Abstract

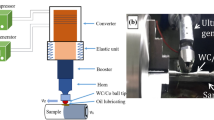

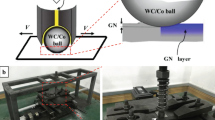

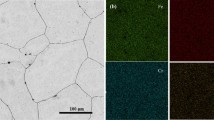

In this work, a gradient twin structure of a CrCoNi medium entropy alloy (MEA) was constructed by using the ultrasonic vibration surface friction treatment (UV-SFT) under different deformation forces. As for such a gradient twin structure, its overall and specific structures were characterized with the optical microscopy (OM) and transmission electron microscopy (TEM), respectively. The microhardness as well as tensile mechanical properties of such a constructed CrCoNi MEA with gradient twin structures were tested, and its strain hardening ability was evaluated and analyzed. As for a CrCoNi MEA, experimental results show that the UV-SFT successfully leads to its gradient twin structure with similar layers under different deformation forces, which can be divided into three regions: (1) a transition zone, (2) a severe plastic deformation zone, and (3) a nano-grain zone. The UV-SFT process of 300, 450, and 750 N enhances the microhardness value by 2.44 times, 2.55 times, and 2.77 times that of the core and significantly improves the engineering yield strength (from 209.8 ± 5.0 to 450.5 ± 10.0 MPa, 575.1 ± 5.0, and 610.7 ± 5.0 MPa), engineering ultimate tensile strength (from 474.8 ± 3.0 to 649.3 ± 5.0, 713.7 ± 5.0 MPa, and 803.4 ± 5.0), true yield strength (from 214.7 ± 5.0 to 497.7 ± 10.0, 593.5 ± 10.0, and 627.3 ± 10.0 MPa), as well as true ultimate tensile strength (from 965.6 ± 2.0 to 1100.0 ± 5.0, 1175.9 ± 5.0, and 1340.5 ± 5.0 MPa), respectively. The most noteworthy improvement is that the surface plastic deformation of ultrasonic vibration does not reduce the plasticity of the CrCoNi MEA, which ensures its favorable mechanical properties and fracture toughness.

Similar content being viewed by others

References

Y. Ma, F.P. Yuan, M.X. Yang et al., Dynamic Shear Deformation of a CrCoNi Medium Entropy Alloy with Heterogeneous Grain Structures, Acta. Mater., 2018, 148, p 407–418.

G.A. He, Y.F. Zhao, B. Gan et al., Mechanism of Grain Refinement in an Equiatomic Medium-Entropy Alloy CrCoNi During Hot Deformation, J. Alloy. Compd., 2020, 815, p 152382.

S.Q. Xia, M.C. Gao and Y. Zhang, Abnormal Temperature Dependence of Impact Toughness in AlxCoCrFeNi System High Entropy Alloys, Mater. Chem. Phys., 2018, 210, p 213–221.

D.Y. Li and Y. Zhang, The Ultrahigh Charpy Impact Toughness of Forged AlxCoCrFeNi High Entropy Alloys at Room and Cryogenic Temperatures, Intermetallics, 2016, 70, p 24–28.

X.L. Wu, M.X. Yang, P. Jiang et al., Deformation Nanotwins Suppress Shear Banding During Impact Test of CrCoNi Medium-Entropy Alloy, Scripta. Mater., 2020, 178, p 452–456.

M.X. Yang, L.L. Zhou, C. Wang et al., High Impact Toughness of CrCoNi Medium-Entropy Alloy at Liquid-Helium Temperature, Scripta. Mater., 2019, 172, p 66–71.

J.P. Liu, J.X. Chen, T.W. Liu et al., Superior Strength-Ductility CoCrNi Medium-Entropy Alloy Wire, Scripta. Mater., 2020, 181, p 19–24.

Y.L. Zhao, T. Yang, Y. Tong et al., Heterogeneous Precipitation Behavior and Stacking-Fault-Mediated Deformation in a CoCrNi-Based Medium-Entropy Alloy, Acta. Mater., 2017, 138, p 72–82.

S. Pan, C.C. Zhao, P.B. Wei et al., Sliding Wear of CoCrNi Medium-Entropy Alloy at Elevated Temperatures: Wear Mechanism Transition and Subsurface Microstructure Evolution, Wear, 2019, 440–441, p 203108.

G. Laplanche, A. Kostka, C. Reinhart et al., Reasons for the Superior Mechanical Properties of Medium-Entropy CrCoNi Compared to High-Entropy CrMnFeCoNi, Acta. Mater., 2017, 128, p 292–303.

W. Woo, M. Naeem, J.S. Jeong et al., Comparison of Dislocation Density, Twin Fault Probability, and Stacking Fault Energy Between CrCoNi and CrCoNiFe Medium Entropy Alloys Deformed at 293 and 140K, Mater. Sci. Eng. A, 2020, 781, p 139224.

K.M. Rahman, V.A. Vorontsov and D. Dye, The Effect of Grain Size on the Twin Initiation Stress in a TWIP Steel, Acta. Mater., 2015, 89, p 247–257.

L. Wang, J.A. Benito, J. Calvo and J.M. Cabrera, Twin-Induced Plasticity of an ECAP-Processed TWIP Steel, J. Mater. Eng. Perform., 2017, 26(2), p 554–562.

L. Wang, J.A. Benito, J. Calvo and J.M. Cabrera, Equal Channel Angular Pressing of a TWIP Steel: Microstructure and Mechanical Response, J. Mater. Sci., 2017, 52(11), p 6291–6309.

R.J. Mohammad and P. Hesam, Elucidating the Microscopic Origin of Electrochemical Corrosion and Electrical Conductivity by Lattice Response to Severe Plastic Deformation in Al-Mn-Si Alloy, Mater. Res. Bull., 2018, 108, p 195–206.

R.J. Mohammad, P. Hesam, K.G.S. Mohammadreza, K. Gholamreza and S. Masoud, On the Effect of Non-Isothermal Annealing and Multi-Directional Forging on the Microstructural Evolutions and Correlated Mechanical and Electrical Characteristics of Hot-Deformed Al-Mg alloy, Mater. Sci. Eng. A, 2016, 657, p 431–440.

P. Hesam, H.S. Shim, Y.K. Kim, M.S. Rizi, H. Noh and S.I. Hong, Microstructure Evolution and Mechanical Properties of (CoCrNi)90(AlTiZr)5(CuFeMo)5 Multicomponent Alloy: a Pathway Through Multicomponent Alloys Toward New Superalloys, J. Alloy. Compd., 2021, 860, p 158412.

H.S. Shim, P. Hesam and S.I. Hong, Hierarchical Structured as-Cast Crfenimn0.5cu0.5 High Entropy Alloy with Excellent Tensile Strength/Ductility Properties, Scripta Mater., 2022, 210, p 114473.

L. Wang, M.Y. Li, H. Tan, Y.M. Feng and Y.T. Xi, Enhanced Mechanical Properties of a Gradient Nanostructured Medium Manganese Steel and its Grain Refinement Mechanism, J. Mater. Eng. Perform., 2020, 29(6), p 3812–3823.

X.L. Wu, P. Jiang, L. Chen et al., Extraordinary Strain Hardening by Gradient Structure, Proc. Natl. Acad. Sci. U.S.A., 2014, 111, p 7197–7201.

S.Q. Yuan, B. Gan, L. Qian et al., Gradient Nanotwinned CrCoNi Medium-Entropy Alloy with Strength-Ductility Synergy, Scripta Mater., 2021, 203, p 114117.

W. Guo, Z.R. Pei, X.H. Sang et al., Shape-Preserving Machining Produces Gradient Nanolaminate Medium Entropy Alloys with High Strain Hardening Capability, Acta. Mater., 2019, 170, p 176–186.

Y. Liu, Y. He and S.L. Cai, Effect of Gradient Microstructure on the Strength and Ductility of Medium-Entropy Alloy Processed by Severe Torsion Deformation, Mater. Sci. Eng. A, 2021, 801, p 140429.

H. Huang, J.Y. Wang, H.L. Yang et al., Strengthening CoCrNi Medium-Entropy Alloy by Tuning Lattice Defects, Scripta. Mater., 2020, 188, p 216–221.

W.J. Lu, X. Luo, D. Ning et al., Excellent Strength-Ductility Synergy Properties of Gradient Nano-Grained Structural CrCoNi Medium-Entropy Alloy, J. Mater. Sci. Technol., 2022, 112, p 195–201.

F. Yin, S. Hu, R. Xu et al., Ultrastrong Medium Entropy Alloy with Simultaneous Strength-Ductility Improvement via Heterogeneous Nanocrystalline Structures, Mater. Sci. Eng. A, 2021, 823, p 141631.

Z. Li, X. Li, Z.Y. Huang et al., Ultrasonic-Vibration-Enhanced Plasticity of an Entropic Alloy at Room Temperature, Acta. Mater., 2022, 225, p 117569.

D. Barbier, N. Gey, S. Allain, N. Bozzolo and M. Humbert, Analysis of the Tensile Behavior of a TWIP Steel Based on the Texture and Microstructure Evolutions, Mater. Sci. Eng. A, 2009, 500, p 196–206.

N. Ao, D.X. Liu, X.C. Xu, X.H. Zhang and D. Liu, Gradient Nanostructure Evolution and Phase Transformation of α Phase in Ti-6Al-4V Alloy Induced by Ultrasonic Surface Rolling Process, Mater. Sci. Eng. A, 2019, 742, p 820–834.

N. Ao, D.X. Liu, X.H. Zhang and C.S. Liu, Enhanced Fatigue Performance of Modified Plasma Electrolytic Oxidation Coated Ti-6Al-4V alloy: Effect of Residual Stress and Gradient Nanostructure, Appl. Surf. Sci., 2019, 489, p 595–607.

N. Ao, D.X. Liu, X.H. Zhang, K.F. Fan, H.L. Shi, Z. Liu and C.S. Liu, The Effect of Residual Stress and Gradient Nanostructure on the Fretting Fatigue Behavior of Plasma Electrolytic Oxidation Coated Ti-6Al-4V Alloy, J. Alloy. Compd., 2019, 811, p 152017.

R.B. Lindsay, Mechanical radiation, McGraw-Hill, New York, 1960.

F. Ahmadi, M. Farzin and M. Mandegari, Effect of Grain Size on Ultrasonic Softening of Pure Aluminum, Ultrasonics, 2015, 63, p 111–117.

E. Bitzek and P. Gumbsch, Dynamic Aspects of Dislocation Motion: Atomistic Simulations, Mater. Sci. Eng. A, 2005, 400, p 40–44.

S. Vercammen, B. Blanpain, B.C. Cooman and P. Wollants, Cold Rolling Behaviour of an Austenitic Fe-30Mn-3Al-3Si TWIP Steel: the Importance of Deformation TwinNING, Acta. Mater., 2004, 52, p 2005–2012.

O. Bouaziz and N. Guelton, Modelling of TWIP Effect on Work-Hardening, Mater. Sci. Eng A, 2001, 319–321, p 246–249.

M.N. Shiekhelsouk, V. Favier and K.I. Cherkaoui, Modelling the Behaviour of Polycrystalline Austenitic Steel with Twinning-Induced Plasticity Effect, Int. J. Plast, 2009, 25, p 105–133.

C. Suh, G. Song, M. Suh and Y. Pyoun, Fatigue and Mechanical Characteristics of Nano-Structured tool Steel by Ultrasonic Cold Forging Technology, Mater. Sci. Eng. A, 2007, 443, p 101–106.

S.H. Luo, Y.H. Li, L.C. Zhou, X.F. Nie, G.Y. He, Y.Q. Li and W.F. He, Surface Nanocrystallization of Metallic Alloys with Different Stacking Fault Energy Induced by Laser Shock Processing, Mater. Des., 2016, 104, p 330–326.

C. Ma, M.T. Andani, H. Qin, N.S. Moghaddam, H. Ibrahim, A. Jahadakbar, A. Amerinatanzi, Z. Ren, H. Zhang, G.L. Doll, Y. Dong, M. Elahinia and C. Ye, Improving Surface Finish and Wear Resistance of Additive Manufactured Nickel-Titanium by Ultrasonic Nano-Crystal Surface Modification, J. Mater. Process. Technol., 2017, 249, p 433–440.

D.A. Hughes, R.A. Lebensohn, H.R. Wenk and A. Kumar, Stacking Fault Energy and Microstructure Effects on Torsion Texture Evolution, Proc. R. Soc. A, 2000, 456, p 921–953.

J.E. Jin and Y.K. Lee, Strain Hardening Behavior of a Fe-18Mn-0.6C-1.5Al TWIP Steel, Mater. Sci. Eng. A, 2009, 527, p 157–161.

Acknowledgments

The present work has been financially supported by National Natural Science Foundation of China Project (Grant No.: 12102340), Young Scientific Research and Innovation Team of the Xi'an Shiyou University (Grant No.: 2019QNKYCXTD14), State Key Laboratory of Metastable Materials Science and Technology (Grant No.: 202111), State Key Lab of Advanced Metals and Materials (Grant No.: 2021-Z06), Opening project fund of Materials Service Safety Assessment Facilities (Grant No.: MSAF-2021-101), China Scholarship Council Foundation (Grant No.: 202208615046), and Postgraduate Innovation and Practical Ability Training Program of the Xi'an Shiyou University (Grant No.: YCS21211057). The authors also acknowledge a Discovery Grant and a Collaborative Research and Development (CRD) Grant from the Natural Sciences and Engineering Research Council (NSERC) of Canada to D. Yang.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Xi, Y., Zhao, X., Wang, L. et al. Effect of Ultrasonic Vibration Surface Plastic Deformation Forces on Microstructure and Mechanical Properties of a Medium Entropy Alloy. J. of Materi Eng and Perform 32, 4712–4723 (2023). https://doi.org/10.1007/s11665-022-07410-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-07410-2