Abstract

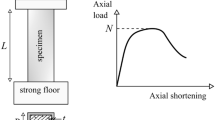

The present work examines the effectiveness of a strain-compensated Arrhenius-type constitutive model, Artificial Neural Network (ANN) and Support Vector Regression (SVR), to predict the flow stress in tube route and slab route Zircaloy-4 sheets at elevated temperatures. Isothermal tensile tests were conducted from a temperature range of 298-498 K at three different strain rates, namely 0.001, 0.005, and 0.01 s−1. The predictive performance of all three models was evaluated using correlation coefficient and average absolute relative error. The results revealed that the ANN and SVR models provide more precise predictions compared to the strain-compensated Arrhenius-type constitutive model. The SVR model with a medium Gaussian kernel performed better in flow stress prediction than the quadratic kernel for tube route and slab route sheets. Among ANN and SVR, the ANN model has a better correlation coefficient, and SVR model has a low average absolute relative error. Finally, the ANN and SVR model were cross-validated and showed superior performance in predicting flow stress.

Similar content being viewed by others

References

V. Kalavathi and R. Kumar Bhuyan, A Detailed Study on Zirconium and Its Applications in Manufacturing Process with Combinations of Other Metals, Oxides and Alloys - A Review, Mater. Today Proc., 2019, 19, p 781–786.

K.-Y. Kim and J.-W. Seo, Numerical Optimization for the Design of a Spacer Grid with Mixing Vanes in a Pressurized Water Reactor Fuel Assembly, Nuclear Technol., 2005, 149(1), p 62–70.

H. Abe, T. Abe, S. Kishita, S. Kano, Y. Li, H. Yang, K. Tawara et al., Development of Advanced Expansion Due to Compression (A-EDC) Test Method for Safety Evaluation of Degraded Nuclear Fuel Cladding Materials, J. Nucl. Sci. Technol., 2015, 52(10), p 1232–1239.

A.K. Gupta, H.N. Krishnamurthy, P. Puranik, S.K. Singh, and A. Balu, An Exponential Strain Dependent Rusinek-Klepaczko Model for Flow Stress Prediction in Austenitic Stainless Steel 304 at Elevated Temperatures, J. Mater. Res. Technol., 2014, 3(4), p 370–377.

K. Limbadri, S.K. Singh, K. Satyanarayana, A.K. Singh, A. Maruthi Ram, M. Ravindran, M. Krishna et al., Effect of Processing Routes on Orientation-Dependent Tensile Flow Behavior of Zircaloy-4 at Elevated Temperatures, Metallogr. Microstruct. Anal, 2019, 8(3), p 393–405.

Y.C. Lin and X.-M. Chen, A Critical Review of Experimental Results and Constitutive Descriptions for Metals and Alloys in Hot Working, Mater. Design, 2011, 32(4), p 1733–1759.

F. Garofalo, An empirical Relation Defining the Stress Dependence of Minimum Creep Rate in Metals, Trans. AIME, 1963, 227, p 351–356.

Y. Han, H. Wu, W. Zhang, D. Zou, G. Liu, and G. Qiao, Constitutive Equation and Dynamic Recrystallization Behavior of As-Cast 254SMO Super-Austenitic Stainless Steel, Mater. Design, 2015, 69, p 230–240.

Y.C. Lin, M.-S. Chen, and J. Zhong, Constitutive Modeling for Elevated Temperature Flow Behavior of 42CrMo Steel, Comput. Mater. Sci., 2008, 42(3), p 470–477.

J. Cai, F. Li, T. Liu, B. Chen, and M. He, Constitutive Equations for Elevated Temperature Flow Stress of Ti-6Al-4V Alloy Considering the Effect of Strain, Mater. Design, 2011, 32(3), p 1144–1151.

L. Kanthi, S. Kurra, and S.K. Singh, Flow Stress Prediction of Zircaloy-4 at Elevated Temperatures Using KHL Constitutive Model, Adv. Mater. Process. Technol., 2020, 6(2), p 310–319.

P.F. Bariani, T. Dal Negro, and S. Bruschi, Testing and Modelling of Material Response to Deformation in Bulk Metal Forming, CIRP Ann., 2004, 53(2), p 573–595.

H.K.D.H. Bhadeshia, Neural Networks in Materials Science, Encycl. Mater. Sci. Technol., 2008, 39, p 1–5.

E. Hazir, T. Ozcan, and K.H. Koç, Prediction of Adhesion Strength Using Extreme Learning Machine and Support Vector Regression Optimized with Genetic Algorithm, Arab. J. Sci. Eng., 2020, 45(8), p 6985–7004.

G. Allegri, Modelling Fatigue Delamination Growth in Fibre-Reinforced Composites: Power-Law Equations or Artificial Neural Networks?, Mater. Design, 2018, 155, p 59–70.

F. Musharavati and A.S.M. Hamouda, Application of artificial neural networks for modelling correlations in age hardenable aluminium alloys, J. Adv. Mater. Manufact. Eng., 2010, 41(1–2), p 140–146.

P.L. Narayana, C.-L. Li, J.-K. Hong, S.-W. Choi, C.H. Park, S.-W. Kim, S.E. Kim et al., Characterization of Hot Deformation Behavior and Processing Maps of Ti-19Al-22Mo Alloy, Metals Mater. Int., 2019, 25(4), p 1063–1071.

N.S. Reddy, High Temperature Deformation Behavior of Ti-6Al-4V Alloy with an Equiaxed Microstructure: a Neural Networks Analysis, Metals Mater. Int., 2008, 14(2), p 213–221.

C.H. Park, D. Cha, M. Kim, N.S. Reddy, and J.-T. Yeom, Neural Network Approach to Construct a Processing Map from a Non-linear Stress-Temperature Relationship, Metals Mater. Int., 2019, 25(3), p 768–778.

E. Maleki and O. Unal, Shot Peening Process Effects on Metallurgical and Mechanical Properties of 316 L Steel Via: Experimental and Neural Network Modeling, Metals Mater. Int., 2021, 27(2), p 262–276.

A. Canakci, T. Varol, and S. Ozsahin, Prediction of Effect of Volume Fraction, Compact Pressure and Milling Time on Properties of Al-Al2O3 MMCs Using Neural Networks, Metals Mater. Int., 2013, 19(3), p 519–526.

K. Muralidharan and D. Vasudevan, Applications of Artificial neural Networks in Prediction of Performance, Emission and Combustion Characteristics of Variable Compression Ratio Engine Fuelled with Waste Cooking Oil Biodiesel, J. Braz. Soc. Mech. Sci. Eng., 2015, 37(3), p 915–928.

J. Liu, H. Li, D. Li, and Y. Wu, Application of Novel Physical Picture Based on Artificial Neural Networks to Predict Microstructure Evolution of Al-Zn-Mg-Cu Alloy During Solid Solution Process, Trans. Nonferrous Metals Soc. China, 2015, 25(3), p 944–953.

L. Guo, B. Li, and Z. Zhang, Constitutive Relationship Model of TC21 Alloy Based on Artificial Neural Network, Trans. Nonferrous Metals Soc. China, 2013, 23(6), p 1761–1765.

A.K. Dabrowska, Artificial Neural Networks for Prediction of Local Thermal Insulation of Clothing Protecting Against Cold, Int. J. Cloth. Sci. Technol., 2018, 30(1), p 82–100.

O.A. Mohamed, S.H. Masood, and J.L. Bhowmik, Influence of Processing Parameters on Creep and Recovery Behavior of FDM Manufactured Part Using Definitive Screening Design and ANN, Rapid Prototyp. J., 2017, 23(6), p 998–1010.

Y. Lin, Z. Zheng, H. Zhang, and Y. Han, Effect of Heat Treatment Process on Tensile Properties of 2A97 Al-Li Alloy: Experiment and BP Neural Network Simulation, Trans. Nonferrous Metals Soc. China, 2013, 23(6), p 1728–1736.

V. Senthilkumar, A. Balaji, and D. Arulkirubakaran, Application of Constitutive and Neural Network Models for Prediction of High Temperature Flow Behavior of Al/Mg Based Nanocomposite, Trans. Nonferrous Metals Soc. China, 2013, 23(6), p 1737–1750.

Y. Mao and L. Zeng, Comparative Study of Response Surface Methodology and Hybrid Back-Propagation Network for Optimizing Friction Coefficient for Textured Surface Under Cavitation Conditions, Ind. Lubricat. Tribol., 2018, 70(5), p 856–864.

R. Palanivel, I. Dinaharan, and R.F. Laubscher, Application of an Artificial Neural Network Model to Predict the Ultimate Tensile Strength of Friction-Welded Titanium Tubes, J. Brazil. Soc. Mech. Sci. Eng., 2019, 41(2), p 111.

N.S. Dey, R. Mohanty, and K.L. Chugh, Speech and Speaker Recognition System Using Artificial Neural Networks and Hidden Markov Model, In: 2012 International Conference on Communication Systems and Network Technologies, IEEE, 2012, p 311–315.

J. Yan, Q. Pan, A. Li, and W. Song, Flow Behavior of Al-6.2Zn-0.70Mg-0.30Mn-0.17Zr Alloy During Hot Compressive Deformation Based on Arrhenius and ANN Models, Trans. Nonferrous Metals Soc. China, 2017, 27(3), p 638–647.

N.K. Geetha and P. Bridjesh, Overview of Machine Learning and Its Adaptability in Mechanical Engineering, Mater. Today: Proc. 2020 p 10–12.

Y. Rabbani, M. Shirvani, S.H. Hashemabadi, and M. Keshavarz, Application of Artificial Neural Networks And Support Vector Regression Modeling in Prediction of Magnetorheological Fluid Rheometery, Colloids Surf. A Physicochem. Eng. Aspects, 2017, 520, p 268–278.

R.K. Desu, S.C. Guntuku, B. Aditya, and A.K. Gupta, Support Vector Regression based Flow Stress Prediction in Austenitic Stainless Steel 304, Proced. Mater. Sci., 2014, 6, p 368–375. https://doi.org/10.1016/j.mspro.2014.07.047

H. Wang, E. Li, and G.Y. Li, The Least Square Support Vector Regression Coupled with Parallel Sampling Scheme Metamodeling Technique and Application in Sheet Forming Optimization, Mater. Design, 2009, 30(5), p 1468–1479.

R.A. Mozumder, B. Roy, and A.I. Laskar, Support Vector Regression Approach to Predict the Strength of FRP Confined Concrete, Arab. J. Sci. Eng., 2017, 42(3), p 1129–1146.

K. Limbadri, H.N. Krishnamurthy, A. Maruthi Ram, N. Saibaba, V.V. Kutumba Rao, J.N. Murthy, A.K. Gupta et al., Development of Johnson Cook Model for Zircaloy-4 with Low Oxygen Content, Mater. Today Proc., 2017, 4(2), p 966–974.

K. Limbadri, K. Toshniwal, K. Suresh, A. Kumar Gupta, V. Kutumbarao, M. Ram, M. Ravindran et al., Stress Variation of Zircaloy-4 and Johnson Cook Model for Rolled Sheets, Mater. Today: Proc., 2018, 5(2), p 3793–3801.

A.T.C. Goh, Back-Propagation Neural Networks for Modeling Complex Systems, Art. Intell. Eng., 1995, 9(3), p 143–151.

D. Batra, Comparison Between Levenberg-Marquardt and Scaled Conjugate Gradient Training Algorithms for Image COMPRESSION Using MLP, Int. J. Image Process. (IJIP), 2014, 8(6), p 412–422.

S. Mishra, R. Prusty, and P.K. Hota, Analysis of Levenberg-Marquardt and Scaled Conjugate Gradient Training Algorithms for Artificial Neural Network Based LS and MMSE Estimated Channel Equalizers. In 2015 International Conference on Man and Machine Interfacing (MAMI), 2015, pp. 1–7. IEEE.

A. Saxena, A. Kumaraswamy, N. Kotkunde, and K. Suresh, Constitutive Modeling of High-Temperature Flow Stress of Armor Steel in Ballistic Applications: A Comparative Study, J. Mater. Eng. Perform., 2019, 28(10), p 6505–6513.

A. Shokry, S. Gowid, G. Kharmanda, and E. Mahdi, Constitutive Models for the Prediction of the Hot Deformation Behavior of the 10% Cr Steel Alloy, Materials, 2019, 12(18), p 2873.

W.S. Lee and H.F. Lam, The Deformation Behaviour and Microstructure Evolution of High-Strength Alloy Steel at High Rate of Strain, J. Mater. Process. Technol., 1996, 57(3–4), p 233–240.

N. Haghdadi, A. Zarei-Hanzaki, A.R. Khalesian, and H.R. Abedi, Artificial Neural Network Modeling to Predict the Hot Deformation Behavior of an A356 Aluminum Alloy, Mater. Design, 2013, 49, p 386–391.

L. Ping, X. Kemin, L. Yan, and T. Jianrong, Neural Network Prediction of Flow Stress of Ti-15-3 Alloy Under Hot Compression, J. Mater. Process. Technol., 2004, 148(2), p 235–238.

P. Changizian, A. Zarei-Hanzaki, and A.A. Roostaei, The High Temperature Flow Behavior Modeling of AZ81 Magnesium Alloy Considering Strain Effects, Mater. Design, 2012, 39, p 384–389.

N. Haghdadi, H.R. Abedi, and O. Sabokpa, The Effect of Thermomechanical Parameters on the Eutectic Silicon Characteristics in a Non-modified Cast A356 Aluminum Alloy, Mater. Sci. Eng. A, 2012, 549, p 93–99.

R. Kapoor, D. Pal, and J.K. Chakravartty, Use of Artificial Neural Networks to Predict The Deformation Behavior of Zr-2.5Nb-0.5Cu, J. Mater. Process. Technol., 2005, 169(2), p 199–205.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kanthi, L., Wankhede, P., Kurra, S. et al. Flow Stress Modeling of Tube and Slab Route Sheets of Zircaloy-4 Using Machine Learning Techniques and Arrhenius Type Constitutive Equations. J. of Materi Eng and Perform 32, 462–474 (2023). https://doi.org/10.1007/s11665-022-07102-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-07102-x