Abstract

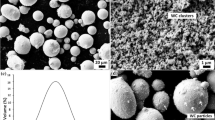

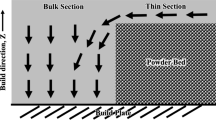

The Laser Powder Bed Fusion (LPBF) process offers the capacity to produce parts with complicated geometries that cannot be manufactured using traditional manufacturing processes. The aerospace industry is particularly interested in this capability because it may enable the creation of high-temperature structural parts with sophisticated cooling channel layouts. This would allow future gas turbines to operate at higher temperatures, resulting in higher efficiency. However, if they are to realize this promise, they must first enhance their knowledge of the influence of the LPBF process on alloy microstructures and its subsequent effect on mechanical properties. Furthermore, this study offers information on how to comprehend microstructural development and the impact it has on the mechanical characteristics of the CM247LC alloy processed by LPBF. Using the Direct Metal Laser Sintering technique based on Laser Power Bed Fusion, the CM247LC nickel-based superalloy was manufactured. When the CM247LC alloy was examined microscopically, carbides and cracks (both straight and serrated) were found. Electron Backscatter Diffraction studies revealed elongated grains in the longitudinal section and equiaxed clusters in the transverse section. Longitudinal sections have been determined to be predominantly composed of columnar grains with cells that have an average size of 0.7 µm. The γ/γ′ eutectic, as well as highly concentrated precipitates and highly concentrated dislocations, separate these cells from neighboring cells and grains. Up to 10 nm of the γ′ can be found inside the cells, despite having a diameter of up to 40 nm at the cell walls. The calculated rate of cooling during solidification is around 106 K/s based on the observed cell diameters. Tensile tests on samples that had just been manufactured reveal that yield strength is comparable to previous studies. High precipitate concentrations, dislocations density, fine cell structure, and γ' inside cells are interpreted as the sources of high strength in as-fabricated conditions.

Similar content being viewed by others

References

Z. Sun and J.C. Ion, Laser Welding of Dissimilar Metal Combinations, Mater. Sci., 1995, 30, p 4205–4214.

J.P. Kruth, M.C. Leu, and T. Nakagawa, Progress in Additive Manufacturing and Rapid Prototyping, CIRP Ann., 1998, 47, p 525–540.

H. Hilal, R. Lancaster, S. Jeffs, J. Boswell, D. Stapleton, and G. Baxter, The Influence of Process Parameters and Build Orientation on the Creep Behaviour of a Laser Powder Bed Fused Ni-based Superalloy for Aerospace Applications, Mater, 2019, 12, p 1390–1403.

S.S. Babu, N. Raghavan, J. Raplee, S.J. Foster, C. Frederick, M. Haines, R. Dinwiddie, M.K. Kirka, A. Plotkowski, Y. Lee, and R.R. Dehoff, Additive Manufacturing of Nickel Superalloys: Opportunities for Innovation and Challenges Related to Qualification, Metall. Mater. Trans. A., 2018, 49, p 3764–3780.

J.F.S. Markanday, Applications of Alloy Design to Cracking Resistance of Additively Manufactured Ni-Based Alloys, Mater. Sci. Technol., 2022, 38, p 1300–1314.

X. Wang, L.N. Carter, N.J.E. Adkins, K. Essa, and M.M. Attallah, Novel Hybrid Manufacturing Process of CM247LC and Multi-Material Blisks, Micromachines, 2020, 11, p 492–509.

E.C. Santos, M. Shiomi, K. Osakada, and T. Laoui, Rapid Manufacturing of Metal Components by Laser Forming, Int. J. Mach. Tools Manuf., 2006, 46, p 1459–1468.

D.D. Gu, W. Meiners, K. Wissenbach, and R. Poprawe, Laser Additive Manufacturing of Metallic Components: Materials, Processes and Mechanisms, Int. Mater. Rev., 2012, 57, p 133–164.

N. Chapman, S. Gray, J. Sumner, and J. Nicholls, Stress Corrosion Testing of CMSX-4, CM247LC DS and IN6203DS Ni-Base Superalloys, Oxid. Met., 2021, 95, p 85–104.

Z. Gao, P. Zhang, Q. Niu, J. Li, L. Nie, X. Gong, and X. Song, Deformation mechanisms in the Directionally Solidified Nickel-Based CM247LC at Room Temperature, Philos. Mag. Lett., 2022, 102, p 190–199.

S.K. Selvaraj, G. Sundaramali, S. Jithin Dev, R. Srii Swathish, R. Karthikeyan, K.E. Vijay Vishaal, and V. Paramasivam, Recent Advancements in the Field of Ni-Based Superalloys, Adv. Mater. Sci. Eng., 1–60 (2021).

S. Banoth, C.W. Li, Y. Hiratsuka, and K. Kakehi, The Effect of Recrystallization on Creep Properties of Alloy IN939 Fabricated by Selective Laser Melting Process, Metals., 2020, 10, p 1016–1032.

M.K. Kumawat, C. Parlikar, Md.Z. Alam, and D.K. Das, Type-I Hot Corrosion of Ni-Base Superalloy CM247LC in Presence of Molten Na2SO4 Film, Metall. Mater. Trans. A., 2021, 52, p 378–393.

P. Zhang, Y. Yuan, Z.H. Gao, J. Li, Q. Niu, X.B. Shi, Y.L. Zhou, and Y.F. Gu, Microtwinning in the Nickel-Based Superalloy CM247LC during Compression Tests, Philos. Mag., 2022, 102, p 2235–2255.

D. Wang, S. Li, G. Deng, Y. Liu, and M.M. Attallah, A Melt Pool Temperature Model in Laser Powder Bed Fabricated CM247LC Ni Superalloy to Rationalize Crack Formation and Microstructural Inhomogeneities, Metall. Mater. Trans. A., 2021, 52, p 5221–5234.

A. Meyer, E. Daenicke, K. Horke, M. Moor, S. Müller, I. Langer, and R.F. Singer, Metal Injection Moulding of Nickel-Based Superalloy CM247LC, Powder Metall., 2016, 59, p 51–56.

J. Bratberg, H. Mao, L. Kjellqvist, A. Engström, P. Mason, and Q. Chen, The Development and Validation of a New Thermodynamic Database for Ni-Based Alloys, Superalloys 2012. E.S. Huron, R.C. Reed, M.C. Hardy, M.J. Mills, R.E. Montero, P.D. Portella, J. Telesman Ed., John Wiley & Sons Inc, Hoboken, NJ, USA, 2012, p 803–812

R. Engeli, Selective laser melting & heat treatment of γ′-strengthened Ni-base superalloys for high temperature applications, ETH Zurich, (2017).

R. Muñoz-Moreno, V.D. Divya, O.M.D.M. Messé, T. Illston, S. Baker, and H.J. Stone, Effect of Heat Treatments on the Microstructure and Texture of CM247LC Processed by Selective Laser Melting, Superalloys 2016. M. Hardy, E. Huron, U. Glatzel, B. Griffin, B. Lewis, C. Rae, V. Seetharaman, S. Tin Ed., John Wiley & Sons Inc, Hoboken, NJ, USA, 2016, p 375–382

P. Bidare, A. Mehmeti, A. Jiménez, S. Li, C. Garman, S. Dimov, and K. Essa, High-Density Direct Laser Deposition (DLD) of CM247LC Alloy: Microstructure, Porosity and Cracks, Int. J. Adv. Manuf. Technol., 2022, 120, p 8063–8074.

J. Xu, H. Gruber, R. Lin Peng, and J. Moverare, A Novel γ′-Strengthened Nickel-Based Superalloy for Laser Powder Bed Fusion, Mater., 2020, 13, p 4930–4942.

L.N. Carter, C. Martin, P.J. Withers, and M.M. Attallah, The Influence of the Laser Scan Strategy on Grain Structure and Cracking Behaviour in SLM Powder-Bed Fabricated Nickel Superalloy, J. Alloys Compd., 2014, 615, p 338–347.

D. Clark, M.R. Bache, and M.T. Whittaker, Shaped Metal Deposition of a Nickel Alloy for Aero Engine Applications, J. Mater. Process. Technol., 2008, 203, p 439–448.

M. Gaumann, C. Bezençon, P. Canalis, and W. Kurz, Single-Crystal Laser Deposition of Superalloys: Processing-Microstructure Maps, Acta Mater., 2001, 49, p 1051–1062.

G.P. Dinda, A.K. Dasgupta, and J. Mazumder, Laser Aided Direct Metal Deposition of Inconel 625 Superalloy: Microstructural Evolution and Thermal Stability, Mater. Sci. Eng. A., 2009, 509, p 98–104.

J. Chen, L. Xue, and S.H. Wang, Experimental Studies on Process-Induced Morphological Characteristics of Macro- and Microstructures in Laser Consolidated Alloys, J. Mater. Sci., 2011, 46, p 5859–5875.

R. Rosenthal and D.R.F. West, Continuous γ′ Precipitation in Directionally Solidified IN738 LC Alloy, Mater. Sci. Technol., 1999, 15, p 1387–1394.

A. Mitchell, and T. Wang, Solidification and Precipitation in IN718, in: Superalloys 718, 625, 706 and Various Derivatives, (2001) in Superalloys 718 625 706 Var. Deriv. 2001 (TMS, 2001), p 81–90.

L.E. Murr, S.M. Gaytan, D.A. Ramirez, E. Martinez, J. Hernandez, K.N. Amato, P.W. Shindo, F.R. Medina, and R.B. Wicker, Metal Fabrication by Additive Manufacturing using Laser and Electron Beam Melting Technologies, J. Mater. Sci. Technol., 2012, 28, p 1–14.

L.L. Parimi, R.G.A.D. Clark, and M.M. Attallah, Microstructural and Texture Development in Direct Laser Fabricated IN718, Mater. Charact., 2014, 89, p 102–111.

P. Kanagarajah, F. Brenne, and T. Niendorf, Inconel 939 Processed by Selective Laser Melting: Effect of Microstructure and Temperature on the Mechanical Properties under Static and Cyclic Loading, Mater. Sci. Eng. A., 2013, 588, p 188–195.

K. Kunze, T. Etter, J. Grässlin, and V. Shklover, Texture, Anisotropy in Microstructure and Mechanical Properties of IN738LC Alloy Processed by Selective Laser Melting (SLM), Mater. Sci. Eng. A., 2015, 620, p 213–222.

D. Zhang, W. Niu, X. Cao, and Z. Liu, Effect of Standard Heat Treatment on the Microstructure and Mechanical Properties of Selective Laser Melting Manufactured Inconel 718 Superalloy, Mater. Sci. Eng. A., 2015, 644, p 32–40.

M. Dimter, R. Mayer, L. Hummeler, R. Salzberger, J. Kotila, and T. Syvanen, Method and Device for Manufacturing a Three-Dimensional Object, US patent. No. US8034279B2, (2011).

ASTM E3-“Standard Guide for Preparation of Metallographic Specimens,” ASTM International, (2017).

W.S. Rasband, ImageJ, U.S. National Institute of Health, Besthesda, Maryland, USA, 1997–2015 http://imagej.nih.gov/ij/

ASTM E384-“Standard Test Method for Microindentation Hardness of Materials,” ASTM International, (2022).

ASTM E8-“Standard Test Methods for Tension Testing of Metallic Materials,” ASTM International, (2022).

V.D. Divya, R. Munoz-Moreno, O.M.D.M. Messe, J.S. Barnard, S. Baker, T. Illston, and H.J. Stone, Microstructure of Selective Laser Melted CM247LC Nickel-Based Superalloy and its Evolution through Heat Treatment, Mater. Charact., 2016, 114, p 62–74.

J.F.S. Markanday, K.A. Christofidou, J.R. Miller, E.R. Livera, N.G. Jones, E.J. Pickering, W. Li, Y. Pardhi, C.N. Jones, and H.J. Stone, The Microstructural Evolution of CM247LC Manufactured Through Laser Powder Bed Fusion, Metall. Mater. Transac. A., 2023, 54, p 1758–1775.

K. Kim, J. Koo, E. Park, N. Kim, and W. Kim, Anisotropic Thermal Conductivity of Nickel-Based Superalloy CM247LC Fabricated via Selective Laser Melting, Appl. Sci., 2021, 11, p 4843–4853.

M.S. Chiou, S.R. Jian, A.C. Yeh, and C.M. Kuo, Effects of Al Addition on the High Temperature Oxidation Behavior of CM-247 LC Ni-Based Superalloy, PRICM. F. Marquis Ed., John Wiley & Sons Inc, Hoboken, NJ, USA, 2013, p 521–527

R. Muñoz-Moreno, V.D. Divya, S.L. Driver, O.M.D.M. Messé, T. Illston, S. Baker, M.A. Carpenter, and H.J. Stone, Effect of Heat Treatment on the Microstructure, Texture and Elastic Anisotropy of the Nickel-Based Superalloy CM247LC Processed by Selective Laser Melting, Mater. Sci. Eng. A., 2016, 674, p 529–539.

W.M. Tucho, P. Cuvillier, A. Sjolyst-Kverneland, and V. Hansena, Microstructure and Hardness Studies of Inconel 718 Manufactured by Selective Laser Melting Before and After Solution Heat Treatment, Mater. Sci. Eng. A, 2017, 689, p 220–232.

T. Sonar, V. Balasubramanian, S. Malarvizhi, T. Venkateswaran, and D. Sivakumar, An overview on welding of Inconel 718 alloy–Effect of welding processes on microstructural evolution and mechanical properties of joints, Mater. Charact., 2021, 174, 110997.

O. Adegoke, J. Andersson, H. Brodin, and R. Pederson, Influence of Laser Powder Bed Fusion Process Parameters on Voids Cracks, and Microhardness of Nickel-Based Superalloy, Mater., 2020, 13, p 3770–3793.

I.S. Kim, B.G. Choi, H.U. Hong, Y.S. Yoo, and C.Y. Jo, Anomalous Deformation Behavior and Twin Formation of Ni-Base Superalloys at the Intermediate Temperatures, Mater. Sci. Eng. A., 2011, 528, p 7149–7155.

A.J. Ramirez and J.C. Lippold, High Temperature Behavior of Ni-Base Weld Metal, Mater. Sci. Eng. A., 2004, 380, p 259–271.

A.J. Ramirez, and J.C. Lippold, High Temperature Behavior of Ni-Base Weld Metal, Mater. Sci. Eng. A., 2004, 380, p 245–258.

G.A. Young, T.E. Capobianco, M.A. Penik, B.W. Morris, and J.J. McGEE, The Mechanism of Ductility Dip Cracking in Nickel-Chromium Alloys 13 (n.d.).

X. Wang, L.N. Carter, B. Pang, M.M. Attallah, and M.H. Loretto, Microstructure and Yield Strength of SLM-Fabricated CM247LC Ni-Superalloy, Acta Mater., 2017, 128, p 87–95.

N. Jeyaprakash and C.H. Yang, Improvement of Tribo-Mechanical Properties of Directionally Solidified CM-247 LC Nickel-Based Super Alloy Through Laser Material Processing, Int. J. Adv. Manuf. Technol., 2020, 106, p 4805–4814.

L. Carter, M. Attallah, and R. Reed, Laser Powder Bed Fabrication of Nickel-base Superalloys: Influence of Parameters; Characterisation, Quantification and Mitigation of Cracking. in Superalloys 2012, edited by E.S. Huron, R.C. Reed, M.C. Hardy, M.J. Mills, R.E. Montero, P.D. Portella, J. Telesman (John Wiley & Sons, Inc., Hoboken, NJ, USA, 2012), p 577–586.

Acknowledgment

The authors are grateful to Hindustan Aeronautics Limited (Aero Engine Research and Design Centre), Bangalore, for designing and facilitating the as-built CM247LC specimens for testing and characterization.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there are no financial or non-financial interests that are directly or indirectly related to the work submitted for publication.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Raghu, R., Chandramohan, P., Kumar, D.P. et al. Structural Characterization and Strength Assessment of Laser Powder Bed Fusion Manufactured CM247LC Nickel Based Super Alloy. J. of Materi Eng and Perform 32, 11310–11325 (2023). https://doi.org/10.1007/s11665-023-08550-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-023-08550-9