Abstract

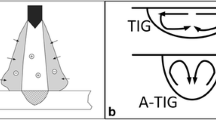

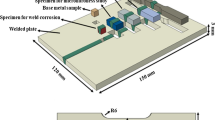

The deposition of austenitic stainless steel coatings on high-strength low-alloy steel surfaces was a common method in engineering. However, excessive dilution of the substrate resulting in degradation of the coating properties is a constant challenge. In this paper, tungsten argon arc welding (TIG) technology was optimized based on the response surface method to produce a very low dilution (4%) stainless steel coating on the surface of Q355 steel. The intergranular corrosion sensitivity of the two coatings was tested by the double-loop electrochemical potentiodynamic reactivation technique. The DOS value of the coating made by the TIG technique (6.83%) is lower than that of the coating made by flux-cored arc welding (9.31%). The improved intergranular corrosion resistance is attributed to the dilution rate, grain size, grain boundary type, and inclusions. A technique of manufacturing low dilution coatings is provided, achieving a 50% savings in welding material.

Similar content being viewed by others

Data Availability

The datasets supporting the conclusions of this article are included within the article and its additional files.

References

P. Luchtenberg, P.T. de Campos, P. Soares, C.A.H. Laurindo, O. Maranho and R.D. Torres, Effect of Welding Energy on the Corrosion and Tribological Properties of Duplex Stainless Steel Weld Overlay Deposited by GMAW/CMT Process, Surf. Coat. Technol., 2019, 375, p 688–693. https://doi.org/10.1016/j.surfcoat.2019.07.072

M. Moradi, M.K. Moghadam and M. Kazazi, Improved Laser Surface Hardening of AISI 4130 Low Alloy Steel with Electrophoretically Deposited Carbon Coating, Optik, 2019, 178, p 614–622.

F. Weng, S. Gao, J. Jiang, J. Wang and P. Guo, A Novel Strategy to Fabricate thin 316L Stainless Steel Rods by Continuous Directed Energy Deposition in Z Direction, Addit. Manuf., 2019, 27, p 474–481.

H. Zhang, C. Zhang, Q. Wang, C. Wu, S. Zhang, J. Chen and A.O. Abdullah, Effect of Ni Content on Stainless Steel Fabricated by Laser Melting Deposition, Opt. Lasers. Technol., 2018, 101, p 363–371.

S. Shukla, A.P. Patil, A.P. Kawale, R.K. Haldkar, A. Dahiwale and A. Bansod, Effect of Grain Refinement on Sensitization of High Manganese Austenitic Stainless Steel, Materials Today: Proceedings, 2021, 44, p 2802–2807. https://doi.org/10.1016/j.matpr.2020.12.833

W. Wang, Y. Hu, M. Zhang and H. Zhao, Microstructure and Mechanical Properties of Dissimilar Friction Stir Welds in Austenitic-Duplex Stainless Steels, Mater. Sci. Eng., A, 2020, 787, p 139499. https://doi.org/10.1016/j.msea.2020.139499

Q. Xiao, C. Jang, C. Kim, H. Kim, J. Chen and H.B. Lee, Corrosion Behavior of Stainless Steels in Simulated PWR Primary Water: The Effect of Composition and Matrix Phases, Corrosion Sci., 2020, 177, 108991. https://doi.org/10.1016/j.corsci.2020.108991

S.-X. Li, Y.-N. He, S.-R. Yu and P.-Y. Zhang, Evaluation of the Effect of Grain Size on Chromium Carbide Precipitation and Intergranular Corrosion of 316L Stainless Steel, Corrosion Sci., 2013, 66, p 211–216. https://doi.org/10.1016/j.corsci.2012.09.022

J. Li, H. Li, Y. Liang, P. Liu, L. Yang and Y. Wang, Effects of Heat Input and Cooling Rate During Welding on Intergranular Corrosion Behavior of High Nitrogen Austenitic Stainless Steel Welded Joints, Corrosion Sci., 2020, 166, p 108445. https://doi.org/10.1016/j.corsci.2020.108445

X. Qin, X. Guo, J. Lu, L. Chen, J. Qin and W. Lu, Erosion-Wear and Intergranular Corrosion Resistance Properties of AISI 304L Austenitic Stainless Steel after Low-Temperature Plasma Nitriding, J. Alloy. Compd., 2017, 698, p 1094–1101. https://doi.org/10.1016/j.jallcom.2016.12.164

Z. Lai, P. Bi, L. Wen, Y. Xue and Y. Jin, Local Electrochemical Properties of Fusion Boundary Region in SA508-309L/308L Overlay Welded Joint, Corrosion Sci., 2019, 155, p 75–85. https://doi.org/10.1016/j.corsci.2019.04.021

S.K. Pradhan, P. Bhuyan and S. Mandal, Individual and Synergistic Influences of Microstructural Features on Intergranular Corrosion Behavior in Extra-low Carbon type 304L Austenitic Stainless Steel, Corrosion Sci., 2018, 139, p 319–332. https://doi.org/10.1016/j.corsci.2018.05.014

A. La Fontaine, H.-W. Yen, P. Trimby, S. Moody, S. Miller, M. Chensee, S. Ringer and J. Cairney, Martensitic Transformation in an Intergranular Corrosion Area of Austenitic Stainless Steel During Thermal Cycling, Corrosion Sci., 2014, 85, p 1–6. https://doi.org/10.1016/j.corsci.2014.04.048

N.V. Rao, G.M. Reddy and S. Nagarjuna, Weld Overlay Cladding of High Strength Low Alloy Steel with Austenitic Stainless Steel-Structure and Properties, Mater. Des., 2011, 32(4), p 2496–2506. https://doi.org/10.1016/j.matdes.2010.10.026

H. Yousefi Azad, S.H. Mousavi Anijdan and H. Najafi, The Effect of PWHT on the Microstructural Evolution, Carbides Formation and Mechanical Properties of a Nb Containing Martensitic Heat Resistance Steel Used in Gas Turbine, Mater. Sci. Eng., A, 2020, 793, p 139810. https://doi.org/10.1016/j.msea.2020.139810

G. Dak and C. Pandey, A Critical Review on Dissimilar Welds Joint Between Martensitic and Austenitic Steel for Power Plant Application, J. Manuf. Process., 2020, 58, p 377–406. https://doi.org/10.1016/j.jmapro.2020.08.019

M. Shamanian, A. Eghlimi, M. Eskandarian and J.A. Szpunar, Interface Microstructure Across Cladding of Super Duplex Stainless Steel with Austenitic Stainless Steel Buffer Layer, Surf. Coat. Technol., 2014, 259, p 532–542. https://doi.org/10.1016/j.surfcoat.2014.10.034

A. Eghlimi, M. Shamanian, M. Eskandarian, A. Zabolian, M. Nezakat and J.A. Szpunar, Evaluation of Microstructure and Texture Across the Welded Interface of Super Duplex Stainless Steel and High Strength Low Alloy Steel, Surf. Coat. Technol., 2015, 264, p 150–162. https://doi.org/10.1016/j.surfcoat.2014.12.060

A. Eghlimi, M. Shamanian, M. Eskandarian, A. Zabolian and J.A. Szpunar, Characterization of Microstructure and Texture Across Dissimilar Super Duplex/Austenitic Stainless Steel Weldment Joint by Austenitic Filler Metal, Mater. Charact., 2015, 106, p 208–217. https://doi.org/10.1016/j.matchar.2015.05.036

X. Di, Z. Zhong, C. Deng, D. Wang and X. Guo, Microstructural Evolution of Transition Zone of clad X70 with Duplex Stainless Steel, Mater. Des., 2016, 95, p 231–236. https://doi.org/10.1016/j.matdes.2016.01.087

Y. Zhai, L. Yang, T. He and Y. Liu, Weld Morphology and Microstructure During Simulated Local Dry Underwater FCTIG, J. Mater. Process. Technol., 2017, 250, p 73–80. https://doi.org/10.1016/j.jmatprotec.2017.07.010

L. Yang, Y. Wang, T. Sun, Y. Huang, Y. Zhai and T. He, Microstructure and Mechanical Properties of FCTIG-Welded DH36 Steel with Rutile-Type and Basic-Type Flux Cored Wires, J. Mater. Process. Technol., 2020, 275, 116363. https://doi.org/10.1016/j.jmatprotec.2019.116363

M. Ragavendran, N. Chandrasekhar, R. Ravikumar, R. Saxena, M. Vasudevan and A.K. Bhaduri, Optimization of Hybrid Laser–TIG Welding of 316LN Steel Using Response Surface Methodology (RSM), Opt. Lasers. Eng., 2017, 94, p 27–36. https://doi.org/10.1016/j.optlaseng.2017.02.015

N.R. Baddoo, Stainless Steel in Construction: A Review of Research, Applications, Challenges and Opportunities, J. Constr. Steel. Res., 2008, 64(11), p 1199–1206. https://doi.org/10.1016/j.jcsr.2008.07.011Get

J. Verma and R.V. Taiwade, Effect of Welding Processes and Conditions on the Microstructure, Mechanical Properties and Corrosion Resistance of Duplex Stainless Steel Weldments—A Review, J. Manuf. Process., 2017, 25, p 134–152. https://doi.org/10.1016/j.jmapro.2016.11.003

F. Mas, C. Tassin, F. Roch, M. Yescas, P. Todeschini and Y. Bréchet, Growth Morphologies and Primary Solidification Modes in a Dissimilar Weld Between a Low-Alloy Steel and an Austenitic Stainless Steel, Metals, 2018, 8(4), p 284.

Y. Wu and B. Patchett, Formation of Crack-Susceptible Structures of Weld Overlay of Corrosion Resistant Alloys, Mater. Perform. Sulphur Energy, 1992, 1992, p 283–295.

B.O. Okonkwo, H. Ming, J. Wang, F. Meng, X. Xu and E.-H. Han, Microstructural Characterization of Low Alloy Steel A508–309/308L Stainless Steel Dissimilar Weld Metals, Int. J. Press. Ves. Pip., 2021, 190, p 104297.

T. Nelson, J. Lippold and M. Mills, Nature and Evolution of the Fusion Boundary in Ferritic-Austenitic Dissimilar Metal Welds—Part 2: On-Cooling Transformations, Welding Research, 2000, 10, p 267–277.

H. Kokawa, M. Shimada, M. Michiuchi, Z.J. Wang and Y.S. Sato, Arrest of Weld-Decay in 304 Austenitic Stainless Steel by Twin-Induced Grain Boundary Engineering, Acta Mater., 2007, 55(16), p 5401–5407. https://doi.org/10.1016/j.actamat.2007.06.005

M. Michiuchi, H. Kokawa, Z.J. Wang, Y.S. Sato and K. Sakai, Twin-Induced Grain Boundary Engineering for 316 Austenitic Stainless Steel, Acta Mater., 2006, 54(19), p 5179–5184. https://doi.org/10.1016/j.actamat.2006.06.030

V. Randle, Twinning-Related Grain Boundary Engineering, Acta Mater., 2004, 52(14), p 4067–4081. https://doi.org/10.1016/j.actamat.2004.05.031

K.S. de Assis, A.C. Rocha, I.C.P. Margarit-Mattos, F.A.S. Serra and O.R. Mattos, Practical Aspects on the Use of On-site Double Loop Electrochemical Potentiodynamic Reactivation Technique (DL-EPR) for Duplex Stainless Steel, Corrosion Sci., 2013, 74, p 250–255. https://doi.org/10.1016/j.corsci.2013.04.050

S. Rahimi, D.L. Engelberg and T.J. Marrow, A New Approach for DL-EPR Testing of Thermo-Mechanically Processed Austenitic Stainless Steel, Corrosion Sci., 2011, 53(12), p 4213–4222. https://doi.org/10.1016/j.corsci.2011.08.033

S. Kobayashi, R. Kobayashi and T. Watanabe, Control of Grain Boundary Connectivity Based on Fractal Analysis for Improvement of Intergranular Corrosion Resistance in SUS316L Austenitic Stainless Steel, Acta Mater., 2016, 102, p 397–405. https://doi.org/10.1016/j.actamat.2015.08.075

J. Zhang, L. Xu, Y. Han, L. Zhao and B. Xiao, New perspectives on the Grain Boundary Misorientation Angle Dependent Intergranular Corrosion of Polycrystalline Nickel-Based 625 Alloy, Corrosion Sci., 2020, 172, p 108718. https://doi.org/10.1016/j.corsci.2020.108718

P. Schmuki, H. Hildebrand, A. Friedrich and S. Virtanen, The Composition of the Boundary Region of MnS Inclusions in Stainless Steel and its Relevance in Triggering Pitting Corrosion, Corrosion Sci., 2005, 47(5), p 1239–1250. https://doi.org/10.1016/j.corsci.2004.05.023

Acknowledgments

This work is supported by the National Natural Science Foundation of China under Grant No. 51875403, China Postdoctoral Science Foundation under Grant 2020M670651, and State Key Laboratory of Advanced Welding and Joining, Harbin Institute of Technology.

Author information

Authors and Affiliations

Contributions

Yaowei Wang was involved in conceptualization, methodology, formal analysis, Writing—original draft. Lijun Yang contributed to project administration, funding acquisition. Yiming Huang was involved in software, Writing—review & editing. Lixin Wang contributed to investigation, visualization.

Corresponding authors

Ethics declarations

Conflict of interest

No conflict of interest exists in the submission of this manuscript, and the manuscript has been approved by all authors for publication.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Wang, Y., Huang, Y., Wang, L. et al. Intergranular Corrosion Resistance of Stainless Steel Coating with Ultralow Dilution Rates Manufactured by Tungsten Arc Welding Technology. J. of Materi Eng and Perform 31, 2445–2456 (2022). https://doi.org/10.1007/s11665-021-06358-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-06358-z