Abstract

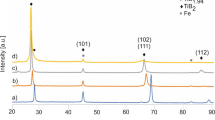

In-situ synthesized TiB2/6061 composites were prepared from Al-K2TiF6-KBF4 by high energy ball milling and stir casting. Phase analysis and microstructure observation of the samples were characterized by XRD, SEM and EDS, respectively. The effect of TiB2 particle content on the microstructure, tensile properties and wear resistance of the composites was studied. The results show that the average size of TiB2 particles is 1 μm, which is polygonal shape. The average grain size of the composites can be refined significantly as the TiB2 particle mass content increased from 1 to 3%; however, the grain coarsening occurs in the 5 wt.% TiB2/6061composites. The 3 wt.% TiB2/6061 composites have best tensile strength, yield strength and Young’s modulus among the composites in ranges of the TiB2 mass fraction from 1 to 5%. Strengthening mechanisms of the TiB2/6061 composites were fine grain strengthening, Orwan strengthening and CTE strengthening, in which the CTE strengthening plays an important role as increasing the TiB2 content. The pin-on-disk wear test results indicated that the average friction coefficient and wear rate of the TiB2/6061 composites increased firstly and then decreased with increasing the TiB2 content from 1 to 5 wt.%. The wear mechanism of the TiB2/6061 composites was discussed.

taken from TiB2/6061 composites

taken from TiB2/6061 composites

Similar content being viewed by others

References

T.K. Ye, Y.X. Xu and J. Ren, Effects of SiC Particle Size on Mechanical Properties of SiC Particle Reinforced Aluminum Metal Matrix Composite, Mat. Sci. Eng. A, 2019, 753, p 146–155.

M. Cabeza, I. Feijoo, P. Merino, G. Pena, M.C. Pérez, S. Cruza and P. Rey, Effect of High Energy Ball Milling on the Morphology, Microstructure and Properties of Nano-Sized TiC Particle-Reinforced 6005A Aluminium Alloy Matrix Composite, Powder. Technol., 2017, 321, p 31–43.

G.Q. Huang, J. Wu, W.T. Hou and Y.F. Shen, Microstructure, Mechanical Properties and Strengthening Mechanism of Titanium Particle Reinforced Aluminum Matrix Composites Produced by Submerged Friction Stir Processing, Mat. Sci. Eng. A, 2018, 734, p 353–363.

R.F. Liu, W.X. Wang, H.S. Chen, M.B. Tan and Y.Y. Zhang, Microstructure Evolution and Mechanical Properties of Micro-/Nano-Bimodal Size B4C Particles Reinforced Aluminum Matrix Composites Prepared by SPS Followed by HER, Vacuum, 2018, 151, p 39–50.

V.G. Arigela, N.R. Palukuri, D. Singh, S.K. Kolli, J. Rengaswamy, P. Chekhonin, J. Scharnweber and W. Skrotzki, Evolution of Microstructure and Mechanical Properties in 2014 and 6063 Similar and Dissimilar Aluminium Alloy Laminates Produced by Accumulative Roll Bonding, J. Alloy. Compd., 2019, 790, p 917–927.

P. Garg, A. Jamwal, D. Kumar, K.K. Sadasivuni, C.M. Hussain and P. Gupta, Advance Research Progresses in Aluminium Matrix Composites: Manufacturing and Applications, J. Mater. Res. Technol., 2019, 8(5), p 4924–4939.

Z.N. Chen, T.M. Wang, Y.P. Zheng, Y.F. Zhao, H.J. Kang and L. Gao, Development of TiB2 Reinforced Aluminum Foundry Alloy Based In Situ Composites – Part I: An Improved Halide Salt Route to Fabricate Al–5 wt.%TiB2 Master Composite, Mat. Sci. Eng. A, 2014, 605, p 301–309.

M. Ao, H.M. Liu and C.F. Dong, The Effect of La2O3 Addition on Intermetallic-Free Aluminium Matrix Composites Reinforced with TiC and Al2O3 Ceramic Particles, Ceram. Int., 2019, 45(9), p 12001–12009.

V. Chak, H. Chattopadhyay and T.L. Dora, A Review on fabrication Methods, Reinforcements and Mechanical Properties of Aluminum Matrix Composites, J. Manuf. Process., 2020, 56, p 1059–1074.

N. Muralidharan, K. Chockalingam, I. Dinaharan and K. Kalaiselvan, MICROSTRUCTURE and Mechanical behavior of AA2024 Aluminum Matrix Composites Reinforced with In Situ Synthesized ZrB2 Particles, J. Alloy. Compd., 2018, 735, p 2167–2174.

S.A. Sajjadi, H.R. Ezatpour and H. Beygi, Microstructure and Mechanical Properties of Al–Al2O3 Micro and Nano Composites Fabricated by Stir Casting, Mat. Sci. Eng. A, 2011, 528(29), p 8765–8771.

P. Samal, P.R. Vundavilli, A. Meher and M.M. Mahapatra, Recent Progress in Aluminum Metal matrix Composites: A Review on Processing, Mechanical and Wear Properties, J. Manuf. Process, 2020, 59, p 131–152.

K. Sinan, Effects of TiB2 Nanoparticle Content on the Microstructure and Mechanical Properties of Aluminum Matrix Nanocomposites, Mater Test, 2017, 59(10), p 844–852.

A.R. Najarian, R. Emadi and M. Hamzeh, Fabrication of as-Cast Al Matrix Composite Reinforced by Al2O3/Al3Ni Hybrid Particles Via in-Situ Reaction and Evaluation of its Mechanical Properties, Mat. Sci. Eng. B, 2018, 231, p 57–65.

Y. Afkham, R.A. Khosroshahi, S. Rahimpour, C. Aavani, D. Brabazon and R.T. Mousavian, Enhanced Mechanical Properties of In Situ Aluminium Matrix Composites Reinforced by Alumina Nanoparticles, Arch. Civ. Mech. Eng., 2018, 18(1), p 215–226.

K.N. Mathan and K.L. Annamalai, Characterization and Tribological analysis on AA 6061 Reinforced with AlN and Zrb2 In Situ Composites, J. Mater. Res. Technol., 2019, 8(1), p 969–980.

C.S. Ramesh, S. Pramod and R. Keshavamurthy, A Study on Microstructure and Mechanical Properties of Al 6061–TiB2 In-Situ Composites, Mat. Sci. Eng. A, 2011, 528(12), p 4125–4132.

Y. Pazhouhanfar and B. Eghbali, Microstructural Characterization and Mechanical Properties of TiB2 Reinforced Al6061 Matrix Composites Produced Using Stir Casting Process, Mat. Sci. Eng. A, 2018, 710, p 172–180.

J. Zhang, D. Zhang, H. Zhu and Z. Xie, In-Situ TiC Reinforced Al-4Cu Matrix Composite: Processing, Microstructure and Mechanical Properties, Mat. Sci. Eng. A, 2020, 794, p 139946.

H. Yang, T. Gao, Y. Wu, H. Zhang, J. Nie and X. Liu, Microstructure and Mechanical Properties at Both Room and High Temperature of In-Situ TiC Reinforced Al–4.5Cu Matrix Nanocomposite, J. Alloy. Compd., 2018, 767, p 606–616.

T. Gao, L. Liu, J. Song, G. Liu and X. Liu, Synthesis and Characterization of an In-Situ Al2O3/Al–Cu Composite with a Heterogeneous Structure, J. Alloy. Compd., 2021, 868, p 159283.

S. Lei, X.F. Li, Y.Q. Deng, Y.K. Xiao, Y.C. Chen and H.W. Wang, Microstructure and Mechanical Properties of Electron Beam Freeform Fabricated TiB2/Al-Cu Composite, Mater. Lett., 2020, 277, p 128273.

X.X. Dong, H. Youssef, Y.J. Zhang, H.L. Yang, S.H. Wang and S.X. Ji, Advanced Heat Treated Die-Cast Aluminium Composites Fabricated by TiB2 Nanoparticle Implantation, Mater. Des., 2019, 186, p 108372.

J. Liu, Z.W. Liu, Z.W. Dong, X.L. Cheng, Q.L. Zheng, J. Li, Z. Sha, Z.F. Huang, Y.M. Gao, J.D. Xing and Q.Y. Han, On the Preparation and Mechanical Properties of In Situ Small-Sized TiB2/Al-4.5Cu Composites Via Ultrasound Assisted RD Method, J. Alloy. Compd., 2018, 765, p 1008–1017.

S. Mozammil, J. Karloopia, R. Verma and P.K. Jha, Effect of Varying TiB2 Reinforcement and its Ageing Behaviour on Tensile and Hardness Properties of In-Situ Al-4.5%Cu-xTiB2 Composite, J. Alloy. Compd., 2019, 793, p 454–466.

F. Chen, Z. Chen, F. Mao, T. Wang and Z. Cao, TiB2 Reinforced Aluminum Based In Situ Composites Fabricated by Stir Casting, Mat. Sci. Eng. A, 2015, 625, p 357–368.

S.L. Zhang, J. Yang, B.R. Zhang, Y.T. Zhao, G. Chen, X.X. Shi and Z.P. Liang, A Novel Fabrication Technology of In Situ TiB2/6063Al Composites: High Energy Ball Milling and Melt In Situ Reaction, J. Alloy. Compd., 2015, 639, p 215–223.

L. Lü, M.O. Lai, Y. Su, H.L. Teo and C.F. Feng, In Situ TiB2 Reinforced Al Alloy Composites, Scripta Mater., 2001, 45(9), p 1017–1023.

K.L. Tee, L. Lu and M.O. Lai, Synthesis of In Situ Al-TiB2 Composites Using Stir Cast Route, Compos. Struct., 1999, 47(1–4), p 589–593.

J.V. Wood, D.G. McCartney, K. Dinsdale, J.L.F. Kellie and P. Davies, Casting and Mechanical Properties of a Reactively Cast Al-TiB2 Alloy, Cast Metal., 1995, 8(1), p 57–64.

J. Yi, G. Wang, S.K. Li, Z.W. Liu and Y.L. Gong, Effect of Post-Weld Heat Treatment on Microstructure and Mechanical Properties of Welded Joints of 6061–T6 Aluminum Alloy, T. Nonferr. Metal. Soc., 2019, 29(10), p 2035–2046.

S. Agrawal, A.K. Ghose and I. Chakrabarty, Effect of Rotary Electromagnetic Stirring During Solidification of In-Situ Al-TiB2 Composites, Mater. Design., 2017, 113, p 195–206.

A. Kumar, R.K. Gautam and R. Tyagi, Dry Sliding Wear characteristics of In Situ Synthesized Al-Tic Composites, Compos. Interface., 2016, 23(6), p 469–480.

Z.Y. Yu, N.Q. Zhao, E.Z. Liu, C.S. Shi, X.W. Du and J. Wang, Low-Temperature Synthesis of Aluminum Borate Nanowhiskers on the Surface of Aluminum Powder Promoted by Ball-Milling Pretreatment, Powder. Technol., 2011, 212(2), p 310–315.

R. Raghu, J. Nampoothiri and T.S. Kumar, In-Situ Generation of MgAl2O4 Particles in Al-Mg Alloy Using H3BO3 Addition for Grain Refinement Under Ultrasonic Treatment, Measurement, 2018, 129, p 389–394.

I.S. Lee, C. Hsu, C.F. Chen, N.J. Ho and P.W. Kao, Particle-Reinforced Aluminum Matrix Composites Produced from Powder Mixtures Via Friction Stir Processing, Compos. Sci. Technol., 2011, 71(5), p 693–698.

T.W. Clyne and P.J. Withers, An Introduction to Metal Matrix Composites, 1st ed. Cambridge University Press, Cambridge, 1993.

S. Jayalakshmi, S. Gupta, S. Sankaranarayanan, S. Sahu and M. Gupta, Structural and Mechanical Properties of Ni60Nb40 Amorphous Alloy Particle Reinforced Al-Based composites Produced by Microwave-Assisted Rapid Sintering, Mat. Sci. Eng. A, 2013, 581, p 119–127.

G. Huang, J. Wu, W. Hou and Y. Shen, Microstructure, Mechanical Properties and Strengthening Mechanism of Titanium Particle Reinforced Aluminum Matrix Composites Produced by Submerged Friction Stir Processing, Mat. Sci. Eng. A, 2018, 734, p 353–363.

B. Bhushan, Introduction to Tribology, 2nd ed. Wiley, Chichester, 2013.

Acknowledgments

This study was funded by National Natural Science Foundation for Youths (CN) (No. 51805235), Scientific Research Foundation of Educational Department of Liaoning Province for Basic Research (CN) (No. LJ2019JL008), Guidance Project of Natural Science Foundation of Liaoning Province (CN) (2019-ZD-0049), Discipline Innovation Team of Liaoning Technical University(LNTU20TD-18)and the PhD Research Startup Fund of Liaoning Technical University (CN) (No. 14-1034).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhuang, W., Yang, H., Yang, W. et al. Microstructure, Tensile Properties, and Wear Resistance of In Situ TiB2/6061 Composites Prepared by High Energy Ball Milling and Stir Casting. J. of Materi Eng and Perform 30, 7730–7740 (2021). https://doi.org/10.1007/s11665-021-05964-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-05964-1