Abstract

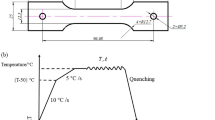

The present study investigates the variations in the microstructure and mechanical properties of AA2024 aluminum alloy as a consequence of thermal and strain gradient in combined hot forming cold die quenching (HFQ) and equal channel angular pressing (ECAP) method. Solution-treated AA2024 aluminum alloy was HFQ–ECAPed for five passes of deformation and 3D simulations plus microstructural evolutions, and mechanical properties over the thickness of the sample were investigated. Furthermore, after each ECAP pass, intermediate solution treatment was applied, and a group of specimens was subjected to aging treatment following the deformation. 3D simulations illustrated strain uniformity by increasing the number of deformation passes with its maximum uniformity after four passes. Microstructural observations demonstrated evident grain refinement in successive passes, which were higher in the central and top parts of the sample than in the lower area. Also, a high quantity of shear bands occurred in the workpiece after the first ECAP pass. However, shear banding was deducted in the consecutive passes of deformation and intermediate solutionizing. Preferable properties in central regions were seen comparing tensile properties in surface area and central parts. Besides, the microhardness test resulted in more uniform outcomes by enhancement in the number of ECAP passes. Hardness variations showed an increase in average hardness after the first pass of deformation (compared to the annealed condition (Baghbani Barenji et al. in J Mater Res Technol 9:1683–1697, 2020) and then a negligible decrease in the following two passes. The hardness quantities again increased in the fourth pass and then dramatically decreased after the fifth pass due to the partial decomposition of the solid solution. Besides, due to strain distribution, hardness values illustrate the maximum and minimum amount in the uppermost and lowermost areas, respectively. The overall conclusions of this article presented mechanical similarities in the surface and inner parts of the material.

Similar content being viewed by others

References

E. L. Rooy, Aluminum and Aluminum Alloys, in ASM Handbook, vol. 15, (1988), pp. 743e770

J.C. Williams and E.A. Starke, Progress in Structural Materials for Aerospace Systems, Acta Mater., 2003, 51(19), p 5775–5799. https://doi.org/10.1016/j.actamat.2003.08.023

T. Dursun and C. Soutis, Recent Developments in Advanced Aircraft Aluminium Alloys, Mater. Des., 2014, 56, p 862–871. https://doi.org/10.1016/j.matdes.2013.12.002

M. Alvand, M. Naseri, E. Borhani, and H. Abdollah-Pour, Microstructure and Crystallographic Texture Characterization of Friction Stir Welded Thin AA2024 Aluminum Alloy, Iran. J. Mater. Sci. Eng., 2018, 15, p 53–63.

Z. Horita, T. Fujinami, M. Nemoto et al., Equal-Channel Angular Pressing of Commercial Aluminum Alloys: Grain Refinement, Thermal Stability and Tensile Properties, Metall. Mater. Trans. A, 2000, 31, p 691–701. https://doi.org/10.1007/s11661-000-0011-8

W.J. Kim, C.S. Chung, D.S. Ma, S.I. Hong, and H.K. Kim, Optimization of Strength and Ductility of 2024 Al by Equal Channel Angular Pressing (ECAP) and Post-ECAP Aging, Scr. Mater., 2003, 49, p 333–338. https://doi.org/10.1016/S1359-6462(03)00260-4

M.H. Goodarzy, H. Arabi, M.A. Boutorabi, S.H. Seyedein, and S.H. Najafabadi, The Effects of Room Temperature ECAP and Subsequent Aging on Mechanical Properties of 2024 Al Alloy, J. Alloys Compd., 2014, 585, p 753–759. https://doi.org/10.1016/j.jallcom.2013.09.202

G. Kotan, E. Tan, Y.E. Kalay, and C.H. Gür, Homogenization of ECAPed Al 2024 Alloy through Age-Hardening, Mater. Sci. Eng. A, 2013, 559, p 601–606. https://doi.org/10.1016/j.msea.2012.08.148

J. Mao, S.B. Kang, and J.O. Park, Grain Refinement, Thermal Stability and Tensile Properties of 2024 Aluminum Alloy after Equal-Channel Angular Pressing, J. Mater. Process. Technol., 2005, 159, p 314–320. https://doi.org/10.1016/j.jmatprotec.2004.05.020

J.-Y. Jeon, R. Matsumoto, and H. Utsunomiya, Die Quenching Limit of AA2024 Aluminum Alloy Billet on Servo Press, J. Mater. Process. Technol., 2014, 214, p 2514–2521. https://doi.org/10.1016/j.jmatprotec.2014.05.015

S. Cheng, Y.H. Zhao, Y.T. Zhu, and E. Ma, Optimizing the Strength and Ductility of Fine Structured 2024 Al Alloy by Nano-Precipitation, Acta Mater., 2007, 55, p 5822–5832. https://doi.org/10.1016/j.actamat.2007.06.043

Wu. Dong, W. Li, K. Liu, Y. Yang, and S. Hao, Optimization of Cold Spray Additive Manufactured AA2024/Al2O3 Metal Matrix Composite with Heat Treatment, J. Mater. Sci. Technol., 2022, 106, p 211–224. https://doi.org/10.1016/j.jmst.2021.07.036

N.A. Krasilnikov and A. Sharafutdiniv, High Strength and Ductility of Nanostructured Al-Based Alloy, Prepared by High-Pressure Technique, Mater. Sci. Eng. A, 2007, 463, p 74–77. https://doi.org/10.1016/j.msea.2006.08.117

G. Tan, Y.E. Kalay, and C.H. Gür, Long-Term Thermal Stability of Equal Channel Angular Pressed 2024 Aluminum Alloy, Mater. Sci. Eng. A, 2016, 677, p 307–315. https://doi.org/10.1016/j.msea.2016.09.048

J. Zhou, S. Xu, S. Huang, X. Meng, J. Sheng, H. Zhang, J. Li, Y. Sun, and E.A. Boateng, Tensile Properties and Microstructures of a 2024-t351 Aluminum Alloy Subjected to Cryogenic Treatment, Metals, 2016, 6, p 279. https://doi.org/10.3390/met6110279

S.H. Mousavi Anijdan, D. Sadeghi-Nezhad, H. Lee, W. Shin, N. Park, M.J. Nayyeri, H.R. Jafarian, and A.R. Eivani, TEM Study of S’ Hardening Precipitates in the Cold Rolled and Aged AA2024 Aluminum Alloy: Influence on the Microstructural Evolution, Tensile Properties & Electrical Conductivity, J. Mater. Res. Technol., 2021, 13, p 798–807. https://doi.org/10.1016/j.jmrt.2021.05.003

S. Krymskiy, O. Sitdikov, E. Avtokratova, and M. Markushev, 2024 Aluminum Alloy Ultrahigh-Strength Sheet due to Two-Level Nanostructuring under Cryorolling and Heat Treatment, Trans. Nonferrous Metals Soc. China, 2020, 30(1), p 14–26. https://doi.org/10.1016/S1003-6326(19)65176-9

J.L. García-Hernández, C.G. Garay-Reyes, I.K. Gómez-Barraza, M.A. Ruiz-Esparza-Rodríguez, E.J. Gutiérrez-Castañeda, I. Estrada-Guel, M.C. Maldonado-Orozco, and R. Martínez-Sánchez, Influence of Plastic Deformation and Cu/Mg Ratio on the Strengthening Mechanisms and Precipitation Behavior of AA2024 Aluminum Alloys, J. Mater. Res. Technol., 2019, 8(6), p 5471–5475. https://doi.org/10.1016/j.jmrt.2019.09.015

X.-K. Meng, H. Wang, W.-S. Tan, J. Cai, J.-Z. Zhou, and L. Liu, Gradient Microstructure and Vibration Fatigue Properties of 2024-T351 Aluminium Alloy treated by Laser Shock Peening, Surf. Coat. Technol., 2020, 391, p 125698. https://doi.org/10.1016/j.surfcoat.2020.125698

Y. Zhao, X. Wang, T. Cao, J.-K. Han, M. Kawasaki, J.-I. Jang, H.N. Han, U. Ramamurty, L. Wang, and Y. Xue, Effect of Grain Size on the Strain Rate Sensitivity of CoCrFeNi High-Entropy Alloy, Mater. Sci. Eng. A, 2020, 782, p 139281. https://doi.org/10.1016/j.msea.2020.139281

R.Z. Valiev and T.G. Langdon, Principles of Equal-Channel Angular Pressing as a Processing Tool for Grain Refinement, Prog. Mater. Sci., 2006, 51, p 881–981.

R. Bakhshi, M.H. Farshidi, and S.A. Sajjadi, Strengthening of Aluminium Alloy 7005 through Imposition of Severe Plastic Deformation Supplemented by Different Ageing Treatments, Trans. Nonferrous Metals Soc. China, 2021, 31(10), p 2909–2921. https://doi.org/10.1016/S1003-6326(21)65702-3

R.B. Figueiredo and T.G. Langdon, Fabricating Ultrafine-Grained Materials through the Application of Severe Plastic Deformation: A Review of Developments in Brazil, J. Mater. Res. Technol., 2012, 1(1), p 55–62. https://doi.org/10.1016/S2238-7854(12)70010-8

R.N. Harsha, V.M. Kulkarni, and B.S. Babu, Severe Plastic Deformation: A Review, Mater. Today Proc., 2018, 5(10), p 22340–22349. https://doi.org/10.1016/j.matpr.2018.06.600

H.N. Radhi, A.M.H. Aljassani, and M.T. Mohammed, Effect of ECAP on Microstructure, Mechanical and Tribological Properties of Aluminum and Brass Alloys: A Review, Mater. Today Proc., 2020, 26(2), p 2302–2307. https://doi.org/10.1016/j.matpr.2020.02.497

C.G. de Faria, R.B. Figueiredo, M.T.P. Aguilar, and P.R. Cetlin, Strain Path Effects on the Development of Shear Bands during Shear Tests in Aluminum Alloy Processed by ECAP, J. Mater. Res. Technol., 2015, 4(3), p 297–303. https://doi.org/10.1016/j.jmrt.2015.01.009

W.J. Kim and J.Y. Wang, Microstructure of the Post-ECAP Aging Processed 6061 Al Alloys, Mater. Sci. Eng. A, 2007, 464, p 23–27. https://doi.org/10.1016/j.msea.2007.03.074

C.M. Cepeda-Jiménez, J.M. García-Infanta, O.A. Ruano, and F. Carreño, Mechanical Properties at Room Temperature of an Al-Zn-Mg-Cu Alloy Processed by Equal Channel Angular Pressing, J. Alloys Compd., 2011, 509, p 8649–8656. https://doi.org/10.1016/j.jallcom.2011.06.070

E.A. El-Danaf, Mechanical Properties, Microstructure and Texture of Single Pass Equal Channel Angular Pressed 1050, 5083, 6082 and 7010 Aluminum Alloys with Different Dies, Mater. Des., 2011, 32, p 3838–3853. https://doi.org/10.1016/j.matdes.2011.03.006

G. Ingarao, Manufacturing Strategies for Efficiency in Energy and Resources Use: The Role of Metal Shaping Processes, J. Clean. Prod, 2017, 142, p 2872–2886. https://doi.org/10.1016/j.jclepro.2016.10.182

E.G. Hertwich, S. Ali, L. Ciacci, T. Fishman, N. Heeren, E. Masanet et al., Material Efficiency Strategies to Reducing Greenhouse Gas Emissions Associated with Buildings, Vehicles, and Electronics: A Review, Environ. Res. Lett., 2019, 14, p 043004. https://doi.org/10.1088/1748-9326/ab0fe3

W. Yuna, C. Liu, H. Liao, J. Jiang, and A. Ma, Joint Effect of Micro-Sized Si Particles and Nano-Sized Dispersoids on the Flow Behavior and Dynamic Recrystallization of Near-Eutectic Al-Si Based Alloys during Hot Compression, J. Alloys Compd., 2021, 856, p 158072. https://doi.org/10.1016/j.jallcom.2020.158072

X. Zhuo, X. Haichao, W. Yuna, H. Zhichao, J. Jiang and A. Ma, Effect of Eutectic Si Size on the Flow Behavior and Hot Processing Map of Near Eutectic Al-Si Alloys, J. Mater. Res. Technol., 2021, 15, p 5694–5705. https://doi.org/10.1016/j.jmrt.2021.11.015

X. Zhuo, Q. Zhang, H. Liu, H. Zhichao, P. Zhang, J. Jiang, A. Ma, and W. Yuna, Enhanced Tensile Strength and Ductility of an Al-6Si-3Cu Alloy Processed by Room Temperature Rolling, J. Alloys Compd., 2022, 899, p 163321. https://doi.org/10.1016/j.jallcom.2021.163321

V.M. Segal, New Hot Thermo-Mechanical Processing of Heat Treatable Aluminum Alloys, J. Mater. Process. Technol., 2015 https://doi.org/10.1016/j.jmatprotec.2015.12.009

J. Jin, X. Wang, L. Deng, and J. Luo, A Single-Step Hot Stamping-Forging Process for Aluminum Alloy Shell Parts with Non-Uniform Thickness, J. Mater. Process. Technol., 2015 https://doi.org/10.1016/j.jmatprotec.2015.07.009

J. Lin, T.A. Dean, and R.P. Garrett, A Process in Forming High Strength and Complex-Shaped Al-Alloy Sheet Components. UK Patent WO2008059242 (2008)

P. Hidalgo-Manrique, S. Cao, H.R. Shercliff, R.D. Hunt, and J.D. Robson, Microstructure and Properties of Aluminium Alloy 6082 Formed by the Hot Form Quench Process, Mater. Sci. Eng. A, 2021, 804, p 140751. https://doi.org/10.1016/j.msea.2021.140751

S. Yuan, X. Fan, and Z. He, Hot Forming-Quenching Integrated Process with Cold-Hot Dies for 2A12 Aluminum Alloy Sheet, Proc. Eng., 2014, 81, p 1780–1785. https://doi.org/10.1016/j.proeng.2014.10.232

A. Foster, D. Szegda, and J. Sellors, Design Considerations for HFQ® Hot Stamped Aluminium Structural Panels. In: MATEC web conference, vol. 21, (2015) pp. 05014 https://doi.org/10.1051/matecconf/20152105014

X. Fan, Z. He, S. Yuan, and K. Zheng, Experimental Investigation on Hot Forming-Quenching Integrated Process of 6A02 Aluminum Alloy Sheet, Mater. Sci. Eng. A, 2013, 573, p 154–160. https://doi.org/10.1016/j.msea.2013.02.058

N. N, M.S. Mohamed, J. Cai, J. Lin, D. Balint, and T.A. Dean, Experimental and Numerical Studies on the Formability of Materials in Hot Stamping and Cold Die Quenching Processes. In: AIP conference proceedings, AIP (2011), pp. 1555–1561

M.S. Mohamed, A.D. Foster, J. Lin, D.S. Balint, and T.A. Dean, Investigation of Deformation and Failure Features in Hot Stamping of AA6082: Experimentation and Modelling, Int. J. Mach. Tools Manuf., 2012, 53, p 27–38. https://doi.org/10.1016/j.ijmachtools.2011.07.005

R.P. Garrett, J. Lin, and T.A. Dean, Solution Heat Treatment and Cold Die Quenching in Forming AA 6xxx Sheet Components: Feasibility Study, Adv. Mater. Res., 2005, 8, p 673–680. https://doi.org/10.4028/www.scientific.net/AMR.6-8.673

K. Zhao, Y. Chang, P. Hu, and Y. Wu, Influence of Rapid Cooling Pretreatment on Microstructure and Mechanical Property of Hot Stamped AHSS Part, J. Mater. Process. Technol., 2016, 228, p 68–75. https://doi.org/10.1016/j.jmatprotec.2014.09.022

X. Fan, Z. He, W. Zhou, and S. Yuan, Formability and Strengthening Mechanism of Solution Treated Al-Mg-Si Alloy Sheet under Hot Stamping Conditions, J. Mater. Process. Technol., 2016, 228, p 179–185. https://doi.org/10.1016/j.jmatprotec.2015.10.016

Y.F. Jiang, H. Ding, M.H. Cai, Y. Chen, Y. Liu, and Y.S. Zhang, Investigation into the Hot Forming-Quenching Integrated Process with Cold Dies for High Strength Aluminum Alloy, Mater. Charact., 2019, 158, p 109967. https://doi.org/10.1016/j.matchar.2019.109967

X. Fan, X. Wang, Y. Lin, Z. He, and S. Yuan, Deformation and Strengthening Behaviors of Al-Cu-Mg Alloy Thick Plate during Hot Forming-Quenching Integrated Process, J. Mater. Res. Technol., 2022, 16, p 1231–1242. https://doi.org/10.1016/j.jmrt.2021.12.069

A. Baghbani Barenji, A.R. Eivani, M. Hasheminiasari, N. Park, and H.R. Jafarian, Application of Hot Forming Cold Die Quenching for Facilitating Equal Channel Angular Pressing of AA2024 Aluminum Alloy, J. Alloys Compd., 2019, 791, p 265–277. https://doi.org/10.1016/j.jallcom.2019.03.059

A. Baghbani Barenji, A.R. Eivani, M. Hasheminiasari, and H.R. Jafarian, Effects of Hot Forming Cold Die Quenching and Inter-Pass Solution Treatment on the Evolution of Microstructure and Mechanical Properties of AA2024 Aluminum Alloy after Equal Channel Angular Pressing, J. Mater. Res. Technol., 2020, 9, p 1683–1697. https://doi.org/10.1016/j.jmrt.2019.11.092

A. Baghbani Barenji, A.R. Eivani, H.R. Jafarian, and N. Park, Effects of Hot Forming Cold Die Quenching and Solution Treatment on Formability and Pressing Load During Equal Channel Angular Deformation of AA2024 Aluminum Alloy, J. Mater. Res. Technol., 2020, 9(3), p 5599–5609. https://doi.org/10.1016/j.jmrt.2020.03.085

L. Wang, M. Strangwood, D. Balint, J. Lin, and T.A. Dean, Formability and Failure Mechanisms of AA2024 under Hot Forming Conditions, Mater. Sci. Eng. A., 2011, 528, p 2648–2656. https://doi.org/10.1016/j.msea.2010.11.084

N.Q. Chinh, J. Gubicza, T. Czeppe, J. Lendvai, C. Xu, R.Z. Valiev et al., Developing a Strategy for the Processing of Age-Hardenable Alloys by ECAP at Room Temperature, Mater. Sci. Eng. A, 2009, 516, p 248–252. https://doi.org/10.1016/j.msea.2009.03.049

M.R. Roshan, S.A.J. Jahromi, and R. Ebrahimi, Predicting the Critical Pre-Aging Time in ECAP Processing of Age-Hardenable Aluminum Alloys, J. Alloys Compd., 2011, 509, p 7833–7839. https://doi.org/10.1016/j.jallcom.2011.05.025

A.R. Eivani and A.K. Taheri, A New Method for Estimating Strain in Equal Channel Angular Extrusion, J. Mater. Process. Technol., 2007, 183, p 148–153. https://doi.org/10.1016/j.jmatprotec.2006.09.020

Y. Iwahashi, Z. Horita, M. Nemoto, and T.G. Langdon, The Process of Grain Refinement in Equal-Channel Angular Pressing, Acta Mater., 1998, 46, p 3317–3331. https://doi.org/10.1016/S1359-6454(97)00494-1

N. El Mahallawy, F.A. Shehata, M.A. El Hameed, M.I.A. El Aal, and H.S. Kim, 3D FEM Simulations for the Homogeneity of Plastic Deformation in Al-Cu Alloys during ECAP, Mater. Sci. Eng. A, 2010, 527(6), p 1404–1410. https://doi.org/10.1016/j.msea.2009.10.032

A. Ghosh and Ma. Ghosh, 3D FEM Simulation of Al-Zn-Mg-Cu Alloy during Multi-Pass ECAP with Varying Processing Routes, Mater. Today Commun., 2021, 26, p 102112. https://doi.org/10.1016/j.mtcomm.2021.102112

A.A.L. El Mohamed Ibrahim Abd, 3D FEM Simulations and Experimental Validation of Plastic Deformation of Pure Aluminum Deformed by ECAP and Combination of ECAP and Direct Extrusion, Trans. Nonferrous Metals Soc. China, 2017, 27(6), p 1338–1352. https://doi.org/10.1016/S1003-6326(17)60155-9

S. Dumoulin, H.J. Roven, J.C. Werenskiold, and H.S. Valberg, Finite Element Modeling of Equal Channel Angular Pressing: Effect of Material Properties, Friction and Die Geometry, Mater. Sci. Eng. A, 2005, 410–411, p 248–251. https://doi.org/10.1016/j.msea.2005.08.103

M. Ebrahimi, S. Attarilar, C. Gode et al., Damage Prediction of 7025 Aluminum Alloy during Equal-Channel Angular Pressing, Int. J. Miner. Metall. Mater., 2014, 21, p 990–998. https://doi.org/10.1007/s12613-014-1000-z

V.L. Sordi, A.A. Mendes Filho, G.T. Valio, P. Springer, J.B. Rubert, and M. Ferrante, Equal-Channel Angular Pressing: Influence of Die Design on Pressure Forces, Strain Homogeneity, and Corner Gap Formation, J. Mater. Sci., 2016, 51, p 2380–2393. https://doi.org/10.1007/s10853-015-9547-2

M. Prell, C. Xu, and T.G. Langdon, The Evolution of Homogeneity on Longitudinal Sections during Processing by ECAP, Mater. Sci. Eng. A., 2008, 480, p 449–455. https://doi.org/10.1016/j.msea.2007.08.011

S.C. Yoon and H.S. Kim, Finite Element Analysis of the Effect of the Inner Corner Angle in Equal Channel Angular Pressing, Mater. Sci. Eng. A, 2008, 490, p 438–444. https://doi.org/10.1016/j.msea.2008.01.066

A.V. Nagasekhar and H.S. Kim, Plastic Deformation Characteristics of Cross-Equal Channel Angular Pressing, Comput. Mater. Sci., 2008, 43, p 1069–1073. https://doi.org/10.1016/j.commatsci.2008.02.030

X.H. An, Q.Y. Lin, S.D. Wu, and Z.F. Zhang, Microstructural Evolution and Shear Fracture of Cu-16 at.% Al Alloy Induced by Equal Channel Angular Pressing, Mater. Sci. Eng. A, 2010, 527, p 4510–4514. https://doi.org/10.1016/j.msea.2010.03.101

A.A.S. Mohammed, E.A. El-danaf, and A.A. Radwan, A Criterion for Shear Banding Localization in Polycrystalline FCC Metals and Alloys and Critical Working Conditions for Different Microstructural Variables, J. Mater. Process. Technol., 2007, 186, p 14–21. https://doi.org/10.1016/j.jmatprotec.2006.11.028

J. Papasidero, V. Doquet, and S. Lepeer, Multiscale Investigation of Ductile Fracture Mechanisms and Strain Localization under Shear Loading in 2024–T351 Aluminum Alloy and 36NiCrMo16 Steel, Mater. Sci. Eng. A, 2014, 610, p 203–219. https://doi.org/10.1016/j.msea.2014.05.032

M. Ebrahimi, M.H. Shaeri, R. Naseri, and C. Gode, Equal Channel Angular Extrusion for Tube Configuration of Al-Zn-Mg-Cu Alloy, Mater. Sci. Eng. A, 2018, 731, p 569–576. https://doi.org/10.1016/j.msea.2018.06.080

H. Miyamoto, Corrosion of Ultrafine Grained Materials by Severe Plastic Deformation, an OVERVIEW, Mater. Trans., 2016, 57, p 559–572. https://doi.org/10.2320/matertrans.M2015452

M. Ebrahimi, Sh. Attarilar, M.H. Shaeri, C. Gode, H. Armoon, and F. Djavanroodi, An Investigation into the Effect of Alloying Elements on Corrosion Behavior of Severely Deformed Cu-Sn Alloys by Equal Channel Angular Pressing, Arch. Civ. Mech. Eng., 2019, 19(3), p 842–850. https://doi.org/10.1016/j.acme.2019.03.009

F. Djavanroodi, B. Omranpour, M. Ebrahimi, and M. Sedighi, Designing of ECAP Parameters Based on Strain Distribution Uniformity, Prog. Nat. Sci. Mater. Int., 2012, 22, p 452–460. https://doi.org/10.1016/j.pnsc.2012.08.001

F. Djavanroodi, M. Daneshtalab, and M. Ebrahimi, A Novel Technique to Increase Strain Distribution Homogeneity for ECAPed Materials, Mater. Sci. Eng. A, 2012, 535, p 115–121. https://doi.org/10.1016/j.msea.2011.12.050

H.K.Z. Xing and S. Kang, Softening Behavior of 8011 Alloy Produced by Accumulative Roll Bonding Process, Scr. Mater., 2001, 45, p 597–604.

C. Xu, M. Furukawa, Z. Horita, and T.G. Langdon, Influence of ECAP on Precipitate Distributions in a Spray-Cast Aluminum Alloy, Acta Mater., 2005, 53, p 749–758. https://doi.org/10.1016/j.actamat.2004.10.026

B.B. Straumal, B. Baretzky, A.A. Mazilkin, F. Phillipp, O.A. Kogtenkova, M.N. Volkov et al., Formation of Nano Grained Structure and Decomposition of Supersaturated Solid Solution during High Pressure Torsion of Al-Zn and Al-Mg Alloys, Acta Mater., 2004, 52, p 4469–4478. https://doi.org/10.1016/j.actamat.2004.06.006

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Baghbani Barenji, A., Eivani, A.R., Vafaeenezhad, H. et al. Finite Element Simulation and Experimental Investigation of Hot Forming Cold Die Quenching and Equal Channel Angular Pressing of AA2024 Aluminum Alloy. J. of Materi Eng and Perform 32, 6942–6956 (2023). https://doi.org/10.1007/s11665-022-07584-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-07584-9