Abstract

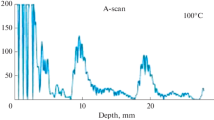

Nonlinear ultrasonic (NLU) has been established as an effective method for the non-destructive evaluation of power plant materials for various types of damage, including estimation of creep damage. However, the information obtained through NLU measurement may not be sufficient to predict either the failure probability or remaining creep life of any power plant component. A procedure has been formulated to estimate the probability of failure vis-a-vis creep life of power plant materials through a two-parameter Weibull analysis of NLU data. The investigation involved creep testing of P92 steel at 625 °C for three different applied stresses 120, 140, and 160 MPa. Subsequently, the extent of damage was estimated using Weibull distribution analysis from NLU parameter β, measured in the same specimen at different interruptions. The variation in cumulative distribution function (CDF) and the damage accumulation rate with increased damage, were examined. Further, the behavior of predicted NLU parameter β obtained using inverse CDF was evaluated with respect to measured β. Damage accumulation during creep deformation was confirmed through significant microstructural changes such as the growth and coarsening of precipitates, micro-crack formation, and their coalescence. Weibull distribution-based analysis established its potential as an alternative method for predicting the failure probability and life of power plant components under creep deformation from the NLU measurements.

Similar content being viewed by others

References

A.A. Wahab, 3D Analysis of Creep Void Formation in Steam-Methane Reformer Tubes. PhD. thesis, (University of Canterbury, New Zealand, 2007)

T. Sakthivel, S. Panneer Selvi, P. Parameswaran, and K. Laha, Creep Deformation and Rupture Behaviour of Thermal Aged P92 Steel, Mater. High Temp., 2016, 33(1), p 33–43.

W.G. Seo, J.Y. Suh, A. Singh, J.H. Shim, H. Lee, K. Yoo, and S.H. Choi, Microstructural Evolution of P92 Steel in IN740H/P92 Dissimilar Weld Joints during Creep Deformation, Mater. Sci. Eng. A, 2021, 821, p 141614.

I. Fedorova, A. Belyakov, P. Kozlov, V. Skorobogatykh, I. Shenkova, and R. Kaibyshev, Laves-Phase Precipitates in a Low-Carbon 9% Cr Martensitic Steel during Aging and Creep at 923 K, Mater. Sci. Eng. A, 2014, 615, p 153–163.

G. Sposito, C. Ward, P. Cawley, P.B. Nagy, and C. Scruby, A review of Non-Destructive Techniques for the Detection of Creep Damage in Power Plant Steels, NDT E Int., 2010, 43(7), p 555–567.

K.Y. Jhang and K.C. Kim, Evaluation of Material Degradation Using Nonlinear Acoustic Effect, Ultrasonics, 1999, 37(1), p 39–44.

D.C. Hurley, D. Balzar, P.T. Purtscher, and K.W. Hollman, Nonlinear Ultrasonic Parameter in Quenched Martensitic Steels, J. Appl. Phys., 1998, 83(9), p 4584–4588.

J. Kang, J. Qu, A. Saxena, L. Jacobs, On the detection of creep damage in a directionally solidified nickel base superalloy using nonlinear ultrasound. In AIP Conference Proceedings vol. 700, (American Institute of Physics, 2004) pp. 1248–1255

T. Ohtani, K. Kawashima, M. Drew, and P. Guagliard, Nonlinear Acoustic Evaluation of Creep Damage in Boiler Heat Exchange Tubes, Jpn. J. Appl. Phys., 2007, 46(7S), p 4577.

M. Sahu and S.P. Sagar, A Non-Invasive Technique to Estimate the Onset of Creep Strength Deterioration, J. Mater. Eng. Perform., 2022, 31(2), p 1642–1653.

V. Rathod, O.P. Yadav, A. Rathore, and R. Jain, Probabilistic Modeling of Fatigue Damage Accumulation for Reliability Prediction, J. Quality Reliab. Eng., 2011, 2011, 718901. https://doi.org/10.1155/2011/718901

D. Ling, Research on Weibull Distribution and Its Applications in Mechanical Reliability Engineering [Dissertation thesis]. University of Electronic Science and Technology of China. (2010)

A.A. Ameen and U.A. Akkash, 2021 Maximum Likelihood Estimation and Bayesian Estimation of Three-Parameter Weibull Distribution Based on Interval-Censored Data, Journal of Physics Conference Series, 1818, 1, p 012199.

W.A.N.G. Tianshuai, H.E. Xiaofan, W.A.N.G. Jinyu, and L.I. Yuhai, Detail Fatigue Rating Method Based on Bimodal Weibull Distribution for DED Ti-65 Al-2Zr-1Mo-1V Titanium Alloy, Chinese Journal of Aeronautics, 2022, 35(4), p 281–291.

W. Weibull, A Statistical Theory of the Strength of Material, Ingeniors Vetenskapa Acad. Handligar, 1939, 151, p 1–45.

B.K. Choudhary, W.G. Kim, M.D. Mathew, J. Jang, T. Jayakumar, and Y.H. Jeong, On the Reliability Assessment of Creep Life for Grade 91 Steel, Procedia Eng., 2014, 86, p 335–341.

H. Rinne, The Weibull Distribution: a Handbook, Chapman and Hall/CRC, United Kingdom, 2008.

C.D. Lai, L. Zhang, and M. Xie, Mean Residual Life and Other Properties of Weibull Related Bathtub Shape Failure Rate Distributions, Int. J. Reliab. Qual. Saf. Eng., 2004, 11(02), p 113–132.

S.J. Wu Reliability Analysis Using the Least Squares Method in Nonlinear Mixed-Effect Degradation Models. (The University of Wisconsin-Madison, Dissertations Publishing 1996) p. 9627093

M. Sivapragash, P.R. Lakshminarayanan, R. Karthikeyan, K. Raghukandan and M. Hanumantha, Fatigue Life Prediction of ZE41A Magnesium Alloy Using Weibull Distribution, Mater. Des., 2008, 29(8), p 1549–1553.

S.J. Kim, Y.S. Kong, Y.J. Roh, and W.G. Kim, Statistical Properties of Creep Rupture Data Distribution for STS304 Stainless Steels, Mater. Sci. Eng. A, 2008, 483, p 529–532.

M. Evans, and A.R. Ward, Statistical and Probabilistic Modelling of Uniaxial Creep Life of a Ti-6246 Alloy, Mater. Sci. Technol., 2000, 16(10), p 1149–1157.

M. Sahu, A. Ghosh, J. Kumar, S.N. Singh, and S.P. Sagar, Weibull Parameter Based Probability Distribution for Predicting Creep Life of Power Plant Materials: A Non-Destructive Approach, Mater. Today Proc., 2022, 59, p 1111–1118.

K.H. Matlack, J.Y. Kim, L.J. Jacobs, and J. Qu, Review of Second Harmonic Generation Measurement Techniques for Material State Determination in Metals, J. Non-destructive Eval., 2015, 34(1), p 1–23.

J.D. Kalbfleisch, and R.L. Prentice, The Statistical Analysis of Failure Time Data, Wiley, London, 2011.

V. Sklenička, K. Kuchařová, P. Král, M. Kvapilová, M. Svobodová, and J. Čmakal, The Effect of Hot Bending and Thermal Ageing on Creep and Microstructure Evolution in Thick-Walled P92 Steel Pipe, Mater. Sci. Eng. A, 2015, 644, p 297–309.

X. Wu, W. Beres, and S. Yandt, Challenges in Life Prediction of Gas Turbine Critical Components, Can. Aeronaut Space J., 2008, 54(2), p 31–39.

O. Prat, J. Garcia, D. Rojas, G. Sauthoff, and G. Inden, The Role of Laves Phase on Microstructure Evolution and Creep Strength of Novel 9% Cr Heat Resistant Steels, Intermetallics, 2013, 32, p 362–372.

M.K. Sahu, C. Dutta, A. Ghosh, S.P. Sagar, A Digital Image Processing Tool for Size and Number Density Distribution of Precipitates in Creep-Exposed Material. In Soft Computing for Problem Solving (Springer, Singapore, 2019) pp. 653–659

E.E. Underwood, Quantitative Metallography, ASM Int. ASM Handbook, 1985, 9, p 123–134.

A. Hikata, and C. Elbaum, Generation of Ultrasonic Second and Third Harmonics Due To Dislocations, I. Phys. Rev., 1966, 144(2), p 469.

G.E. Dieter, Mechanical Metallurgy, Mc Graw Hill Book, New York, 1986.

D.C. Wallace, Thermoelasticity of Stressed Materials and Comparison of Various Elastic Constants, Phys. Rev., 1967, 162(3), p 776.

J.H. Cantrell, Crystalline Structure and Symmetry Dependence of Acoustic Nonlinearity Parameters, J. Appl. Phys., 1994, 76(6), p 3372–3380.

Acknowledgments

The authors are gratefully to the Director, CSIR-NML for providing kind permission to utilize the infrastructural facilities to carry out the experimental work. The financial support received from Science and Engineering Research Board to carry out the investigation is also gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sahu, M., Ghosh, A., Kumar, J. et al. Probability Analysis in Predicting Creep Life of Power Plant Material Using High Power Ultrasound. J. of Materi Eng and Perform 33, 1760–1771 (2024). https://doi.org/10.1007/s11665-023-08113-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-023-08113-y