Strength Characteristics of Laves Phases in Titanium Alloys, Mater. Des., 2019, 179, p 107891. https://doi.org/10.1016/j.matdes.2019.107891

Acknowledgments

This research was supported by the National Natural Science Foundation of China (No. 51801029), the Natural Science Foundation of Guangdong Province (Nos. 2022A0505050052 and 2022A1515012591).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhang, Q., Yang, K., Yuan, W. et al. Effect of Annealing Temperature on Microstructure and Mechanical Properties of Fe50Mn25Co10Cr10Ti5 High Entropy Alloy. J. of Materi Eng and Perform (2023). https://doi.org/10.1007/s11665-023-08646-2

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11665-023-08646-2