Abstract

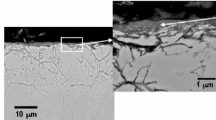

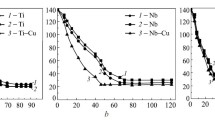

Understanding the effect of coating thickness on the wetting behavior of metal melts and ceramics can help rationalize the design of coatings. The wetting behavior and interfacial phenomena of liquid aluminum on alumina, Ni-coated alumina, and bulk nickel at 700 °C were investigated by the sessile drop technique. The wettability of aluminum on Ni-coated alumina with the thicker film is better than that on bulk nickel. Nickel film deposited on alumina improved the wettability with aluminum and promoted the formation of the precursor film. An interesting phenomenon was found that the liquid precursor film is unstable during wetting, and new small separated droplets are formed in the precursor film.

Similar content being viewed by others

References

Y.V. Naidich, V.S. Zhuravlev, I.I. Gab, B.D. Kostyuk, V.P. Krasovskyy, A.A. Adamovskyy and N.Y. Taranets, Liquid Metal Wettability And Advanced Ceramic Brazing, J. Eur. Ceram. Soc., 2008, 28, p 717–728.

N. Eustathopoulos, M.G. Nicholas, B. Drevet, Wettability at High Temperature, Elsevier Science Ltd., 1999, p 360–368.

R. Asthana, N. Sobczak, Wettability, Spreading, and Interracial Phenomena in High-Temperature Coatings, JOM-e, 2000, 52(1), https://www.tms.org/pubs/journals/JOM/0001/Asthana/Asthana-0001-text.html.

N. Mori, S. Matsuo, K. Ogi and K. Matsuda, Effect of Ni Coating on Wetting Behavior of Molten Al to Graphite, J. Jpn. Inst. Metals, 1987, 51, p 240–247.

C.A. León, G. Mendoza-Suarez and R.A.L. Drew, Wettability and Spreading Kinetics of Molten Aluminum on Copper-Coated Ceramics, J. Mater. Sci., 2006, 41, p 5081–5087.

Y.J. Ko, J. Yoon, J. Lee and J.H. Han, Effects of Cu Interlayer on the Wettability of Aluminum on Carbon, J. Alloys Compd., 2013, 574, p 526–531.

A. M. Razzaq et al. A Brief Research Review For Improvement Methods The Wettability Between Ceramic Reinforcement Particulate and Aluminium Matrix Composites, IOP Conf. Ser.: Mater. Sci. Eng., 2017, 203, 012002.

T.P.D. Rajan, R.M. Pillai and B.C. Pai, Reinforcement Coatings and Interfaces in Aluminium Metal Matrix Composites, J. Mater. Sci., 1998, 33, p 3491–3503.

Q.G. Xu, L.W. Guo, L. Zhang and H. Liu, Wettability of Zirconium-Coated Alumina by Molten Aluminum, Surf. Coat. Technol., 2016, 302, p 150–157.

C.A. León and R.A.L. Drew, The Influence of Nickel Coating on the Wettability of Aluminum on Ceramics, Compos. Part A, 2002, 33, p 1429–1432.

Y.Q. Yao, Z.F. Xu, K. Sugio, Y. Choi, S. Kang, R. Fu and G. Sasaki, Nickel Formation on Graphite Sheet Surface for Improving Wettability with Magnesium Alloy, Mater. Trans., 2015, 56(10), p 1693–1697.

A. Alten, E. Erzi, Ö. Gürsoy, G.H. Ağaoğlu, D. Dispinar and G. Orhan, Production and Mechanical Characterization of Ni-Coated Carbon Fibers Reinforced Al-6063 Alloy Matrix Composites, J. Alloys Compd., 2019, 787, p 543–550.

C. Tekmen, F. Saday, U. Cocen and L.Y. Ljungberg, An Investigation of the Effect of SiC Reinforcement Coating on the Wettability of Al/SiC System, J. Comp. Mater., 2008, 42(16), p 1671–1679.

H. Okamoto, Al-Ni (Aluminum-Nickel), J. Phs. Eqil. and Diff., 2004, 25, p 394.

H.L. Chen, E. Doernberg, P. Svobod and R. Schmid-Fetzer, Thermodynamics of the Al3Ni Phase and Revision of the Al-Ni System, Thermochim. Acta, 2011, 512, p 189–195.

K. Bouche, F. Barbier and A. Coulet, Phase Formation During Dissolution of Nickel in Liquid Aluminium, Z. Met., 1997, 88, p 446–451.

H. Mehrer and W. Sprengel, Reaction Diffusion and Interdiffusion in Some Binary Metallic Systems, Philos. Mag., 2013, 93, p 1971–1986.

I. Kwiecien, P. Bobrowski, A. Wierzbicka-Miernik et al., Growth Kinetics of the Selected Intermetallic Phases in Ni/Al/Ni System with Various Nickel Substrate Microstructure, Nanomaterials, 2019, 9, p 134.

F.M. d’Heurle, Interface Reactions with Formation of a Solid Phase on a Solid Substrate: A Short Overview, Mater. Sci. Forum, 1994, 155–156, p 1–14.

V.I. Dybkov, Reaction Diffusion and Solid State Chemical Kinetics, The IPMS Publications, Kyiv, Ukraine, 2002, p 121–178

C.L. Tsao and S.W. Chen, Interfacial Reactions in the Liquid Diffusion Couples of Mg/Ni, Al/Ni and Al/(Ni)-Al2O3 Systems, J. Mater. Sci., 1995, 30, p 5215–5222.

A.M. Rashidi and A. Amadeh, Growth Kinetics of Aluminide Layers on Nanocrystalline Nickel, Int. J. Mod. Phys.: Conf Ser., 2012, 5, p 654–660.

S.W. Ip, R. Sridhar, J.M. Toguri, T.F. Stephenson and A.E.M. Warner, Wettability of Nickel Coated Graphite by Aluminum, Mater. Sci. Eng. A, 1998, 244, p 31–38.

T.J. Singler, J.A. Clum and E.R. Prack, Wetting Dynamics of Molten Solder Alloys on Metal Substrates, J. Electron. Packag., 1992, 114, p 128–134.

E. Saiz and A.P. Tomsia, Atomic Dynamics and Marangoni Films During Liquid-Metal Spreading, Nat. Mater., 2004, 3, p 903–909.

N. Sobczak, K. Nogi, H. Fujii, T. Matsumoto, K. Tamada and R. Asthana, The Effect of Cr Thin Film on Wettability and Bonding in Ni/Alumina Couple, Proceedings of the International Conference on Joining of Advanced and Specialty Materials (JASM-VI), editors: J.E. Indacochea and J.N. Dupont et al, ASM 2003, pp 108-115, https://www.researchgate.net/publication/235696200_The_Effect_of_Cr_Thin_Film_on_Wettability_and_Bonding_in_NiAlumina_Couple.

F. Brochard, Motions of Droplets on Solid Surfaces Induced by Chemical or Thermal Gradients, Langmuir, 1995, 5, p 432–438.

P.G. de Gennes, Wetting: Statics and Dynamics, Rev. Mod. Phys., 1985, 57, p 827–863.

R. Novakovic, M. Mohr, D. Giuranno et al., Surface Properties of Liquid Al-Ni Alloys: Experiments vs Theory, Microgravity Sci. Tec., 2020, 32, p 1049–1064.

I.F. Bainbridge and J.A. Taylor, The Surface Tension of Pure Aluminum and Aluminum Alloys, Metall. Mater. Trans. A, 2013, 44, p 3901–3909.

B.J. Keene, Review of Data for the Surface Tension of Pure Metals, Inter. Mater. Rev., 1993, 38, p 157–192.

G. Kaptay, Nano-Calphad: Extension of the Calphad Method To Systems With Nano-Phases And Complexions, J. Mater. Sci., 2012, 47, p 8320–8335.

C. J. Smithells, Metals Reference Book, 7nd ed., E. A. Brandes and G. B. Brook, Ed., The Bath Press, 1992, 8-9.

D. Quéré, Wetting and Roughness, Annu. Rev. Mater. Res., 2008, 38, p 71–99.

Acknowledgments

The authors acknowledge the financial support from the National Natural Science Foundation of China (Grant No. 50704001).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Xu, Q., Lin, H. & Liu, H. Effect of Coating Thickness on Wetting Behavior of Nickel-Coated Alumina by Molten Aluminum. J. of Materi Eng and Perform 31, 8261–8269 (2022). https://doi.org/10.1007/s11665-022-06837-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-06837-x