Abstract

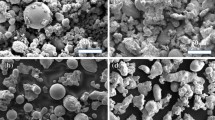

In this study, pure tungsten parts were fabricated by laser powder bed fusion (LPBF). The effects of volumetric energy density (VED) during LPBF process and hot isostatic pressing (HIP) treatments on the densification behavior, microstructural evolution, mechanical properties and thermal conductivity of printed parts were systematically investigated. The maximum relative densities of 95.91 and 98.97% for the as-built and HIP treated samples were achieved, respectively. The microstructural characterization showed that the as-built samples had columnar grains with a strong texture along the building direction. The preferred orientation disappeared and the deformed microstructure transferred into substructured and recrystallized grains after HIPing at 1600 °C. The mechanical testing results indicated that the highest microhardness of 450 HV and the maximum ultimate compressive strength of ~ 1.22 GPa were achieved in the specimen fabricated at the VED of 312.50 J/mm3, respectively, under the conditions of as-built and HIPped at 1600 °C. The corresponding thermal conductivity was improved to 158 W/m∙K after HIPping, which implies a promising candidate for the application in the nuclear fusion reactor.

Similar content being viewed by others

References

L.L. Snead, D.T. Hoelzer, M. Rieth, and A.A.N. Nemith (2019) Refractory Alloys: Vanadium, Niobium, Molybdenum, Tungsten, in G.R. Odette, S.J. Zinkle (Eds.) Structural Alloys for Nuclear Energy Application pp 585-640

X.F. Xie, K. Jing, Z.M. Xie, R. Liu, J.F. Yang, Q.F. Fang, C.S. Liu, and X.B. Wu, Mechanical Properties and Microstructures of W-TiC and W-Y2O3 Alloys Fabricated by Hot-pressing Sintering, Mater. Sci. Eng. A, 2021, 819, p 141496.

B. Zeep, P. Norajitra, V. Piotter, J. Boehm, R. Ruprecht, and J. Hausselt, Net Shaping of Tungsten Components by Micro Powder Injection Moulding, Fusion Eng. Des., 2007, 82(15–24), p 2660–2665.

M. Duerrschnabel, S. Antusch, B. Holtermann, U. Jaentsch, S. Baumgaertner, C. Bonnekoh, M. Hoffmann, and M. Rieth, Elucidating the Microstructure of Tungsten Composite Materials Produced by Powder Injection Molding, Nucl. Mater. Energy, 2020, 24, p 100766.

X.X. Zhang, Q.Z. Yan, C.T. Yang, T.N. Wang, M. Xia, and C.C. Ge, Recrystallization Temperature of Tungsten with Different Deformation Degrees, Rare Met., 2016, 35, p 566–570.

S. Deng, J. Li, R. Li, H. Zhao, T. Yuan, L. Li, and Y. Zhang, The Effect of Particle Size on the Densification Kinetics of Tungsten Powder During Spark Plasma Sintering, Int. J. Refract. Met. Hard Mater., 2020, 93, p 105358.

A. Iveković, N. Omidvari, B. Vrancken, K. Lietaert, L. Thijs, K. Vanmeensel, J. Vleugels, and J.-P. Kruthc, Selective Laser Melting of Tungsten and Tungsten Alloys, Int. J. Refract. Met. Hard Mater., 2018, 72, p 27–32.

X. Zhou, X. Liu, D. Zhang, Z. Shen, and W. Liu, Balling Phenomena in Selective Laser melted Tungsten, J. Mater. Process. Technol., 2015, 222, p 33–42.

K. Deprez, S. Vandenberghe, K.V. Audenhaege, J.V. Vaerenbergh, and R.V. Holen, Rapid Additive Manufacturing of MR Compatible Multipinhole Collimators with Selective Laser Melting of Tungsten Powder, Med. Phys., 2013, 40(1), p 012501.

R.K. Enneti, R. Morgan, and S.V. Atre, Effect of Process Parameters on the Selective Laser Melting (SLM) of Tungsten, Int. J. Refract. Met. Hard Mater., 2018, 71, p 315–319.

D.Z. Wang, K.L. Li, C.F. Yu, J. Ma, W. Liu, and Z.J. Shen, Cracking Behavior in Additively Manufactured Pure Tungsten, Acta Metall. Sin. Engl. Lett., 2019, 32, p 127–135.

Q. Qin, F. Yang, T. Shi, Z. Guo, and P. Cao, Spheroidization of Tantalum Powder by Radio Frequency Inductively Coupled Plasma Processing, Adv. Powder Technol., 2019, 30(8), p 1709–1714.

S. Wen, C. Wang, Y. Zhou, L. Duan, Q. Wei, S. Yang, and Y. Shi, High-density Tungsten Fabricated by Selective Laser Melting: Densification, Microstructure, Mechanical and Thermal Performance, Opt. Laser Technol., 2019, 116, p 128–138.

J. Huang, M. Li, J. Wang, Z. Pei, P. Mclntyre, and C. Ma, Selective Laser Melting of Tungsten: Effects of Hatch Distance and Point Distance on Pore Formation, J. Manuf. Process., 2021, 61, p 296–302.

M. Guo, D. Gu, L. Xi, H. Zhang, J. Zhang, J. Yang, and R. Wang, Selective Laser Melting Additive Manufacturing of Pure Tungsten: Role of Volumetric Energy Density on Densification, Microstructure and Mechanical Properties, Int. J. Refract. Met. Hard Mater., 2019, 84, p 105025.

T. Todo, T. Ishimoto, O. Gokcekaya, J. Oh, and T. Nakano, Single Crystalline-Like Crystallographic Texture Formation of Pure Tungsten Through Laser Powder Bed Fusion, Scr. Mater., 2022, 206, p 114252.

O. Gokcekaya, T. Ishimoto, T. Todo, P. Wang, and T. Nakano, Influence of Powder Characteristics on Densification Via Crystallographic Texture Formation: Pure Tungsten Prepared by Laser Powder Bed Fusion, Addit. Manuf. Lett., 2021, 1, p 100016.

J. Chen, K. Li, Y. Wang, L. Xing, C. Yu, H. Liu, J. Ma, W. Liu, and Z. Shen, The Effect of Hot Isostatic Pressing on Thermal Conductivity of Additively Manufactured Pure Tungsten, Int. J. Refract. Met. Hard Mater., 2020, 87, p 105135.

Q. Qin, F. Yang, T. Shi, Z. Guo, H. Sun, P. Li, X. Lu, C. Chen, J. Hao, and P. Cao, Spheroidization of Tantalum Powder by Radio Frequency Inductively Coupled Plasma Processing, Adv. Powder Technol., 2019, 30(8), p 1709–1714.

P. Mercelis and J.P. Kruth, Residual Stresses in Selective Laser Sintering and Selective Laser Melting, Rapid Prototyp. J., 2006, 12(5), p 254–265.

T. Simson, A. Emmel, A. Dwars, and J. Böhm, Residual Stress Measurements on AISI 316L Samples Manufactured by Selective Laser Melting, Addit. Manuf., 2017, 17, p 183–189.

K. Li, D. Wang, L. Xing, Y. Wang, C. Yu, J. Chen, T. Zhang, J. Ma, W. Liu, and Z. Shen, Crack Suppression in Additively Manufactured Tungsten by Introducing Secondary-Phase Nanoparticles into the Matrix, Int. J. Refract. Met. Hard Mater., 2019, 79, p 158–163.

D. Wang, Z. Wang, K. Li, J. Ma, W. Liu, and Z. Shen, Cracking in laser additively manufactured W: Initiation Mechanism and a Suppression Approach by Alloying, Mater. Des., 2019, 162, p 384–393.

E. Lassner and W.D. Schubert, Tungsten: Properties, Chemistry, Technology of the Element, Alloys, and Chemical Compounds, Vienna University of Technology, Kluwer Academic/Plenum Publishers, New York, 1999.

J. Xue, Z. Feng, J. Tang, C. Tang, and Z. Zhao, Selective Laser Melting Additive Manufacturing of Tungsten with Niobium Alloying: Microstructure and Suppression Mechanism of Microcracks, J. Alloy. Compd., 2021, 874(6), p 159879.

H.H. Zhu, L. Lu, and J.Y.H. Fuh, Study on Shrinkage Behaviour of Direct Laser Sintering Metallic Powder, Proc. Inst. Mech. Eng. Part B J. Eng. Manuf., 2006, 220(2), p 183–190.

G. Yang, P. Yang, K. Yang, N. Liu, and H. Tang, Effect of Processing Parameters on the Density, Microstructure and Strength of Pure Tungsten Fabricated by Selective Electron Beam Melting, Int. J. Refract. Met. Hard Mater., 2019, 84(1), p 105040.

J. Braun, L. Kaserer, J. Stajkovic, K.H. Leitz, and G. Leichtfried, Molybdenum and Tungsten Manufactured by Selective Laser Melting—Analysis of Defect Structure and Solidification Mechanisms, Int. J. Refract. Met. Hard Mater., 2019, 84(84), p 104999.

X. Zhao, L. Xin, J. Chen, L. Xue, and W. Huang, The Effect of Hot Isostatic Pressing on Crack Healing, Microstructure, Mechanical Properties of Rene88DT Superalloy Prepared by Laser Solid Forming, Mater. Sci. Eng. A, 2009, 504(1–2), p 129–134.

B. AlMangour, D. Grzesiak, and J.M. Yang, Selective Laser Melting of TiB2/H13 Steel Nanocomposites: Influence of Hot Isostatic Pressing Post-Treatment, J. Mater. Process. Technol., 2017, 244, p 344–353.

A. Epishin, B. Fedelich, T. Link, T. Feldmann, and I.L. Svetlov, Pore annihilation in a Single-Crystal Nickel-Base Superalloy During Hot Isostatic Pressing: Experiment and Modelling, Mater. Sci. Eng. A, 2013, 586, p 342–349.

M. Vilanova, F. Garciandia, S. Sainz, D. Jorge-Badiola, T. Guraya, and M. San Sebastian, The Limit of Hot isostatic pressing for Healing Cracks Present in an Additively Manufactured Nickel Superalloy, J. Mater. Process. Technol., 2021, 300, p 117398.

Q. Han, R. Mertens, M.L. Montero-Sistiaga, S. Yang, R. Setchi, K. Vanmeensel, B.V. Hooreweder, S.L. Evans, and H. Fan, Laser Powder Bed Fusion of Hastelloy X: Effects of Hot Isostatic Pressing and the Hot Cracking Mechanism, Mater. Sci. Eng. A, 2018, 732, p 228–239.

V. Livescu, C.M. Knapp, G.T. Gray, R.M. Martinez, B.M. Morrow, and B.G. Ndefru, Additively Manufactured Tantalum Microstructures, Materialia, 2018, 1, p 15–24.

Y.J. Liang, X. Cheng, J. Li, and H.M. Wang, Microstructural Control During Laser Additive Manufacturing of Single-Crystal Nickel-Base Superalloys: New Processing-Microstructure Maps Involving Powder Feeding, Mater. Des., 2017, 130, p 197–207.

J. Nie, C. Chen, L. Liu, X. Wang, R. Zhao, S. Shuai, J. Wang, and Z. Ren, Effect of Substrate Cooling on the Epitaxial Growth of Ni-Based Single-Crystal Superalloy Fabricated by Direct Energy Deposition, J. Mater. Sci. Technol. Shenyang, 2020, 62, p 148–161.

A.T. Sidambe, Y. Tian, P.B. Prangnell, and P. Fox, Effect of Processing Parameters on the Densification, Microstructure and Crystallographic Texture During the Laser Powder Bed Fusion of Pure Tungsten, Int. J. Refract Metal Hard Mater., 2019, 78, p 254–263.

K. Tsuchida, T. Miyazawa, A. Hasegawa, S. Nogami, and M. Fukuda, Recrystallization Behavior of Hot-Rolled Pure Tungsten and Its Alloy Plates During High-temperature Annealing, Nucl. Mater. Energy, 2018, 15, p 158–163.

X. Ren, H. Liu, F. Lu, L. Huang, and X. Yi, Effects of Processing Parameters on the Densification, Microstructure and Mechanical Properties of Pure Tungsten Fabricated by Optimized Selective Laser Melting: From Single and Multiple Scan Tracks to Bulk Parts, Int. J. Refract. Met. Hard Mater., 2021, 96, p 105490.

Y. Wang and J. Zhao, Numerical Simulations of Thermal Conductivity in Void-Containing Tungsten: Topological Feature of Voids, J. Nucl. Mater., 2021, 543, p 152601.

Acknowledgments

This work was sponsored by the Guangdong Academy of Science Project of Science and Technology Development (2020GDASYL-20200103142, 2022GDASZH-2022010107) and Guangzhou Science and Technology Planning Project (202007020008, 202206040001), Guangdong Key Science and Technology Project (2018B090904004).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

See Tables

3,

4 and

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Shi, Q., Du, W., Qin, F. et al. Pure Tungsten Fabricated by Laser Powder Bed Fusion with Subsequent Hot Isostatic Pressing: Microstructural Evolution, Mechanical Properties, and Thermal Conductivity. J. of Materi Eng and Perform 32, 10910–10923 (2023). https://doi.org/10.1007/s11665-023-07891-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-023-07891-9