Abstract

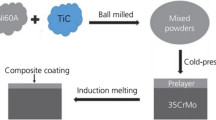

Ni45 alloy coating with the directional structure was prepared by using the induction remelting and forced cooling. The microstructure, phase constitution, microhardness, and wear resistance of the coating were investigated by SEM, XRD, microhardness tester, and tribometer. The results showed that the directional structure is formed in the coating, and compared with the simple remelting coatings, the coating with the directional structure exhibits denser microstructure, wider interface and excellent wear resistance. The wear weight loss of the coating with the directional structure is about 10 times less, 9.3 times less and 10.3 times less than that of the as-sprayed coating at loading 50, 100 and 150 N, respectively. And that is 0.12 times less at 50 N, 1.2 times less at 100 N, and 1.3 times less at 150 N than that of simple remelting coating.

Similar content being viewed by others

References

A. Conde, F. Zubiri and Y.J. de Damborenea, Cladding of Ni–Cr–B–Si Coatings with a High Power Diode Laser, Mater. Sci. Eng. A, 2002, 334, p 233–238. https://doi.org/10.1016/s0921-5093(01)01808-1

L.J. Silva, C.J. Scheuer and A.S.C.M. d’Oliveira, Effect of Microstructure on Wear Performance of NiCrSiBC Coatings, Wear, 2019, 428–429, p 387–394. https://doi.org/10.1016/j.wear.2019.04.005

Y.M. Zou, Y.S. Wu, J.Z. Wang, Z.G. Qiu and D.C. Zeng, Preparation, Mechanical Properties and Cyclic Oxidation Behavior of the Nanostructured NiCrCoAlY-TiB2 Coating, Ceram Int., 2018, 44, p 19362–19369. https://doi.org/10.1016/j.ceramint.2018.07.165

M.Y. Zhang, M. Li, J. Chi, S.F. Wang, S. Yang, J. Yang and Y.J. Wei, Effect of Ti on Microstructure Characteristics, Carbide Precipitation Mechanism and Tribological Behavior of Different WC Types Reinforced Ni Based Gradient Coating, Surf. Coat. Technol., 2019, 374, p 645–675. https://doi.org/10.1016/j.surfcoat.2019.06.066

H. Liu, W.D. Xuan, X.F. Ren, B.J. Wang, J.B. Yu and Z.M. Ren, Effect of a High Magnetic Field on the Microstructure of directionally Solidified NiAl-Cr(Mo)-Si Near-Eutectic Alloy at Different Withdrawal Rates, J. Alloys Compd., 2017, 898, p 407–412. https://doi.org/10.4028/www.scientific.net/msf.898.407

X.T. Luo, Y.J. Li, C.X. Li, G.J. Yang and C.J. Li, Effect of Spray Conditions on Deposition Behavior and Microstructure of Cold Sprayed Ni Coatings Sprayed with a Porous Electrolytic Ni Powder, Surf. Coat. Technol., 2016, 289, p 85–93. https://doi.org/10.1016/j.surfcoat.2016.01.058

K. Bobzin, M. Öte, J. Schein, S. Zimmermann, K. Möhwald and C. Lummer, Modelling the Plasma Jet in Multi-Arc Plasma Spraying, J. Therm. Spray Tech., 2016, 25, p 1111–1126. https://doi.org/10.1007/s11666-016-0438-0

M. Karbasi, M.R. Ghavidel and A. Nekahi, Corrosion Behavior of HVOF Sprayed Coatings of Ni-TiC and Ni-(Ti, W)C SHS Produced Composite Powders and Ni + TiC Mixed Powder, Mater. Corros., 2014, 65, p 485–492. https://doi.org/10.1002/maco.201206536

Z.A. Jin, L.N. Zhu, H.D. Wang, M. Liu, J.J. Kang, G.Z. Ma and S.Y. Chen, Microstructures and Wear Resistance of Al-25 wt.%Si Coatings Prepared by High-Efficiency Supersonic Plasma Spraying, J. Therm. Spray Tech., 2019, 28, p 1308–1317. https://doi.org/10.1007/s11666-019-00898-6

B.Y. Han, S.Y. Bei, K.B. Zhou, Y.X. Liu, Y. Zhang, X. Yan, W.X. Hang, F.F. Cui, W.W. Xu, W. Du and S. Zhu, Effect of Laser Remelting on Microstructure and Properties of Two Ni-Base Coatings by Supersonic Particles Deposition, Surf. Topogr.: Metrol. Prop., 2020, 8, p 045014. https://doi.org/10.1088/2051-672x/abc0fa

H.M. Xu, H.H. Huang and Z.F. Liu, Influence of Plasma Transferred arc Remelting on Microstructure and Properties of PTAW-Deposited Ni-Based Overlay Coating, J. Therm. Spray Tech., 2021, 30, p 946–958. https://doi.org/10.1007/s11666-021-01183-1

C.G. Pei, Z.X. Guo and J.G. Xiao, Effect of Laser Remelting Treatment on Al85Ni8Y4Ce3 Amorphous Coating, Surf. Eng., 2021, 37, p 642–649. https://doi.org/10.1080/02670844.2020.1800347

M.L. Wang, G.J. Zhang, H.Z. Cui, Y.P. Lu, Y. Zhao, N. Wei and T.Q. Li, Effect of Plasma Remelting on Microstructure and Properties of a CoCrCuNiAl0.5 high-Entropy Alloy Prepared by Spark Plasma Sintering, J. Mater. Sci., 2021, 56, p p5878-5898. https://doi.org/10.1007/s10853-020-05570-x

D.L. Zou, D.R. Yan, L.S. Xiao and Y.C. Dong, Characterization of Nanostructured TiN Coatings Fabricated by Reactive Plasma Spraying, Surf. Coat. Technol., 2008, 202, p 1928–1934. https://doi.org/10.1016/j.surfcoat.2007.08.022

X.L. Chen, X.O. Qin, Z.H. Zhu and K. Gao, Microstructural Evolution and Wear Properties of the Continual Local Induction Cladding NiCrBSi Coatings, J. Mater. Process. Tech., 2018, 262, p 257–268. https://doi.org/10.1016/j.jmatprotec.2018.05.034

D. Shu, Z.G. Li, K. Zhang, C.W. Yao, D.Y. Li and Z.B. Dai, Properties of WC Reinforced Ni60 Coating Prepared by High Frequency Induction Cladding, Mater. Lett., 2017, 195, p 178–181. https://doi.org/10.1016/j.matlet.2017.02.076

T.S. Dong, L. Liu, G.L. Li, R. Wang, J.M. Yuan and Y. Feng, Effect of Induction Remelting on Microstructure and Wear Resistance of Plasma Sprayed NiCrBSiNb Coatings, Surf. Coat. Technol., 2019, 364, p 347–357. https://doi.org/10.1016/j.surfcoat.2019.02.083

J.B. Chen, Y.C. Dong, L.N. Wan, Y. Yang, Z.H. Chu, J.X. Zhang, J.N. He and D.Y. Li, Effect of Induction Remelting on the Microstructure and Properties of in Situ TiN-Reinforced NiCrBSi Composite Coatings, Surf. Coat. Technol., 2018, 340, p 159–166. https://doi.org/10.1016/j.surfcoat.2018.02.024

M. Pourgharibshahi, M. Divandari, H.S. Larijani and P. Ashtari, Controlled Diffusion Solidification Processing: A Review, J. Mater. Process. Tech., 2017, 250, p 203–219. https://doi.org/10.1016/j.jmatprotec.2017.07.018

H. Zhang, H. Springer, R. Aparicio-Fernández and D. Raabe, Improving the Mechanical Properties of Fe – TiB2 High Modulus Steels Through Controlled Solidification Processes, Acta Mater., 2016, 118, p 187–195. https://doi.org/10.1016/j.actamat.2016.07.056

Y. Liu, J.C. An, G. Yang, L. Shi and Y.J. Wang, Feathery Microstructure Formation of Ti48Al2Cr2Nb Alloy by Rapidly Quenched Solidification, Cryst. Res. Technol., 2018, 53, p 1800041. https://doi.org/10.1002/crat.201800041

M.X. Guo, F. Wang and L. Yi, The Microstructure Controlling and Deformation Behaviors of Cu–Fe–C Alloy Prepared by Rapid Solidification, Mater. Sci. Eng. A, 2016, 657, p 197–209. https://doi.org/10.1016/j.msea.2016.01.068

J.S. Wei and F.X. Gan, Theoretical Explanation of Different Crystallization Processes Between as-Deposited and Melt-Quenched Amorphous Ge2Sb2Te5 Thin Films, Thin Solid Films, 2003, 441, p 292–297. https://doi.org/10.1016/S0040-6090(03)00977-5

F. Coudon, G. Cailletaud, J. Cormier and L. Marcin, A Multiscale Model for Nickel-Based Directionally Solidified Materials, Int. J. Plasticity, 2019, 115, p 1–17. https://doi.org/10.1016/j.ijplas.2018.10.003

C.J. Cui, L.L. Tian, J. Zhang, S.G. Yu, L. Liu and H.Z. Fu, Microstructure and Property of Directionally Solidified Ni–Si Hypereutectic Alloy, Appl. Phys. A, 2016, 122, p 213. https://doi.org/10.1007/s00339-016-9702-x

Y.S. Fan, X.G. Yang, L. Tan, D.Q. Shi, S.L. Li and P. Wang, Experiment and Modelling on the Effect of Microstructural Morphology on Fatigue Life of a Ni-Based Superalloy, Mater. Sci. Eng. A, 2020, 786, p 139368. https://doi.org/10.1016/j.msea.2020.139368

N. Ying, P.B. Oliete and I.R. Merino, Influence of Microstructural Size on the Thermal Shock Behavior of Al2O3-Er3Al5O12 Directionally Solidified Eutectics, Scr. Mater., 2019, 160, p 20–24. https://doi.org/10.1016/j.scriptamat.2018.09.036

X.A. Hu, X.G. Yang, D.Q. Shi, H.C. Yu and T.T. Ren, Constitutive Modeling of a Directionally Solidified Nickel-Based Superalloy DZ125 Subjected to Thermal Mechanical Creep Fatigue Loadings, Rare Met., 2019, 38, p 922–936. https://doi.org/10.1007/s12598-016-0713-8

C.Y. Sun, L. Li and M.W. Fu, Element Diffusion Model of Bimetallic Hot Deformation in Metallurgical Bonding Process, Mater. Des., 2016, 94, p 433–443. https://doi.org/10.1016/j.matdes.2016.01.058

K. Kılıçay, S. Buytoz and M. Ulutan, Microstructural and Tribological Properties of Induction Cladded NiCrBSi/WC Composite Coatings, Surf. Coat. Technol., 2020, 396, 125974. https://doi.org/10.1016/j.surfcoat.2020.125974

J.H. Chang, C.P. Chang, J.M. Chou, R.I. Hsieh and J.L. Lee, Microstructure and Bonding Behavior on the Interface of an Induction-Melted Ni-Based Alloy Coating and AISI 4140 Steel Substrate, Surf. Coat. Technol., 2010, 204, p 3173–3181. https://doi.org/10.1016/j.surfcoat.2010.03.002

Y.X. Qiao, J. Huang, D. Huang, J. Chen, W. Liu, Z.B. Wang and Z.B. Zheng, Effects of Laser Scanning Speed on Microstructure, Microhardness, and Corrosion Behavior of Laser Cladding Ni45 Coatings, J. Chem., 2020, 2020, p 1–11. https://doi.org/10.1155/2020/1438473

Funding

This work was supported by the National Natural Science Foundation of China under Grant (No.51365024); and the Natural Science Foundation of Gansu Province (No.20JR5RA471).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

No potential conflict of interest was reported by the authors.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yang, X., Wang, X., Fu, X. et al. Preparation of Ni45 Alloy Coating with Directional Structure and its Wear Resistance. J. of Materi Eng and Perform 31, 8285–8293 (2022). https://doi.org/10.1007/s11665-022-06836-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-06836-y