Abstract

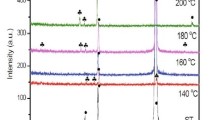

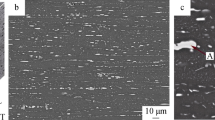

In order to obtain the optimal parameters for thixoforging of A356 aluminum alloy parts, the effects of heating temperature and holding time on the microstructure and mechanical properties of the formed parts with or without T6 heat treatment obtained via thixoforging hot-deformation A356 aluminum alloy directly heated to semi-solid temperature were investigated. Microstructure results showed that lower temperature and shorter holding time refined the grains. The tensile tests results showed that optimal parameters for thixoforging of A356 were heating temperature of 590 °C and holding time of 1 min. TEM results showed that needle-like β" aging precipitated particles with a size of 5 × 5 × 50 nm and equiaxed silicon particles of 50 nm were uniformly distributed in the matrix after T6 heat treatment, which were the strengthening phases of A356 alloy. The needle-like β’’ phases were parallel to the < 001 > crystal orientation of the matrix. The strengthening phase precipitated by aging increased the yield strength and tensile strength and decreased the elongation. The thixoforging parts under optimal parameters exhibited a yield strength of 291.3 MPa, the tensile strength of 324.9 MPa and the elongation of 10.2% after standard T6 heat treatment.

Similar content being viewed by others

References

K. Kawajiri, M. Kobayashi, and K. Sakamoto, Lightweight Materials Equal Lightweight Greenhouse Gas Emissions?: A Historical Analysis of Greenhouse Gases of Vehicle Material Substitution, J. Clean. Prod., 2020, 253, p 119805. https://doi.org/10.1016/j.jclepro.2019.119805

K. Zheng, D.J. Politis, L. Wang, and J. Lin, A Review on Forming Techniques for Manufacturing Lightweight Complex—Shaped Aluminium Panel Components, Int. J. Lightweight Mater. Manuf., 2018, 1, p 55-80. https://doi.org/10.1016/j.ijlmm.2018.03.006

L. Ren, L. Fan, M. Zhou, Y. Guo, Y. Zhang, C.J. Boehlert, and G. Quan, Magnesium Application in Railway Rolling Stocks: A New Challenge and Opportunity for Lightweighting, Int. J. Lightweight Mater. Manuf., 2018, 1, p 81-88. https://doi.org/10.1016/j.ijlmm.2018.05.002

J. Hirsch, Recent Development in Aluminium for Automotive Applications, Trans. Nonferrous Met. Soc. China., 2014, 24, p 1995-2002. https://doi.org/10.1016/S1003-6326(14)63305-7

G. Liu, J. Gao, C. Che, Z. Lu, W. Yi, and L. Zhang, Optimization of Casting Means and Heat Treatment Routines for Improving Mechanical and Corrosion Resistance Properties of A356-0.54Sc Casting Alloy, Mater. Today Commun., 2020, 24, p 101227. https://doi.org/10.1016/j.mtcomm.2020.101227

M. Gurtaran and M. Uludağ, Effect of Ti Addition Holding Time on Casting Quality and Mechanical Properties of A356 Alloy, SN Appl. Sci., 2020, 2, p 1833. https://doi.org/10.1007/s42452-020-03659-1

M.S. Salleh, M.Z. Omar, J. Syarif, and M.N. Mohammed, An Overview of Semisolid Processing of Aluminium Alloys, ISRN Mater. Sci., 2013, 2013, p 679820. https://doi.org/10.1155/2013/679820

M.C. Flemings, Behavior of Metal Alloys in the Semisolid State, Metall. Trans. A., 1991, 22, p 957-981. https://doi.org/10.1007/BF02661090

D.B. Spencer, R. Mehrabian, and M.C. Flemings, Rheological Behavior of Sn-15 pct Pb in the Crystallization Range, Metall. Mater. Trans. B., 1972, 3, p 1925-1932. https://doi.org/10.1007/BF02642580

H.V. Atkinson, Modelling the Semisolid Processing of Metallic Alloys, Prog. Mater. Sci., 2005, 50, p 341-412. https://doi.org/10.1016/j.pmatsci.2004.04.003

M. Li, Y. Li, G. Bi, X. Huang, T. Chen, and Y. Ma, Effects of Melt Treatment Temperature and Isothermal Holding Parameter on Water-Quenched Microstructures of A356 Aluminum Alloy Semisolid Slurry, Trans. Nonferrous Met. Soc. China., 2018, 28, p 393-403. https://doi.org/10.1016/S1003-6326(18)64673-4

J. Jiang, Y. Wang, G. Xiao, and X. Nie, Comparison of Microstructural Evolution of 7075 Aluminum Alloy Fabricated by SIMA and RAP, J. Mater. Process. Technol., 2016, 238, p 361-372. https://doi.org/10.1016/j.jmatprotec.2016.06.020

R.G. Guan, Z.Y. Zhao, Y.D. Li, T.J. Chen, S.X. Xu, and P.X. Qi, Microstructure and Properties of Squeeze Cast A356 Alloy Processed with a Vibrating Slope, J. Mater. Process. Technol., 2016, 229, p 514-519. https://doi.org/10.1016/j.jmatprotec.2015.09.038

E. Tzimas and A. Zavaliangos, Mechanical Behavior of Alloys with Equiaxed Microstructure in the Semisolid State at High Solid Content, Acta Mater., 1999, 47, p 517-528. https://doi.org/10.1016/S1359-6454(98)00356-5

C.P. Chen and C.-Y.A. Tsao, Semi-Solid Deformation of Non-Dendritic Structures—I, Phenomenol. Behav. Acta Mater., 1997, 45, p 1955-1968. https://doi.org/10.1016/S1359-6454(96)00312-6

C.M. Gourlay and A.K. Dahle, Dilatant Shear Bands in Solidifying Metals, Nature, 2007, 445, p 70-73. https://doi.org/10.1038/nature05426

K.M. Kareh, C. O’Sullivan, T. Nagira, H. Yasuda, and C.M. Gourlay, Dilatancy in Semi-Solid Steels at High Solid Fraction, Acta Mater., 2017, 125, p 187-195. https://doi.org/10.1016/j.actamat.2016.11.066

M.H. Sheikh-Ansari and M. Aghaie-Khafri, Shear Localization in Semi-Solid Deformation: A Bifurcation Theory Approach, Mech. Res. Commun., 2018, 89, p 1-5. https://doi.org/10.1016/j.mechrescom.2018.02.002

Q. Chen, G. Chen, X. Ji, F. Han, Z. Zhao, J. Wan, and X. Xiao, Compound Forming of 7075 Aluminum Alloy Based on Functional Integration of Plastic Deformation and Thixoformation, J. Mater. Process. Technol., 2017, 246, p 167-175. https://doi.org/10.1016/j.jmatprotec.2017.03.023

Z. Ma, H. Zhang, W. Song, X. Wu, L. Jia, and H. Zhang, Pressure-Driven Mold Filling Model of Aluminum Alloy Melt/Semi-Solid Slurry Based on Rheological Behavior, J. Mater. Sci. Technol., 2020, 39, p 14-21. https://doi.org/10.1016/j.jmst.2019.07.048

M. Qi, Y. Kang, Y. Xu, J. Li, and A. Liu, New Technique for Preparing A356 Alloy Semisolid Slurry and its Rheo-Diecast Microstructure and Properties, Trans. Nonferrous Met. Soc. China., 2021, 31, p 1868-1884. https://doi.org/10.1016/S1003-6326(21)65623-6

B. Binesh and M. Aghaie-Khafri, RUE-Based Semi-Solid Processing: Microstructure Evolution and Effective Parameters, Mater. Des., 2016, 95, p 268-286. https://doi.org/10.1016/j.matdes.2016.01.117

M. Kiuchi and R. Kopp, Mushy/Semi-Solid Metal Forming Technology - Present and Future, CIRP Ann., 2002, 51, p 653-670. https://doi.org/10.1016/S0007-8506(07)61705-3

J. Jiang, Y. Liu, G. Xiao, Y. Wang, and X. Xiao, Effects of Plastic Deformation of Solid Phase on Mechanical Properties and Microstructure of Wrought 5A06 Aluminum Alloy in Directly Semisolid Thixoforging, J. Alloys Compd., 2020, 831, p 154748. https://doi.org/10.1016/j.jallcom.2020.154748

G. Xiao, J. Jiang, Y. Liu, Y. Wang, and B. Guo, Recrystallization and Microstructure Evolution of Hot Extruded 7075 Aluminum Alloy during Semi-Solid Isothermal Treatment, Mater. Charact., 2019, 156, p 109874. https://doi.org/10.1016/j.matchar.2019.109874

Y. Birol, Solid Fraction Analysis with DSC in Semi-Solid Metal Processing, J. Alloys Compd., 2009, 486, p 173-177. https://doi.org/10.1016/j.jallcom.2009.06.165

D. Zhang, H. Dong, and H. Atkinson, What is the Process Window for Semi-Solid Processing?, Metall. Mater. Trans. A., 2016, 47, p 1-5. https://doi.org/10.1007/s11661-015-3185-9

R. Gecu, S. Acar, A. Kisasoz, K. Altug Guler, and A. Karaaslan, Influence of T6 Heat Treatment on A356 and A380 Aluminium Alloys Manufactured by Thixoforging Combined with Low Superheat Casting, Trans. Nonferrous Met. Soc. China., 2018, 28, p 385-392. https://doi.org/10.1016/S1003-6326(18)64672-2

K.N. Campo, E.S.N. Lopes, C.J. Parrish, and R. Caram, Rapid Quenching of Semisolid Ti-Cu Alloys: Insights into Globular Microstructure Formation and Coarsening, Acta Mater., 2017, 139, p 86-95. https://doi.org/10.1016/j.actamat.2017.08.006

Y. Wang, S. Zhao, X. Zhao, and Y. Zhao, Microstructural Coarsening of 6061 Aluminum Alloy Semi-Solid Billets Prepared via Recrystallization and Partial Melting, J. Mech. Sci. Technol., 2017, 31, p 3917-3923. https://doi.org/10.1007/s12206-017-0737-5

J. Jiang, H.V. Atkinson, and Y. Wang, Microstructure and Mechanical Properties of 7005 Aluminum Alloy Components Formed by Thixoforming, J. Mater. Sci. Technol., 2017, 33, p 379-388. https://doi.org/10.1016/j.jmst.2016.07.014

S. Saffari and F. Akhlaghi, Microstructure and Mechanical Properties of Al-Mg2Si Composite Fabricated In-situ by Vibrating Cooling Slope, Trans. Nonferrous Met. Soc. China., 2018, 28, p 604-612. https://doi.org/10.1016/S1003-6326(18)64693-X

M. Zhu, Z. Jian, G. Yang, and Y. Zhou, Effects of T6 Heat Treatment on the Microstructure, Tensile Properties, and Fracture Behavior of the Modified A356 Alloys, Sustain. Mater. Des. Appl., 2012, 36, p 243-249. https://doi.org/10.1016/j.matdes.2011.11.018

H. Liao, Y. Wu and, K. Ding, Hardening Response and Precipitation Behavior of Al-7%Si-0.3%Mg Alloy in a Pre-aging Process, Mater. Sci. Eng. A., 2013, 560, p 811-816. https://doi.org/10.1016/j.msea.2012.10.041

A. Pola, M. Tocci, and P. Kapranos, Microstructure and Properties of Semi-Solid Aluminum Alloys: A Literature Review, Metals., 2018, 8, p 181. https://doi.org/10.3390/met8030181

L. Fan, M. Zhou, Y. Zhang, Q. Tang, G. Quan, and B. Liu, The Semi-Solid Microstructural Evolution and Coarsening Kinetics of AZ80-02Y-015Ca Magnesium Alloy, Mater. Charact., 2019, 154, p 116-126. https://doi.org/10.1016/j.matchar.2019.05.019

P. Cavaliere, E. Cerri, and P. Leo, Effect of Heat Treatments on Mechanical Properties and Damage Evolution of Thixoformed Aluminium Alloys, Mater. Charact., 2005, 55, p 35-42. https://doi.org/10.1016/j.matchar.2005.02.006

K. Lee, Y.N. Kwon, and S. Lee, Effects of Eutectic Silicon Particles on Tensile Properties and Fracture Toughness of A356 Aluminum Alloys Fabricated by Low-Pressure-Casting, Casting-Forging, and Squeeze-Casting Processes, J. Alloys Compd., 2008, 461, p 532-541. https://doi.org/10.1016/j.jallcom.2007.07.038

H.-M. Guo, X.-J. Yang, and J.-X. Wang, Pressurized Solidification of Semi-Solid Aluminum Die Casting Alloy A356, J. Alloys Compd., 2009, 485, p 812-816. https://doi.org/10.1016/j.jallcom.2009.06.083

W. Mao, Q. Zheng, and D. Zhu, Rheo-squeeze Casting of Semi-Solid A356 Aluminum Alloy Slurry, Trans. Nonferrous Met. Soc. China., 2010, 20, p 1769-1773. https://doi.org/10.1016/S1003-6326(09)60372-1

N. Maruyama, R. Uemori, N. Hashimoto, M. Saga, and M. Kikuchi, Effect of Silicon Addition on the Composition and Structure of Fine-Scale Precipitates in Al-Mg-Si Alloys, Scr. Mater., 1997, 36, p 89-93. https://doi.org/10.1016/S1359-6462(96)00358-2

E. Sjölander and S. Seifeddine, The Heat Treatment of Al-Si-Cu-Mg Casting Alloys, J. Mater. Process. Technol., 2010, 210, p 1249-1259. https://doi.org/10.1016/j.jmatprotec.2010.03.020

H. Azimi, S. Nourouzi, and R. Jamaati, Effects of Ti Particles and T6 Heat Treatment on the Microstructure and Mechanical Properties of A356 Alloy Fabricated by Compocasting, Mater. Sci. Eng. A., 2021, 818, p 141443. https://doi.org/10.1016/j.msea.2021.141443

K. Matsuda, T. Naoi, K. Fujii, Y. Uetani, T. Sato, A. Kamio and S. Ikeno, Crystal Structure of the β′′ Phase in an Al-1.0 Mass%Mg2Si-0.4mass%Si Alloy, Mater. Sci. Eng. A., 1999, 262, p 232-237. https://doi.org/10.1016/S0921-5093(98)00962-9

X. Zhang, L.K. Huang, B. Zhang, Y.Z. Chen, S.Y. Duan, G. Liu, C.L. Yang, and F. Liu, Enhanced Strength and Ductility of A356 Alloy due to Composite Effect of Near-Rapid Solidification and Thermo-Mechanical Treatment, Mater. Sci. Eng. A., 2019, 753, p 168-178. https://doi.org/10.1016/j.msea.2019.03.039

S.J. Andersen, H.W. Zandbergen, J. Jansen, C. TrÆholt, U. Tundal, and O. Reiso, The Crystal Structure of the β″ Phase in Al-Mg-Si Alloys, Acta Mater., 1998, 46, p 3283-3298. https://doi.org/10.1016/S1359-6454(97)00493-X

S.J. Andersen, Quantification of the Mg2Si β″ and β′ Phases in AlMgSi Alloys by Transmission Electron Microscopy, Metall. Mater. Trans. A., 1995, 26, p 1931-1937. https://doi.org/10.1007/BF02670664

H.C. Long, J.H. Chen, C.H. Liu, D.Z. Li, and Y.Y. Li, The Negative Effect of Solution Treatment on the Age Hardening of A356 Alloy, Mater. Sci. Eng. A., 2013, 566, p 112-118. https://doi.org/10.1016/j.msea.2012.12.093

Y.D. Wang, L.H. Wu, P. Xue, H. Zhang, D.R. Ni, and Z.Y. Ma, Improved Strength with Good Conductivity in Cu-Cr-Zr Alloys: Determinant Effect of Under-aging Treatment Before Rolling and Aging, Mater. Sci. Eng. A., 2022, 848, p 143395. https://doi.org/10.1016/j.msea.2022.143395

Y.D. Wang, M. Liu, B.H. Yu, L.H. Wu, P. Xue, D.R. Ni, and Z.Y. Ma, Enhanced Combination of Mechanical Properties and Electrical Conductivity of a Hard State Cu-Cr-Zr Alloy via One-Step Friction Stir Processing, J. Mater. Process. Technol., 2021, 288, p 116880. https://doi.org/10.1016/j.jmatprotec.2020.116880

Acknowledgments

This work was supported by the National Natural Science Foundation of China (NSFC) [51875124] and the National Key Research and Development Project [2019YFB2006503].

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liu, Y., Jiang, J., Xiao, G. et al. Effects of Heating Temperature and Holding Time on Microstructure and Mechanical Properties of Thixoforged A356 Aluminum Alloy Parts. J. of Materi Eng and Perform 32, 2062–2073 (2023). https://doi.org/10.1007/s11665-022-07281-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-07281-7