Abstract

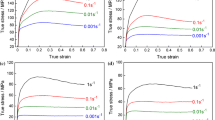

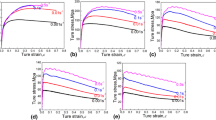

Isothermal compression experiments of as-homogenized Mg-8.5Gd-4.5Y-0.8Zn-0.4Zr alloy are conducted at temperature range of 673-773 K (400-500 °C) and strain rate range of 0.001-1 s−1 in order to identify the optimized processing parameters. Results show that flow stress decreases with the decreasing strain rate at a given temperature and increases with the decreasing temperature at a specific strain rate. Based on the obtained true stress-strain curves, processing maps based on the Prasad criterion and the Murty criterion are separately constructed. Obviously, distributions of power dissipation and the instability regime in the case of the Prasad criterion are different from the corresponding ones in the case of the Murty criterion during hot deformation. Microstructure observations on deformed samples confirm that kink band and dynamic recrystallization, rather than microcrack and flow localization, occur at 698 K and 0.01 s−1. This issue verifies the accuracy of instability regions determined on the base of the Murty criterion. Consequently, the processing window determined on the base of the Murty criterion is more reliable than that identified on the base of the Prasad criterion. The optimized processing parameters are finally ascertained to be 698-748 K, 0.001-0.01 s−1, and 748-773 K, 0.01-0.1 s−1.

Similar content being viewed by others

Change history

23 October 2023

A Correction to this paper has been published: https://doi.org/10.1007/s11665-023-08850-0

References

J. Zhang, S. Liu, R. Wu, L. Hou and M. Zhang, Recent Developments in High-Strength Mg-RE-Based Alloys: Focusing on Mg-Gd and Mg-Y Systems, J. Magnes. Alloys, 2018, 6(3), p 277–291.

H. Pan, Y. Ren, H. Fu, H. Zhao, L. Wang, X. Meng and G. Qin, Recent Developments in Rare-Earth Free Wrought Magnesium Alloys Having High Strength: A Review, J. Alloys Compd., 2016, 663, p 321–331.

X. Zhou, C. Liu, Y. Gao, S. Jiang, W. Liu and L. Lu, Hot Compression Behavior of the Mg-Gd-Y-Zn-Zr Alloy Filled with Intragranular Long-Period Stacking Ordered Phases, J. Alloys Compd., 2017, 724, p 528–536.

T. Homma, N. Kunito and S. Kamado, Fabrication of Extraordinary High-Strength Magnesium Alloy by Hot Extrusion, Scr. Mater., 2009, 61(6), p 644–647.

C. Xu, M. Zheng, S. Xu, K. Wu, E. Wang, S. Kamado, G. Wang and X. Lv, Ultra High-Strength Mg–Gd–Y–Zn–Zr Alloy Sheets Processed by Large-Strain Hot Rolling and Ageing, Mater. Sc. Eng. A, 2012, 547, p 93–98.

M.H. Barezban, H. Mirzadeh, R. Roumina and R. Mahmudi, Constitutive Analysis of Wrought Mg-Gd Magnesium Alloys during Hot Compression at Elevated Temperatures, J. Alloys Compd., 2019, 791, p 1200–1206.

B. Zhang, L. Geng, L. Huang, X. Zhang and C. Dong, Enhanced Mechanical Properties in Fine-Grained Mg–1.0 Zn–0.5 Ca Alloys Prepared by Extrusion at Different Temperatures, Scr. Mater., 2010, 63(10), p 1024–1027.

Y. Sun, Z. Cao, Z. Wan, L. Hu, W. Ye, N. Li and C. Fan, 3D Processing Map and Hot Deformation Behavior of 6A02 Aluminum Alloy, J. Alloys Compd., 2018, 742, p 356–368.

J. Li, J. Liu and Z. Cui, Characterization of Hot Deformation Behavior of Extruded ZK60 Magnesium Alloy Using 3D Processing Maps, Mater. Des., 2014, 56, p 889–897.

Y. Xue, Z. Zhang, G. Lu, Z. Xie, Y. Yang and Y. Cui, Study on Flow Stress Model and Processing Map of Homogenized Mg-Gd-Y-Zn-Zr Alloy during Thermomechanical Processes, J. Mater. Eng. Perform., 2015, 24(2), p 964–971.

X. Shang, J. Zhou, X. Wang and Y. Luo, Optimizing and Identifying the Process Parameters of AZ31 Magnesium Alloy in Hot Compression on the Base of Processing Maps, J. Alloys Compd., 2015, 629, p 155–161.

C. Sun, G. Liu, Q. Zhang, R. Li and L. Wang, Determination of Hot Deformation Behavior and Processing Maps of IN 028 Alloy using Isothermal Hot Compression Test, Mater. Sci. Eng. A, 2014, 595, p 92–98.

Y. Prasad, H. Gegel, S. Doraivelu, J. Malas, J. Morgan, K. Lark and D. Barker, Modeling of Dynamic Material Behavior in Hot Deformation: Forging of Ti-6242, Metall. Trans. A, 1984, 15(10), p 1883–1892.

S.N. Murty and B.N. Rao, On the Flow Localization Concepts In the Processing Maps of Titanium Alloy Ti–24Al–20Nb, J. Mater. Process. Technol., 2000, 104(1–2), p 103–109.

Y. Prasad and T. Seshacharyulu, Processing Maps for Hot Working of Titanium Alloys, Mater. Sc. Eng. A, 1998, 243(1–2), p 82–88.

S.N. Murty and B.N. Rao, On the Development of Instability Criteria during Hotworking with Reference to IN 718, Mater. Sc. Eng. A, 1998, 254(1–2), p 76–82.

B. Li, B. Teng and W. Xu, Hot Deformation Characterization of Homogenized Mg-Gd-Y-Zn-Zr Alloy During Isothermal Compression, JOM, 2019, 71(11), p 4059–4070.

Z. Zhang, Z. Yan, Y. Du, G. Zhang, J. Zhu, L. Ren and Y. Wang, Hot Deformation Behavior of Homogenized Mg-13.5 Gd-3.2 Y-2.3 Zn-0.5 Zr alloy via hot Compression Tests, Materials, 2018, 11(11), p 2282.

Y. Wang, J. Peng, L. Zhong and F. Pan, Modeling and Application of Constitutive Model Considering the Compensation of Strain during Hot Deformation, J. Alloys Compd., 2016, 681, p 455–470.

C. Xu, J. Pan, T. Nakata, X. Qiao, Y. Chi, M. Zheng and S. Kamado, Hot compression deformation behavior of Mg-9Gd-2.9 Y-1.9 Zn-0.4 Zr-0.2 Ca (wt%) alloy, Mater. Charact., 2017, 124, p 40–49.

G. Zhou, Z. Li, D. Li, Y. Peng, H. Zurob and P. Wu, A Polycrystal Plasticity Based Discontinuous Dynamic Recrystallization Simulation Method and Its Application to Copper, Int. J. Plast., 2017, 91, p 48–76.

D.C. Hanselman and B. Littlefield, The Student Edition of Matlab, Prentice Hall, Hoboken, 1997.

L. Xin, L. Shiqiang, W. Kelu, M. Fu, L. Zhenxi and C. Chunxiao, Hot Deformation Mechanism and Process Optimization for Ti-Alloy Ti-6.5 Al-3.5 Mo-1.5 Zr-0.3 Si during α+ β Forging Based on Murty Criterion, Rare Met. Mater. Eng., 2008, 37(4), p 577–583.

J. Shen, L. Hu, Y. Sun, X. Feng, A. Fang and Z. Wan, Hot Deformation Behaviors and Three-Dimensional Processing Map of a Nickel-Based Superalloy with Initial Dendrite Microstructure, J. Alloys Compd., 2020, 822, p 153735.

Y. Sun, X. Feng, L. Hu, H. Zhang and H. Zhang, Characterization on Hot Deformation Behavior of Ti-22Al-25Nb Alloy using a Combination of 3D Processing Maps and Finite Element Simulation Method, J. Alloys Compd., 2018, 753, p 256–271.

Acknowledgments

This work was supported by the National Natural Science Foundation of China (Grant Nos. 51822509, 51805064, 51701034), the Qingnian project of science and technology research program of Chongqing Education Commission of China (Grant Nos. KJQN201801137, KJQN201901106), the Basic and Advanced Research Project of Chongqing Science and Technology Commission (Grant Nos. cstc2018jcyjAX0035).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Chen, Q., Hu, L., Li, M. et al. Optimizing Process Parameters of As-Homogenized Mg-Gd-Y-Zn-Zr Alloy in Isothermal Uniaxial Compression on the Basis of Processing Maps via Prasad Criterion and Murty Criterion. J. of Materi Eng and Perform 31, 2257–2266 (2022). https://doi.org/10.1007/s11665-021-06305-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-06305-y