Abstract

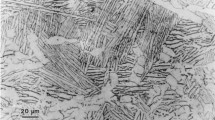

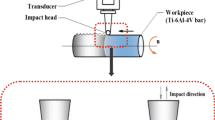

The bio-tribological properties of TB8 titanium alloy treated by ultrasonic surface rolling were studied in the present work. Friction and wear tests were carried out in 15% hyaluronic acid solution. Surface characteristics including morphology, chemical composition, and mechanical properties were investigated to discuss the influence of the ultrasonic surface rolling process on material transfer, tribofilms, and wear mechanisms. Experimental results showed that the highest tensile strength, hardness, and the smallest surface roughness were obtained under 600 N ultrasonic surface rolling process (the highest load within the selected parameter range). The best friction and wear properties correspondingly occurred in 600 N ultrasonic surface rolled samples. The smoothest and densest oxide layers composed of TiO2, TiC, and TiCxOy were found on the friction interfaces of these samples to protect TB8 substrate from further oxidation. Meanwhile, the observed strong relevance between mechanical properties and specific wear rate as well as friction coefficient also revealed that the intrinsic plastic gradient of ultrasonic surface rolled layer can significantly improve the friction and wear properties of TB8 titanium alloy.

Similar content being viewed by others

References

M. Niinomi, Recent Applications, Research and Development in Titanium and its Alloys, Tetsu. Hagane., 2004, 90(7), p 462–471. https://doi.org/10.2355/tetsutohagane1955.90.7_462

R.R. Boyer, Attributes, Characteristics, and Applications of Titanium and its Alloys, Jom., 1989, 62(5), p 21–24. https://doi.org/10.1007/s11837-010-0071-1

W. Liu, S. Liu, and L. Wang, Surface Modification of Biomedical Titanium Alloy: Micromorphology, Microstructure Evolution and Biomedical Applications, Coat. (Basel), 2019, 9(4), p 249. https://doi.org/10.3390/coatings9040249

M. Sarraf, E. Rezvani Ghomi, S. Alipour, S. Ramakrishna, and N. Liana Sukiman, A state-of-the-art Review of the Fabrication and Characteristics of Titanium and its Alloys for Biomedical Applications, Bio-Desing. Manuf., 2021, 5(2), p 371–395. https://doi.org/10.1007/s42242-021-00170-3

T. Xu, Y. Zhang, W. Zhang, J. Tian, L. Zhang, F. Zhang, X. Liu, F. Yong, P. Zhang, and J. Li, Industrial Research and Application of New High-Strength TB8 Titanium Alloy, Sci Press Beijing, 2012, 3, p 1988–1990.

T. Hanawa, Titanium-Tissue Interface Reaction and its Control with Surface Treatment, Front. Bioeng. Biotechnol., 2019, 7, p 170–170. https://doi.org/10.3389/fbioe.2019.00170

S. Kaur, K. Ghadirinejad, and R.H. Oskouei, An Overview on the Tribological Performance of Titanium Alloys with Surface Modifications for Biomedical Applications, Lubr, 2019, 7(8), p 65. https://doi.org/10.3390/lubricants7080065

D. Lee, X. Mi, T.K. Eom, and Y. Lee, Bio-Compatible Properties of Ti–Nb–Zr Titanium Alloy with Extra Low Modulus, J. Biomater. Tiss. Eng., 2016, 6(10), p 798–801. https://doi.org/10.1166/jbt.2016.1508

T. Hanawa, Surface Treatment and Modification of Metals to Add Biofunction, Dent. Mater. J., 2017, 36(5), p 533–538. https://doi.org/10.4012/dmj.2017-154

B.F. Yousif and N.S.M. El-Tayeb, Wear Characteristics of Thermoset Composite Under High Stress Three-Body Abrasive, Tribol Int, 2010, 43(12), p 2365–2371. https://doi.org/10.1016/j.triboint.2010.08.010

G. Fowler, I.R. Pashby, and P.H. Shipway, The Effect of Particle Hardness and Shape When Abrasive Water Jet Milling Titanium Alloy Ti6Al4V, Wear, 2009, 266(7), p 613–620. https://doi.org/10.1016/j.wear.2008.06.013

P.H. Shipway and N.K. Ngao, Microscale Abrasive Wear of Polymeric Materials, Wear, 2003, 255(1), p 742–750. https://doi.org/10.1016/S0043-1648(03)00106-6

B.F. Yousif, Y.H. Arhaim, and A. Shalwan, Correlation Between Frictional Force, Interface Temperature and Specific Wear Rate of Fibre Polymer Composites, Adv. Mater. Res., 2013, 685, p 45–49. https://doi.org/10.4028/www.scientific.net/AMR.685.45

A. Siddharth Sharma, K. Biswas, and B. Basu, Microstructure-Hardness-Fretting Wear Resistance Correlation in Ultrafine Grained Cu–TiB2–Pb Composites, Wear., 2014, 319(1–2), p 160–171. https://doi.org/10.1016/j.wear.2014.07.014

F. Su, C. Liu, and P. Huang, Establishing Relationships Between Electrodeposition Techniques, Microstructure and Properties of Nanocrystalline Co–W Alloy Coatings, J Alloys Compd, 2013, 557, p 228–238. https://doi.org/10.1016/j.jallcom.2013.01.003

S. Das Bakshi, D. Sinha, S. Ghosh Chowdhury, and V.V. Mahashabde, Surface and Sub-Surface Damage of 0.20 wt.% C-Martensite During Three-body Abrasion, Wear, 2018, 394–395, p 217–227. https://doi.org/10.1016/j.wear.2017.07.004

M. Federici, C. Menapace, A. Moscatelli, S. Gialanella, and G. Straffelini, Effect of Roughness on the Wear Behavior of HVOF Coatings Dry Sliding Against a Friction Material, Wear, 2016, 368–369, p 326–334. https://doi.org/10.1016/j.wear.2016.10.013

H. Bai, L. Zhong, L. Kang, J. Liu, W. Zhuang, Z. Lv, and Y. Xu, A Review on Wear-resistant Coating with High Hardness and High Toughness on the Surface of Titanium Alloy, J Alloys Compd, 2021, 882, p 160645. https://doi.org/10.1016/j.jallcom.2021.160645

K. Májlinger, G. Kalácska, I.N. Orbulov, L. Zsidai, B. Bozóki, and R. Keresztes, Global Approach of Tribomechanical Development of Hybrid Aluminium Matrix Syntactic Foams, Tribol. Lett., 2017, 65(1), p 1–13. https://doi.org/10.1007/s11249-016-0798-0

T. Hu, Y. Zhang, and L. Hu, Mechanical and Wear Characteristic of Y-TZP/Al2O3 Nanocomposites, Ind Lubr Tribo, 2014, 66(2), p 209–214. https://doi.org/10.1108/ILT-08-2011-0059

Y. Jian, Z. Huang, J. Xing, and J. Li, Effects of Chromium Additions on the Three-body Abrasive Wear Behavior of fe-3.0 wt.% B Alloy, Wear, 2017, 378–379, p 165–173. https://doi.org/10.1016/j.wear.2017.02.042

A.P. Harsha, U.S. Tewari, and B. Venkatraman, Three-Body Abrasive Wear Behaviour of Polyaryletherketone Composites, Wear, 2003, 254(7), p 680–692. https://doi.org/10.1016/S0043-1648(03)00142-X

J. Larsen-Basse and A. Tadjvar, Slurry Abrasion of Polymers Under Simulated Submarine Conditions, Wear, 1988, 122(2), p 135–149. https://doi.org/10.1016/0043-1648(88)90074-9

G. Meille, R. Dif, J.C. Abry, S. Mezlini, P. Kapsa, and H. Ribes, Relationship Between Hardness and Abrasive Wear for Some Aluminium Alloys, Mater. Sci. Forum., 2002, 396–402(3), p 1517–1524. https://doi.org/10.4028/www.scientific.net/MSF.396-402.1517

T. Ido, T. Yamaguchi, K. Shibata, K. Matsuki, K. Yumii, and K. Hokkirigawa, Sliding Friction Characteristics of Styrene Butadiene Rubbers with Varied Surface Roughness Under Water Lubrication, Tribol. Int., 2019, 133, p 230–235. https://doi.org/10.1016/j.triboint.2019.01.015

X.J. Zhu, C.Z. Cai, G.L. Wang, and J.F. Pei, Investigation on the Processing-Properties of Hot Deformed TA15 Titanium Alloy via Support Vector Regression, Mater. Sci. Forum., 2011, 689, p 134–143. https://doi.org/10.4028/www.scientific.net/MSF.689.134

R. Teharia, R.M. Singari, and H. Kumar, Optimization of Process Variables for Additive Manufactured PLA Based Tensile Specimen Using Taguchi Design and Artificial Neural Network (ANN) Technique, Mater. Today Proc., 2022, 56, p 3426–3432. https://doi.org/10.1016/j.matpr.2021.10.376

I. Balasundar, T. Raghu, and B.P. Kashyap, Taguchi Based Optimisation of Artificial Neural Network to Establish a Direct Microstructure: Mechanical Property Correlation in a Near-α Titanium Alloy, Trans. Indian Metals, 2016, 69(10), p 1929–1941. https://doi.org/10.1007/s12666-016-0852-5

Acknowledgments

This work was financially supported by the National Nature Science Foundation of China (Grant No. 51875246), the Key Scientific and Technological Research and Development Projects of Jilin Provincial Science and Technology Department (Grant No. 20210201056GX), and the “13th Five Year Plan” Science and Technology Research of the Education Department of Jilin Province (Grant No. JJKH20200954KJ).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Liu, Y., Cui, H., Liu, Y. et al. Comprehensive Analysis of the Effect of Ultrasonic Surface Rolling Process on the Friction and Wear Properties of TB8 Titanium Alloy. J. of Materi Eng and Perform 32, 9448–9459 (2023). https://doi.org/10.1007/s11665-022-07794-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-07794-1