Abstract

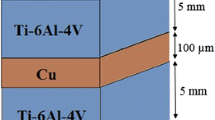

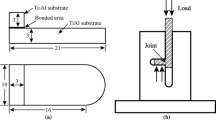

Commercially pure Ti (AMS 4902) was joined using the transient liquid phase bonding technique. The joining process was implemented at various temperatures of 820, 860, 900, and 1000 °C for 90 min under a vacuum atmosphere of 7.99 Pa. The microstructural investigations were carried out comprehensively using scanning electron microscopy equipped with the EDS elemental detector. The mechanical properties were characterized using the microhardness and shear strength tests. Strength properties in terms of ultimate shear strength and ductility were presented as force-extension diagrams. The presence of eutectic intermetallics in the joint centerline indicated that isothermal solidification was not achieved at low bonding temperatures. However, the increase in temperature to 1000 °C resulted in a fully isothermal solidified joint. The elemental gradients between the bonding centerline and the base metal leveled off at high temperatures of 900 and 1000 °C, where the solubility of Ti increased in the Cu crystal structure. A higher hardness of 270 HV with a uniform gradient was also observed across the joint produced at high temperatures of 900 and 1000 °C. A combination of high strength and ductility was obtained for the samples fabricated at 900 and 1000 °C bonding temperatures.

Similar content being viewed by others

References

A. Elrefaey, L. Wojarski and W. Tillmann, Evaluation of Corrosion Performance of Titanium/Steel Joint Brazed by Cu Based Filler Metal, J. Mater. Eng. Perf., 2012, 2, p 707–713.

G. Cam, U. Ozdemir, V. Ventzke and M. Koçak, Microstructural and Mechanical Characterization of Diffusion Bonded Hybrid Joints, J. Mater. Sci., 2008, 43, p 3491–3499.

A. Alansari and Y. Sun, A Comparative Study of the Mechanical Behavior of Thermally Oxidized Commercially Pure Titanium and Zirconium, J. Mech. Beha. Bio. Mater., 2017, 74, p 221–231.

M. Froend, F. Fomin, S. Riekehr, P. Alvarez, F. Zubiri, S. Bauer, B. Klusemann and N. Kashaev, Fiber Laser Welding of Dissimilar Titanium (Ti-6Al-4V/cp-Ti) T-Joints and Their Laser Forming Process for Aircraft Application, Opt. Laser Tech., 2017, 96, p 123–131.

E.S. Ogawa, A.O. Matos, T. Beline, I.S.V. Marques, C. Sukotjo, T.M. Mathew, E.C. Rangel, N.C. Cruz, M.F. Mesquita, R.X. Consani and V.A.R. Barão, Surface-Treated Commercially Pure Titanium for Biomedical Applications: Electrochemical, Structural, Mechanical and Chemical Characterizations, Mater. Sci. Eng. C, 2016, 65, p 251–261.

S. Shakerin, H. Omidvar and S.E. Mirsalehi, The Effect of Substrate’s Heat Treatment on Microstructural and Mechanical Evolution of Transient Liquid Phase Bonded IN-738 LC, Mater. Des., 2016, 89, p 611–619.

V. Maleki, H. Omidvar and M.R. Rahimipour, Effect of Gap Size on Microstructure of the Transient Liquid Phase Bonded IN-738LC Superalloy, Trans. Nonferrous Met. Soc. China, 2016, 26, p 437–447.

V. Jalilvand, H. Omidvar, H.R. Shakeri and M.R. Rahimipour, A Study on the Effect of Process Parameters on the Properties of Joint in TLP-Bonded Inconel 738LC Superalloy, Met. Mater. Trans. B, 2013, 44, p 1222–1231.

V. Maleki, H. Omidvar and M.R. Rahimipour, Influences of Gap Size and Cyclic-Thermal-Shock Treatment on Mechanical Properties of TLP Bonded IN-738LC Superalloy, Trans. Nonferrous Met. Soc. China, 2018, 28, p 920–930.

S. Shakerin, V. Maleki, S.A. Ziaei, H. Omidvar, M.R. Rahimipour and S.E. Mirsalehi, Microstructural and Mechanical Assessment of Transient Liquid Phase Bonded Commercially Pure Titanium, Can. Met. Q., 2017, 56, p 360–367.

S.G. Saremi, S.E. Mirsalehi and A. Shamsipur, Transient Liquid Phase Bonding of AZ31 Magnesium Alloy: Metallurgical Structure and Mechanical Properties, J. Manuf. Process, 2018, 35, p 140–148.

A. Doroudi, A. Shamsipur, H. Omidvar and M. Vatanara, Effect of Transient Liquid Phase Bonding Time on the Microstructure, Isothermal Solidification Completion and the Mechanical Properties During Bonding of Inconel 625 Superalloy, J. Manuf. Process, 2019, 38, p 235–243.

F. Arhami, S.E. Mirsalehi, A. Sadeghian and M.H. Johar, The Joint Properties of a High-Chromium Ni-Based Superalloy Made by Diffusion Brazing: Microstructural Evolution, Corrosion Resistance and Mechanical Behavior, J. Manuf. Process, 2019, 37, p 203–211.

R. Sahraeian, H. Omidvar, S.M.M. Hadavi, S. Shakerin and V. Maleki, An Investigation on High-Temperature Oxidation and Hot Corrosion Resistance Behavior of Coated TLP (Transient Liquid Phase)-Bonded IN738-LC, Trans. Indian Inst. Met., 2018, 71, p 2903–2918.

H. Baker and H. Okamoto, Alloy phase diagrams, vol. 3. ASM International, (ASM Handbook; 1992).

X.R. Wang, Y.Q. Yang, X. Luo, W. Zhang, G.M. Zhao and B. Huang, An Investigation of Ti-43Al-9V/Ti-6Al-4V Interface by Diffusion Bonding, Intermetallics, 2013, 36, p 127–132.

A. AlHazaa, T.I. Khan and I. Haq, Transient Liquid Phase (TLP) Bonding of Al7075 to Ti-6Al-4V alloy, Mater. Charact., 2010, 61, p 312–317.

K. Aydın, Y. Kaya and N. Kahraman, Experimental Study of Diffusion Welding/Bonding of Titanium to Copper, Mater. Des., 2012, 37, p 356–368.

R.H. Shiue and S.K. Wu, Infrared Brazing of Ti50Ni50 Shape Memory Alloy Using Two Ag-Cu-Ti Active Braze Alloys, Intermetallics, 2006, 14, p 630–638.

Y. Li, P. He and J. Feng, Interface Structure and Mechanical Properties of the TiAl/42CrMo Steel Joint Vacuum Brazed with Ag-Cu/Ti/Ag-Cu filler metal, Scrip. Mater., 2006, 55, p 171–174.

L.J. Zhang, T.I. Spiridonova, S.E. Kulkova, R. Yang and Q.M. Hu, Atomic Self-Diffusion Anisotropy of HCP Metals from First-Principles Calculations, Comp. Mater. Sci., 2017, 128, p 236–242.

A. Shamsipur, S.E. Mirsalehi and M. Ataei, Microstructural Characterization and Mechanical Properties of Diffusion-Brazed AZ91C Magnesium Alloy to 316L Stainless Steel, Kovove Mater., 2019, 57, p 299–306.

A.E. Pilehrood, H. Omidvar, A. Shamsipur and M. Khakian-Ghomi, Effect of Transient Liquid Phase Bonding Followed by Homogenization on the Microstructure and Hot Tensile Behavior of Inconel 738 Superalloy, J. Manuf. Process, 2019, 48, p 110–118.

A. Sadeghian, F. Arhami and S.E. Mirsalehi, Phase Formation During Dissimilar Transient Liquid Phase (TLP) Bonding of IN939 to IN625 Using a Ni-Cr-Fe-Si-B Interlayer, J. Manuf. Process, 2019, 44, p 72–80.

Acknowledgments

This research did not receive any specific grant from funding agencies or not-for-profit sectors.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Maleki, V., Shakerin, S., Ziaei, S.A. et al. The Effect of Bonding Temperature on the Microstructural and Mechanical Properties of Transient Liquid Phase Bonded Commercially Pure Ti Joint. J. of Materi Eng and Perform 33, 4613–4619 (2024). https://doi.org/10.1007/s11665-023-07813-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-023-07813-9