Abstract

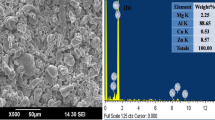

Functionally graded materials (FGMs) with a gradual transition from ceramic to metal are believed to have superior ballistic performance compared to ceramic/metal composite armors. Therefore, multilayered SiC/AA7075 FGM samples of size 50 × 50 mm are synthesized using a relatively simple and inexpensive technique, i.e., powder metallurgy. The armor requirements depend upon the type of threat and hence, the region and circumstances. Therefore, unlike most of the available investigations, the present study deals with FGM armors with low areal density ( < 30 kg/m2) against 7.62 × 39 mm Hardened Steel Core bullets. Two different FGM designs comprising 3 and 5 layers of SiC/AA7075 composite, with 10-30-50 wt.% SiC and 10-20-30-40-50 wt.% SiC, respectively, are developed herein along with a homogeneous composite with 30 wt.% SiC for comparison. The fabrication process involves the stacking of powder blends pertaining to different layers in the die cavity followed by hot pressing at a temperature of 400 °C and 325 MPa pressure. The green compacts are then subjected to pressureless sintering at 540 °C for 3 h. Solution heat treatment and aging are found to enhance the hardness of each layer significantly. The results of the depth of penetration-based ballistic evaluation profoundly establish the superiority of FGM armors over homogeneous composites. Besides, a one-dimensional stress wave propagation-based analysis is also presented herein to explain the reason for the better ballistic performance of FGMs.

Similar content being viewed by others

References

W.W. Chen, A.M. Rajendran, B. Song, and X. Nie, Dynamic Fracture of Ceramics in Armor Applications, J. Am. Ceram. Soc., 2007, 90(4), p 1005–1018.

W.A. Gooch, B.H.C. Chen, M.S. Burkins, R. Palicka, J. Rubin, and R. Ravichandran, Development and Ballistic Testing of a Functionally Gradient Ceramic/Metal Applique, Mater. Sci. Forum, 1999, 308–311, p 614–621.

W.A. Gooch, An Overview of Ceramic Armor Applications, Tech. Conf. IDEE, 2004, (January), p 3–21, https://www.researchgate.net/publication/292398604

E.S.C. Chin, Army Focused Research Team on Functionally Graded Armor Composites, Mater. Sci. Eng. A, 1999, 259(2), p 155–161.

Y. Li, K.T. Ramesh, and E.S.C. Chin, Dynamic Characterization of Layered and Graded Structures under Impulsive Loading, Int. J. Solids Struct., 2001, 38(34–35), p 6045–6061.

R. Rodríguez-Castro, R.C. Wetherhold, and M.H. Kelestemur, Microstructure and Mechanical Behavior of Functionally Graded Al A359/SiCp Composite, Mater. Sci. Eng. A, 2002, 323(1–2), p 445–456.

M.T. Tilbrook, R.J. Moon, and M. Hoffman, Crack Propagation in Graded Composites, Compos. Sci. Technol., 2005, 65(2), p 201–220.

A. Pettersson, P. Magnusson, P. Lundberg, and M. Nygren, Titanium–Titanium Diboride Composites as Part of a Gradient Armour Material, Int. J. Impact Eng., 2005, 32(1–4), p 387–399.

M. Aydin and M.K. Apalak, Experimental Damage Analysis of Al/SiC Functionally Graded Sandwich Plates under Ballistic Impact, Mater. Sci. Eng. A, 2016, 671, p 107–117. https://doi.org/10.1016/j.msea.2016.06.048

C. Wu, J. Wu, K. Ma, D. Zhang, S. Xiong, J. Zhang, G. Luo, F. Chen, Q. Shen, L. Zhang, and E.J. Lavernia, Synthesis of AA7075-AA7075/B4C Bilayer Composite with Enhanced Mechanical Strength via Plasma Activated Sintering, J. Alloys Compd., 2017, 701, p 416–424. https://doi.org/10.1016/j.jallcom.2017.01.065

M.C. Jo, J.H. Choi, J. Yoo, D. Lee, S. Shin, I. Jo, S.K. Lee, and S. Lee, Novel Dynamic Compressive and Ballistic Properties in 7075–T6 Al-Matrix Hybrid Composite Reinforced with SiC and B4C Particulates, Compos. Part B Eng., 2019, 174(March), p 107041. https://doi.org/10.1016/j.compositesb.2019.107041

F. Erdemir, A. Canakci, T. Varol, and S. Özkaya, Corrosion and Wear Behavior of Functionally Graded Al2024/SiC Composites Produced by Hot Pressing and Consolidation, J. Alloys Compd., 2015, 644, p 589.

Z.L. Chao, L.T. Jiang, G.Q. Chen, J. Qiao, Z.H. Yu, Y.F. Cao, and G.H. Wu, The Microstructure and Ballistic Performance of B4C/AA2024 Functionally Graded Composites with Wide Range B4C Volume Fraction, Compos. Part B Eng., 2019, 161(March 2018), p 627–638.

M. Übeyli, E. Balci, B. Sarikan, M.K. Öztaş, N. Camuşcu, R.O. Yildirim, and Ö. Keleş, The Ballistic Performance of SiC-AA7075 Functionally Graded Composite Produced by Powder Metallurgy, Mater. Des., 2014, 56, p 31–36.

E. Balci, B. Sarikan, M. Übeyli, N. Camuşcu, and R.O. Yildirim, On the Ballistic Performance of the AA7075 Based Functionally Graded Material with Boron Carbide Reinforcement, Kov. Mater., 2013, 51(4), p 257–262.

N. Gupta, V.V. Bhanu Prasad, V. Madhu, and B. Basu, Ballistic Studies on TiB2-Ti Functionally Graded Armor Ceramics, Def. Sci. J., 2012, 62(6), p 382–389.

A. Sharma, K.V. Sai Srinivasan, M. Dixit, A.K. Gupta, and R. Sujith, Ballistic Performance of Functionally Graded Boron Carbide Reinforced Al-Zn-Mg-Cu Alloy, J. Mater. Res. Technol., 2022, 18(April), p 4042–4059. https://doi.org/10.1016/j.jmrt.2022.04.059

Ş Karabulut, H. Karakoç, M. Bilgin, H. Canpolat, G.M. Krolczyk, and M. Sarıkaya, A Comparative Study on Mechanical and Ballistic Performance of Functionally Graded Al6061 Composites Reinforced with B4C, SiC, and Al2O3, J. Mater. Res. Technol., 2023, 23, p 5050–5065.

M. Pourmajidian and F. Akhlaghi, Fabrication and Characterization of Functionally Graded Al/SiCp Composites Produced by Remelting and Sedimentation Process, J. Mater. Eng. Perform., 2014, 23(2), p 444–450.

X. Lin, C. Liu, and H. Xiao, Fabrication of Al-Si-Mg Functionally Graded Materials Tube Reinforced with in Situ Si/Mg2Si Particles by Centrifugal Casting, Compos. Part B Eng., 2013, 45, p 8–21.

K.M. Cho, I.D. Choi, and I. Park, Thermal Properties and Fracture Behavior of Compositionally Graded Al-SiCp Composites, Mater. Sci. Forum, 2004, 449–452(I), p 621–624.

C.Y. Huang and Y.L. Chen, Design and Impact Resistant Analysis of Functionally Graded Al2O3-ZrO2 Ceramic Composite, Mater. Des., 2016, 91, p 294–305. https://doi.org/10.1016/j.matdes.2015.11.091

D. Hui and P.K. Dutta, A New Concept of Shock Mitigation by Impedance-Graded Materials, Compos. Part B Eng., 2011, 42, p 2181–2184.

H.A. Bruck, One-Dimensional Model for Designing Functionally Graded Materials to Manage Stress Waves, Int. J. Solids Struct., 2000, 37(44), p 6383–6395.

A.J. Owen and I. Koller, A Note on the Young’s Modulus of Isotropic Two-Component Materials, Polymer, 1996, 37(3), p 527–530.

S.G. Savio, K. Ramanjaneyulu, V. Madhu, and T.B. Bhat, An Experimental Study on Ballistic Performance of Boron Carbide Tiles, Int. J. Impact Eng., 2011, 38, p 535–541.

B. James, Depth of Penetration Testing, Ceram. Trans., 2002, 134, p 165–172.

M.A. Khan, Y. Wang, H. Cheng, F. Nazeer, G. Yasin, M.U. Farooq, A. Malik, and Z. Nazir, Ballistic Behaviour of Spray Formed AA7055 Aluminum Alloy against Tungsten Core Projectile Impact, Vacuum, 2018, 159, p 482–493. https://doi.org/10.1016/j.vacuum.2018.10.073

M.B. Karamis, A. Tasdemirci, and F. Nair, Failure and Tribological Behaviour of the AA5083 and AA6063 Composites Reinforced by SiC Particles under Ballistic Impact, Compos. Part A Appl. Sci. Manuf., 2003, 34(3), p 217–226.

A.G. Ingellis and L. Leone, ASM Handbook, Volume 2: Properties and Selection: Nonferrous Alloys and Special-Purpose Materials ASM Handbook Committee, Prop. Wrought Alum. Alum. Alloy., 1990, 2(17), p 62–122.

A. Nastic, A. Merati, M. Bielawski, M. Bolduc, O. Fakolujo, and M. Nganbe, Instrumented and Vickers Indentation for the Characterization of Stiffness, Hardness and Toughness of Zirconia Toughened Al2O3 and SiC Armor, J. Mater. Sci. Technol., 2015, 31(8), p 773–783. https://doi.org/10.1016/j.jmst.2015.06.005

Acknowledgments

The financial support received from Armament Research Board (ARMREB), Defence Research and Development Organization (DRDO), Government of India under Grant No. ARMREB/CDSW/2018/201 is highly acknowledged. The authors are also grateful to the Director, CDSW Panel Coordinator and Scientists (Dr Prince Sharma and Dr Debarathi) at TBRL Chandigarh for permitting and facilitating the conduct of ballistic testing.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Chouhan, M., Kumar, P., Thakur, L. et al. A Comparative Study on the Ballistic Performance of Multilayered SiC/AA7075 Functionally Graded Armor Materials. J. of Materi Eng and Perform (2023). https://doi.org/10.1007/s11665-023-08398-z

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11665-023-08398-z