Abstract

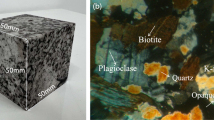

The Inconel 617 alloy has been creep-tested at different combinations of loads (80-350 MPa) and temperatures (650-800 °C), considering its use in the advanced ultra-super critical (AUSC) boiler. The values of Monkman–Grant and modified Monkman–Grant constants obtained by analyzing the creep data are considered as related to the observed microstructural instability during creep at ~ 650-800 °C. The presence of intragranular secondary γ′ precipitates has led to significantly higher strength inside the grains compared to that of their boundaries, found to have a scanty population of secondary (Cr,Mo)23C6 precipitates. As a result, formation of creep cavities leading to intergranular fracture has been observed in the temperature range of 650-750 °C. The creep damage tolerance factor, λ, found as ~ 2.5 by empirical damage analysis on the basis of test results is in tune with the predominance of creep cavitation in the temperature range of 650-750 °C. In contrast, both the obtained value of λ ~ 10.51 and the mixed mode nature of the fracture surface observed for the sample creep tested at 800 °C are considered due to substantial localized plastic deformation or necking. Increased creep ductility with necking is ascribed primarily to the reduced the grain body strength caused by the absence of γ′ precipitates and the grain boundary sliding being restricted by the discrete secondary (Cr,Mo)23C6 precipitates present in abundance along the grain boundary. Based on the plot of applied stress against Larson–Miller parameter, it is possible to predict that the Inconel 617 alloy would withstand the steam pressure of 30 MPa at 750 °C for a design life of 105 h experienced in a typical AUSC boiler tube.

Similar content being viewed by others

References

W.-G. Kim, S.-N. Yin, G.-G. Lee, Y.-W. Kim, and S.-J. Kim, Creep Oxidation Behaviour and Creep Strength Prediction for Alloy 617, Int. J. Press. Vessel. Pip., 2010, 87, p 289–295. https://doi.org/10.1016/j.ijpvp.2010.03.008

W.-G. Kim, J.-Y. Park, I.M.W. Ekaputra, S.-J. Kim, M.-H. Kim, and Y.-W. Kim, Creep Deformation and Rupture Behavior of Alloy 617, Eng. Fail. Anal., 2015, 58, p 441–451. https://doi.org/10.1016/j.engfailanal.2015.07.041

S.K. Sharma, C. Jang, and K.J. Kang, Effect of Thermo-Mechanical Processing on Microstructure and Creep Properties of the Foils of Alloy 617, J. Nucl. Mater., 2009, 389, p 420–426. https://doi.org/10.1016/j.jnucmat.2009.02.029

S. Chomette, J.-M. Gentzbittel, and B. Viguier, Creep Behaviour of as Received, Aged and Cold Worked INCONEL 617 at 850 °C and 950 °C, J. Nucl. Mater., 2010, 399, p 266–274. https://doi.org/10.1016/j.jnucmat.2010.01.019

P.S. Shankar and K. Natesan, Effect of Trace Impurities in Helium on the Creep Behavior of Alloy 617 for Very High Temperature Reactor Applications, J. Nucl. Mater., 2007, 366, p 28–36. https://doi.org/10.1016/j.jnucmat.2006.12.028

J.K. Wright, T.M. Lillo, R.N. Wright, W.-G. Kim, I.-J. Sah, E.-S. Kim, J.-Y. Park, and M.-H. Kim, Creep and Creep-Rupture of Alloy 617, Nucl. Eng. Des., 2018, 329, p 142–146. https://doi.org/10.1016/j.nucengdes.2017.07.014

W.G. Kim, J.-Y. Park, I.M.W. Ekaputra, M.-H. Kim, and Y.-W. Kim, Analysis of Creep Behavior of Alloy 617 for Use of VHTR System, Procedia, Mater. Sci., 2014, 3, p 1285–1290. https://doi.org/10.1016/j.mspro.2014.06.208

F.H. Norton, The Creep of Steel at High Temperatures, McGraw-Hill, NewYork, 1929.

F.C. Monkman and N.J. Grant, An Empirical Relationship between Rupture Life and Minimum Creep Rate in Creep-Rupture Tests, Proc. Am. Soc. Test. Mater., 1956, 56, p 593–620.

F.R. Larson and J. Miller, Time-Temperature Relationship for Rupture and Creep Stresses, Trans. ASME., 1952, 74, p 765–771.

A.K. Roy, M.H. Hasan, and J. Pal, Creep Deformation of Alloys 617 and 276 at 750-950 °C, Mater. Sci. Eng. A., 2009, 520, p 184–188. https://doi.org/10.1016/j.msea.2009.05.029

R. Viswanathan, and W. Bakker, Materials for Ultrasupercritical Coal Power Plants—Boiler Materials: Part 1, J. Mater. Eng. Perform., 2001, 10, p 81–95. https://doi.org/10.1361/105994901770345394

T.B. Gibbons, Superalloys in Modern Power Generation Applications, Mater. Sci. Technol., 2009, 25, p 129–135. https://doi.org/10.1179/174328408X355433

R. Viswanathan, J.F. Henry, J. Tanzosh, G. Stanko, J. Shingledecker, B. Vitalis, and R. Purgert, U.S. Program on Materials Technology for Ultra-Supercritical Coal Power Plants, J. Mater. Eng. Perform., 2005, 14, p 281–292. https://doi.org/10.1361/10599490524039

Q. Wu, H. Song, R.W. Swindeman, J.P. Shingledecker, and V.K. Vasudevan, Microstructure of Long-Term Aged IN617 Ni-Base Superalloy, Metall. Mater. Trans. A., 2008, 39, p 2569–2585. https://doi.org/10.1007/s11661-008-9618-y

W.L. Mankins, J.C. Hosier, and T.H. Bassford, Microstructure and Phase Stability of INCONEL Alloy 617, Metall. Trans., 1974, 5, p 2579–2590. https://doi.org/10.1007/BF02643879

S.F. Di Martino, R.G. Faulkner, S.C. Hogg, S. Vujic, and O. Tassa, Characterisation of Microstructure and Creep Properties of Alloy 617 for High-Temperature Applications, Mater. Sci. Eng. A., 2014, 619, p 77–86. https://doi.org/10.1016/j.msea.2014.09.046

E. Gariboldi, M. Cabibbo, S. Spigarelli, and D. Ripamonti, Investigation on Precipitation Phenomena of Ni-22Cr-12Co-9Mo Alloy Aged and Crept At High Temperature, Int. J. Press. Vessel. Pip., 2008, 85, p 63–71. https://doi.org/10.1016/j.ijpvp.2007.06.014

J.K. Benz, L.J. Carroll, J.K. Wright, R.N. Wright, and T.M. Lillo, Threshold Stress Creep Behavior of Alloy 617 at Intermediate Temperatures, Metall. Mater. Trans. A., 2014, 45, p 3010–3022. https://doi.org/10.1007/s11661-014-2244-y

S. Yamasaki, M. Mitsuhara, and H. Nakashima, Deformation Microstructure and Fracture Behavior in Creep-Exposed Alloy 617, Mater. Trans., 2017, 58, p 442–449. https://doi.org/10.2320/matertrans.M2016407

V. Knezevic, A. Schneider, and C. Landier, Creep Behaviour of Thick-Wall Alloy 617 Seamless Pipes for 700 °C Power Plant Technology, Procedia Eng., 2013, 55, p 240–245. https://doi.org/10.1016/j.proeng.2013.03.249

R. Krishna, H.V. Atkinson, S.V. Hainsworth, and S.P. Gill, Gamma Prime Precipitation, Dislocation Densities, and TiN in Creep-Exposed Inconel 617 Alloy, Metall. Mater. Trans. A., 2016, 47, p 178–193. https://doi.org/10.1007/s11661-015-3193-9

M. Speicher, F. Kauffmann, J.-H. Shim, and M. Chandran, Microstructure Evolution in Alloy 617 B after a Long-Term Creep and Thermal Aging at 700 °C, Mater. Sci. Eng. A., 2018, 711, p 165–174. https://doi.org/10.1016/j.msea.2017.11.004

K. Maile, Qualification of Ni-Based Alloys for Advanced Ultra Supercritical Plants, Procedia Eng., 2013, 55, p 214–220. https://doi.org/10.1016/j.proeng.2013.03.245

S. Bagui, B.P. Sahu, K. Laha, S. Tarafder, and R. Mitra, Creep Deformation Behavior of Inconel 617 Alloy in the Temperature Range of 650 °C to 800 °C, Metall. Mater. Trans. A., 2021, 52, p 94–107. https://doi.org/10.1007/s11661-020-06066-8

S. Bagui, M. Mandal, B.K. Sahoo, K. Laha, S. Tarafder, and R. Mitra, Investigation of Non-Classical Creep Behavior of Inconel 617 Alloy at 700 °C and 800 °C through Interrupted Tests and Microstructural Characterizations, Mater. Sci. Eng. A., 2022 https://doi.org/10.1016/j.msea.2021.142474

F. Dobeš and K. Milička, The Relation between Minimum Creep Rate and Time to Fracture, Met. Sci., 1976, 10, p 382–384. https://doi.org/10.1080/03063453.1976.11683560

W.G. Kim, S.H. Kim, and W.S. Ryu, Evaluation of Monkman-Grant Parameters for Type 316LN and Modified 9Cr-Mo Stainless Steels, KSME Int. J., 2002, 16, p 1420–1427. https://doi.org/10.1007/BF02985134

B.K. Choudhary, S. Saroja, K.B. Sankara Rao, and S.L. Mannan, Creep-Rupture Behavior of Forged, Thick Section 9Cr-1Mo Ferritic Steel, Metall. Mater. Trans. A., 1999, 30, p 2825–2834. https://doi.org/10.1007/s11661-999-0120-y

C. Phaniraj, B.K. Choudhary, K. Bhanu Sankara Rao, and B. Raj, Relationship between Time to Reach Monkman-Grant Ductility and Rupture Life, Scr. Mater., 2003, 48, p 1313–1318. https://doi.org/10.1016/S1359-6462(03)00021-6

O.D. Sherby and P.M. Burke, Mechanical Behavior of Crystalline Solids at Elevated Temperature, Prog. Mater. Sci., 1968, 13, p 323–390. https://doi.org/10.1016/0079-6425(68)90024-8

S.L. Robinson and O.D. Sherby, Mechanical Behavior of Polycrystalline Tungsten at Elevated Temperature, Acta Metall., 1969, 17, p 109–125. https://doi.org/10.1016/0001-6160(69)90132-1

R.W. Bailey, Creep of Steel under Simple and Compound Stress, Engineering, 1930, 121, p 265.

J.S. Lee, H.G. Armaki, K. Maruyama, T. Muraki, and H. Asahi, Causes of Breakdown of Creep Strength in 9Cr-1.8W-0.5Mo-VNb steel, Mater. Sci. Eng. A., 2006, 428, p 270–275. https://doi.org/10.1016/j.msea.2006.05.010

C.V. Rao, N.C.S. Srinivas, G.V.S. Sastry, and V. Singh, Effect of Microstructure on Work Hardening Behaviour of IN-617 Alloy, Mater. Sci. Eng. A., 2021, 800, p 140317. https://doi.org/10.1016/j.msea.2020.140317

R.K. Singh and J.K. Sahu, Yield Strength Anomaly and Dynamic Strain Ageing Behaviour of Recently Developed Advanced Ultra-Supercritical Boiler Grade Wrought Ni-Based Superalloy IN 740H, Mater. High Temp., 2019, 36, p 220–231. https://doi.org/10.1080/09603409.2018.1513675

G.E. Dieter, Mechanical Metallurgy, SI Metric, McGraw-Hill Book company, London, 1988.

C. Jang, D. Lee, and D. Kim, Oxidation Behaviour of an Alloy 617 in Very High-Temperature Air and Helium Environments, Int. J. Press. Vessel. Pip., 2008, 85, p 368–377. https://doi.org/10.1016/j.ijpvp.2007.11.010

D. Saber, I.S. Emam, and R. Abdel-Karim, High Temperature Cyclic Oxidation of Ni Based Superalloys at Different Temperatures in Air, J. Alloys Compd., 2017, 719, p 133–141. https://doi.org/10.1016/j.jallcom.2017.05.130

A.K. Ray, S. Kumar, G. Krishna, M. Gunjan, B. Goswami, and S.C. Bose, Microstructural Studies and Remnant Life Assessment of Eleven Years Service Exposed Reformer Tube, Mater. Sci. Eng. A., 2011, 529, p 102–112. https://doi.org/10.1016/j.msea.2011.09.003

Y. Guo, B. Wang, and S. Hou, Aging Precipitation Behavior and Mechanical Properties of Inconel 617 Superalloy, Acta Metall. Sin. Eng. Lett., 2013, 26, p 307–312. https://doi.org/10.1007/s40195-012-0249-3

A.N. Singh, A. Moitra, P. Bhaskar, G. Sasikala, A. Dasgupta, and A.K. Bhaduri, Study of Aging-Induced Degradation of Fracture Resistance of Alloy 617 Toward High-Temperature Applications, Metall. Mater. Trans. A., 2017, 48, p 3269–3278. https://doi.org/10.1007/s11661-017-4123-9

A. Singh, A. Moitra, P. Bhaskar, G. Sasikala, A. Dasgupta, and A.K. Bhaduri, Effect of Thermal Aging on Microstructure, Hardness, Tensile and Impact Properties of Alloy 617, Mater. Sci. Eng. A., 2018, 710, p 47–56. https://doi.org/10.1016/j.msea.2017.10.078

T. Shrestha, M. Basirat, I. Charit, G.P. Potirniche, and K.K. Rink, Creep Rupture Behavior of Grade 91 Steel, Mater. Sci. Eng. A., 2013, 565, p 382–391. https://doi.org/10.1016/j.msea.2012.12.031

B.F. Dyson and T.B. Gibbons, Tertiary Creep in Nickel-Base Superalloys: Analysis of Experimental Data and Theoretical Synthesis, Acta Metall., 1987, 35, p 2355–2369. https://doi.org/10.1016/0001-6160(87)90083-6

Acknowledgments

Authors sincerely acknowledge the in-house project (No. OLP-0253) of CSIR-National Metallurgical Laboratory, Jamshedpur, to execute the present investigation. Authors are thankful to the help received from the Central Research Facility, IIT Kharagpur, for TEM work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Bagui, S., Sahu, B.P., Mahato, B. et al. Effect of Microstructural Evolution on Creep and Rupture Behavior of Inconel 617 Alloy. J. of Materi Eng and Perform 32, 1292–1309 (2023). https://doi.org/10.1007/s11665-022-07162-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-07162-z