Abstract

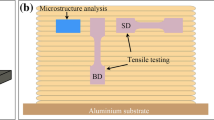

Fabrication of Mg alloys using the additive manufacturing process is quite challenging owing to high oxidation and volatile nature at high temperatures. The present study investigates the effect of wire feed speed (WFS) and travel speed (TS) on single tracks of AZ31 Mg alloy fabricated using the cold metal transfer wire arc additive Manufacturing (CMT-WAAM) process. The WFS and TS of CMT-WAAM are optimized to achieve better deposition quality. An increase in WFS increased the width, height, penetration depth, and heat-affected zone of single tracks. In addition, increasing TS decreased the deposited tracks' contact angle and height. The average grain size at the interface zone, center and top portion of single tracks are 35, 42, and 60 μm. The x-ray diffraction results show only the presence of primary phase α-Mg; interestingly, the β-Mg17Al12 and η-Al8Mn5 secondary phases are identified by SEM + EDS and TEM images. The microhardness increased from the substrate to the top section of single tracks due to the increased volume fraction of secondary-phase particles. Based on the best-chosen process parameters obtained from single-track deposition, a multilayer AZ31 Mg thin wall is deposited. The UTS, YS, and % EL of the deposited thin wall in travel direction (TD) are 222 MPa, 102 MPa, and 18%, while in build direction are 202 MPa, 110 MPa, and 14%, respectively. The tensile strength and elongation % of TD and BD samples exhibited comparable properties and were higher than cast AZ31 Mg alloy.

Similar content being viewed by others

References

D. Galeazzi, R.H.G.E. Silva, A.B. Viviani, P.R. Jaeger, and M.B. Schwedersky, Evaluation of Thermal and Geometric Properties of Martensitic Stainless Steel Thin Walls Built by Additive Manufacturing Cold Metal Transfer (CMT) Processes, Int. J. Adv. Manuf. Technol., 2022, 120, p 2151–2165. https://doi.org/10.1007/s00170-022-08921-x

C.S. Frandsen, M.M. Nielsen, A. Chaudhuri, J. Jayaram, and K. Govindan, In Search for Classification and Selection of Spare Parts Suitable for Additive Manufacturing: A Literature Review, Int. J. Prod. Res., 2020, 58, p 970–996. https://doi.org/10.1080/00207543.2019.1605226

J. Li, Y. Qiu, J. Yang, Y. Sheng, Y. Yi, X. Zeng et al., Effect of Grain Refinement Induced by Wire and Arc Additive Manufacture (WAAM) on the Corrosion Behaviors of AZ31 Magnesium Alloy in NaCl Solution, J. Magnes. Alloy, 2023, 11, p 217–229. https://doi.org/10.1016/j.jma.2021.04.007

Z. Qiang Liu, P. Lei Zhang, S. Wei Li, D. Wu, and Z. Shui Yu, Wire and Arc Additive Manufacturing of 4043 Al Alloy Using a Cold Metal Transfer Method, Int. J. Miner. Metall. Mater., 2020, 27, p 783–791. https://doi.org/10.1007/s12613-019-1930-6

S.K. Manjhi, B.S.S. Kumar, J.P. Rodrigues, P. Sekar, S. Bontha, and A.S.S. Balan, An Experimental Investigation on Microstructure, Mechanical Properties and Corrosion Performance of CMT-Wire Arc Additively Manufactured Al-4043 Alloy, Trans. Indian Inst. Met., 2023 https://doi.org/10.1007/s12666-023-02965-7

Q. Wu, J. Lu, C. Liu, X. Shi, Q. Ma, S. Tang, H. Fan, and S. Ma, Obtaining Uniform Deposition with Variable Wire Feeding Direction During Wire-Feed Additive Manufacturing, Mater. Manuf. Process., 2017, 32, p 1881–1886. https://doi.org/10.1080/10426914.2017.1364860

Y. Zhang, M. Gao, and X. Zeng, Effect of Process Parameters on Mechanical Properties of Wire and Arc Additive-Manufactured AlCu6Mn, JOM, 2019, 71, p 886–892. https://doi.org/10.1007/s11837-018-3210-8

W. Wu, W. Xu, J. Xue, and P. Yao, Effect of Cooling and CMT Mode Process on Additive Manufacturing, Mater. Manuf. Process., 2022, 37, p 1298–1309. https://doi.org/10.1080/10426914.2021.2006221

M. Javaid and A. Haleem, Additive Manufacturing Applications in Medical Cases: A Literature Based Review, Alex. J. Med., 2018, 54, p 411–422. https://doi.org/10.1016/j.ajme.2017.09.003

G. Liu and J. Xiong, External Filler Wire Based GMA-AM Process of 2219 Aluminum Alloy, Mater. Manuf. Process., 2020, 35, p 1268–1277. https://doi.org/10.1080/10426914.2020.1779936

N. E. Imoudu, Y. Z. Ayele, and A. Barabadi, The characteristic of cold metal transfer (CMT) and its application for cladding. 2017 IEEE International Conference on Industrial Engineering and Engineering Management, vol. 2017 (2018), p 1883–1887. doi: https://doi.org/10.1109/IEEM.2017.8290218

P. Wang, H. Zhang, H. Zhu, Q. Li, and M. Feng, Wire-Arc Additive Manufacturing of AZ31 Magnesium Alloy Fabricated by Cold Metal Transfer Heat Source: Processing, Microstructure, and Mechanical Behavior, J. Mater. Process. Technol., 2021 https://doi.org/10.1016/j.jmatprotec.2020.116895

J. Guo, Y. Zhou, C. Liu, Q. Wu, X. Chen, and J. Lu, Wire Arc Additive Manufacturing of AZ31 Magnesium Alloy: Grain Refinement by Adjusting Pulse Frequency, Materials (Basel), 2016, 9, p 10. https://doi.org/10.3390/ma9100823

H. Takagi, H. Sasahara, T. Abe, H. Sannomiya, S. Nishiyama, S. Ohta, and K. Nakamura, Material-Property Evaluation of Magnesium Alloys Fabricated Using Wire-and-Arc-Based Additive Manufacturing, Addit. Manuf., 2018, 24, p 498–507. https://doi.org/10.1016/j.addma.2018.10.026

R. Mola, T. Bucki, and M. Gwoździk, The Effect of a Zinc Interlayer on the Microstructure and Mechanical Properties of a Magnesium Alloy (AZ31)–Aluminum Alloy (6060) Joint Produced by Liquid-Solid Compound Casting, JOM, 2019, 71, p 2078–2086. https://doi.org/10.1007/s11837-019-03405-y

S. Jhavar, N.K. Jain, and C.P. Paul, Enhancement of Deposition Quality in Micro-Plasma Transferred Arc Deposition Process, Mater. Manuf. Process., 2014, 29, p 1017–1023. https://doi.org/10.1080/10426914.2014.892984

T.C. Nguyen, D.C. Weckman, D.A. Johnson, and H.W. Kerr, The Humping Phenomenon During High Speed Gas Metal Arc Welding, Sci. Technol. Weld. Join., 2005, 10, p 447–459. https://doi.org/10.1179/174329305X44134

X. Meng, G. Qin, and Z. Zou, Investigation of Humping Defect in High Speed Gas Tungsten Arc Welding by Numerical Modelling, Mater. Des., 2016, 94, p 69–78. https://doi.org/10.1016/j.matdes.2016.01.019]

M.J. Benoit, S.D. Sun, M. Brandt, and M.A. Easton, Processing Window for Laser Metal Deposition of Al 7075 Powder with Minimized Defects, J. Manuf. Process., 2021, 64, p 1484–1492. https://doi.org/10.1016/j.jmapro.2021.02.031

X. Fang, J. Yang, S. Wang, C. Wang, K. Huang, H. Li, and B. Lu, Additive Manufacturing of High Performance AZ31 Magnesium Alloy with Full Equiaxed Grains: Microstructure, Mechanical Property, and Electromechanical Corrosion Performance, J. Mater. Process. Technol., 2022 https://doi.org/10.1016/j.jmatprotec.2021.117430

P. Minarika, J. Veselva, J. Cizekb, M. Zemkovaa, T. Vlasakb, T. Krajnaka, J. Kubasekc, R. Krala, D. Hofmana, and J. Straska, Effect of Secondary Phase Particles on Thermal Stability of Ultra-Fine Grained Mg-4Y-3RE Alloy Prepared by Equal Channel Angular Pressing, Mater. Charact., 2018, 140, p 207–216. https://doi.org/10.1016/j.matchar.2018.04.006

D.M. Kochmann and K.C. Le, A Continuum Model for Initiation and Evolution of Deformation Twinning, J. Mech. Phys. Solids, 2009, 57, p 987–1002. https://doi.org/10.1016/j.jmps.2009.03.001

Acknowledgments

This study is financially supported by the Department of Science and Technology (DST) Government of India (Grant number SP/YO/2019/1287(G). The author acknowledges Prof. Udaya Bhat K, Professor Department of Metallurgical and Materials Engineering NITK, Surathkal, for providing their TEM lab facility.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

All authors declare no conflict of interest

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Manjhi, S.K., Sekar, P., Bontha, S. et al. Effect of CMT-WAAM Process Parameters on Bead Geometry, Microstructure and Mechanical Properties of AZ31 Mg Alloy. J. of Materi Eng and Perform (2023). https://doi.org/10.1007/s11665-023-08498-w

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11665-023-08498-w