Abstract

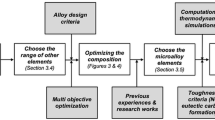

The study evaluates the microstructure, abrasion resistance, and corrosion behavior of newly designed cost-effective (Cr-Mo-W-V) steels. Six steels were designed with the help of computational thermodynamics to achieve a ferritic or duplex matrix with embedded hard carbides. The precursors of alloying elements were two commercial steels, namely HCx® and 316L. The wet abrasion tests and the corrosion tests revealed that the designed Cr-Mo-W-V steels have remarkable abrasion and corrosion resistance compared to the expensive commercial steel used as a precursor (HCx®). The least alloyed steel had the highest abrasion resistance owing to its low matrix/carbide hardness ratio and the presence of small intragranular carbides that led to a greater influence of the microstructure on the abrasion resistance than the hardness. Nickel played a key role in the formation of a passivation layer before the onset of corrosion; however, it must be added along with chromium and molybdenum for improved performance.

© of (a) HCx®, (b) 316L

©: (a) 5%, (b) 10%, (c) 15%, (d) 20%, (e) 30%, (f) 50%. Nominal carbon content indicated by the dotted line

Similar content being viewed by others

References

Stachowiak GW, Batchelor AW. Abrasive, erosive and cavitaion wear. Eng. Tribol., 2006, p. 501–50. https://doi.org/10.1016/B978-075067836-0/50012-2.

D. Hamm, C.O. Olsson and, D. Landolt, Effect of Chromium Content and Sweep Rate on Passive Film Growth on Iron-Chromium Alloys Studied by EQCM and XPS, Corros. Sci, 2002, 44, p 1009–1025. https://doi.org/10.1016/S0010-938X(01)00126-3

Pistorius PC. 2012 Accelerated Corrosion of Stainless Steel in Thiocyanate ‐ Containing Solutions PP 104

Y. Yu, S. Shironita, K. Souma and, M. Umeda, Effect of Chromium Content on the Corrosion Resistance of Ferritic Stainless Steels in Sulfuric Acid Solution, Heliyon, 2018, 4, e00958. https://doi.org/10.1016/j.heliyon.2018.e00958

N. Espallargas, P.D. Jakobsen, L. Langmaack and, F.J. Macias, Influence of Corrosion on the Abrasion of Cutter Steels Used in TBM Tunnelling, Rock. Mech. Rock. Eng, 2014, 48, p 261–275. https://doi.org/10.1007/s00603-014-0552-6

W.S. Labiapari, M.A.N. Ardila, H.L. Costa and, J.D.B. de Mello, Micro Abrasion-Corrosion of Ferritic Stainless Steels, Wear, 2017, 376–377, p 1298–1306. https://doi.org/10.1016/j.wear.2017.01.083

J.O. Bello, R.J.K. Wood and, J.A. Wharton, Synergistic Effects of Micro-Abrasion-Corrosion of UNS S30403, S31603 and S32760 Stainless Steels, Wear, 2007, 263, p 149–159. https://doi.org/10.1016/j.wear.2006.12.044

M. Maher, I. Iraola-Arregui, H. Ben Youcef, B. Rhouta and, V. Trabadelo, The Synergistic Effect of Wear-Corrosion in Stainless Steels: A Review, Mater. Today. Proc, 2021 https://doi.org/10.1016/j.matpr.2021.05.010

M. Arikan, H. Çimenoğlu and, E. Kayali, The Effect of Titanium on the Abrasion Resistance of 15Cr–3Mo white Cast Iron, Wear, 2001, 247, p 231–235. https://doi.org/10.1016/S0043-1648(00)00523-8

J.D. Bressan and R.A. Schopf, Abrasive wear Resistance of Tool Steels Evaluated by the Pin-On-Disc Testing, AIP. Conf. Proc, 2011, 1353, p 1753–1758. https://doi.org/10.1063/1.3589769

E. Gordo, N. Khattab and, J.M. Torralba, Sinterability and Properties of HCx PM Steel Diluted with Stainless Steels, Rev. Metal, 2010 https://doi.org/10.3989/revmetalm.2005.v41.iextra.1005

X.G. Lu, Z. Wang, Y. Cui and, Z. Jin, Computational Thermodynamics, Computational Kinetics, and Materials Design, Chin. Sci. Bull, 2014, 59, p 1662–1671. https://doi.org/10.1007/s11434-014-0219-4

Javaheri V. 2019 Design, Thermomechanical Processing and Induction Hardening of a New Medium-carbon Steel Microalloyed with Niobium. https://doi.org/10.13140/RG.2.2.24058.85446.

E. Costa and A. Silva, Using Computational Thermodynamics to Understand the Evolution of Solidification Segregation During Steel Processing, J. Phase. Equilibria. Diffus, 2020 https://doi.org/10.1007/s11669-020-00812-6

X. Xu, W. Xu, F.H. Ederveen and, S. van der Zwaag, Design of Low Hardness Abrasion Resistant Steels, Wear, 2013, 301, p 89–93. https://doi.org/10.1016/j.wear.2013.01.002

C. Zhang, F. Zhang, S. Chen and, W. Cao, Computational Thermodynamics Aided High-Entropy Alloy Design, Jom, 2012, 64, p 839–845. https://doi.org/10.1007/s11837-012-0365-6

R. Shi and A.A. Luo, Applications of CALPHAD Modeling and Databases in Advanced Lightweight Metallic Materials, Calphad. Comput. Coupling. Phase. Diagrams. Thermochem, 2018, 62, p 1–17. https://doi.org/10.1016/j.calphad.2018.04.009

Z. Sun, Y. Ma, D. Ponge, S. Zaefferer, E.A. Jägle, B. Gault et al., Thermodynamics-Guided Alloy and Process Design for Additive Manufacturing, Nat. Commun, 2022, 13, p 1–12. https://doi.org/10.1038/s41467-022-31969-y

B. Schaffernak and H. Cerjak, Design of Improved Heat Resistant Materials by Use of Computational Thermodynamics, VTT. Symp (Valtion Tek Tutkimuskeskus), 2001, 25, p 365–378.

A. Kroupa, Modelling of Phase Diagrams and Thermodynamic Properties Using Calphad Method - Development of Thermodynamic Databases, Comput. Mater. Sci, 2013, 66, p 3–13. https://doi.org/10.1016/j.commatsci.2012.02.003

S.L. Chen, S. Daniel, F. Zhang, Y.A. Chang, X.Y. Yan, F.Y. Xie et al., The PANDAT Software Package and its Applications, Calphad. Comput. Coupling. Phase. Diagram. Thermochem, 2002, 26, p 175–188. https://doi.org/10.1016/S0364-5916(02)00034-2

J.C. Zhao and, M.F. Henry, CALPHAD - Is it Ready for Superalloy Design?, Adv. Eng. Mater, 2002, 4, p 501–508. https://doi.org/10.1002/1527-2648(20020717)4:7%3c501::AID-ADEM501%3e3.0.CO;2-3

C.W. Bale, E. Bélisle, P. Chartrand, S.A. Decterov, G. Eriksson, A.E. Gheribi et al., FactSage Thermochemical Software and Databases, 2010–2016, Calphad. Comput. Coupling. Phase. Diagram. Thermochem, 2016, 54, p 35–53. https://doi.org/10.1016/j.calphad.2016.05.002

R.H. Davies, A.T. Dinsdale, J.A. Gisby, J.A.J. Robinson and, S.M. Martin, MTDATA - Thermodynamic and Phase Equilibrium Software from the National Physical Laboratory, Calphad. Comput. Coupling. Phase. Diagram. Thermochem, 2002, 26, p 229–271. https://doi.org/10.1016/S0364-5916(02)00036-6

K. Shobu, CaTCalc: new Thermodynamic Equilibrium Calculation Software, Calphad. Comput. Coupling. Phase. Diagram. Thermochem, 2009, 33, p 279–287. https://doi.org/10.1016/j.calphad.2008.09.015

P.F. Shi, A. Engström, B. Sundman and, J. Agren, Thermodynamic Calculations and Kinetic Simulations of Some Advanced Materials, Mater. Sci. Forum, 2011, 675(677), p 961–974. https://doi.org/10.4028/www.scientific.net/MSF.675-677.961

M. Dadfar, M.H. Fathi, F. Karimzadeh, M.R. Dadfar and, A. Saatchi, Effect of TIG Welding on Corrosion Behavior of 316L Stainless Steel, Mater. Lett, 2007, 61, p 2343–2346. https://doi.org/10.1016/j.matlet.2006.09.008

F.J.G. Silva, J. Santos and, R. Gouveia, Dissolution of Grain Boundary Carbides by the Effect of Solution Annealing Heat Treatment and Aging Treatment on Heat-resistant Cast Steel HK30, Metal. (Basel), 2017 https://doi.org/10.3390/met7070251

A. Sundström, J. Rendón and, M. Olsson, Wear Behaviour of Some Low Alloyed Steels Under Combined Impact/abrasion Contact Conditions, Wear, 2001, 250, p 744–754. https://doi.org/10.1016/S0043-1648(01)00712-8

A.R. Chintha, Metallurgical Aspects of Steels Designed to Resist Abrasion, and Impact-abrasion Wear, Mater Sci Technol, 2019, 35, p 1133–1148. https://doi.org/10.1080/02670836.2019.1615669

V. Ratia, K. Valtonen, A. Kemppainen and, V.T. Kuokkala, High-stress Abrasion and Impact-abrasion Testing of Wear Resistant Steels, Tribol. Online, 2013, 8, p 152–161. https://doi.org/10.2474/trol.8.152

M. Orečný, M. Buršák, M. Šebek and, L. Falat, Influence of Hardness, Matrix and Carbides in Combination with Nitridation on Abrasive Wear Resistance of X210Cr12 Tool Steel, Metal. (Basel), 2016 https://doi.org/10.3390/met6100236

L. Bourithis, G.D. Papadimitriou and, J. Sideris, Comparison of Wear Properties of Tool Steels AISI D2 and O1 with the Same Hardness, Tribol. Int, 2006, 39, p 479–489. https://doi.org/10.1016/j.triboint.2005.03.005

J. Rendón and M. Olsson, Abrasive Wear Resistance of Some Commercial Abrasion Resistant Steels Evaluated by Laboratory Test Methods, Wear, 2009, 267, p 2055–2061. https://doi.org/10.1016/j.wear.2009.08.005

P.J. Mutton and J.D. Watson, Some Effects of Microstructure on the Abrasion Resistance of Metals, Wear, 1978, 48, p 385–398. https://doi.org/10.1016/0043-1648(78)90234-X

K. Singh, R.K. Khatirkar and, S.G. Sapate, Microstructure Evolution and Abrasive Wear Behavior of D2 Steel, Wear, 2015, 328–329, p 206–216. https://doi.org/10.1016/j.wear.2015.02.019

Q.B. Nguyen, C.Y.H. Lim, V.B. Nguyen, Y.M. Wan, B. Nai, Y.W. Zhang et al., Slurry Erosion Characteristics and Erosion Mechanisms of Stainless Steel, Tribol Int, 2014, 79, p 1–7. https://doi.org/10.1016/j.triboint.2014.05.014

L. Xu, S. Wei, Y. Ji, G. Zhang, J. Li and, R. Long, Effect of Carbon on Frictional Wear Behaviours of High Vanadium High Speed Steel Under Dry Sliding Condition, Mater. Sci. Forum, 2010, 654–656, p 370–373. https://doi.org/10.4028/www.scientific.net/MSF.654-656.370

V. Javaheri, D. Porter and, V.T. Kuokkala, Slurry Erosion of Steel – Review of Tests, Mechanisms and Materials, Wear, 2018, 408–409, p 248–273. https://doi.org/10.1016/j.wear.2018.05.010

C.B. von der Ohe, R. Johnsen and, N. Espallargas, Modeling the Multi-degradation Mechanisms of Combined Tribocorrosion Interacting with Static and Cyclic Loaded Surfaces of Passive Metals Exposed to Seawater, Wear, 2010, 269, p 607–616. https://doi.org/10.1016/j.wear.2010.06.010

C. Trevisiol, A. Jourani and, S. Bouvier, Effect of Hardness, Microstructure, Normal Load and Abrasive Size on Friction and on Wear Behaviour of 35NCD16 Steel, Wear, 2017, 388, p 101–111. https://doi.org/10.1016/j.wear.2017.05.008

K. Wang and D. Li, Formation of Core (M7C3)-Shell (M23C6) Structured Carbides in White Cast Irons: A Thermo-Kinetic Analysis, Comput. Mater. Sci, 2018, 154, p 111–121. https://doi.org/10.1016/j.commatsci.2018.07.032

Cowan RL, Tedmon CS. Intergranular Corrosion of Iron-Nickel-Chromium Alloys. Adv Corros Sci Technol 1973, p. 293–400. https://doi.org/10.1007/978-1-4615-8258-8_3.

J. Chen, Q. Xiao, Z. Lu, X. Ru, G. Han, Y. Tian et al., The Effects of Prior-deformation on Anodic Dissolution Kinetics and Pitting Behavior of 316L Stainless Steel, Int. J. Electrochem. Sci, 2016, 11, p 1395–1415.

Y. Ait Albrimi, A. Eddib, J. Douch, Y. Berghoute, M. Hamdani and, R.M. Souto, Electrochemical Behaviour of AISI 316 Austenitic Stainless Steel in Acidic Media Containing Chloride Ions, Int. J. Electrochem. Sci, 2011, 6, p 4614–4627.

A. Fattah-Alhosseini and S. Vafaeian, Effect of solution pH on the electrochemical behaviour of AISI 304 Austenitic and AISI 430 Ferritic Stainless Steels in Concentrated Acidic Media, Egypt. J. Pet, 2015, 24, p 333–341. https://doi.org/10.1016/j.ejpe.2015.07.016

B. Jegdić, D.M. Dražić and, J.P. Popić, Corrosion Potential of 304 Stainless Steel in Sulfuric Acid, J. Serbian. Chem. Soc, 2006, 71, p 543–551. https://doi.org/10.2298/JSC0605543J

H. Katsuya, A. Takashi, Y. Takashi, T. Yutaka, N. Koe and, H. Yuzo, Effect of Al Si Mo on Passivation Characteristics of Fe-10Cr Alloys, Mater. Tran, 2001, 42, p 1723–1730.

M.F. Ashby and, D.R.H. Jones, Steels 2—Alloy Steels, Eng. Mater, 2013, 2, p 221–236. https://doi.org/10.1016/b978-0-08-096668-7.00013-9

N. Rujeerapaiboon, N. Anuwongnukroh, S. Dechkunakorn and, M. Jariyaboon, The Effects of Different Bending Techniques on Corrosion Resistance and Nickel Release of Superelastic Orthodontic NiTi Archwires, IOP. Conf. Ser. Mater. Sci. Eng, 2017 https://doi.org/10.1088/1757-899X/191/1/012038

Acknowledgments

The authors would like to thank the OCP foundation for the financial support through the doctoral program from Mohammed VI Polytechnic University. The help of CEIT-BRTA research center (Spain) in performing the experiments is highly acknowledged.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interests

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Maher, M., Iraola-Arregui, I., Idouhli, R. et al. Computational Thermodynamics-Aided Design of (Cr-Mo-W-V) Steels with Enhanced Corrosion and Abrasion Resistance. J. of Materi Eng and Perform 32, 7297–7310 (2023). https://doi.org/10.1007/s11665-022-07621-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-07621-7