Abstract

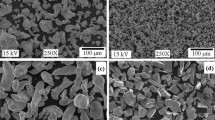

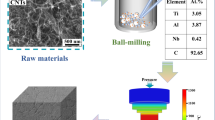

Ni3Si-based composites with different TiC contents are fabricated by in situ reaction sintering method. The phase composition, microstructure, microhardness, and tribological properties of the composites are studied. The results show that the addition of TiC particles prevents the formation of γ-Ni31Si12 phase, and the composites mainly consist of β1-Ni3Si and TiC phases. The composites have high hardness and relative density, and the values are above 580 HV and 87%, respectively. The friction coefficients are as low as 0.22. The wear rates of the composites are in the order of 10–6 mm3 m−1, which are two orders of magnitude lower than that of Ni3Si alloy. The primary wear mechanism of Ni3Si alloy is oxidation wear and slight abrasive wear, and the composites with TiC addition are oxidation wear and fatigue wear. The incorporation of TiC particles improves the tribological performance of Ni3Si alloy significantly. The composite with 20 wt.% TiC has the optimal tribological property.

Similar content being viewed by others

References

T. Takasugi, C.T. Liu, L. Heatherly, E.H. Lee and E.P. George, Boron Contaminations and their Kinetics in Ni3(Si, Ti) Alloys, Intermetallics, 1998, 6(5), p 369–377.

T. Takasugi and S. Hanada, The Influence of Second-Phase Dispersion on Environmental Embrittlement of Ni3(Si, Ti) Alloys, MRS Proceedings, 1998, 552, p 1–6.

C.M. Ward-Close, R. Minor ,and P.J. Doorbar, Intermetallic-Matrix Composites—A Review, Intermetallics, 1996, 4(3), p 217–229.

S.Q. Wang, X.X. Li, K.M. Chen ,and H.J. Jin, TiC/Ni3Al Coating on Steel Via Combustion Synthesis During Casting, Mater. Lett., 2007, 61(11–12), p 2531–2534.

S.Y. Zhu, Q.L. Bi, J. Yang, W.M. Liu ,and Q.J. Xue, Ni3Al Matrix High Temperature Self-Lubricating Composites, Tribol. Int., 2011, 44(4), p 445–453.

H. Liu, X. Zhang, Y. Jiang ,and R. Zhou, Microstructure and High Temperature Oxidation Resistance of in-Situ Synthesized TiN/Ti3Al Intermetallic Composite Coatings on Ti6Al4V Alloy by Laser Cladding Process, J. Alloys Compd., 2016, 670, p 268–274.

M.Y. Niu, Q.L. Bi, J. Yang ,and W.M. Liu, Tribological Performances of Ni3Si–Cr7C3 Composite Coatings Under Water and Acid Environments, Tribol. Int., 2012, 48, p 216–225.

T. Takasugi, H. Kawai ,and Y. Kaneno, The Effect of Cr Addition on Mechanical and Chemical Properties of Ni3Si Alloys, Mater. Sci. Eng. A, 2002, 329–331, p 446–454.

T. Takasugi, Microstructure and Tensile Properties of Ni3 (Si, Ti) Alloys Containing Second Phase Dispersions, Mater. Sci. Technol., 2000, 16, p 73–80.

T. Takasugi, Microstructural Control and Mechanical Properties of Nickel Silicides, Intermetallics, 2000, 8(5–6), p 575–584.

X.D. Lu, H.M. Wang and Z.R. Zhou, Reciprocating Sliding Wear Behavior of Laser-Clad Small Amplitude Mo2Ni3Si/NiSi Metal Silicide Composite Coatings, Appl. Surf. Sci., 2005, 240(1–4), p 432–440.

Y. Wang, and H.M. Wang, Wear Resistance of Laser Clad Ti2Ni3Si Reinforced Intermetallic Composite Coatings on Titanium Alloy, Appl. Surf. Sci., 2004, 229(1–4), p 81–86.

X.D. Lu and H.M. Wang, High-Temperature Phase Stability and Tribological Properties of Laser Clad Mo2Ni3Si/NiSi Metal Silicide Coatings, Acta Mater., 2004, 52(18), p 5419–5426.

M.Y. Niu, Q.L. Bi, L.Q. Kong, J. Yang ,and W.M. Liu, A Study of Ni3Si-Based Composite Coating Fabricated by Self-Propagating High Temperature Synthesis Casting Route, Surf. Coat. Technol., 2011, 205(17–18), p 4249–4253.

Y.Q. Pu, Q.L. Bi, J. Yang, J.M. Chen ,and Q.J. Xue, Effects of C Alloying on Microstructure and Properties of Ni-Si-Cr Ternary Alloys, Mater. Sci. Eng. A, 2008, 496(1–2), p 316–322.

Q.L. Bi, P.Q. La, W.M. Liu, Q.J. Xue ,and Y.T. Ding, Microstructure and Properties of Ni3Si Alloyed with Cr Fabricated by Self-Propagating High-Temperature Synthesis Casting Route, Metall. Mater. Trans. A, 2005, 36, p 1301–1307.

S. Van Dyck, L. Delaey, L. Froyen ,and L. Buekenhout, Reactive Powder Metallurgy of Ni3Si-Based Alloys, Intermetallics, 1995, 3(4), p 309–314.

Y. Miura, Y. Kaneno, T. Takasugi ,and A. Kakituji, Characterization of Ni3(Si, Ti) Intermetalic Alloys Synthesized by Powder Metallurgical Method, MRS Proc., 2013, 1516, p 121–126.

X. Zhang, M. Niu, C. Wu ,and J. Chen, The Effect of Titanium Addition on the Microstructure, Mechanical and Tribological Properties of Ni3Si Alloys Prepared by Powder Metallurgy Method, Materialwiss. Werkst., 2019, 50(12), p 1537–1544.

C. Wu, M. Niu, S. Bao, Y. Sun ,and X. Zhang, Friction and Wear Properties of Ni3Si Alloy with Ti Addition at High Temperatures, Materials, 2020, 13(4), p 982.

M. Niu, X. Zhang, J. Chen ,and X. Yang, Friction and Wear Properties of Ni3Si Alloy Under Different Vacuum Conditions, Vacuum, 2019, 161, p 443–449.

M. Niu, X. Zhang, F. Tu ,and J. Liang, The Tribological Properties of Ni3Si Alloys with Ti Addition Against Different Counterface Materials Under Seawater Condition, Mater. Res. Express, 2018, 5(11), 116533.

T. Takasugi, O. Izumi ,and M. Yoshida, Mechanical Properties of Recrystallized L12-type Ni3(Si, Ti) Intermetallics, J. Mater. Sci., 1991, 26(5), p 1173–1178.

F. Weitzer, M. Naka, N. Krendelsberger, F. Stein, C. He, Y. Du ,and J.C. Schuster, The Ternary System Nickel/Silicon/Titanium Revisited Zeitschrift für anorganische und allgemeine, Chemie, 2010, 636(6), p 982–990.

Y. Fujimoto, Y. Kaneno ,and T. Takasugi, Alloying Effect on Mechanical Properties and Oxidation Resistance of Cold-Rolled Ni3(Si, Ti) foils, Mater. Res. Soc. Symp. Proc., 2009, 1128, p 245–250.

T. Takasugi, H. Kawai ,and Y. Kaneno, Mechanical and Chemical Properties of Ni3Si and Ni3(Si, Ti) Alloys Multiphased by Chromium Addition, Mater. Sci. Technol., 2001, 17, p 671–680.

K.C. Ludema, O.O. Ajayi, Friction, Wear, Lubrication: A Textbook in Tribology (2nd ed.), 2nd ed., CRC Press, 2018

T. Takasugi, D. Shindo, O. Izumi ,and M. Hirabayashi, Metallographic and Structural Observations in the Pseudo-Binary Section Ni3Si-Ni3Ti of the Ni-Si-Ti System, Acta Metall. Mater., 1990, 38(5), p 739–745.

T. Takasugi, M. Nagashima ,and O. Izumi, Strengthening and Ductilization of Ni3Si by the Addition of Ti Elements, Acta Metall. Mater., 1990, 38(5), p 747–755.

G. Carja, E. Husanu, C. Gherasim ,and H. Iovu, Layered Double Hydroxides Reconstructed in NiSO4 Aqueous Solution as Highly Efficient Photocatalysts for Degrading Two Industrial Dyes, Appl. Catal. B, 2011, 107(3), p 253–259.

Z. Yu, D. Chen, M. Rønning, T. Vrålstad, E. Ochoa-Fernández, A. Holmen, Large-scale synthesis of carbon nanofibers on Ni-Fe-Al hydrotalcite derived catalysts: I. Preparation and characterization of the Ni–Fe–Al hydrotalcites and their derived catalysts, Appl. Catal. A: Gen., 338(1), 136–146 (2008)

J. Li, F. Meng, S. Suri, W. Ding, F. Huang ,and N. Wu, Photoelectrochemical Performance Enhanced by a Nickel Oxide−Hematite p−n junction Photoanode, Chem. Commun., 2012, 48(66), p 8213–8215.

C. Hallin, R. Yakimova, B. Pécz, A. Georgieva, T. Marinova, L. Kasamakova, R. Kakanakov ,and E. Janzén, Improved Ni Ohmic Contact on n-type 4H-SiC, J. Electron. Mater., 1997, 26(3), p 119–122.

T. Marinova, V. Krastev, C. Hallin, R. Yakimova ,and E. Janzén, Interface Chemistry and Electric Characterisation of Nickel Metallisation on 6H-SiC, Appl. Surf. Sci., 1996, 99(2), p 119–125.

Y. Xu, J. Yang, T. Liao, R. Ge, Y. Liu, J. Zhang, Y. Li, M. Zhu, S. Li and W. Li, Bifunctional Water Splitting Enhancement by Manipulating Mo-H bonding Energy of Transition Metal-Mo2C Heterostructure catalysts, Chem. Eng. J., 2022, 431, 134126.

X. Zhao and G. Lu, Improving Catalytic Activity and Stability by in-Situ Regeneration of Ni-Based Catalyst for Hydrogen Production from Ethanol Steam Reforming Via Controlling of Active Species Dispersion, Int. J. Hydrogen Energy, 2016, 41(32), p 13993–14002.

J. Li, B.B. Yang, Y.H. Lu, L. Xin, Z.H. Wang ,and T. Shoji, The degradation Mechanism of Inconel 690TT Induced by Fretting Wear in Air, Tribol. Int., 2017, 116, p 147–154.

A. Busiakiewicz, W. Kozłowski, P. Dąbrowski, M. Rogala ,and Z. Klusek, Temperature-Induced Segregation of Co- and Ni-rich Nanoparticles on Rutile TiO2(001), Mater. Res. Express, 2016, 3(8), 085004.

X. Gai, Y. Bai, J. Li, S. Li, W. Hou, Y. Hao, X. Zhang, R. Yang ,and R.D.K. Misra, Electrochemical Behaviour of Passive Film Formed on the Surface of Ti-6Al-4V Alloys Fabricated by Electron Beam melting, Corros. Sci., 2018, 145, p 80–89.

C.L. Chu, R.M. Wang, T. Hu, L.H. Yin, Y.P. Pu, P.H. Lin, S.L. Wu, C.Y. Chung, K.W.K. Yeung ,and P.K. Chu, Surface Structure and Biomedical Properties of Chemically Polished and Electropolished NiTi Shape Memory Alloys, Mater. Sci. Eng., C, 2008, 28(8), p 1430–1434.

C.L. Chu, C.Y. Chung, J. Zhou, Y.P. Pu ,and P.H. Lin, Fabrication and Characteristics of Bioactive Sodium Titanate/Titania Graded Film on NiTi Shape Memory Alloy, J Biomed Mater Res A, 2005, 75A(3), p 595–602.

Y.-L. Lin, T.-J. Wang ,and Y. Jin, Surface Characteristics of Hydrous Silica-Coated TiO2 Particles, Powder Technol., 2002, 123(2), p 194–198.

Y. Qin and M. Hu, Characterization and Field Emission Characteristics of Carbon Nanotubes Modified by Titanium Carbide, Appl. Surf. Sci., 2008, 254(11), p 3313–3317.

S. Kim and S.K. Lim, Preparation of TiO2-Embedded Carbon Nanofibers and their Photocatalytic Activity in the Oxidation of Gaseous Acetaldehyde, Appl. Catal. B, 2008, 84(1), p 16–20.

J. Du, J. Zhang, Z. Liu, B. Han, T. Jiang ,and Y. Huang, Controlled Synthesis of Ag/TiO2 Core−Shell Nanowires with Smooth and Bristled Surfaces via a One-Step Solution Route, Langmuir, 2006, 22(3), p 1307–1312.

Q. Ling, J. Sun ,and Q. Zhou, Preparation and Characterization of Visible-Light-Driven Titania Photocatalyst Co-Doped with Boron and Nitrogen, Appl. Surf. Sci., 2008, 254(10), p 3236–3241.

W.A.M. Aarnink, A. Weishaupt ,and A. van Silfhout, Angle-Resolved X-Ray Photoelectron Spectroscopy (ARXPS) and a Modified Levenberg-Marquardt Fit Procedure: a New Combination for Modeling Thin Layers, Appl. Surf. Sci., 1990, 45(1), p 37–48.

B. Deng, J. Li, H. Shang, W. Liu, Q. Wan, M. Chen, M. Qu, G. Peng (2020) Improving cyclic stability of LiNi0.6Co0.2Mn0.2O2-SiOx/graphite full cell using tris(trimethylsilyl)phosphite and fluoroethylene carbonate as combinative electrolyte additive, Ionics, 26(5), 2247–2257

K.J. Kim, D.W. Moon, S.H. Nam, W.J. Lee and H.G. Kim, XPS Sputter Depth Profiling of the Chemical States for SrTiO3/Si Interface by O2+ Ion Beams, Surf. Interface Anal., 1995, 23(13), p 851–857.

M. Garza, J. Liu, N.P. Magtoto and J.A. Kelber, Adhesion Behavior of Electroless Deposited Cu on Pt/Ta Silicate and Pt/SiO2, Appl. Surf. Sci., 2004, 222(1), p 253–262.

P. Zhang, Z. Cai and W. Xiong, Influence of Si Content and Growth Condition on the Microstructure and Mechanical Properties of Ti-Si-N Nanocomposite Films, Surf. Coat. Technol., 2007, 201(15), p 6819–6823.

Acknowledgments

This work was supported by the National Natural Science Foundation of China (No. 51805227 and No. 51505199) and the open project of Zhenjiang Key Laboratory of Marine Functional Thin Film Materials High Technology Research (No. ZHZ2019011).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Niu, M., Bao, S., Wu, J. et al. Fabrication and Properties of Ni3Si-TiC Composites by In Situ Reaction Sintering. J. of Materi Eng and Perform 32, 6083–6091 (2023). https://doi.org/10.1007/s11665-022-07538-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-07538-1