Abstract

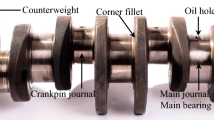

Improving the tribology performance of the crankshaft surface is of great significance to enhance vehicle running stability and reduce energy consumption. After vibration polishing on the surface of nodular cast iron, the graphite balls fall off to form in situ microtexture, which enhances the dynamic lubrication performance of the oil film. The surface tribological properties were evaluated by simulation and friction and wear experiments, and the effects of in situ microtexture parameters on hydrodynamic lubrication were discussed. Theoretical analysis and experimental results show that the surface has an in situ microtexture, which is helpful to decrease wear and increase hydrodynamic lubrication performance. When the texture diameter was 50 μm and the in situ texture density was 9%, the crankshaft has the highest hydrodynamic lubrication effect, and the reduction friction was obvious. The tribological performance of the crankshaft was also increased by the bearing capacity of film between friction pairs. Compared with forged steel, the surface wear of nodular cast iron is slight, and the wear behavior mainly includes microcutting and extrusion wear debris. The size and density of in situ texture are the keys to improving wear resistance.

Similar content being viewed by others

References

G.A. Artola, A. Monzón, J. Lacaze, and J. Sertucha, Tensile Properties and Fracture Toughness at Service Temperatures of an Optimized Pearlitic Ductile Iron Alloy for Automotive Crankshafts, Mat. Sci. Eng. A., 2022, 831, p 142206.

O. Asi, Failure Analysis of a Crankshaft Made from Ductile Cast Iron, Eng. Fail. Anal., 2006, 13, p 1260–1267.

Q. Liu, B.Q. Huo, Y.S. Liu, and J.C. Zhu, A Study on Diesel Engine Crankshaft Bearing Failure Analysis with Consideration of Bearing Lubrication, Ind. Lubr. Tribol., 2022, 74(1), p 118–126.

J. Zhang and Q.B. Dong, Lubrication Performance Analysis of Crankshaft Bush in Compressor, Eng. Fail. Anal., 2018, 90, p 277–289.

E. Zadorozhnaya, I. Levanov, and V. Erkin, Assessing Resource of Internal Combustion Engine Crankshaft Bearing in Consideration of Transient Regime, Procedia. Eng., 2017, 206, p 734–738.

S. Han and H. Huh, Evaluation of a Cast-joining Process of Dual-metal Crankshafts with Nodular Cast Iron and Forged Steel for Medium Speed Diesel Engines, Int. J. Adv. Manuf. Tech., 2012, 63, p 319–327.

K. Wang and Z. Ding, Wear Damage Analysis of Crankshaft Journal of a Low-speed Diesel Engine, Intern. Combust. Engines., 2020, 01, p 31–34.

F.X. Wang, W. Zhen, and J.X. Deng, Repair and Analysis of Crankshaft for Large Marine Low Speed Diesel Engine, Intern. Combust. Engine Parts., 2021, 11, p 173–175. ((in Chinese))

D.Q. He, C. He, W.S. Li, L.L. Shang, L.P. Wang, and G.G. Zhang, Tribological Behaviors of In-Situ Textured DLC Films under Dry and Lubricated Conditions, Appl. Surf. Sci., 2020, 525, p 146581.

Y.F. Xu, Q. Zheng, R. Abuflaha, D. Olson, O. Furlong, T. You, Q.Q. Zhang, X.G. Hu, and W.T. Tysoe, Influence of Dimple Shape on Tribofilm Formation and Tribological Properties of Textured Surfaces under Full and Starved Lubrication, Tribol. Int., 2019, 136, p 267–275.

J.S. Chen and Z. Wu, Effect of Textured Dimples on the Tribological Behavior of WC/Co Cemented Carbide in Dry Sliding with Al2O3/WC Ceramic, Micromachines, 2022, 13(8), p 1269.

G. Wieslaw, P. Pawel, W. Slawomir, K. Waldemar, and W. Michal, Evolutions of Cylinder Liner Surface Texture and Tribological Performance of Piston Ring-liner Assembly, Tribol. Int., 2018, 127, p 545–556.

H. Li, J.S. Zhao, S.X. Cui, Z.W. Zhang, and S.B. Yang, Influence of Surface Profile on Lubrication Performance of Engine Main bearings, Lubr. Eng., 2018, 43, p 49–54.

L.J. Yang, Y. Ding, B. Cheng, J.T. He, and G.W. Wang, Investigations on Femtosecond Laser Modified Micro-textured Surface with Anti-friction Property on Bearing Steel GCr15, Appl. Surf. Sci., 2018, 434, p 831–842.

M.K. Gupta, Q.H. Song, Z.Q. Liu, R. Singh, M. Sarikaya, and N. Khanna, Tribological Behavior of Textured Tools in Sustainable Turning of Nickel Based Super Alloy, Tribol. Int., 2021, 155, p 106775.

S.A. Yassmin, M.P. Jose, A.F.M. Arif, F.L. Amorim, R.D. Torres, and S.C. Veldhuis, The Effect of Laser Micro-scale Textured Tools on the Tool-chip Interface Performance and Surface Integrity during Austenitic Stainless-steel Turning, Appl. Surf. Sci., 2020, 510, p 145455.

B. Noël and T. Bernard, Numerical Analysis of a Surface-textured Mechanical Seal Operating in Mixed Lubrication Regime, Tribol. Int., 2012, 49, p 80–89.

I. Etsion, Improving Tribological Performance of Mechanical Components by Laser Surface Texturing, Tribol. Lett., 2004, 17(4), p 733–737.

J. Yang, Z. Liu, Q. Cheng, and T. Deng, The Effect of Wear on the Frictional Vibration Suppression of Water-lubricated Rubber Slat with/without Surface Texture, Wear, 2019, 426–427(30), p 1304–1317.

C. Shen and M.M. Khonsari, Tribological and Sealing Performance of Laser Pocketed Piston Rings in a Diesel Engine, Tribol. Lett., 2016, 64(2), p 26.

X.X. Zhou, X.J. Pang, S.W. Yue, Y.Y. Hang, H. Zhang, and B. Yu, Tribological Properties of the Lubricant Combination of Surface Texture and Ionic Liquids, Tribology., 2021, 41(06), p 995–1003. ((in Chinese))

D. Li, X.F. Yang, C.Y. Lu, J. Cheng, S.R. Wang, and Y.J. Wang, Tribological Characteristics of a Cemented Carbide Friction Surface with Chevron Pattern Micro-texture Based on Different Texture Density, Tribol. Int., 2020, 142, p 106016.

Y.Q. Xing, J.X. Deng, X.S. Wang, K. Ehmann, and J. Cao, Experimental Assessment of Laser Textured Cutting Tools in Dry Cutting of Aluminum Alloys, J. Manuf. Sci. E., 2016, 138(7), p 071006.

H. Zhang, D.Y. Zhang, M. Hua, G.N. Dong, and K.S. Chin, A Study on the Tribological Behavior of Surface Texturing on Babbitt Alloy under Mixed or Starved Lubrication, Tribol. Lett., 2014, 56(2), p 305–315.

D.S. Yan, N.S. Qu, H.S. Li, and X.L. Wang, Significance of Dimple Parameters on the Friction of Sliding Surfaces Investigated by Orthogonal Experiments, Tribol. T., 2010, 53(5), p 703–712.

H. Zhang, Y. Liu, M. Hafezi, M. Hua, and G.N. Dong, A Distribution Design for Circular Concave Textures on Sectorial Thrust Bearing Pads, Tribol. Int., 2020, 149, p 105733.

D.Y. Zhang, F.F. Zhao, Y. Li, P.Y. Li, Q.F. Zeng, and G.N. Dong, Study on Tribological Properties of Multi-layer Surface Texture on Babbitt Alloys Surface, Appl. Surf. Sci., 2016, 390, p 540–549.

H. Zhang, M. Hua, G.N. Dong, D.Y. Zhang, and K.S. Chin, A Mixed Lubrication Model for Studying Tribological Behaviors of Surface Texturing, Tribol. Int., 2016, 93, p 583–592.

Y.Q. Xing, X. Li, R.Y. Hu, X.Y. Long, Z. Wu, and L. Liu, Numerical Analyses of Rectangular Micro-textures in Hydrodynamic Lubrication Regime for Sliding Contacts, Meccanica, 2021, 56(7), p 1–18.

Q.M. Hou, X.F. Yang, D. Li, J. Cheng, S.R. Wang, J.P. Xiao, and W.Y. Li, Tribological Performance of Hydrophobic and micro/nano Triangle Textured Rake Face of Cutting Tools, Appl. Surf. Sci., 2022, 571, p 151250.

J.H. Wang, Z.J. Yan, Z.Y. Shen, and X.X. Pan, Three-Dimensional CFD Analysis of the Influence of Surface Texture Morphology Parameters on Lubrication Performance, Lubr. Eng., 2021, 46(07), p 37–43. ((in Chinese))

K.M. Pedersen and N.S. Tiedje, Graphite Nodule Count and Size Distribution in Thin-walled Ductile Cast Iron, Mater. Charact., 2008, 59(8), p 1111–1121.

E.S. Rebouas, A.M. Braga, R.C.P. Marques, and P.P.R. Filho, A New Approach to Calculate the Nodule Density of Ductile Cast Iron Graphite Using a Level Set, Measurement, 2016, 89, p 316–321.

C.J. Li, J.S. Zhao, G.X. Zhu, X.C. Li, and G.D. Zhang, Influence of Crankshaft Journal Profile on Lubrication of Main Bearing, Lubr. Eng., 2021, 46(04), p 51–56. ((in Chinese))

J.L. Xu, Q. Yu, W.T. Liu, and L. Zou, Lubrication Characteristics Research Based on CFD for Tooth Surface Micro-dimple, Chin. Hydrau. Pneumatics., 2020, 03, p 76–83. ((in Chinese))

H. Li, H. Zhou, D.P. Zhang, P. Zhang, T. Zhou, and W. Su, Comparative Study of Induction Quenching and Laser Surface Texturing on Anti-wear Performance of 40Cr Steel, J. Mater. Eng. Perform., 2021, 30, p 2238–2244.

K. Zhan, Y.L. Zhang, L. Bao, Z. Yang, B. Zhao, and V. Ji, Surface Characteristic and Wear Resistance of QT-700-2 Nodular Cast Iron after Laser Quenching Combing with Shot Peening Treatment, Surf. Coat. Tech., 2021, 423, p 127589.

Z. Wu, Y.Q. Xing, and J.S. Chen, Improving the Performance of Micro-Textured Cutting Tools in Dry Milling of Ti-6Al-4V Alloys, Micromachines., 2021, 12(8), p 945–945.

Y.Q. Xing, J.X. Deng, Z. Wu, and F.F. Wu, High Friction and Low Wear Properties of Laser-Textured Ceramic Surface Under Dry Friction, Opt. Laser. Technol., 2017, 93, p 24–32.

Y.Q. Xing, X.S. Wang, Z.H. Du, Z.W. Zhu, Z. Wu, and L. Liu, Synergistic Effect of Surface Textures and DLC Coatings for Enhancing Friction and Wear Performances of Si3N4/TiC Ceramic, Ceram. Int., 2021, 48(15), p 514–524.

Funding

This work is supported by The National Natural Science Foundation of China (51872122), Natural Science Foundation of Shandong Province (ZR2022ME041) Project of Shandong Province Higher Educational Youth Innovation Science and Technology Program (2019KJB021), Shandong Provincial Central Leading Local Science and Technology Development Fund Project (YDZX2022003) and Taishan Scholars and Youth Innovation in Science & Technology Support Plan of Shandong Province University.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declared that they have no conflicts of interest to this work. We declare that we do not have any commercial or associative interest that represents a conflict of interest in connection with the work submitted.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhang, Y., Yang, X., Cong, J. et al. In Situ Microtexture Hydrodynamic Lubrication Characteristics of Ductile Cast Iron Crankshaft Surface. J. of Materi Eng and Perform 32, 7390–7405 (2023). https://doi.org/10.1007/s11665-022-07663-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-07663-x