Abstract

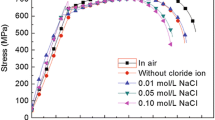

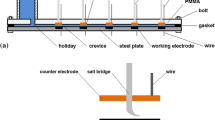

The present work investigates the effect of microstructure, pH as well as the role of aggressive chloride ions on the corrosion behavior of American Petroleum Institute (API) X70 and X80 steel grades. The corrosion behavior was studied using single-run cyclic polarization in different solutions followed by microstructural analysis of the corroded samples to determine the mode and extent of corrosion damage. The solutions consist of a near-neutral aqueous sodium chloride solution, mildly alkaline carbonate-bicarbonate solution (pH-8.8), and highly alkaline carbonate-bicarbonate solution (pH-12) with and without the presence of chlorides. Ferrite phase in both the steel was found to dissolve preferentially in the different solutions leading to pitting as a result of microgalvanic coupling with the cementite and/or bainite phase. Interestingly, the corrosion resistance of the X70 grade was found to be greater than X80 at near-neutral as well as low alkaline carbonate-bicarbonate solutions, whereas the X80 performed better in higher pH solutions. Such contrasting corrosion behavior is attributed to the compactness, thickness, and electronic resistance of the passive oxide/hydroxide films formed during polarization in both the steel.

Similar content being viewed by others

References

L. Dai, H. Bian, L. Wang, M. Potier-Ferry, and J. Zhang, Prestress Loss Diagnostics in Pretensioned Concrete Structures with Corrosive Cracking, J. Struct. Eng., 2020, 146(3), p 04020013.

H. Liu, Y. Dai, and Y.F. Cheng, Corrosion of Underground Pipelines in Clay Soil With Varied Soil Layer Thicknesses and Aerations, Arab. J. Chem., 2020, 13(2), p 3601–3614.

L. Wang, L. Dai, H. Bian, Y. Ma, and J. Zhang, Concrete Cracking Prediction under Combined Prestress and Strand Corrosion, Struct. Infrastruct. Eng., 2019, 15(3), p 285–295.

M.C. Li and Y.F. Cheng, Corrosion of the Stressed Pipe Steel in Carbonate-Bicarbonate Solution Studied by Scanning Localized Electrochemical Impedance Spectroscopy, Electrochim. Acta, 2008, 53(6), p 2831–2836.

L. Fan, Z.-Y. Liu, W.-M. Guo, J. Hou, C.-W. Du, and X.-G. Li, A New Understanding of Stress Corrosion Cracking Mechanism of X80 Pipeline Steel at Passive Potential in High-pH Solutions, Acta Metallurgica Sinica (English Letters), 2015, 28(7), p 866–875.

P. Liang, X. Li, C. Du, and X. Chen, Stress Corrosion Cracking of X80 Pipeline Steel in Simulated Alkaline Soil Solution, Mater. Des., 2009, 30(5), p 1712–1717.

X. Zhou, T. Wu, L. Tan, J. Deng, C. Li, and W. Qiu, A Study on Corrosion of X80 Steel in a Simulated Tidal Zone, J. Market. Res., 2021, 12, p 2224–2237.

H.B. Xue and Y.F. Cheng, Passivity and Pitting Corrosion of X80 Pipeline Steel in Carbonate/Bicarbonate Solution Studied by Electrochemical Measurements, J. Mater. Eng. Perform., 2010, 19(9), p 1311–1317.

S. Savoye, L. Legrand, G. Sagon, S. Lecomte, A. Chausse, R. Messina, and P. Toulhoat, Experimental Investigations on Iron Corrosion Products Formed in Bicarbonate/Carbonate-Containing Solutions at 90 °C, Corros. Sci., 2001, 43(11), p 2049–2064.

L. Wei, X. Pang, C. Liu, and K. Gao, Formation Mechanism and Protective Property of Corrosion Product Scale on X70 Steel under Supercritical CO2 Environment, Corros. Sci., 2015, 100, p 404–420.

F.F. Eliyan and A. Alfantazi, Mechanisms of Corrosion and Electrochemical Significance of Metallurgy and Environment with Corrosion of Iron and Steel in Bicarbonate and Carbonate Solutions—A Review, Corrosion, 2014, 70(9), p 880–898.

J.-B. Li and J.-E. Zuo, Influences of Temperature and pH Value on the Corrosion Behaviors of X80 Pipeline Steel in Carbonate/Bicarbonate Buffer Solution, Chin. J. Chem., 2008, 26(10), p 1799–1805.

S.T. Adamy and F.R. Cala, Inhibition of Pitting in Ferrous Materials by Carbonate as a Function of Temperature and Alkalinity, Corrosion, 1999, 55(9), p 825–839.

J. Han, S. Nešić, Y. Yang, and B.N. Brown, Spontaneous Passivation Observations During Scale Formation on Mild Steel in CO2 Brines, Electrochim. Acta, 2011, 56(15), p 5396–5404.

J. Han, J. Zhang, and J.W. Carey, Effect of Bicarbonate on Corrosion of Carbon Steel in CO2 Saturated Brines, Int. J. Greenhouse Gas Control, 2011, 5(6), p 1680–1683.

Z. Lu, C. Huang, D. Huang, and W. Yang, Effects of a Magnetic Field on the Anodic Dissolution, Passivation and Transpassivation Behaviour of Iron in Weakly Alkaline Solutions with or Without Halides, Corros. Sci., 2006, 48(10), p 3049–3077.

F.F. Eliyan, E.-S. Mahdi, and A. Alfantazi, Electrochemical Evaluation of the Corrosion Behaviour of API-X100 Pipeline Steel in Aerated Bicarbonate Solutions, Corros. Sci., 2012, 58, p 181–191.

J.M. Kolotyrkin, Pitting Corrosion of Metals, Corrosion, 2013, 19(8), p 261t–268t.

D.G. Li, Y.R. Feng, Z.Q. Bai, J.W. Zhu, and M.S. Zheng, Influence of Temperature, Chloride Ions and Chromium Element on the Electronic Property of Passive Film Formed on Carbon Steel in Bicarbonate/Carbonate Buffer Solution, Electrochim. Acta, 2007, 52(28), p 7877–7884.

J. Jelinek and P. Neufeld, Temperature Effect on Pitting Corrosion of Mild Steel in De-Aerated Sodium Bicarbonate-Chloride Solutions, Corros. Sci., 1980, 20(4), p 489–496.

M.M. El-Naggar, Effects of Cl−, NO3− and SO42− anions on the anodic behavior of carbon steel in deaerated 0.50M NaHCO3 solutions, Appl. Surf. Sci., 2006, 252(18), p 6179–6194.

J. Neshati, H.P. Masiha, M.G. Mahjani, and M. Jafarian, Study of Corrosion of Carbon Steel API 5L (X60) in NaHCO3/NaCl Solutions by Electrochemical Noise and Impedance Measurements, Corros. Eng., Sci. Technol., 2007, 42(4), p 371–376.

Y. Tang and Y. Zuo, The Metastable Pitting of Mild Steel in Bicarbonate Solutions, Mater. Chem. Phys., 2004, 88(1), p 221–226.

C.S. Brossia and G.A. Cragnolino, Effect of Environmental Variables on Localized Corrosion of Carbon Steel, Corrosion, 2000, 56(5), p 505–514.

S. Choudhary, K. Mondal, S. Mukherjee, and R. Sundara Bharathy, Effect of Scale Spallation During Coiling on the Electrochemical and Pickling Behavior of a Hot-Rolled Dual-Phase Steel, J. Mater. Eng. Perform., 2018, 27(12), p 6505–6515.

F.F. Eliyan and A. Alfantazi, Corrosion of the Heat-Affected Zones (HAZs) of API-X100 Pipeline Steel in Dilute Bicarbonate Solutions at 90 °C—An Electrochemical Evaluation, Corros. Sci., 2013, 74, p 297–307.

S. Hara, T. Kamimura, H. Miyuki, and M. Yamashita, Taxonomy for Protective Ability of Rust Layer Using its Composition Formed on Weathering steel bridge, Corros. Sci., 2007, 49(3), p 1131–1142.

T. Kamimura, S. Hara, H. Miyuki, M. Yamashita, and H. Uchida, Composition and Protective Ability of Rust Layer Formed on Weathering Steel Exposed to Various Environments, Corros. Sci., 2006, 48(9), p 2799–2812.

M.A. Kindi, G.R. Joshi, K. Cooper, J. Andrews, P. Arellanes-Lozada, R. Leiva-Garcia, D.L. Engelberg, O. Bikondoa, and R. Lindsay, Substrate Protection with Corrosion Scales: Can We Depend on Iron Carbonate?, ACS Appl. Mater. Interfaces, 2021, 13(48), p 58193–58200.

G.A. Zhang and Y.F. Cheng, Micro-Electrochemical Characterization and Mott–Schottky Analysis of Corrosion of Welded X70 Pipeline Steel in Carbonate/Bicarbonate Solution, Electrochim. Acta, 2009, 55(1), p 316–324.

J. Stiksma and S.A. Bradford, Stress Corrosion Cracking of Dual-Phase Steel in Carbonate/Bicarbonate Solutions, Corrosion, 1985, 41(8), p 446–450.

F.F. Eliyan and A. Alfantazi, Sensitivity of the Passive Films on API-X100 Steel Heat-Affected Zones (HAZs) Towards Trace Chloride Concentrations in Bicarbonate Solutions at High Temperature, Mater. Corros., 2014, 65(11), p 1111–1119.

F. Mohammadi, F.F. Eliyan, and A. Alfantazi, Corrosion of Simulated Weld HAZ of API X-80 Pipeline Steel, Corros. Sci., 2012, 63, p 323–333.

A. Torres-Islas, J.G. Gonzalez-Rodriguez, J. Uruchurtu, and S. Serna, Stress Corrosion Cracking Study of Microalloyed Pipeline Steels in Dilute NaHCO3 Solutions, Corros. Sci., 2008, 50(10), p 2831–2839.

H. Mitsui, R. Takahashi, H. Asano, N. Taniguchi, and M. Yui, Susceptibility to Stress Corrosion Cracking for Low-Carbon Steel Welds in Carbonate-Bicarbonate Solution, Corrosion, 2008, 64(12), p 939–948.

J.G. Gonzalez-Rodriguez, M. Casales, V.M. Salinas-Bravo, J.L. Albarran, and L. Martinez, Effect of Microstructure on the Stress Corrosion Cracking of X-80 Pipeline Steel in Diluted Sodium Bicarbonate Solutions, Corrosion, 2002, 58(7), p 584–590.

P.K. Neetu, S. Katiyar, and K. Sangal, Mondal, Effect of Various Phase Fraction of Bainite, Intercritical Ferrite, Retained Austenite and Pearlite on the Corrosion Behavior of Multiphase Steels, Corros. Sci., 2021, 178, p 109043.

P.K. Katiyar, P.K. Behera, S. Misra, and K. Mondal, Effect of Microstructures on the Corrosion Behavior of Reinforcing Bars (Rebar) Embedded in Concrete, Met. Mater. Int., 2019, 25(5), p 1209–1226.

A.P. Moon, S. Sangal, S. Layek, S. Giribaskar, and K. Mondal, Corrosion Behavior of High-Strength Bainitic Rail Steels, Metall. Mater. Trans. A, 2015, 46(4), p 1500–1518.

P.K. Rai, S. Shekhar, M. Nakatani, M. Ota, S.K. Vajpai, K. Ameyama, and K. Mondal, Effect of Harmonic Microstructure on the Corrosion Behavior of SUS304L Austenitic Stainless Steel, Metall. Mater. Trans. A, 2016, 47(12), p 6259–6269.

T.K. Rout, Electrochemical Impedance Spectroscopy Study on Multi-Layered Coated Steel Sheets, Corros. Sci., 2007, 49(2), p 794–817.

Y. Zhao, P. Liang, Y. Shi, Y. Zhang, and T. Yang, The Pitting Susceptibility Investigation of Passive Films Formed on X70, X80, and X100 Pipeline Steels by Electrochemical Noise and Mott–Schottky Measurements, Int. J. Corros., 2015, 2015, p 1–10.

Y.F. Cheng and J.L. Luo, A Comparison of the Pitting Susceptibility and Semiconducting Properties of the Passive Films on Carbon Steel in Chromate and Bicarbonate Solutions, Appl. Surf. Sci., 2000, 167(1), p 113–121.

Y.M. Zeng and J.L. Luo, Electronic Band Structure of Passive Film on X70 Pipeline Steel, Electrochim. Acta, 2003, 48(23), p 3551–3562.

P.K. Behera, P.K. Katiyar, S. Misra, and K. Mondal, Effect of Pre-induced Plastic Strains on the Corrosion Behavior of Reinforcing Bar in 35 pct NaCl Solution, Metall. Mater. Trans. A, 2021, 52(2), p 605–626.

P. Murkute, R. Kumar, S. Choudhary, H.S. Maharana, J. Ramkumar, and K. Mondal, Comparative Atmospheric Corrosion Behavior of a Mild Steel and an Interstitial Free Steel, J. Mater. Eng. Perform., 2018, 27(9), p 4497–4506.

C.J. Strachan, T. Rades, K.C. Gordon, and J. Rantanen, Raman Spectroscopy for Quantitative Analysis of Pharmaceutical Solids, J. Pharm. Pharmacol., 2007, 59(2), p 179–192.

E. Poorqasemi, O. Abootalebi, M. Peikari, and F. Haqdar, Investigating Accuracy of the Tafel Extrapolation Method in HCl Solutions, Corros. Sci., 2009, 51(5), p 1043–1054.

M.A. Amin, K.F. Khaled, and S.A. Fadl-Allah, Testing Validity of the Tafel Extrapolation Method for Monitoring Corrosion of Cold Rolled Steel in HCl Solutions—Experimental and Theoretical Studies, Corros. Sci., 2010, 52(1), p 140–151.

Y. Song, G. Jiang, Y. Chen, P. Zhao, and Y. Tian, Effects of Chloride Ions on Corrosion of Ductile Iron and Carbon Steel in Soil Environments, Sci. Rep., 2017, 7(1), p 6865.

E.B. Castro, C.R. Valentini, C.A. Moina, J.R. Vilche, and A.J. Arvia, The Influence of Ionic Composition on the Electrodissolution and Passivation of Iron Electrodes in Potassium Carbonate-Bicarbonate Solutions in the 8.4-10.5 pH range at 25 °C, Corros. Sci., 1986, 26(10), p 781–793.

S. Simard, M. Drogowska, H. Me´Nard, and L. Brossard, Electrochemical Behaviour of 1024 Mild Steel in Slightly Alkaline Bicarbonate Solutions, J. Appl. Electrochem., 1997, 27(3), p 317–324.

A.Q. Fu and Y.F. Cheng, Electrochemical Polarization Behavior of X70 Steel in Thin Carbonate/Bicarbonate Solution Layers Trapped under a Disbonded Coating and its Implication on Pipeline SCC, Corros. Sci., 2010, 52(7), p 2511–2518.

X. Hao, J. Dong, I.-I. Etim, J. Wei, and W. Ke, Sustained Effect of Remaining Cementite on the Corrosion Behavior of Ferrite-pearlite Steel under the Simulated Bottom Plate Environment of Cargo Oil Tank, Corros. Sci., 2016, 110, p 296–304.

M. Kadowaki, I. Muto, K. Takahashi, T. Doi, H. Masuda, H. Katayama, K. Kawano, Y. Sugawara, and N. Hara, Anodic Polarization Characteristics and Electrochemical Properties of Fe<sub>3</sub>C in Chloride Solutions, J. Electrochem. Soc., 2019, 166(12), p C345–C351.

Z. Wang, X. Zhang, L. Cheng, J. Liu, and K. Wu, Role of Inclusion and Microstructure on Corrosion Initiation and Propagation of Weathering Steels in Marine Environment, J. Market. Res., 2021, 10, p 306–321.

J. Wei, J.H. Dong, W. Ke, and X.Y. He, Influence of Inclusions on Early Corrosion Development of Ultra-Low Carbon Bainitic Steel in NaCl Solution, Corrosion, 2015, 71(12), p 1467–1480.

B. Forero, M.M.G. Núñez, and I. Bott, Analysis of the Corrosion Scales Formed on API 5L X70 and X80 Steel Pipe in the Presence of CO2, Mater. Res., 2012, 17, p 461–471.

M. Morcillo, B. Chico, J. Alcántara, I. Díaz, R. Wolthuis, and D. de la Fuente, SEM/Micro-Raman Characterization of the Morphologies of Marine Atmospheric Corrosion Products Formed on Mild Steel, J. Electrochem. Soc., 2016, 163(8), p C426–C439.

A. Raman, S. Nasrazadani, and L. Sharma, Morphology of Rust Phases Formed on Weathering Steels in Various Laboratory Corrosion Tests, Metallography, 1989, 22(1), p 79–96.

R.A. Antunes, R.U. Ichikawa, L.G. Martinez, and I. Costa, Characterization of Corrosion Products on Carbon Steel Exposed to Natural Weathering and to Accelerated Corrosion Tests, Int. J. Corros., 2014, 2014, p 419570.

A.C. Larson, R.B. Von Dreele, General Structure Analysis System (GSAS)(Report LAUR 86-748), Los Alamos, New Mexico: Los Alamos National Laboratory, (2004)

B.W.A. Sherar, P.G. Keech, Z. Qin, F. King, and D.W. Shoesmith, Nominally Anaerobic Corrosion of Carbon Steel in Near-Neutral pH Saline Environments, Corrosion, 2010, 66(4), p 045001–045001.

J. Gu, Y. Xiao, N. Dai, X. Zhang, Q. Ni, and J. Zhang, The Suppression of Transformation of γ-FeOOH to α-FeOOH Accelerating the Steel Corrosion in Simulated Industrial Atmospheric Environment with a DC Electric Field Interference, Corros. Eng. Sci. Technol., 2019, 54(3), p 249–256.

J.M. McIntyre and H.Q. Pham, Electrochemical Impedance Spectroscopy; a Tool for Organic Coatings Optimizations, Prog. Org. Coat., 1996, 27(1), p 201–207.

F. Mansfeld, Use of Electrochemical Impedance Spectroscopy for the Study of Corrosion Protection by Polymer Coatings, J. Appl. Electrochem., 1995, 25(3), p 187–202.

Y. Deo, R. Ghosh, A. Nag, D.V. Kumar, R. Mondal, and A. Banerjee, Direct and Pulsed Current Electrodeposition of Zn-Mn Coatings from Additive-Free Chloride Electrolytes for Improved Corrosion Resistance, Electrochim. Acta, 2021, 399, p 139379.

G.S. Frankel, T. Li, and J.R. Scully, Perspective—Localized Corrosion: Passive Film Breakdown versus Pit Growth Stability, J. Electrochem. Soc., 2017, 164(4), p C180–C181.

C.A. Gervasi, M.E. Folquer, A.E. Vallejo, and P.E. Alvarez, Electron Transfer Across Anodic Films Formed on Tin in Carbonate-Bicarbonate Buffer Solution, Electrochim. Acta, 2005, 50(5), p 1113–1119.

N. Sato, Chapter 8—Electrode Reactions In Electron Transfer, Electrochemistry at Metal and Semiconductor Electrodesed., N. Sato, Ed., Elsevier Science, 1998, p 235-288

X.-C. Han, J. Li, K.-Y. Zhao, W. Zhang, and J. Su, Effect of Chloride on Semiconducting Properties of Passive Films Formed on Supermartensitic Stainless Steel in NaHCO3 Solution, J. Iron Steel Res. Int., 2013, 20(5), p 74–79.

I.G. Ogunsanya and C.M. Hansson, The Semiconductor Properties of Passive Films and Corrosion Behavior of Stainless Steel Reinforcing Bars in Simulated Concrete Pore Solution, Materialia, 2019, 6, p 100321.

D.L.A. de Faria, S. Venâncio Silva, and M.T. de Oliveira, Raman Microspectroscopy of Some Iron Oxides and Oxyhydroxides, J. Raman Spectrosc., 1997, 28(11), p 873–878.

S.J. Oh, D.C. Cook, and H.E. Townsend, Characterization of Iron Oxides Commonly Formed as Corrosion Products on Steel, Hyperfine Interact., 1998, 112(1), p 59–66.

X. Zhang, K. Xiao, C. Dong, J. Wu, X. Li, and Y. Huang, In Situ Raman Spectroscopy Study of Corrosion Products on the Surface of Carbon Steel in Solution Containing Cl− and SO42, Eng. Fail. Anal., 2011, 18(8), p 1981–1989.

P. Dillmann, F. Mazaudier, and S. Hœrlé, Advances in Understanding Atmospheric Corrosion of Iron. I. Rust Characterisation of Ancient Ferrous Artefacts Exposed to Indoor Atmospheric Corrosion, Corros. Sci., 2004, 46(6), p 1401–1429.

U. Schwertmann, R.M. Taylor, Iron Oxides, Minerals in Soil Environmentsed., 1989, p 379-438

P. Bénézeth, J.L. Dandurand, and J.C. Harrichoury, Solubility Product of Siderite (FeCO3) as a Function of Temperature (25-250 °C), Chem. Geol., 2009, 265(1), p 3–12.

S. Hœrlé, F. Mazaudier, P. Dillmann, and G. Santarini, Advances in Understanding Atmospheric Corrosion of Iron. II. Mechanistic Modelling of Wet–Dry Cycles, Corros. Sci., 2004, 46(6), p 1431–1465.

Acknowledgments

We sincerely appreciate Tata Steel, Jamshedpur, India, for the necessary financial support.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there are no conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ghosh, R., Chinara, M., Godbole, K. et al. Electrochemical Behavior of X70 and X80 Pipeline Steels in a Simulated Soil Environment with and without the Presence of Chlorides. J. of Materi Eng and Perform (2023). https://doi.org/10.1007/s11665-023-08536-7

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11665-023-08536-7