Abstract

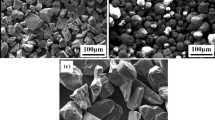

Two-step sintering is proposed to enhance the compactness and phase stability of yttria-stabilized zirconia (YSZ) coating on Inconel 625. The sintering treatment is denoted as low step (LS), low-first step (LFS), high-first step (HFS), and high step (HS). Low and high refer to 750 and 1200 °C, respectively. The YSZ layer was investigated using a scanning electron microscope, x-ray diffractometer, and electron backscattered diffractometer. The results revealed that three relatively compact and uniform layers consisting of Y-ZrO2 (~20 μm) and Fe2O3 (~2 μm) and Cr2O3 (~10 μm) were developed as a result of LFS treatment. The LFS treatment triggered optimum ZrO2 grain growth and the formation of the thermally grown oxides. The LS treatment was not sufficient to induce grain recrystallization and coating compaction. HFS and HS treatment resulted in a higher coating porosity and induced microcracks in the coatings. A nearly balanced fraction of 58:42 for the monoclinic and tetragonal ZrO2 phase was obtained in the LFS coating. The coating exhibited the highest hardness of 1027.10 HV, the best adhesion strength, and the lowest thermal conductivity of 4.73 W/mK. The LFS treatment is beneficial in obtaining a compact YSZ layer with high phase stability and low thermal conductivity.

Similar content being viewed by others

References

S. Sampath, U. Schulz, M.O. Jarligo, and S. Kuroda, Processing Science of Advanced Thermal-Barrier Systems, MRS. Bull., 2012, 37, p 903–910.

B. Alavi, H. Aghajani, and A. Rasooli, Electrophoretic Deposition Of Electroless Nickel Coated YSZ Core-Shell Nanoparticles on a Nickel Based Superalloy, J. Eur. Ceram. Soc., 2019, 39, p 2526–2534.

O. Khanali, S. Baghshahi, and M. Rajabi, Fabrication and Characterization of YSZ/Al2O3 Nano-Composite Coatings on Inconel by Electrophoretic Deposition, J. Mater. Res., 2017, 32, p 3402–3408.

M. Bai, F. Guo, and P. Xiao, Fabrication of Thick YSZ Thermal Barrier Coatings Using Electrophoretic Deposition, Ceram. Int., 2014, 40, p 16611–16616.

B. Lv, H. Xie, R. Xu, X. Fan, W. Zhang, and T.J. Wang, Effects of Sintering and Mixed Oxide Growth on the Interface Cracking of Air-Plasma-Sprayed Thermal Barrier Coating System at High Temperature, Appl. Surf. Sci., 2016, 360, p 461–469.

U. Schulz, Phase Transformation in EB-PVD Yttria Partially Stabilized Zirconia Thermal Barrier Coatings during Annealing, J Am. Ceram. Soc., 2000, 83, p 904–910.

F. Guo, Yttria-Stabilized Zirconia for Application in Thermal Barrier Coatings, The University of Manchester (United Kingdom) ProQuest Dissertations Publishing, 2012. https://www.proquest.com/openview/5db2d907eb5d75eea51758bfb9f34cf4/1?pq-origsite=gscholar&cbl=51922.

F. Al Afghani and A. Anawati, Plasma Electrolytic Oxidation of Zircaloy-4 in a Mixed Alkaline Electrolyte, Surf. Coat. Technol., 2021, 426, p 127786.

L. Besra and M. Liu, A Review on Fundamentals and Applications of Electrophoretic Deposition (EPD), Prog. Mater. Sci., 2007, 52, p 1–61.

B. Baufeld, O. van der Biest, and H.J. Rätzer-Scheibe, Lowering the Sintering Temperature for EPD Coatings by Applying Reaction Bonding, J. Eur. Ceram. Soc., 2008, 28, p 1793–1799.

I. Zhitomirsky and L. Gal-Or, Electrophoretic Deposition of Hydroxyapatite, J. Mater. Sci. Mater. Med., 1997, 8, p 213–219.

M. Bai, F. Guo, and P. Xiao, Fabrication of Thick YSZ Thermal Bather Coatings Using Electrophoretic Deposition, Ceram. Int., 2014, 40, p 16611–16616.

O.O. Van Der Biest and L.J. Vandeperre, Electrophoretic Deposition of Materials, Annu. Rev. Mater. Sci., 1999, 29, p 327–352.

X. Meng, T.Y. Kwon, and K.H. Kim, Hydroxyapatite Coating by Electrophoretic Deposition at Dynamic Voltage, Dent. Mater. J., 2008, 27, p 666–671.

H.K. Bowen and T.J. Garinoa, Deposition and Sintering of Particle Films on a Rigid Substrate, J. Am. Ceram. Soc., 1987, 317, p 315–317.

D.L. Johnson, Fundamentals of the Sintering of Ceramics, Mater. Sci. Res., 1978, 11, p 137–149.

K.C. Radford and R.J. Bratton, Zirconia Electrolyte Cells - Part 1 Sintering Studies, J. Mater. Sci., 1979, 14, p 59–65.

C. Ji, I.P. Shapiro, and P. Xiao, Fabrication of Yttria-Stabilized-Zirconia Coatings Using Electrophoretic Deposition: Effects of Agglomerate Size Distribution on Particle Packing, J. Eur. Ceram. Soc., 2009, 29, p 3167–3175.

E.G. Kalinina, A.A. Efimov, and A.P. Safronov, Preparation of YSZ/Al2O3 Composite Coatings via Electrophoretic Deposition of Nanopowders, Inorg. Mater., 2016, 52, p 1301–1306.

M.M.R. Boutz, A.J.A. Winnubst, F. Hartgers, and A.J. Burggraaf, Effect of Additives on Densification and Deformation of Tetragonal Zirconia, J. Mater. Sci., 1994, 29, p 5374–5382.

Q.D. Wang, J. Peng, M.P. Liu, Y. Chen, W.J. Ding, M. Suéry, and J.J. Blandin, Microstructure and Mechanical Extruded Properties of Extruded AM50+xCa Magnesium Alloys, Mater. Sci. Forum., 2009, 488–489, p 119–122.

G. Štefanić, S. Musić, and R. Trojko, The Influence of Thermal Treatment on the Phase Development in HfO 2-Al 2O 3 and ZrO 2-Al 2O 3 Systems, J. Alloys. Compd., 2005, 388, p 126–137.

I.C. Cosentino, E.N.S. Muccillo, and R. Muccillo, The Influence of Fe2O3 in the Humidity Sensor Performance of ZrO2:TiO2-Based Porous Ceramics, Mater. Chem. Phys., 2007, 103, p 407–414.

O. Khanali, S. Ariaee, M. Rajabi, and S. Baghshahi, An Investigation on the Properties of YSZ/Al2O3 Nanocomposite Coatings on Inconel by Electrophoretic Deposition, J. Compos. Mater., 2018, 52, p 81–89.

U. Sutharsini, M. Thanihaichelvan, and R. Singh, Two-Step Sintering of Ceramics, Sintering of Functional Materials, 2018, p 3–22. https://www.intechopen.com/chapters/54691.

M.J. Zamharir, H. Aghajani, and A.T. Tabrizi, Evaluation of Adhesion Strength of TiN Layer Applied on 316L Substrate by Electrophoretic Deposition, J. Aust. Ceram. Soc., 2021, 57, p 1219–1230. https://doi.org/10.1007/s41779-021-00621-1.

Q.R. Hou, J. Gao, and S.J. Li, Adhesion and its Influence on Micro-Hardness of DLC and SiC Films, Eur. Phys. J. B., 1999, 8, p 493–496.

P.J. Whalen, F. Reidinger, and R.F. Antrim, Prevention of Low-Temperature Surface Transformation by Surface Recrystallization in Yttria-Doped Tetragonal Zirconia, J. Am. Ceram. Soc, 1989, 72, p 319–321.

H.W. Sheng, K. Lu, and E. Ma, Melting and Freezing Behavior Of Embedded Nanoparticles in Ball-Milled Al-10 wt.% M (M = In, Sn, Bi, Cd, Pb) Mixtures, Acta. Mater., 1998, 46, p 5195–5205.

D.R. Clarke, C.G. Levi, and A.G. Evans, Enhanced Zirconia Thermal Barrier Coating Systems, Proc. Inst. Mech. Eng. Part. A. J. Power. Energy., 2006, 220, p 85–92.

S.E. Redfern, R.W. Grimes, and R.D. Rawlings, The Hydroxylation of T-ZrO2 Surfaces, J. Mater. Chem., 2001, 11, p 449–455.

P. Bindu and S. Thomas, Estimation of Lattice Strain in ZnO Nanoparticles: x-ray Peak Profile Analysis, J. Theor. Appl. Phys., 2014, 8, p 123–134.

V. Mote, Y. Purushotham, and B. Dole, Williamson-Hall Analysis in Estimation of Lattice Strain in Nanometer-Sized ZnO Particles, J. Theor. Appl. Phys., 2012 https://doi.org/10.1186/2251-7235-6-6

F. Guo and P. Xiao, Effect of Fe 2O 3 Doping on Sintering of Yttria-Stabilized Zirconia, J. Eur. Ceram. Soc., 2012, 32, p 4157–4164.

P. Li, I.-W. Chen, and J.E. Penner-Hahn, Effect of Dopants on Zirconia Stabilization—An x-ray Absorption Study: III, Charge-Compensating Dopants, J. Am. Ceram. Soc., 1994, 77, p 1289–1295.

J.Z. Jiang, F.W. Poulsen, and S. Mørup, Structure and Thermal Stability of Nanostructured Iron-Doped Zirconia Prepared by High-Energy Ball Milling, J. Mater. Res., 1999, 14, p 1343–1352.

S. Figueroa, J. Desimoni, P.C. Rivas, M.C. Caracoche, and O. De Sanctis, Local Structures in the ZrO2-15 mol.% Fe2O3 System Obtained by Ball Milling, J. Am. Ceram. Soc., 2006, 89, p 3759–3764.

F.J. Berry, M.H. Loretto, and M.R. Smith, Iron-Zirconium Oxides: An Investigation of Structural Transformations by x-ray Diffraction, Electron Diffraction, and Iron-57 Mössbauer Spectroscopy, J. Solid. State. Chem., 1989, 83, p 91–99.

F. CrespoPetit, Effect of Porosity on the Mechanical Properties of Zirconia Based Ceramics Obtained via 3d Printing, 2016, Bachelor thesis, Volume I, Universitat Politècnica de Catalunya (UPC), 2016 Open access at https://upcommons.upc.edu/bitstream/handle/2117/87702/Mem%c3%b2ria.pdf?sequence=1&isAllowed=y.

D. Zhang, Z. Zhao, B. Wang, S. Li, and J. Zhang, Investigation of a New Type of Composite Ceramics for Thermal Barrier Coatings, Mater. Des., 2016, 112, p 27–33.

M. Yashima and S. Tsunekawa, Structures and the Oxygen Deficiency of Tetragonal and Monoclinic Zirconium Oxide Nanoparticles, Acta. Crystallogr. Sect. B. Struct. Sci., 2006, 62, p 161–164.

X. Li, K. Maute, M.L. Dunn, and R. Yang, Strain Effects on the Thermal Conductivity of Nanostructures, Phys. Rev. B., 2010 https://doi.org/10.1103/PhysRevB.81.245318

Acknowledgment

This work was supported by Universitas Indonesia through PUTI Saintekes Grant No. NKB-4899/UN2.RST/HKP.05.00/2020. The author would like to acknowledge Research Center for Physics - Indonesian Institute of Sciences (P2F-LIPI) for the experimental and characterization facilities.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Desiati, R.D., Anawati, A. & Sugiarti, E. Two-Step Sintering Improved Compaction of Electrophoretic-Deposited YSZ Coatings. J. of Materi Eng and Perform 31, 9888–9899 (2022). https://doi.org/10.1007/s11665-022-07004-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-07004-y