Abstract

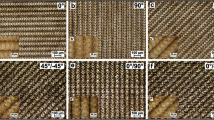

This study used surface roughness and wettability tests to evaluate the texture created by laser processing parameters on the AISI 316LVM metal surface. On the metal surface, the texture was created using a nanosecond fiber laser according to the experiment series consisting of different levels of six different process parameters. The effect of the surface roughness of the processed texture and the laser texturing parameters on the wettability was associated with the contact angle. It has been determined that the movement of the laser beam during texture creation, i.e., the angle at which the laser beam moves on the defined geometry during texturing, significantly affected the changes in the wettability behavior of the surfaces. It was revealed that the surface roughness alone did not affect the wettability. The hatching strategy and the overlap ratios affected the surface roughness of the textured surface. It was revealed that surface wettability was affected by surface topography and roughness, which varied according to laser surface texturing parameters. The texture (E16), formed with the laser texturing parameters of 70% power, 1000 mm/s scan speed, 100 kHz frequency, 0.03 mm line spacing, and 75 ns pulse width, exhibited hydrophobic behavior with a contact angle of 114.5° and surface roughness (Sa) of 1.45 µm. E4, E6, E9, E11, E15, E17, and E18 surfaces exhibited a superhydrophilic behavior.

Similar content being viewed by others

References

P. Kaul and P. Jaiswal, Bioimplants Market by Type (Cardiovascular Bioimplants, Dental Bioimplants, Orthopedic Bioimplants, Spinal Bioimplants, and Ophthalmology Bioimplants), Material (Metallic Biomaterials, Ceramic Biomaterials, Polymers Biomaterials, And Natural Biomaterials), Global Opportunity Analysis And Industry Forecast 2017-2023. Allied Market Research Web, https://www.alliedmarketresearch.com/bioimplants-market. Accessed 20 May (2022)

Y. Ahmed and M.A. Ur Rehman, Improvement in the Surface Properties of Stainless Steel via Zein/Hydroxyapatite Composite Coatings for Biomedical Applications, Surf. Interfaces, 2020, 20, p 100589.

E. Chikarakara, S. Naher, and D. Brabazon, Process Mapping of Laser Surface Modification of AISI 316L Stainless Steel for Biomedical Applications, Appl. Phys. A Mater., 2010, 101(2), p 367–371.

M.J.K. Lodhi, K.M. Deen, M.C. Greenlee-Wacker, and W. Haider, Additively Manufactured 316l Stainless Steel with Improved Corrosion Resistance and Biological Response for Biomedical Applications, Addit. Manuf., 2019, 27, p 8–19.

J. Buhagiar, A. Spiteri, M. Sacco, E. Sinagra, and H. Dong, Augmentation of Crevice Corrosion Resistance of Medical Grade 316LVM Stainless Steel by Plasma Carburizing, Corros. Sci., 2012, 59, p 169–178.

G.A. Chen, Thouas, Metallic Implant Biomaterials, Mater. Sci. Eng. R Rep., 2015, 87, p 1–57.

M. Talha, C.K. Behera, S. Kumar, O. Pal, G. Singh, and O.P. Sinha, Long Term and Electrochemical Corrosion Investigation of Cold Worked AISI 316L and 316LVM Stainless Steels in Simulated Body Fluid, RSC Adv., 2014, 4(26), p 13340–13349.

A. Shahryari, S. Omanovic, and J.A. Szpunar, Electrochemical Formation of Highly Pitting Resistant Passive Films on a Biomedical Grade 316LVM Stainless Steel Surface, Mater. Sci. Eng. C, 2008, 28(1), p 94–106.

J. Lou, B. Ren, J. Zhang, H. He, Z. Gao, and W. Xu, Evaluation of Biocompatibility of 316 L Stainless Steels Coated with TiN, TiCN, and Ti-DLC Films, Coatings, 2022, 12(8), p 1073.

K. Yang and Y. Ren, Nickel-Free Austenitic Stainless Steels for Medical Applications, Sci. Technol. Adv. Mater., 2010, 11(1), p 014105.

A. Bagno and C. Di Bello, Surface Treatments and Roughness Properties of Ti-Based Biomaterials, J. Mater. Sci. Mater. Med., 2004, 15(9), p 935–949.

Y. Wang, M. Zhang, K. Li, and J. Hu, Study on the Surface Properties and Biocompatibility of Nanosecond Laser Patterned Titanium Alloy, Opt. Laser Technol., 2021, 139, p 106987.

M. Stoilov, L. Stoilov, N. Enkling, H. Stark, J. Winter, M. Marder, and D. Kraus, Effects of Different Titanium Surface Treatments on Adhesion, Proliferation and Differentiation of Bone Cells: An In Vitro Study, J. Funct. Biomater., 2022, 13(3), p 143.

M. Hočevar, B. Šetina Batič, M. Godec, V. Kononenko, D. Drobne, and P. Gregorčič, The Interaction Between the Osteosarcoma Cell and Stainless Steel Surface, Modified by High-Fluence, Nanosecond Laser Pulses, Surf. Coat. Technol., 2020, 394, p 125878.

S. Pattanayak and S. Kumar Sahoo, Micro Engraving on 316L Stainless Steel Orthopedic Implant Using Fiber Laser, Opt. Fiber Technol., 2020, 63, p 102479.

Ş Kasman and I.E. Saklakoglu, Determination of Process Parameters in the Laser Micromilling Application Using Taguchi Method: A Case Study for AISI H13 Tool Steel, Int. J. Adv. Manuf. Technol., 2012, 58(1), p 201–209.

A. Cunha, V. Oliveira, R. Vilar, 11-Ultrafast Laser Surface Texturing of Titanium Alloys, Laser Surface Modification of Biomaterialsed., R. Vilar, Ed., Woodhead Publishing, 301-322. (2016)

J. Yan, N. Takayama, 4-Laser Processing Technologies, Micro and Nanoscale Laser Processing of Hard Brittle Materialsed., J. Yan, N. Takayama, Eds., Elsevier, 53-74. (2020)

H. Kenar, E. Akman, E. Kacar, A. Demir, H. Park, H. Abdul-Khaliq, C. Aktas, and E. Karaoz, Femtosecond Laser Treatment of 316L Improves Its Surface Nanoroughness and Carbon Content and Promotes Osseointegration: An In Vitro Evaluation, Colloids Surf. B Biointerfaces, 2013, 108, p 305–312.

F.S.M. Ismail, R. Rohanizadeh, S. Atwa, R.S. Mason, A.J. Ruys, P.J. Martin, and A. Bendavid, The Influence of Surface Chemistry and Topography on the Contact Guidance of MG63 Osteoblast Cells, J. Mater. Sci. Mater. Med., 2007, 18(5), p 705–714.

D. Lakstein, W. Kopelovitch, Z. Barkay, M. Bahaa, D. Hendel, and N. Eliaz, Enhanced Osseointegration of Grit-Blasted, NaOH-Treated and Electrochemically Hydroxyapatite-Coated Ti-6Al-4V Implants in Rabbits, Acta Biomater., 2009, 5(6), p 2258–2269.

P.R. Klokkevold, R.D. Nishimura, M. Adachi, and A. Caputo, Osseointegration Enhanced by Chemical Etching of the Titanium Surface: A Torque Removal Study in the Rabbit, Clin. Oral. Implants Res., 1997, 6, p 442–447.

C.A. Simmons, N. Valiquette, and R.M. Pilliar, Osseointegration of Sintered Porous-Surfaced and Plasma Spray-Coated Implants: An Animal Model Study of Early Postimplantation Healing Response and Mechanical Stability, J. Biomed. Mater. Res., 1999, 47(2), p 127–138.

R. Brånemark, L. Emanuelsson, A. Palmquist, and P. Thomsen, Bone Response to Laser-Induced Micro- and Nano-Size Titanium Surface Features, Nanomed. Nanotechnol. Biol. Med., 2011, 7(2), p 220–227.

L. Qin, Q. Zeng, W. Wang, Y. Zhang, and G. Dong, Response of MC3T3-E1 Osteoblast Cells to the Microenvironment Produced on Co-Cr-Mo Alloy Using Laser Surface Texturing, J. Mater. Sci., 2014, 49(6), p 2662–2671.

N. Mirhosseini, P.L. Crouse, M.J.J. Schmidth, L. Li, and D. Garrod, Laser Surface Micro-Texturing of Ti-6Al-4V Substrates for Improved Cell Integration, Appl. Surf. Sci., 2007, 253(19), p 7738–7743.

G. Menci, A.G. Demir, D.G. Waugh, J. Lawrence, and B. Previtali, Laser Surface Texturing of β-Ti Alloy for Orthopaedics: Effect of Different Wavelengths and Pulse Durations, Appl. Surf. Sci., 2019, 489, p 175–186.

F. Rupp, R.A. Gittens, L. Scheideler, A. Marmur, B.D. Boyan, Z. Schwartz, and J. Geis-Gerstorfer, A Review on the Wettability of Dental Implant Surfaces I: Theoretical and Experimental Aspects, Acta Biomater., 2014, 10(7), p 2894–2906.

G. Zhao, A.L. Raines, M. Wieland, Z. Schwartz, and B.D. Boyan, Requirement for Both Micron- and Submicron Scale Structure for Synergistic Responses of Osteoblasts to Substrate Surface Energy and Topography, Biomaterials, 2007, 28(18), p 2821–2829.

J.H. Park, C.E. Wasilewski, N. Almodovar, R. Olivares-Navarrete, B.D. Boyan, R. Tannenbaum, and Z. Schwartz, The Responses to Surface Wettability Gradients Induced by Chitosan Nanofilms on Microtextured Titanium Mediated by Specific Integrin Receptors, Biomaterials, 2012, 33(30), p 7386–7393.

R.A. Gittens, T. McLachlan, R. Olivares-Navarrete, Y. Cai, S. Berner, R. Tannenbaum, Z. Schwartz, K.H. Sandhage, and B.D. Boyan, The Effects of Combined Micron-/Submicron-Scale Surface Roughness and Nanoscale Features on Cell Proliferation and Differentiation, Biomaterials, 2011, 32(13), p 3395–3403.

E.P. Vieira, S. Rocha, M. Carmo Pereira, H. Möhwald, and M.A.N. Coelho, Adsorption and Diffusion of Plasma Proteins on Hydrophilic and Hydrophobic Surfaces: Effect of Trifluoroethanol on Protein Structure, Langmuir, 2009, 25(17), p 9879–9886.

S. Kedia, S.K. Bonagani, A.G. Majumdar, V. Kain, M. Subramanian, N. Maiti, and J.P. Nilaya, Nanosecond Laser Surface Texturing of type 316L Stainless Steel for Contact Guidance of Bone Cells and Superior Corrosion Resistance, Colloid Interface Sci. Commun., 2021, 42, p 100419.

C. Hallgren, H. Reimers, D. Chakarov, J. Gold, and A. Wennerberg, An In Vivo Study of Bone Response to Implants Topographically Modified by Laser Micromachining, Biomaterials, 2003, 24(5), p 701–710.

Z. Yu, S. Yin, W. Zhang, X. Jiang, and J. Hu, Picosecond Laser Texturing on Titanium Alloy for Biomedical Implants in Cell Proliferation and Vascularization, J. Biomed. Mater. Res. B Appl. Biomater., 2020, 108(4), p 1494–1504.

M. Teixidor, A. Grzenda, and J. Bustillo, Ciurana, Modeling Pulsed Laser Micromachining of Micro Geometries Using Machine-Learning Techniques, J. Intell. Manuf., 2015, 26(4), p 801–814.

L. Hribar, P. Gregorčič, M. Senegačnik, and M. Jezeršek, The Influence of the Processing Parameters on the Laser-Ablation of Stainless Steel and Brass during the Engraving by Nanosecond Fiber Laser, Nanomaterials, 2022, 12(2), p 232.

A.L.L. Barboza, K.W. Kang, R.D. Bonetto, C.L. Llorente, P.D. Bilmes, and C.A. Gervasi, Blasting and Passivation Treatments for ASTM F139 Stainless Steel for Biomedical Applications: Effects on Surface Roughness, Hardening, and Localized Corrosion, J. Mater. Eng. Perform., 2015, 24(1), p 175–184.

P. Pawlus, R. Reizer, and W. Zelasko, Prediction of Parameters of Equivalent Sum Rough Surfaces, Materials, 2020, 13(21), p 4898.

Q. Zeng, Y. Qin, W. Chang, and X. Luo, Correlating and Evaluating the Functionality-Related Properties with Surface Texture Parameters and Specific Characteristics of Machined Components, Int. J. Mech. Sci., 2018, 149, p 62–72.

ISO 21920-2. Geometrical product specifications (GPS)—Surface Texture: Profile—Part 2: Terms, Definitions and Surface Texture Parameters. International Organisation for Standardization. (2021)

A. Samanta, Q. Wang, S.K. Shaw, and H. Ding, Roles of Chemistry Modification for Laser Textured Metal Alloys to Achieve Extreme Surface Wetting Behaviors, Mater. Des., 2020, 192, p 108744.

U. Trdan, M. Hočevar, and P. Gregorčič, Transition from Superhydrophilic to Superhydrophobic State of Laser Textured Stainless Steel Surface and Its Effect on Corrosion Resistance, Corros. Sci., 2017, 123, p 21–26.

A. Cunha, A.P. Serro, V. Oliveira, A. Almeida, R. Vilar, and M.C. Durrieu, Wetting Behaviour of Femtosecond Laser Textured Ti-6Al-4V Surfaces, Appl. Surf. Sci., 2013, 265, p 688–696.

E. Allahyari, J. Jj Nivas, S.L. Oscurato, M. Salvatore, G. Ausanio, A. Vecchione, R. Fittipaldi, P. Maddalena, R. Bruzzese, and S. Amoruso, Laser Surface Texturing of Copper and Variation of the Wetting Response with the Laser Pulse Fluence, Appl. Surf. Sci., 2019, 470, p 817–824.

J. Li, Y. Zhou, F. Fan, F. Du, and H. Yu, Controlling Surface Wettability and Adhesive Properties by Laser Marking Approach, Opt. Laser Technol., 2019, 115, p 160–165.

N. Hideo, I. Ryuichi, H. Yosuke, and S. Hiroyuki, Effects of Surface Roughness on Wettability, Acta Mater., 1998, 46(7), p 2313–2318.

C. Leone, S. Genna, and F. Tagliaferri, Multiobjective Optimization of Nanosecond Fiber Laser Milling of 2024 T3 Aluminium Alloy, J. Manuf. Process., 2020, 57, p 288–301.

K.L. Wlodarczyk, M. Ardron, A.J. Waddie, M.R. Taghizadeh, N.J. Weston, and D.P. Hand, Tamper-Proof Markings for the Identification and Traceability of High-Value Metal Goods, Opt. Express, 2017, 25(13), p 15216–15230.

A. Kaldos, H.J. Pieper, E. Wolf, and M. Krause, Laser Machining in Die Making—A Modern Rapid Tooling Process, J. Mater. Process. Technol., 2004, 155, p 1815–1820.

J. Meijer, K. Du, A. Gillner, D. Hoffmann, V.S. Kovalenko, T. Masuzawa, A. Ostendorf, R. Poprawe, and W. Schulz, Laser Machining by Short and Ultrashort Pulses, State of the Art and New Opportunities in the Age of the Photons, CIRP Ann. Manuf. Technol., 2002, 51(2), p 531–550.

V. Semak and A. Matsunawa, The Role of Recoil Pressure in Energy Balance During Laser Materials Processing, J. Phys. D Appl. Phys., 1997, 30(18), p 2541–2552.

C. Leone, S. Genna, F. Tagliaferri, B. Palumbo, and M. Dix, Experimental Investigation on Laser Milling of Aluminium Oxide Using a 30W Q-Switched Yb:YAG Fiber Laser, Opt. Laser Technol., 2016, 76, p 127–137.

Y. Jiao, E. Brousseau, Q.Q. Han, H.X. Zhu, and S. Bigot, Investigations in Nanosecond Laser Micromachining on the Zr52.8Cu17.6Ni14.8Al9.9Ti4.9 Bulk Metallic Glass: Experimental and Theoretical Study, J. Mater. Process. Technol., 2019, 273, p 116232.

Ş Kasman and İE. Saklakoğlu, Experimental Investigation and Mathematical Modeling of Laser Deep Engraving Process for Microapplication, Arab. J. Sci. Eng., 2013, 38(6), p 1539–1549.

Ş Kasman, Impact of Parameters on the Process Response: A Taguchi Orthogonal Analysis for Laser Engraving, Measurement, 2013, 46(8), p 2577–2584.

C.N. Elias, Y. Oshida, J.H.C. Lima, and C.A. Muller, Relationship Between Surface Properties (Roughness, Wettability and Morphology) of Titanium and Dental Implant Removal Torque, J. Mech. Behav. Biomed. Mater., 2008, 1(3), p 234–242.

M. Pang, X. Liu, and K. Liu, Effect of Wettability on the Friction of a Laser-Textured Cemented Carbide Surface in Dilute Cutting Fluid, Adv. In Mech. Eng., 2017, 9(12), p 1687814017738154.

L. Qin, H. Wu, J. Guo, X. Feng, G. Dong, J. Shao, Q. Zeng, Y. Zhang, and Y. Qin, Fabricating Hierarchical Micro and Nano Structures on Implantable Co-Cr-Mo Alloy for Tissue Engineering by One-Step Laser Ablation, Colloids Surf. B Biointerfaces, 2018, 161, p 628–635.

D.V. Ta, A. Dunn, T.J. Wasley, R.W. Kay, J. Stringer, P.J. Smith, C. Connaughton, and J.D. Shephard, Nanosecond Laser Textured Superhydrophobic Metallic Surfaces and Their Chemical Sensing Applications, Appl. Surf. Sci., 2015, 357, p 248–254.

C.J. Alberti, E. Saito, F.E. de Freitas, D.A.P. Reis, J.P.B. Machado, and A.G. dos Reis, Effect of Etching Temperature on Surface Properties of Ti6Al4V Alloy for Use in Biomedical Applications, Mater. Res-Ibero-Am. J., 2019, 22, p e20180782.

Z. Yang, Y.L. Tian, C.J. Yang, F.J. Wang, and X.P. Liu, Modification of Wetting Property of Inconel 718 Surface by Nanosecond Laser Texturing, Appl. Surf. Sci., 2017, 414, p 313–324.

S.H. van der Poel, M. Mezera, G.W.R.B.E. Römer, E.G. de Vries, and D.T.A. Matthews, Fabricating Laser-Induced Periodic Surface Structures on Medical Grade Cobalt-Chrome-Molybdenum: Tribological, Wetting Leach. Prop. Lubr., 2019, 7(8), p 70.

K.J. Kubiak, M.C.T. Wilson, T.G. Mathia, and P. Carval, Wettability Versus Roughness of Engineering Surfaces, Wear, 2011, 271(3), p 523–528.

A. Purnama, V. Furlan, D. Dessi, A.G. Demir, R. Tolouei, C. Paternoster, L. Levesque, B. Previtali, and D. Mantovani, Laser Surface Texturing of SS316L for Enhanced Adhesion of HUVECs, Surf. Eng., 2020, 36(12), p 1240–1249.

X. Wang, J. Duan, M. Jiang, F. Zhang, S. Ke, B. Wu, and X. Zeng, Investigation of Processing Parameters for Three-Dimensional Laser Ablation Based on Taguchi Method, Int. J. Adv. Manuf. Technol., 2017, 93(5), p 2963–2974.

T. Canel, F. Gölbaşi, and Z. Gezer, The Effects of Laser Machining Parameters on Roughness and Contact Angle for Boron Carbide Ceramic Surface, Materwiss. Werksttech., 2021, 52(12), p 1382–1393.

Ş Kasman, İC. Uçar, and S. Ozan, Investigation of Laser Surface Texturing Parameters of Biomedical Grade Co-Cr-Mo Alloy, Int. J. Adv. Manuf. Technol., 2023, 125, p 4271–4291.

Acknowledgments

The present study was supported by Dokuz Eylul University under project no. 2021.KB.FEN.043. The authors would like to acknowledge this financial support.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there are no conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kasman, Ş., Uçar, I.C. & Ozan, S. The Effects of Laser Surface Texturing Parameters on the Surface Characteristics of Biomedical-Grade Stainless Steel. J. of Materi Eng and Perform (2023). https://doi.org/10.1007/s11665-023-08374-7

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11665-023-08374-7