Abstract

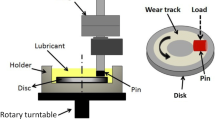

In the present work, DLC coating was prepared on GCr15 bearing steel by magnetron sputtering method. The tribological behavior of GCr15 steel and DLC coating was studied at the speed range of 0.4 to 4.0 cm/s under two viscosity grades fully formulated lubricating oils (0W-20, 0W-40). The results show that viscosity of oil and sliding speed have a great effect on the DLC coating tribological properties. Compared to GCr15 steel at the speed of 0.4cm/s, there was a 41.67% reduction in the friction coefficient and 86.35% reduction in the wear rate of DLC coating in 0W-20 oil. The anti-friction and anti-wear advantages of DLC coating gradually disappear in low viscosity lubricating oil with the increase in sliding speed. The oil chain length and slip characteristics on DLC coating are two main factors that affect lubrication performance. The low viscosity lubricating oil, 0W-20, requires less energy to move and penetrate the lubricant molecules on DLC coating. This study will provide an experimental and theoretical basis for the application of low viscosity lubricating oil on DLC coating in the internal combustion engine industry.

Similar content being viewed by others

References

K. Holmberg, P. Andersson, and A. Erdemir, Global Energy Consumption due to Friction in Passenger Cars, Tribol. Int., 2012, 47, p 221–234.

McGrawHill, Internal Combustion Engine Fundamentals, Internal Combustion Engine Fundamentals, 1988

K. Holmberg, P. Andersson, N.-O. Nylund, K. Mäkelä, and A. Erdemir, Global Energy Consumption due to Friction in Trucks and Buses, Tribol. Int., 2014, 78, p 94–114.

K. Holmberg and A. Erdemir, Influence of Tribology on Global Energy Consumption, Costs and Emissions, Friction, 2017, 5(3), p 263–284.

H. Ronkainen and K. Holmber, Tribology of Diamond-like Carbon Films Fundamentals and Applications, 2008

K. Bewilogua and D. Hofmann, History of Diamond-Like Carbon Films—From First Experiments to Worldwide Applications, Surf. Coat. Technol., 2014, 242, p 214–225.

B. Podgornik and J. Vižintin, Tribological Reactions Between Oil Additives and DLC Coatings for Automotive Applications, Surf. Coat. Technol., 2005, 200(5–6), p 1982–1989.

G. Vaitkunaite, C. Espejo, C. Wang, B. Thiébaut, C. Charrin, A. Neville, and A. Morina, MoS2 Tribofilm Distribution from Low Viscosity Lubricants and its Effect on Friction, Tribol. Int., 2020, 151, p 106531.

B. Vengudusamy, J.H. Green, G.D. Lamb, and H.A. Spikes, Behaviour of MoDTC in DLC/DLC and DLC/Steel Contacts, Tribol. Int., 2012, 54, p 68–76.

W. Yue, C. Liu, Z. Fu, C. Wang, H. Huang, and J. Liu, Synergistic Effects Between Sulfurized W-DLC Coating and MoDTC Lubricating Additive for Improvement of Tribological Performance, Tribol. Int., 2013, 62, p 117–123.

J.M. Martin, C. Grossiord, T.L. Mogne, and J.J.W. Igarashi, Transfer Films and Friction under Boundary Lubrication, Wear, 2000, 245(1), p 107–115.

M. Ueda, A. Kadiric, and H. Spikes, Wear of Hydrogenated DLC in MoDTC-Containing Oils, Wear, 2021, 474–475, p 203869.

T. Haque, A. Morina, A. Neville, R. Kapadia, and S. Arrowsmith, Effect of Oil Additives on the Durability of Hydrogenated DLC Coating under Boundary Lubrication Conditions, Wear, 2009, 266(1–2), p 147–157.

Z. Cao, Y. Xia, L. Liu, and X. Feng, Study on the Conductive and Tribological Properties of Copper Sliding Electrical Contacts Lubricated by Ionic Liquids, Tribol. Int., 2019, 130, p 27–35.

M. Azzi, M. Paquette, J.A. Szpunar, J.E. Klemberg-Sapieha, and L. Martinu, Tribocorrosion Behaviour of DLC-Coated 316L Stainless Steel, Wear, 2009, 267(5–8), p 860–866.

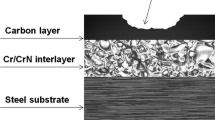

X. Sui, J. Liu, S. Zhang, J. Yang, and J. Hao, Microstructure, Mechanical and Tribological Characterization of CrN/DLC/Cr-DLC Multilayer Coating with Improved Adhesive Wear Resistance, Appl. Surf. Sci., 2018, 439, p 24–32.

M. Ebrahimi, F. Mahboubi, and M.R. Naimi-Jamal, Wear Behavior of DLC Film on Plasma Nitrocarburized AISI 4140 Steel by Pulsed DC PACVD: Effect of Nitrocarburizing Temperature, Diam. Relat. Mater., 2015, 52, p 32–37.

M. Yan, X. Wang, S. Zhang, S. Zhang, X. Sui, W. Li, J. Hao, and W. Liu, Friction and Wear Properties of GLC and DLC Coatings under Ionic Liquid Lubrication, Tribol. Int., 2020, 143, p 106067.

F.D. Duminica, R. Belchi, L. Libralesso, and D. Mercier, Investigation of Cr(N)/DLC Multilayer Coatings Elaborated by PVD for High Wear Resistance and Low Friction Applications, Surf. Coat. Technol., 2018, 337, p 396–403.

G.M. Pharr and W.C.J.M.B. Oliver, Measurement of Thin Film Mechanical Properties using Nanoindentation, MRS Bull., 1992, 17(07), p 28–33.

W.C. Oliver and G.M.J.J.O.M.R. Pharr, Measurement of Hardness and Elastic Modulus by Instrumented Indentation: Advances in Understanding and Refinements to Methodology, J. Mater. Res., 2004, 19(1), p 3–20.

P. Zhang, S.X. Li, and Z.F.J.M.S. Zhang, General Relationship Between Strength and Hardness, Mater. Sci. Eng., 2011, 529, p 62–73.

D.J.M.T. Tabor, The Hardness of Metals, 1951

C. Hua, J. Guo, J. Liu, X. Yan, Y. Zhao, L. Chen, J. Wei, L. Hei, and C. Li, Influence of Diamond Surface Chemical States on the Adhesion Strength Between Y2O3 Film and Diamond Substrate, Mater. Des., 2016, 105, p 81–88.

Y. Ye, Y. Wang, H. Chen, J. Li, Y. Yao, and C. Wang, Doping Carbon to Improve the Tribological Performance of CrN Coatings in Seawater, Tribol. Int., 2015, 90, p 362–371.

J. Yao, L. Lv, Y. He, and D. Wang, Size Effect of (Al2O3–Y2O3)/YSZ Micro-Laminated Coating on High-Temperature Oxidation Resistance, Appl. Surf. Sci., 2013, 279, p 85–91.

A.J. Gant, M.G. Gee, and L.P. Orkney, The Wear and Friction Behaviour of Engineering Coatings in Ambient Air and Dry Nitrogen, Wear, 2011, 271(9–10), p 2164–2175.

S. Neuville, Quantum Electronic Mechanisms of Atomic Rearrangements during Growth of Hard Carbon Films, Surf. Coat. Technol., 2011, 206(4), p 703–726.

B. Vengudusamy, R.A. Mufti, G.D. Lamb, J.H. Green, and H.A. Spikes, Friction Properties of DLC/DLC Contacts in Base Oil, Tribol. Int., 2011, 44(7–8), p 922–932.

K. Topolovec-Miklozic, F. Lockwood, and H. Spikes, Behaviour of Boundary Lubricating Additives on DLC Coatings, Wear, 2008, 265(11–12), p 1893–1901.

H.S. Zhang, J.L. Endrino, and A. Anders, Comparative Surface and Nano-Tribological Characteristics of Nanocomposite Diamond-Like Carbon Thin Films Doped by Silver, Appl. Surf. Sci., 2008, 255(5), p 2551–2556.

I. Sugimoto, F. Honda, and K. Inoue, Analysis of Wear Behavior and Graphitization of Hydrogenated DLC under Boundary Lubricant with MoDTC, Wear, 2013, 305(1–2), p 124–128.

S. Kosarieh, A. Morina, E. Lainé, J. Flemming, and A. Neville, The Effect of MoDTC-type Friction Modifier on the Wear Performance of a Hydrogenated DLC Coating, Wear, 2013, 302(1–2), p 890–898.

H. Okubo, C. Tadokoro, T. Sumi, N. Tanaka, and S. Sasaki, Wear Acceleration Mechanism of Diamond-like Carbon (DLC) Films Lubricated with MoDTC Solution: Roles of Tribofilm Formation and Structural Transformation in Wear Acceleration of DLC Films Lubricated with MoDTC Solution, Tribol. Int., 2019, 133, p 271–287.

I. Velkavrh and M. Kalin, Comparison of the Effects of the Lubricant-Molecule Chain Length and the Viscosity on the Friction and Wear of Diamond-Like-Carbon Coatings and Steel, Tribol. Int., 2012, 50, p 57–65.

M. Kalin, J. Vižintin, J. Barriga, K. Vercammen, K.V. Acker, and A. Arnšek, The Effect of Doping Elements and Oil Additives on the Tribological Performance of Boundary-Lubricated DLC/DLC Contacts, Tribol. Lett., 2004, 17(4), p 679–688.

M. Kalin and J. Vižintin, Real Contact Temperatures as the Criteria for the Reactivity of Diamond-Like-Carbon Coatings with Oil Additives, Thin Solid Films, 2010, 518(8), p 2029–2036.

O.N. Shebanova and P.J.J.O.R.S. Lazor, Raman Study of Magnetite (Fe3O4): Laser-Induced Thermal Effects and Oxidation, J. Raman Spectrosc., 2003, 34(11), p 845–852.

A. Erdemir, O.L. Eryilmaz, I.B. Nilufer, G.R.J.S. Fenske, and C. Technology, Synthesis of Superlow-Friction Carbon Films from Highly Hydrogenated Methane Plasmas, Surf. Coat. Technol., 2000, 133, p 448–454.

C. Donnet, J. Fontaine, A. Grill, and T.J.T.L. Le Mogne, The Role of Hydrogen on the Friction Mechanism of Diamond-Like Carbon Films, Tribol. Lett., 2001, 9(3), p 137–142.

A. Erdemir, Superlubricity in Diamondlike Carbon Films, 2007

J. Wang, J. Ma, W. Huang, L. Wang, H. He, and C. Liu, The Investigation of the Structures and Tribological Properties of F-DLC Coatings Deposited on Ti-6Al-4V Alloys, Surf. Coat. Technol., 2017, 316, p 22–29.

Acknowledgment

The authors wish to acknowledge the financial support of Open Fund of the Yellow River Water Environment Key Laboratory of Gansu Province, China (Grant No. 221162).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yang, G., Xu, L., Li, D. et al. Study on the Lubrication Mechanism of Diamond-Like Carbon Coating in Two Formulated Lubricants with Two Viscosity Grades. J. of Materi Eng and Perform 31, 6711–6721 (2022). https://doi.org/10.1007/s11665-022-06708-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-06708-5