Abstract

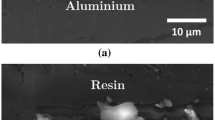

To improve the wear resistance of carburized 18CrNi4A steel used in aerospace transmission components with high-impact and heavy-duty conditions, DLC, TiAlN, and DLC/TiAlN coatings were deposited on carburized 18CrNi4A steel surfaces by magnetron sputtering. The surface and cross-sectional morphologies, chemical compositions, and mechanical properties of these coatings were characterized by SEM, XRD, nanoindentation, and micro-scratch tests. The tribological properties of carburized 18CrNi4A steel and these coatings with heavy-duty conditions of dry sliding, lubricant, and grease were investigated. In addition, TiAlN coatings were deposited on spline coupling teeth, and the anti-wear performance was investigated using a self-made spline coupling test rig. The results show that these coatings have lower coefficient of friction (CoF) and wear rate than carburized 18CrNi4A steel. DLC/TiAlN coating exhibits the lowest coefficient of friction and wear rate in aerospace synthetic lubricants (Mobil Jet Oil II) and molybdenum disulfide lithium grease (RIPP 7254), providing the best tribological properties. The wear mechanism of heavy-duty conditions with dry sliding, lubricant and grease were discussed. In addition, the TiAlN-coated spline coupling exhibited better wear resistance than the general spline coupling.

Similar content being viewed by others

References

Z.H. Jiang, Z.M. Li, X.J. Tong, and Z. Li, Microstructure and Properties Study of 32Cr3MoVE Deep Nitrided Steel, Hangkong Cailiao Xuebao J. Aeronaut. Mater., 2010, 30, p 30–34. https://doi.org/10.3969/j.issn.1005-5053.2010.2.006

C.K. Liu, B. Zhang, X. Chen, J.L. Ren, C.H. Tao, and Y.H. He, Research on Fatigue Damage of Ferromagnetic Material by Metal Magnetic Memory Methods, in International Conference on Manufacturing Science and Engineering (ICMSE 2009), (Zhuhai, People’s Republic of China, 2009), pp. 4501-+

C.L. Shi, S.Y. Dong, B.S. Xu, and P. He, Stress Concentration Degree Affects Spontaneous Magnetic Signals of Ferromagnetic Steel Under Dynamic Tension Load, NDT E Int., 2010, 43, p 8–12. https://doi.org/10.1016/j.ndteint.2009.08.002

X. Xue, J. Jia, Q. Huo, and J. Jia, Experimental Investigation and Prediction Method of Fretting Wear in Rack-Plane Spline Couplings, Proc. Inst. Mech. Eng. Part J J. Eng. Tribol., 2021, 235, p 1025–1037. https://doi.org/10.1177/1350650120939838

X.Z. Xue, S.M. Wang, J. Yu, and L.Y. Qin, Wear Characteristics of the Material Specimen and Method of Predicting Wear in Floating Spline Couplings of Aero-engine, Int. J. Aerosp. Eng., 2017 https://doi.org/10.1155/2017/1859167

X.Z. Xue, S.M. Wang, and B. Li, Modification Methodology of Fretting Wear in Involute Spline, Wear, 2016, 368, p 435–444. https://doi.org/10.1016/j.wear.2016.10.015

A. Erdemir and C. Donnet, Tribology of Diamond-Like Carbon Films: Recent Progress and Future Prospects, J. Phys. D Appl. Phys., 2006, 39, p R311–R327. https://doi.org/10.1088/0022-3727/39/18/r01

F. Findik, Latest Progress on Tribological Properties of Industrial Materials, Mater. Des., 2014, 57, p 218–244. https://doi.org/10.1016/j.matdes.2013.12.028

P.J. Kelly and R.D. Arnell, Magnetron Sputtering: A Review of Recent Developments and Applications, Vacuum, 2000, 56, p 159–172. https://doi.org/10.1016/s0042-207x(99)00189-x

P.H. Mayrhofer, C. Mitterer, L. Hultman, and H. Clemens, Microstructural Design of Hard Coatings, Prog. Mater Sci., 2006, 51, p 1032–1114. https://doi.org/10.1016/j.pmatsci.2006.02.002

S. PalDey, and S.C. Deevi, Single Layer and Multilayer Wear Resistant Coatings of (Ti, Al)N: A Review, Mater. Sci. Eng. Struct. Mater. Prop. Microstruct. Process., 2003, 342, p 58–79. https://doi.org/10.1016/s0921-5093(02)00259-9

N.K. Manninen, F. Ribeiro, A. Escudeiro, T. Polcar, S. Carvalho, and A. Cavaleiro, Influence of Ag Content on Mechanical and Tribological Behavior of DLC Coatings, Surf. Coat. Technol., 2013, 232, p 440–446. https://doi.org/10.1016/j.surfcoat.2013.05.048

X.R. Shi, T.W. Liskiewicz, B.D. Beake, Z.M. Sun, and J. Chen, Fretting Wear Behavior of Graphite-Like Carbon Films with Bias-Graded Deposition, Appl. Surf. Sci., 2019, 494, p 929–940. https://doi.org/10.1016/j.apsusc.2019.07.265

C.W. Zou, H.J. Wang, L. Feng, and S.W. Xue, Effects of Cr Concentrations on the Microstructure, Hardness, and Temperature-Dependent Tribological Properties of Cr-DLC Coatings, Appl. Surf. Sci., 2013, 286, p 137–141. https://doi.org/10.1016/j.apsusc.2013.09.036

A.A. Voevodin, S.D. Walck, and J.S. Zabinski, Architecture of Multilayer Nanocomposite Coatings with Super-Hard Diamond-Like Carbon Layers for Wear Protection at High Contact Loads, Wear, 1997, 203, p 516–527. https://doi.org/10.1016/s0043-1648(96)07425-x

R. Ananthakumar, B. Subramanian, A. Kobayashi, and M. Jayachandran, Electrochemical Corrosion and Materials Properties of Reactively Sputtered TiN/TiAlN Multilayer Coatings, Ceram. Int., 2012, 38, p 477–485. https://doi.org/10.1016/j.ceramint.2011.07.030

Q. Luo, S. Yang, and K.E. Cooke, Hybrid HIPIMS and DC Magnetron Sputtering Deposition of TiN Coatings: Deposition Rate, Structure and Tribological Properties, Surf. Coat. Technol., 2013, 236, p 13–21. https://doi.org/10.1016/j.surfcoat.2013.07.003

M. Braic, V. Braic, M. Balaceanu, G. Pavelescu, A. Vladescu, I. Tudor, A. Popescu, Z. Borsos, C. Logofatu, and C.C. Negrila, Microchemical and Mechanical Characteristics of Arc Plasma Deposited TiAlN and TiN/TiAlN Coatings, J. Optoelectron. Adv. Mater., 2005, 7, p 671–676.

O. Comakli, Influence of CrN, TiAlN Monolayers and TiAlN/CrN Multilayer Ceramic Films on Structural, Mechanical and Tribological Behavior of Beta-Type Ti45Nb Alloys, Ceram. Int., 2020, 46, p 8185–8191. https://doi.org/10.1016/j.ceramint.2019.12.046

J.H. Hsieh, C. Liang, C.H. Yu, and W. Wu, Deposition and Characterization of TiAlN and Multi-layered TiN/TiAlN Coatings Using Unbalanced Magnetron Sputtering, Surf. Coat. Technol., 1998, 108, p 132–137. https://doi.org/10.1016/s0257-8972(98)00684-7

K. Katahira, Y. Watanabe, H. Ohmori, and T. Kato, ELID Grinding and Tribological Characteristics of TiAlN Film, Int. J. Mach. Tools Manuf, 2002, 42, p 1307–1313. https://doi.org/10.1016/s0890-6955(02)00076-7

A. Rizzo, L. Mirenghi, M. Massaro, U. Galietti, L. Capodieci, R. Terzi, L. Tapfer, and D. Valerini, Improved Properties of TiAlN Coatings Through the Multilayer Structure, Surf. Coat. Technol., 2013, 235, p 475–483. https://doi.org/10.1016/j.surfcoat.2013.08.006

M.W. Bai, L.Q. Yang, J.Y. Li, L. Luo, S.K. Sun, and B. Inkson, Mechanical and Tribological Properties of Si and W Doped Diamond Like Carbon (DLC) Under Dry Reciprocating Sliding Conditions, Wear, 2021 https://doi.org/10.1016/j.wear.2021.204046

J. Du, T.M. Hao, X. Zhang, G.S. Su, P.R. Zhang, Y.J. Sun, J.J. Zhang, and C.H. Xu, Finite Element Investigation of Cutting Performance of Cr/W-DLC/DLC Composite Coated Cutting Tool, Int. J. Adv. Manuf. Technol., 2021 https://doi.org/10.1007/s00170-021-08093-0

P. Wongpanya, P. Silawong, and P. Photongkam, Nanomechanical Properties and Thermal Stability of Al-N-co-Doped DLC Films Prepared by Filtered Cathodic Vacuum Arc Deposition, Surf. Coat. Technol., 2021 https://doi.org/10.1016/j.surfcoat.2021.127655

W.J. Yu, W.J. Huang, J.J. Wang, Y.Y. Su, Q. Long, L.Q. Wang, and L.F. Zhu, High-Temperature Tribological Performance of the Si-Gradually Doped Diamond-Like Carbon Film, Vacuum, 2021 https://doi.org/10.1016/j.vacuum.2021.110387

O. Sharifahmadian and F. Mahboubi, A Comparative Study of Microstructural and Tribological Properties of N-DLC/DLC Double Layer and Single Layer Coatings Deposited by DC-Pulsed PACVD Process, Ceram. Int., 2019, 45, p 7736–7742. https://doi.org/10.1016/j.ceramint.2019.01.076

X.D. Sui, J.Y. Liu, S.T. Zhang, J. Yang, and J.Y. Hao, Microstructure, Mechanical and Tribological Characterization of CrN/DLC/Cr-DLC Multilayer Coating with Improved Adhesive Wear Resistance, Appl. Surf. Sci., 2018, 439, p 24–32. https://doi.org/10.1016/j.apsusc.2017.12.266

P.V. Badiger, V. Desai, M.R. Ramesh, S. Joladarashi, and H. Gourkar, Tribological Behaviour of Monolayer and Multilayer Ti-Based Thin Solid Films Deposited on Alloy Steel, Mater. Res. Express, 2019 https://doi.org/10.1088/2053-1591/aaef6d

H. Elmkhah, F. Mahboubi, A. Abdollah-Zadeh, and A.R.S. Rouhaghdam, A New Approach to Improve the Surface Properties of H13 Steel for Metal Forming Applications by Applying the TiAlN Multi-layer Coating, J. Manuf. Process., 2018, 32, p 873–877. https://doi.org/10.1016/j.jmapro.2018.04.010

D.W. Kim and K.W. Kim, Effects of Sliding Velocity and Normal Load on Friction and Wear Characteristics of Multi-layered Diamond-Like Carbon (DLC) Coating Prepared by Reactive Sputtering, Wear, 2013, 297, p 722–730. https://doi.org/10.1016/j.wear.2012.10.009

D.W. Kim and K.W. Kim, Effects of Sliding Velocity and Ambient Temperature on the Friction and Wear of a Boundary-Lubricated Multi-layered DLC Coating, Wear, 2014, 315, p 95–102. https://doi.org/10.1016/j.wear.2014.04.002

A. Krella, Resistance of PVD Coatings to Erosive and Wear Processes: A Review, Coatings, 2020 https://doi.org/10.3390/coatings10100921

S.J. McMaster, T.W. Liskiewicz, A. Neville, and B. Beake, Probing Fatigue Resistance in Multi-layer DLC coatings by Micro- and Nano-impact: Correlation to Erosion Tests, Surf. Coat. Technol., 2020 https://doi.org/10.1016/j.surfcoat.2020.126319

H.D. Zhang, F.S. Mei, Y. Yu, X.L. Lin, and J.X. Gao, Improvement on the Mechanical, Tribological Properties and Cutting Performance of AlTiN-Based Coatings by Compositional and Structural Design, Surf. Coat. Technol., 2021 https://doi.org/10.1016/j.surfcoat.2021.127503

M.H. Sulaiman, R.N. Farahana, K. Bienk, C.V. Nielsen, and N. Bay, Effects of DLC/TiAlN-Coated Die on Friction and Wear in Sheet-Metal Forming Under Dry and Oil-Lubricated Conditions: Experimental and Numerical Studies, Wear, 2019 https://doi.org/10.1016/j.wear.2019.203040

L. Xiao, Y.Q. Xu, X.W. Sun, H. Xu, and L. Zhang, Experimental Investigation on the Effect of Misalignment on the Wear Failure for Spline Couplings, Eng. Fail. Anal., 2022 https://doi.org/10.1016/j.engfailanal.2021.105755

L.L. Liu, W. Tani, L. Zhou, Z.C. Wu, Q.D. Ruan, X.Y. Li, A.M. Qasirn, S.H. Cui, T.J. Li, R.K.Y. Fu, X.B. Tian, Z.Z. Wu, and P.K. Chu, Comparative Study of TiAlN Coatings Deposited by Different High-Ionization Physical Vapor Deposition Techniques, Ceram. Int., 2020, 46, p 10814–10819. https://doi.org/10.1016/j.ceramint.2020.01.092

Q.Z. Wang, F. Zhou, X.N. Wang, K.M. Chen, M.L. Wang, T. Qian, and Y.X. Li, Comparison of Tribological Properties of CrN, TiCN and TiAlN Coatings Sliding Against SiC Balls in Water, Appl. Surf. Sci., 2011, 257, p 7813–7820. https://doi.org/10.1016/j.apsusc.2011.04.035

Z.Q. Li, H.H. Zhang, W.F. He, L. Xu, G.A. Zhang, X.F. Nie, B. Liao, and Y.H. Li, Tribological Performance of GLC, WC/GLC and TiN Films on the Carburized M50NiL Steel, Surf. Coat. Technol., 2019, 361, p 1–8. https://doi.org/10.1016/j.surfcoat.2019.01.038

I. Gomez, A. Claver, J.A. Santiago, I. Fernandez, J.F. Palacio, C. Diaz, S. Mandl, and J.A. Garcia, Improved Adhesion of the DLC Coating Using HiPIMS with Positive Pulses and Plasma Immersion Pretreatment, Coatings, 2021 https://doi.org/10.3390/coatings11091070

W.C. Oliver and G.M. Pharr, Measurement of Hardness and Elastic Modulus by Instrumented Indentation: Advances in Understanding and Refinements to Methodology, J. Mater. Res., 2004, 19, p 3–20. https://doi.org/10.1557/jmr.2004.19.1.3

W.C. Oliver and G.M. Pharr, An Improved Technique for Determining Hardness and Elastic-modulus Using Load and Displacement Sensing Indentation Experiments, J. Mater. Res., 1992, 7, p 1564–1583. https://doi.org/10.1557/jmr.1992.1564

G.S. Fox-Rabinovich, B.D. Beake, J.L. Endrino, S.C. Veldhuis, R. Parkinson, L.S. Shuster, and M.S. Migranov, Effect of Mechanical Properties Measured at Room and Elevated Temperatures on the Wear Resistance of Cutting Tools with TiAlN and AlCrN Coatings, Surf. Coat. Technol., 2006, 200, p 5738–5742. https://doi.org/10.1016/j.surfcoat.2005.08.132

K. De Moerlooze and F. Albender, On the Relationship Between Normal Load and Friction Force in Pre-sliding Frictional Contacts. Part 2: Experimental Investigation, Wear, 2010, 269, p 183–189. https://doi.org/10.1016/j.wear.2010.02.008

B. Selcuk, R. Ipek, and M.B. Karamis, A Study on Friction and Wear Behaviour of Carburized, Carbonitrided and Borided AISI 1020 and 5115 Steels, J. Mater. Process. Technol., 2003, 141, p 189–196. https://doi.org/10.1016/s0924-0136(02)01038-5

C.C. Viafara and A. Sinatora, Unlubricated Sliding Friction and Wear Of Steels: An Evaluation of the Mechanism Responsible for the T-1 Wear Regime Transition, Wear, 2011, 271, p 1689–1700. https://doi.org/10.1016/j.wear.2010.12.085

W.H. Kao, Microstructure, Adhesion and Tribological Properties of W-C : H-x% Coatings Deposited on M2 and WC Substrates, Mater. Sci. Eng. Struct. Mater. Prop. Microstruct. Process., 2006, 432, p 253–260. https://doi.org/10.1016/j.msea.2006.06.008

Y.M. Li, Q.B. Yue, H.Y. Li, and H.B. He, Friction and Wear Characteristics of 20Cr Steel Substrate and TiAlN Coating under Different Lubrication Conditions, Int. J. Precis. Eng. Manuf., 2018, 19, p 1521–1528. https://doi.org/10.1007/s12541-018-0179-8

W.Y.H. Liew, Low-Speed Milling of Stainless Steel with TiAlN Single-layer and TiAlN/AlCrN Nano-multilayer Coated Carbide Tools Under Different Lubrication Conditions, Wear, 2010, 269, p 617–631. https://doi.org/10.1016/j.wear.2010.06.012

R. Peng, P.Y. Zhang, Z.X. Tian, D.P. Zhu, C. Chen, B.F. Yin, and X.J. Hua, Effect of Textured DLC Coatings on Tribological Properties of Titanium Alloy Under Grease Lubrication, Mater. Res. Express, 2020 https://doi.org/10.1088/2053-1591/ab9ced

Y.Y. Xiao, W.K. Shi, J. Luo, and Y.J. Liao, The Tribological Performance of TiN, WC/C and DLC Coatings Measured by the Four-Ball Test, Ceram. Int., 2014, 40, p 6919–6925. https://doi.org/10.1016/j.ceramint.2013.12.015

W.H. Zhuang, X.Q. Fan, W. Li, H. Li, L. Zhang, J.F. Peng, Z.B. Cai, J.L. Mo, G.G. Zhang, and M.H. Zhu, Comparing Space Adaptability of Diamond-Like Carbon and Molybdenum Disulfide Films Toward Synergistic Lubrication, Carbon, 2018, 134, p 163–173. https://doi.org/10.1016/j.carbon.2018.03.059

M. Heitkemper, A. Fischer, C. Bohne, and A. Pyzalla, Wear Mechanisms of Laser-Hardened Martensitic High-Nitrogen-Steels Under Sliding Wear, Wear, 2001, 250, p 477–484. https://doi.org/10.1016/s0043-1648(01)00659-7

K. Valtonen, N. Ojala, O. Haiko, and V.T. Kuokkala, Comparison of Various High-Stress Wear Conditions and Wear Performance of Martensitic Steels, Wear, 2019, 426, p 3–13. https://doi.org/10.1016/j.wear.2018.12.006

S.Q. Wang, L. Wang, Y.T. Zhao, Y. Sun, and Z.R. Yang, Mild-to-Severe Wear Transition and Transition Region of Oxidative Wear in Steels, Wear, 2013, 306, p 311–320. https://doi.org/10.1016/j.wear.2012.08.017

J.Y. Mao, G.Y. Chen, J. Zhao, Y.Y. He, and J.B. Luo, An Investigation on the Tribological Behaviors of Steel/Copper and Steel/Steel Friction Pairs Via Lubrication with a Graphene Additive, Friction, 2021, 9, p 228–238. https://doi.org/10.1007/s40544-019-0327-x

T.H. Zhang and Y. Huan, Nanoindentation and Nanoscratch Behaviors of DLC Coatings on Different Steel Substrates, Compos. Sci. Technol., 2005, 65, p 1409–1413. https://doi.org/10.1016/j.compscitech.2004.12.011

Z.F. Zhou, K.Y. Li, I. Bello, C.S. Lee, and S.T. Lee, Study of Tribological Performance of ECR-CVD Diamond-Like Carbon Coatings on Steel Substrates Part 2. The Analysis of Wear Mechanism, Wear, 2005, 258, p 1589–1599. https://doi.org/10.1016/j.wear.2004.10.005

A.A. Voevodin, R. Bantle, and A. Matthews, Dynamic Impact-Wear of TiCxNy and Ti-DLC Composite Coatings, Wear, 1995, 185, p 151–157. https://doi.org/10.1016/0043-1648(95)06603-9

P. Xu, Y. Wang, X.Q. Cao, X.F. Nie, W. Yue, and G.G. Zhang, The Tribological Properties of DLC/SiC and DLC/Si3N4 Under Different Relative Humidity: The Transition from Abrasive Wear to Tribo-Chemical Reaction, Ceram. Int., 2021, 47, p 3901–3910. https://doi.org/10.1016/j.ceramint.2020.09.252

B.D. Beake, J.L. Endrino, C. Kimpton, G.S. Fox-Rabinovich, and S.C. Veldhuis, Elevated Temperature Repetitive Micro-Scratch Testing of AlCrN, TiAlN and AlTiN PVD Coatings, Int. J. Refract Metal Hard Mater., 2017, 69, p 215–226. https://doi.org/10.1016/j.ijrmhm.2017.08.017

E. Contreras Romero, A. Hurtado Macias, J. Mendez Nonell, O. Solis Canto, and M. Gomez Botero, Mechanical and Tribological Properties of Nanostructured TiAlN/TaN Coatings Deposited by DC Magnetron Sputtering, Surf. Coat. Technol., 2019 https://doi.org/10.1016/j.surfcoat.2019.124941

A.H. Liu, J.X. Deng, H.B. Cui, Y.Y. Chen, and J. Zhao, Friction and Wear Properties of TiN, TiAIN, AlTiN and CrAlN PVD Nitride Coatings, Int. J. Refract Metal Hard Mater., 2012, 31, p 82–88. https://doi.org/10.1016/j.ijrmhm.2011.09.010

P.V. Moghaddam, B. Prakash, E. Vuorinen, M. Fallqvist, J.M. Andersson, and J. Hardell, High Temperature Tribology of TiAlN PVD Coating Sliding Against 316L Stainless Steel and Carbide-Free Bainitic Steel, Tribol. Int., 2021 https://doi.org/10.1016/j.triboint.2020.106847

B. Vengudusamy, J.H. Green, G.D. Lamb, and H.A. Spikes, Tribological Properties of Tribofilms Formed from ZDDP in DLC/DLC and DLC/Steel Contacts, Tribol. Int., 2011, 44, p 165–174. https://doi.org/10.1016/j.triboint.2010.10.023

B. Vengudusamy, J.H. Green, G.D. Lamb, and H.A. Spikes, Behaviour of MoDTC in DLC/DLC and DLC/Steel Contacts, Tribol. Int., 2012, 54, p 68–76. https://doi.org/10.1016/j.triboint.2012.04.028

R. Zahid, H.H. Masjuki, M. Varman, R.A. Mufti, M.A. Kalam, and M. Gulzar, Effect of Lubricant Formulations on the Tribological Performance of Self-mated Doped DLC Contacts: A Review, Tribol. Lett., 2015 https://doi.org/10.1007/s11249-015-0506-5

Acknowledgments

The authors gratefully acknowledge the support of the National Key R&D Program of China (Grant No. 2020YFB2010200) and the Integration of Industry, Education and Research of Aero Engine (Group) Corporation of China (Grant No. HFZL2019CXY004-2). The authors would like to acknowledge the editors and the anonymous reviewers for their valuable comments and suggestions.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Xiao, L., Xu, Y., Chen, Z. et al. Tribological Properties of Diamond-Like Carbon, TiAlN, and Diamond-Like Carbon/TiAlN Coatings Deposited on Carburized 18CrNi4A Steel for Heavy-Duty Aerospace Transmission Components. J. of Materi Eng and Perform 33, 601–617 (2024). https://doi.org/10.1007/s11665-023-07996-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-023-07996-1