Abstract

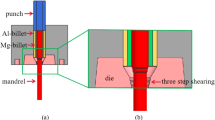

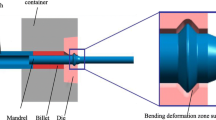

In this paper, the influence of tube extrusion shear (TES) and ordinary extrusion processes on the multiple-physical fields, microstructure, and bonding layer of Mg/Al bimetallic composite tubes at different preheating temperatures were investigated. Based on the characteristics of the TES process, the corresponding three-dimensional finite element thermal–mechanical coupling model and conditions were established by using DEFORM-3D. The variations of strain and stress of Mg/Al bimetallic composite tube at different deformation temperatures, and the effects of process parameters including extrusion velocity, preheating temperature, thicknesses of magnesium alloy billet, and friction factors on forming load were investigated. In addition, the change in multiple-physical fields in the whole TES process is simulated under preferable parameters. The results of OM and SEM show that the TES process can obviously refine the grains. And the metallurgical bonding effect of the Mg/Al bimetallic composite tube prepared by TES process is excellent under preferable process parameters, the hardness of the bonding layer is ~ 137.30 HV, and the shear bond strength is ~ 18.86 MPa.

Similar content being viewed by others

References

J.F. Song, J. She, D.L. Chen and F.S. Pan, Latest Research Advances on Magnesium and Magnesium Alloys Worldwide, J. Magnes. Alloys, 2020, 8, p 1–41.

G.H. Wu, C.L. Wang, M. Sun and W.J. Ding, Recent Developments and Applications on High-Performance Cast Magnesium Rare-Earth Alloys, J. Magnes. Alloys, 2021, 9, p 1–20.

S. Ahmadi, V. Alimirzaloo, G. Faraji and A. Doniavi, Properties Inhomogeneity of AM60 Magnesium Alloy Processed by Cyclic Extrusion Compression Angular Pressing Followed by Extrusion, Trans. Nonferrous Metal. Soc., 2021, 31, p 655–665.

S.G. Hong, S.H. Park and C.S. Lee, Role of 10–12 Twinning Characteristics in the Deformation Behavior of a Polycrystalline Magnesium Alloy, Acta Mater., 2010, 58, p 5873–5885.

S.M. Fatemi, A.A. KazemiAsl and H. Paul, Effects of Pretwins on Texture And Microstructural Evolutions of AZ31 Magnesium Alloy During High Temperature Deformation, J. Alloys Compd., 2022, 894, 162412.

D.W. Li, H.Y. Wang, D.S. Wei, Z.X. Zhao and Y. Liu, Effects of Deformation Texture and Grain Size on Corrosion Behavior of Mg-3Al-1Zn Alloy Sheets, ACS Omega, 2020, 5, p 1448–1456.

S.V. Lamaka, D. Höche, R.P. Petrauskas, C. Blawert and M.L. Zheludkevich, A New Concept for Corrosion Inhibition of Magnesium: Suppression of Iron Re-Deposition, Electrochem. Commun., 2016, 62, p 5–8.

B. Feng, Y.C. Xin, H.H. Yu, R. Hong and Q. Liu, Mechanical Behavior of a Mg/Al Composite Rod Containing a Soft Mg Sleeve and An Ultra Hard Al Core, Mater. Sci. Eng. A, 2016, 675, p 204–211.

H.J. Hu, X. Hong, Y. Tian and D.F. Zhang, AZ31 Magnesium Alloy tube Manufactured by Composite Forming Technology Including Extruded-Shear and Bending Based on Finite Element Numerical Simulation and Experiments, Int. J. Adv. Manuf. Technol., 2021, 115, p 2395–2402.

A.R. Eivani, H.R. Mirzakoochakshirazi and H.R. Jafarian, Investigation of Joint Interface and Cracking Mechanism of Thick Cladding of Copper on Aluminum by Equal Channel Angular Pressing (ECAP), J. Mater. Res. Technol., 2020, 9, p 3394–3405.

T. Zhang, Y.W. Shao, G.Z. Meng, Z.Y. Cui and F.H. Wang, Corrosion of Hot Extrusion AZ91 Magnesium Alloy: I-Relation Between the Microstructure and Corrosion Behavior, Corros. Sci., 2011, 53, p 1960–1968.

Y. Mahmoodkhani and M.A. Wells, Co-Extrusion Process to Produce Al–Mg Eutectic Clad Magnesium Products at Elevated Temperatures, J. Mater. Process. Technol., 2016, 232, p 175–183.

G.Y. Li, W.M. Jiang, F. Guan, J.W. Zhu, Z. Zhang and Z.T. Fan, Microstructure, Mechanical Properties and Corrosion Resistance of A356 Aluminum/AZ91D Magnesium Bimetal Prepared by a Compound Casting Combined with a Novel Ni-Cu Composite Interlayer, J. Mater. Process. Technol., 2021, 288, 116874.

G.Y. Li, W.M. Jiang, F. Guan, J.W. Zhu, Y. Yu and Z.T. Fan, Improving Mechanical Properties of AZ91D Magnesium/A356 Aluminum Bimetal Prepared by Compound Casting Via a High Velocity Oxygen Fuel Sprayed Ni Coating, J. Magnes. Alloys, 2022, 10, p 1075–1085.

N. Shi, W.X. Wang, T.T. Zhang, H.S. Chen and R.Y. Feng, Interface Bonding and Deformation Behavior of 6061Al/AZ31Mg Composite Tubes Fabricated by Stagger Spinning, Trans. Indian Inst. Met., 2021, 74, p 1373–1385.

G.Y. Li, W.C. Yang, W.M. Jiang, F. Guan, H.X. Jiang, Y. Wu and Z.T. Fan, The Role of Vacuum Degree in the Bonding of Al/Mg Bimetal Prepared by a Compound Casting Process, J. Mater. Process. Technol., 2019, 265, p 112–121.

S.H. You, Y.D. Huang, K.U. Kainer and N. Hort, Recent Research and Developments on Wrought Magnesium Alloys, J. Magnes. Alloys, 2017, 5, p 239–253.

P. Kumar, A. Madhup, P.R. Kalvala and S. Suwas, Texture Evaluation in AZ31/AZ31 Multilayer and AZ31/AA5068 Laminar Composite During Accumulative Roll Bonding, Def. Technol., 2020, 16, p 514–519.

S. Fan, W.M. Jiang, G.Y. Li, J.H. Mo and Z.T. Fan, Fabrication and Microstructure Evolution of Al/Mg Bimetal Using a Near-Net Forming Process, Mater. Manuf. Process., 2017, 32, p 1391–1397.

R. Kocich and L. Kunická, Development of Structure and Properties in Bimetallic Al/Cu Sandwich Composite During Cumulative Severe Plastic Deformation, J. Sandw. Struct. Mater., 2021, 23, p 4252–4275.

A. Sankaran, S. Vadakke Madam, A. Nouri and M.R. Barnett, Attaining High Compressive Strains in Pure Mg at Room Temperature by Encasing With Pure Al, Scr. Mater., 2012, 66, p 725–728.

B. Feng, X.W. Feng, C.J. Yan, Y.C. Xin, H.Y. Wang, J. Wang and K.H. Zheng, On the Rule of Mixtures for Bimetal Composites Without Bonding, J. Magnes. Alloys, 2020, 8, p 1253–1261.

B. Bnwa, F. Wab, Z. Wab, Z. Lab and B. Plma, Fabrication of Fine-Grained, High Strength and Toughness Mg Alloy by Extrusionshearing Process, Trans. Nonferrous Metal. Soc., 2021, 31, p 666–678.

X.X. Wang, X. Zhang, X.Y. Jing, J.C. Yuan and W. Song, Severe Plastic Deformation of Commercially Pure Aluminum Using Novel Equal Channel Angular Expansion Extrusion with Spherical Cavity, Trans. Nonferrous Metal. Soc., 2020, 30, p 2613–2624.

F. Fereshteh-Saniee, N. Fakhar and M. Karimi, Experimental, Analytical, and Numerical Studies on the Forward Extrusion Process, Mater. Manuf. Process., 2013, 28, p 265–270.

X.C. Meng, Y.Y. Jin, S.D. Ji and D.J. Yan, Improving Friction Stir Weldability of Al/Mg Alloys Via Ultrasonically Diminishing Pin Adhesion, J. Mater. Sci. Technol., 2018, 34, p 1817–1822.

C.C. Zhu, L.Q. Sun, W.L. Gao, G.Y. Li and J.J. Cui, The Effect of Temperature on Microstructure and Mechanical Properties of Al/Mg Lap Joints Manufactured by Magnetic Pulse Welding, J. Mater. Res. Technol., 2019, 8(3), p 3270–3280.

Xi. Qin, Study on Extrusion-Shear Composite Forming Technology and Microstructure Properties of Al/Mg Bimetallic Material, Chongq. Univ. Technol., 2020 https://doi.org/10.27753/d.cnki.gcqgx.2020.000289 (inChinese)

Acknowledgments

This work was supported by the Chongqing Talent Plan (CQYC202003047), and Chongqing Natural Science Foundation Project of cstc2018jcyjAX0653.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhao, J., Zhang, H., Zhang, W. et al. Influence of Extrusion Method on Formation of Magnesium-Aluminum Bimetallic Composite Tube. J. of Materi Eng and Perform 32, 7134–7148 (2023). https://doi.org/10.1007/s11665-022-07635-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-07635-1