Abstract

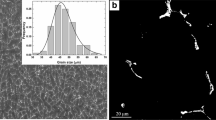

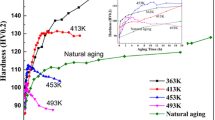

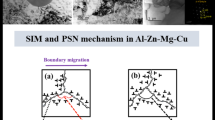

In this work, the precipitation behavior and recrystallization behavior of highly alloyed Al-Zn-Mg-Cu alloy with different Zn/Mg ratio were investigated using optical microscope, scanning electron microscope, X-ray diffraction, transmission electron microscope and tensile test. The results indicated that the primary phase increases with Zn/Mg ratio dropping, which increases the nucleation particles and refines the grains. The real solidification path is between Lever law and Scheil model, which is closer to Scheil model. The precipitates are η′ when Zn/Mg ≥ 4.19 in T6 temper. However, it is the co-precipitation of η' and T' when Zn/Mg < 4.19 and the fraction of η' decreases from 100 to 7.6% as Zn/Mg ratio decrease from 4.19 to 1.91. In addition, the impact of residual eutectic phase in a low Zn/Mg ratio alloy on recrystallization behavior and mechanical properties was discussed. Grain boundary primary phases in low Zn/Mg alloys are difficult to completely dissolve during the solid solution. Interestingly, the particle stimulated nucleation occurs preferentially around the second phase and gradually extends to the center of the grain, and there are still low angle grain boundaries in the center of larger original grain. When Zn/Mg > 1.91, the tensile strength increases with Zn/Mg ratio dropping. After Zn/Mg ≤ 1.91, the tensile strength decreases slightly due to the residual second phase.

Graphical Abstract

Similar content being viewed by others

Data availability

The data presented in this article will be available from the corresponding author at a reasonable request.

References

S. Chen, J. Li, G.Y. Hu, K. Chen, and L. Huang, Effect of Zn/Mg ratios on SCC, Electrochemical Corrosion Properties and Microstructure of Al-Zn-Mg alloy, J. Alloys Compd., 2018, 757, p 259–264. https://doi.org/10.1016/j.jallcom.2018.05.063

G. Graf, P. Spoerk-Erdely, P. Staron, A. Stark, F. Mendez Martin, H. Clemens, and T. Klein, Quench Rate Sensitivity of Age-Hardenable Al-Zn-Mg-Cu Alloys with Respect to the Zn/Mg ratio: An In Situ SAXS and HEXRD Study, Acta Mater., 2022, 227, p 117727. https://doi.org/10.1016/j.actamat.2022.117727

A. Azarniya, A.K. Taheri, and K.K. Taheri, Recent Advances in Ageing of 7xxx Series Aluminum Alloys: A Physical Metallurgy Perspective, J. Alloys Compd., 2019, 781, p 945–983. https://doi.org/10.1016/j.jallcom.2018.11.286

T. Dursun and C. Soutis, Recent Developments in Advanced Aircraft Aluminium Alloys, Mater. Des., 2014, 56, p 862–871. https://doi.org/10.1016/j.matdes.2013.12.002

J. Dong, J.Z. Cui, F.X. Yu, Z.H. Zhao, and Y.B. Zhuo, A New Way to Cast High-Alloyed Al-Zn-Mg-Cu-Zr for Super-High Strength and Toughness, J. Mater. Process. Technol., 2006, 171, p 399–404. https://doi.org/10.1016/j.jmatprotec.2005.07.010

P. Zhang, Y. Li, Y. Liu, Y. Zhang, and J. Liu, Analysis of the Microhardness, Mechanical Properties and Electrical Conductivity of 7055 Aluminum Alloy, Vacuum, 2020, 171, p 109005. https://doi.org/10.1016/j.vacuum.2019.109005

E.A. Starke and J.T. Staley, Application of Modern Aluminum Alloys to Aircraft, Prog. Aerosp. Sci., 1996, 32, p 131–172. https://doi.org/10.1016/0376-0421(95)00004-6

Y. Chen, Y. Yang, Z. Feng, B. Huang, and X. Luo, Surface Gradient Nanostructures in High Speed Machined 7055 Aluminum Alloy, J. Alloys Compd., 2017, 726, p 367–377. https://doi.org/10.1016/j.jallcom.2017.08.018

H. She, D. Shu, J. Wang, and B.D. Sun, Influence of Multi-Microstructural Alterations on Tensile Property Inhomogeneity of 7055 Aluminum Alloy Medium Thick Plate, Mater. Charact., 2016, 113, p 189–197. https://doi.org/10.1016/j.matchar.2016.01.020

Q. Wang, Y. Zhao, K. Yan, and S. Lu, Corrosion Behavior of Spray Formed 7055 Aluminum Alloy Joint Welded by Underwater Friction stir Welding, Mater. Des., 2015, 68, p 97–103. https://doi.org/10.1016/j.matdes.2014.12.019

Z. Chen, Y. Mo, and Z. Nie, Effect of Zn Content on the Microstructure and Properties of Super-High Strength Al-Zn-Mg-Cu Alloys, Metall Mater. Trans. A Phys. Metall. Mater. Sci., 2013, 44, p 3910–3920. https://doi.org/10.1007/s11661-013-1731-x

W.X. Shu, L.G. Hou, C. Zhang, F. Zhang, J.C. Liu, J.T. Liu, L.Z. Zhuang, and J.S. Zhang, Tailored Mg and Cu Contents Affecting the Microstructures and Mechanical Properties of High-Strength Al-Zn-Mg-Cu Alloys, Mater. Sci. Eng. A., 2016, 657, p 269–283. https://doi.org/10.1016/j.msea.2016.01.039

T.F. Chung, M. Kawasaki, P. Wang, K. Nishio, M. Shiojiri, W.C. Li, C.N. Hsiao, and J.R. Yang, Atomic-Resolution Energy Dispersive X-ray Spectroscopy Mapping of η Precipitates in an Al-Mg-Zn-Cu Alloy, Mater. Charact., 2020, 166, p 110448. https://doi.org/10.1016/j.matchar.2020.110448

T.F. Chung, Y.L. Yang, M. Shiojiri, C.N. Hsiao, W.C. Li, C.S. Tsao, Z. Shi, J. Lin, and J.R. Yang, An Atomic Scale Structural Investigation of Nanometre-Sized η Precipitates in the 7050 Aluminium Alloy, Acta Mater., 2019, 174, p 351–368. https://doi.org/10.1016/j.actamat.2019.05.041

B. Chen, Precipitation in an Al-Zn-Mg-Cu Alloy During Isothermal Aging: Atomic-Scale HAADF-STEM Investigation, Mater. Sci. Eng. A., 2017, 691, p 60–70. https://doi.org/10.1016/j.msea.2017.03.032

G. Sha and A. Cerezo, Early-Stage Precipitation in Al-Zn-Mg-Cu alloy (7050), Acta Mater., 2004, 52, p 4503–4516. https://doi.org/10.1016/j.actamat.2004.06.025

K. Wen, Y. Fan, G. Wang, L. Jin, X. Li, Z. Li, Y. Zhang, and B. Xiong, Aging Behavior and Precipitate Characterization of a high Zn-Containing Al-Zn-Mg-Cu Alloy with Various Tempers, Mater. Des., 2016, 101, p 16–23. https://doi.org/10.1016/j.matdes.2016.03.150

Y. Zou, X. Wu, S. Tang, Q. Zhu, H. Song, M. Guo, and L. Cao, Investigation on Microstructure and Mechanical Properties of Al-Zn-Mg-Cu Alloys with Various Zn/Mg ratios, J. Mater. Sci. Technol., 2021, 85, p 106–117. https://doi.org/10.1016/j.jmst.2020.12.045

Y. Wang, X. Wu, L. Cao, X. Tong, Y. Zou, Q. Zhu, S. Tang, H. Song, and M. Guo, Effect of Ag on Aging Precipitation Behavior and Mechanical Properties of Aluminum Alloy 7075, Mater. Sci. Eng. A., 2021, 804, p 140515. https://doi.org/10.1016/j.msea.2020.140515

S. Hou, P. Liu, D. Zhang, J. Zhang, and L. Zhuang, Precipitation Hardening Behavior and Microstructure Evolution of Al–5.1 Mg–0.15Cu Alloy with 3.0Zn (wt%) Addition, J. Mater. Sci., 2018, 53, p 3846–3861. https://doi.org/10.1007/s10853-017-1811-1

P. Zhao, X. Wu, K. Gao, S. Wen, L. Rong, H. Huang, W. Wei, and Z. Nie, Effect of Zn/Mg Ratio on Microstructure and Mechanical Properties of Al-Zn-Mg Alloys, Mater. Lett., 2022, 312, p 131676. https://doi.org/10.1016/j.matlet.2022.131676

Y. Zou, X. Wu, S. Tang, Q. Zhu, H. Song, and L. Cao, Co-Precipitation of T′ and η′ Phase in Al-Zn-Mg-Cu Alloys, Mater. Charact., 2020, 169, p 110610. https://doi.org/10.1016/j.matchar.2020.110610

H.P. Tang, Q.D. Wang, C. Luo, C. Lei, T.W. Liu, Z.Y. Li, H.Y. Jiang, W.J. Ding, J. Fang, and J.W. Zhang, Effects of Aging Treatment on the Precipitation Behaviors and Mechanical Properties of Al-5.0Mg-3.0Zn-1.0Cu Cast Alloys, J. Alloys Compd., 2020, 842, p 155707. https://doi.org/10.1016/j.jallcom.2020.155707

C. Cao, D. Zhang, L. Zhuang, and J. Zhang, Improved Age-Hardening Response and Altered Precipitation Behavior of Al-5.2Mg-0.45Cu-2.0Zn (wt%) Alloy with Pre-Aging Treatment, J. Alloys Compd., 2017, 691, p 40–43. https://doi.org/10.1016/j.jallcom.2016.08.206

S. Hou, D. Zhang, Q. Ding, J. Zhang, and L. Zhuang, Solute Clustering and Precipitation of Al-5.1Mg-0.15Cu-xZn Alloy, Mater. Sci. Eng. A., 2019, 759, p 465–478. https://doi.org/10.1016/j.msea.2019.05.066

X.B. Yang, J.H. Chen, J.Z. Liu, F. Qin, J. Xie, and C.L. Wu, A High-Strength AlZnMg Alloy Hardened by the T-Phase Precipitates, J. Alloys Compd., 2014, 610, p 69–73. https://doi.org/10.1016/j.jallcom.2014.04.185

N. Takata, M. Ishihara, A. Suzuki, and M. Kobashi, Microstructure and Strength of a Novel Heat-Resistant Aluminum Alloy Strengthened by T-Al6Mg11Zn11 Phase at Elevated Temperatures, Mater. Sci. Eng. A., 2019, 739, p 62–70. https://doi.org/10.1016/j.msea.2018.10.034

C. Mondal and A.K. Mukhopadhyay, On the Nature of T(Al2Mg3Zn3) and S(Al2CuMg) Phases Present in As-Cast and Annealed 7055 Aluminum Alloy, Mater. Sci. Eng. A., 2005, 391, p 367–376. https://doi.org/10.1016/j.msea.2004.09.013

Y. Zhao, H. Li, Y. Liu, and Y. Huang, The Microstructures and Mechanical Properties of a Highly Alloyed Al-Zn-Mg-Cu Alloy: The Role of Cu Concentration, J. Mater. Res. Technol., 2022, 18, p 122–137. https://doi.org/10.1016/j.jmrt.2022.02.071

Y. Liu, D. Jiang, W. Xie, J. Hu, and B. Ma, Solidification Phases and their Evolution During Homogenization of a DC Cast Al-8.35Zn-2.5Mg-2.25Cu Alloy, Mater. Charact., 2014, 93, p 173–183. https://doi.org/10.1016/j.matchar.2014.04.004

Y.G. Liao, X.Q. Han, M.X. Zeng, and M. Jin, Influence of Cu on Microstructure and Tensile Properties of 7XXX Series Aluminum Alloy, Mater. Des., 2015, 66, p 581–586. https://doi.org/10.1016/j.matdes.2014.05.003

Y. Ii, P. Li, G. Zhao, X. Liu, and J. Cui, The Constituents in Al-10Zn-2.5Mg-2.5Cu Aluminum Alloy, Mater. Sci. Eng. A., 2005, 397, p 204–208. https://doi.org/10.1016/j.msea.2005.02.013

R. Poganitsch, L. Sigl, F. Jeglitsch, and F. Kutner, Intermetallic Compounds in High Strength Al-Zn-Mg-Cu Alloys, Alum. Dusseld., 1981, 57, p 804–807.

W.X. Shu, L.G. Hou, J.C. Liu, C. Zhang, F. Zhang, J.T. Liu, L.Z. Zhuang, and J.S. Zhang, Solidification Paths and Phase Components at High Temperatures of High-Zn Al-Zn-Mg-Cu Alloys with Different Mg and Cu Contents, Metall Mater. Trans. A Phys. Metall. Mater. Sci., 2015, 46, p 5375–5392. https://doi.org/10.1007/s11661-015-3050-x

W. Yang, S. Ji, M. Wang, and Z. Li, Precipitation Behaviour of Al-Zn-Mg-Cu Alloy and Diffraction Analysis from η′Precipitates in Four Variants, J. Alloys Compd., 2014, 610, p 623–629. https://doi.org/10.1016/j.jallcom.2014.05.061

J.Z. Liu, J.H. Chen, D.W. Yuan, C.L. Wu, J. Zhu, and Z.Y. Cheng, Fine Precipitation Scenarios of AlZnMg(Cu) Alloys Revealed by Advanced Atomic-Resolution Electron Microscopy Study Part I: Structure Determination of the Precipitates in AlZnMg(Cu) Alloys, Mater. Charact., 2015, 99, p 277–286. https://doi.org/10.1016/j.matchar.2014.11.028

M. Dumont, W. Lefebvre, B. Doisneau-Cottignies, and A. Deschamps, Characterisation of the Composition and Volume Fraction of η′ and η Precipitates in an Al-Zn-Mg Alloy by a Combination of Atom Probe, Small-Angle X-ray Scattering and Transmission Electron Microscopy, Acta Mater., 2005, 53, p 2881–2892. https://doi.org/10.1016/j.actamat.2005.03.004

A. Bigot, P. Auger, S. Chambreland, D. Blavette, and A. Reeves, Atomic Scale Imaging and Analysis of T′ Precipitates in Al-Mg-Zn Alloys, Microsc. Microanal. Microstruct., 1997, 8, p 103–113. https://doi.org/10.1051/mmm:1997109

R. Ghiaasiaan, B.S. Amirkhiz, and S. Shankar, Quantitative Metallography of Precipitating and Secondary Phases After Strengthening Treatment of Net Shaped Casting of Al-Zn-Mg-Cu (7000) Alloys, Mater. Sci. Eng. A., 2017, 698, p 206–217. https://doi.org/10.1016/j.msea.2017.05.047

L.K. Berg, J. Gjoønnes, V. Hansen, X.Z. Li, M. Knutson-Wedel, G. Waterloo, D. Schryvers, and L.R. Wallenberg, GP-Zones in Al-Zn-Mg Alloys and their Role in Artificial Aging, Acta Mater., 2001, 49, p 3443–3451. https://doi.org/10.1016/S1359-6454(01)00251-8

N. Afify, A.-F. Gaber, and G. Abbady, Fine Scale Precipitates in Al-Mg-Zn Alloys after Various Aging Temperatures, Mater. Sci. Appl., 2011, 02, p 427–434. https://doi.org/10.4236/msa.2011.25056

F. Cao, J. Zheng, Y. Jiang, B. Chen, Y. Wang, and T. Hu, Experimental and DFT Characterization of η′ Nano-Phase and its Interfaces in Al-Zn-Mg-Cu Alloys, Acta Mater., 2019, 164, p 207–219. https://doi.org/10.1016/j.actamat.2018.10.045

E.O. Hall, The Deformation and Ageing of Mild Steel: III Discussion of Results, Proc. Phys. Soc. Sect. B., 1951, 64, p 747–753. https://doi.org/10.1088/0370-1301/64/9/303

N.J. Petch, The Cleavage Strength of Polycrystals, J. Iron Steel Inst., 1953, 174, p 25–28.

H.R. Shercliff and M.F. Ashby, A Process Model for Age Hardening of Aluminium Alloys—I. The Model, Acta Metall. Mater., 1990, 38, p 1789–1802. https://doi.org/10.1016/0956-7151(90)90291-N

Y. Liu, D. Jiang, B. Li, W. Yang, and J. Hu, Effect of Cooling Aging on Microstructure and Mechanical Properties of an Al-Zn-Mg-Cu Alloy, Mater. Des., 2014, 57, p 79–86. https://doi.org/10.1016/j.matdes.2013.12.024

Z. Wang, Q. Pu, Y. Li, P. Xia, J. Geng, X. Li, M. Wang, D. Chen, and H. Wang, Microstructures and Mechanical Properties of Al-Zn-Mg-Cu Alloy with the Combined Addition of Ti and Zr, J. Mater. Res. Technol., 2023, 22, p 747–761. https://doi.org/10.1016/j.jmrt.2022.11.106

H. She, D. Shu, A. Dong, J. Wang, B. Sun, and H. Lai, Relationship of Particle Stimulated Nucleation, Recrystallization and Mechanical Properties Responding to Fe and Si Contents in Hot-Extruded 7055 Aluminum Alloys, J. Mater. Sci. Technol., 2019, 35, p 2570–2581. https://doi.org/10.1016/j.jmst.2019.07.014

Acknowledgments

This work was supported financially by the National Natural Science Foundation of China (No. U1837207) and Natural Foundation of Hunan Province (No. 2022JJ40608).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhao, Y., Li, H., Liu, Y. et al. Precipitation Behavior, Recrystallization Behavior, and Mechanical Properties of Highly Alloyed Al-Zn-Mg-Cu Alloy with Respect to Zn/Mg Ratio. J. of Materi Eng and Perform (2023). https://doi.org/10.1007/s11665-023-08341-2

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11665-023-08341-2