Abstract

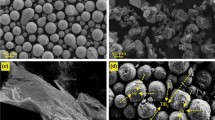

In this study, the researchers have attempted to reinforce ZK60 alloys with 5% SiC, 10% SiC, 5% B4C, 10% B4C and 5%SiC + 5%B4C microparticles and investigated the dry wear behavior of these composites. The reinforced composites were produced by the stirred casting method under the atmosphere of SF6. The high-temperature oxidation tendency of Mg and B elements can cause the oxidized-unsuccessful product in the stirred casting process. Therefore, the researchers used the semi-solid temperature stirring method in production as a new solution. The reinforced composites were homogenized at 420 °C for 24 hours and extruded at a rate of 2.25. Following the production process, all samples underwent microstructural characterization analyses, hardness tests, compression tests and dry wear tests. Comparative analysis was done between the results of unreinforced ZK60 alloy and composites from compression and wear tests. This study's results reveal a superior enhancement; the addition of 5% SiC increased the compressive strength of ZK60 alloy by 15%, while the addition of 5% B4C increased by 26%. Furthermore, adding the 5%SiC reinforcement reduced the wear rate by 4.3%, and the 5% B4C reinforcement reduced the wear rate by 11.1%.

Similar content being viewed by others

References

M. Vignesh Kumar, G. Padmanaban and V. Balasubramanian, Role of Tool Pin Profiles on Wear Characteristics of Friction Stir Processed Magnesium Alloy ZK60/Silicon Carbide Surface Composites, Materwiss Werksttech., 2020, 51, p 140–152.

D.R. Askeland, The Science and Engineering of Materials, Second SI edition, 2nd ed. Chapman & Hall, London, 1991.

K.U. Kainer and B.L. Mordike Eds., Magnesium Alloys and their Applications, Wiley-Vch, Weinheim, 2000

K.U. Kainer, Metal matrix composites, Custom-made Materials for Automotive and Aerospace Engineering. K.U. Kainer Ed., Wiley, Grünstadt, 2006

E. Ghali, Corrosion Resistance of Aluminum and Magnesium Alloys, Understanding, Performance, and Testing, John Wiley Sons, Inc., New Jersey, 2010.

Handbook CAI, ASM Metals Handbook, Metallography and Microstrustures Handbook, Vol 09, ASM International, 2004.

L.P. Barber LP, Characterization of the Solidification Behavior and Resultant Microstructures of Magnesium-Aluminum Alloys. Spectrum, 2004.

Y.C. Lee, A.K. Dahle and D.H. StJohn, Grain refinement of magnesium, Essential Readings in Magnesium Technology. John Wiley & Sons, Hoboken, 2016, p 247–254

M. Tayebi, H. Najafi, S. Nategh et al., Creep Behavior of ZK60 Alloy and ZK60/SiCw Composite After Extrusion and Precipitation Hardening, Met. Mater. Int., 2021, 27, p 3905–3917. https://doi.org/10.1007/s12540-020-00877-5

J.D. Robson and C. Paa-Rai, The Interaction of Grain Refinement and Ageing in Magnesium-Zinc-Zirconium (ZK) Alloys, Acta Mater., 2015, 95, p 10–19.

Z.C. Hildebrand, M. Qian, D.H. StJohn et al., Influence of Zinc on the Soluble Zirconium Content in Magnesium and the Subsequent Grain Refinement by Zirconium, Magnes. Technol., 2004, 2004, p 241–245.

M.S. El-Wazery, A.R. El-Desouky, O.A. Hamed et al., Electrical and Mechanical Performance of Zirconia-Nickel Functionally Graded Materials, Int. J. Eng. Trans. A Basics, 2013, 26, p 375–382.

W.H. Hunt and D.R. Herling, Aluminum Metal Matrix Composites, Adv. Mater. Process., 2004, 162, p 39–44.

S. Seshan, M. Jayamathy, S.V. Kailas et al., The Tensile Behavior of Two Magnesium Alloys Reinforced with Silicon Carbide Particulates, Mater. Sci. Eng. A, 2003, 363, p 345–351.

R.L. Deuis, C. Subramanian and J.M. Yellup, Abrasive Wear of Aluminium Composites—A Review, Wear, 1996, 201, p 132–144.

K. Rahmani and G.H. Majzoobi, The effect of particle size on microstructure, relative density and indentation load of Mg-B4C composites fabricated at different loading rates, J. Compos. Mater., 2020, 54, p 2297–2311.

N.P. Bansal, Handbook of Ceramic Composites, Kluwer academic publishers, NewYork, 2005.

A. Sager, I. Esen, H. Ahlatçi et al., Characterization and Corrosion Behavior of Composites Reinforced with ZK60, AlN, and SiC Particles, Eng. Sci. Technol. Int. J., 2023, 41, p 101389. https://doi.org/10.1016/j.jestch.2023.101389

A. Sager, I. Esen, H. Ahlatçi et al., Dry Wear Behaviour of the New ZK60/AlN/SiC Particle Reinforced Composites, Materials, 2022, 15, p 8582.

A.M. Sadoun, M.M. Mohammed, E.M. Elsayed et al., Effect of Nano Al2O3 Coated Ag Addition on the Corrosion Resistance and Electrochemical Behavior of Cu-Al2O3 Nanocomposites, J. Mater. Res. Technol., 2020, 9, p 4485–4493. https://doi.org/10.1016/j.jmrt.2020.02.076

M. Gu, Z. Wu, Y. Jin et al., Interfacial Reaction and Microstructure in a ZK60-Based Hybrid Composite, J. Mater. Sci., 2000, 35, p 2499–2505.

H. Dieringa and K.U. Kainer, Particles, fibers and short fibers for the reinforcement of metal materials, Metal Matrix Composites: Custom-made Materials for Automotive and Aerospace Engineering. Wley, Weinheim, 2006, p 55–76

A.F. Meselhy and M.M. Reda, Investigation of Mechanical Properties of Nanostructured Al-SiC Composite Manufactured by Accumulative Roll Bonding, J. Compos. Mater., 2019, 53, p 3951–3961.

B.S. Murty, S.K. Thakur and B.K. Dhindaw, On the Infiltration Behavior of Al, Al-Li, and Mg Melts Through SiCp Bed, Metall. Mater. Trans. A Phys. Metall. Mater. Sci., 2000, 31, p 319–325.

A. Matin, F.F. Saniee and H.R. Abedi, Microstructure and Mechanical Properties of Mg/SiC and AZ80/SiC Nano-Composites Fabricated Through Stir Casting Method, Mater. Sci. Eng. A, 2015, 625, p 81–88. https://doi.org/10.1016/j.msea.2014.11.050

M. Elwan, A. Fathy, A. Wagih et al., Fabrication and Investigation on the Properties of Ilmenite (FeTiO3)-based Al Composite by Accumulative Roll Bonding, J. Compos. Mater., 2020, 54, p 1259–1271.

A. Singh and N. Bala, Fabrication and Tribological Behavior of Stir Cast Mg/B4C Metal Matrix Composites, Metall. Mater. Trans. A Phys. Metall. Mater. Sci., 2017, 48, p 5031–5045.

K. Rahmani, G.H. Majzoobi, G. Ebrahim-Zadeh et al., Comprehensive Study on Quasi-Static and Dynamic Mechanical Properties and Wear Behavior of Mg—B4C Composite Compacted at Several Loading Rates Through Powder Metallurgy, Trans. Nonferrous Met. Soc. China, 2021, 31, p 371–381. https://doi.org/10.1016/S1003-6326(21)65502-4

H. Ahmadian, A.M. Sadoun, A. Fathy et al., Utilizing a Unified Conceptual Dynamic Model for Prediction of Particle Size of Duel-Matrix Nanocomposites During Mechanical Alloying, Powder Technol., 2023, 418, p 118291. https://doi.org/10.1016/j.powtec.2023.118291

T. Zhu, Y. Yu, Y. Shen et al., Wear Behavior of Extruded ZK60 Magnesium Alloy in Simulated Body Fluid with Different pH Values, Mater Chem Phys., 2021, 262, p 124292.

Y. Behnamian, D. Serate, E. Aghaie et al., Tribological Behavior of ZK60 Magnesium Matrix Composite Reinforced by Hybrid MWCNTs/B4C Prepared by Stir Casting Method, Tribol. Int., 2022, 165, p 107299. https://doi.org/10.1016/j.triboint.2021.107299

Y. Guo, S. Wang, W. Liu et al., Effect of Laser Shock Peening on Tribological Properties of Magnesium Alloy ZK60, Tribol Int., 2020, 144, p 106138. https://doi.org/10.1016/j.triboint.2019.106138

J. Liang, Z. Lei, Y. Chen et al., Microstructure Evolution of Laser Powder Bed Fusion ZK60 Mg Alloy After Different Heat Treatment, J. Alloys Compd., 2022, 898, p 163046. https://doi.org/10.1016/j.jallcom.2021.163046

L.L. Chang, X.J. Su, J.L. Qin et al., Uneven Microstructure in ZK60 Alloy as a Core of AZ31/ZK60 Composite Rods, Mater. Lett., 2022, 325, p 132666.

A.H. Wang and T.M. Yue, YAG Laser Cladding of an Al-Si Alloy onto an Mg/SiC Composite for the Improvement of Corrosion Resistance, Compos. Sci. Technol., 2001, 61, p 1549–1554.

I. Kerti and F. Toptan, Microstructural Variations in Cast B4C-Reinforced Aluminium Matrix Composites (AMCs), Mater. Lett., 2008, 62, p 1215–1218.

Q.C. Jiang, H.Y. Wang, B.X. Ma et al., Fabrication of B4C Participate Reinforced Magnesium Matrix Composite by Powder Metallurgy, J. Alloys Compd., 2005, 386, p 177–181.

S.M. He, L.M. Peng, X.Q. Zeng et al., Comparison of the Microstructure and Mechanical Properties of a ZK60 Alloy with and Without 1.3 wt.% Gadolinium Addition, Mater. Sci. Eng. A., 2006, 433, p 175–181.

S. Cai, T. Lei, N. Li et al., Effects of Zn on Microstructure, Mechanical Properties and Corrosion Behavior of Mg-Zn Alloys, Mater. Sci. Eng. C, 2012, 32, p 2570–2577. https://doi.org/10.1016/j.msec.2012.07.042

A. Roine, Outokumpu HSC Chemistry for Windows: Chemical Reaction and Equilibrium Software with Extensive Thermochemical Database. User’s Guid Outokumpu HSC Chem ® Wind [Internet]. 2002;268. Available from: http://www.chemistry-software.com/pdf/HSC/fullmanualHSCChemistry5.pdf.

A. Mohamed, M.M. Mohammed, A.F. Ibrahim et al., Effect of Nano Al2O3 Coated Ag Reinforced Cu Matrix Nanocomposites on Mechanical and Tribological Behavior Synthesis by P/M Technique, J. Compos. Mater., 2020, 54, p 4921–4928.

I.R. Najjar, A.M. Sadoun, A. Fathy et al., Prediction of Tribological Properties of Alumina-Coated, Silver-Reinforced Copper Nanocomposites Using Long Short-Term Model Combined with Golden Jackal Optimization, Lubricants, 2022, 10, p 277.

A.M. Sadoun, I.M.R. Najjar, A. Fathy et al., An Enhanced Dendritic Neural Algorithm to Predict the Wear Behavior of Alumina Coated Silver Reinforced Copper Nanocomposites, Alex. Eng J., 2023, 65, p 809–823. https://doi.org/10.1016/j.aej.2022.09.036

A.M. Sadoun, I.R. Najjar, G.S. Alsoruji et al., Utilization of Improved Machine Learning Method Based on Artificial Hummingbird Algorithm to Predict the Tribological Behavior of Cu-Al2O3 Nanocomposites Synthesized by In Situ Method, Mathematics, 2022, 10, p 1266.

Acknowledgment

This study has been supported by The Scientific and Technological Research Council of Turkey under the Project no. 122M233, and the authors thank for the valuable support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Boztas, H., Esen, I., Ahlatci, H. et al. Microstructure Characterization and Wear Behavior of New ZK60 Alloy Reinforced with 5–10% SiC and 5–10% B4C Particles. J. of Materi Eng and Perform (2023). https://doi.org/10.1007/s11665-023-08469-1

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11665-023-08469-1