Abstract

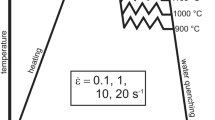

18Ni-2000 MPa maraging steel (M300 grade) is extensively used for performance critical aerospace applications where strength-toughness balance is the basis for material selection. The key to achieve the desired mechanical properties in the final product is to process the material under conditions that will impart an equiaxed, fine grained microstructure. This in turn is controlled by the selected deformation processing conditions such as strain, strain rate and temperature. Therefore, hot deformation behavior of the material is usually studied under wide temperature, and strain rate ranges to map the microstructural evolution with specimens deformed to a given strain. However, the effect of strain on the microstructural evolution, its effect on the initiation and termination of dynamic recrystallization are essential to obtain balanced mechanical properties. In this study, analysis of stress-strain curves was conducted with an intention to obtain fine prior austenite grain (PAG) size through dynamic recrystallization (DRX), and the same was verified experimentally from the microstructures evolved through hot isothermal compression tests on cylindrical specimens subjected to different strains. A single peak type DRX curve was identified for analysis from the high temperature stress-strain curves. The theoretically determined critical strain was used to experimentally verify the initiation of DRX (DRXI) and transition from DRX dominant region to grain growth dominant region (DRXT). Hot isothermal compression tests have been conducted at T=1100°C and ε ̇= 0.1s−1 and obtained PAG size of 7.68 µm in the specimen deformed to theoretically determined optimum strain of 0.6, thereby validating the used models.

Similar content being viewed by others

Data Availability

The raw/processed data required to reproduce these findings cannot be shared at this time as the data also forms part of an ongoing study.

References

R.F. Decker, J.T. Eash and A.J. Goldman, 18% Nickel Martensite Steel, Trans. ASM, 1962, 55, p 58.

S. Floreen, The Physical Metallurgy Maraging Steels, Met. Metall. Trust, 1969, 126, p 115–128.

R. F. Decker, S. Floreen, R. K. Wilson, “Maraging Steels: Recent Developments and Applications,” in Proceedings of the Symposium of TMS Annual Meeting, 1988, no. 25–29, pp. 1–38.

W. Sha, A. Cerezo and G.D.W. Smith, Phase Chemistry and Precipitation Reactions in Maraging Steels: Part IV. Discussion and Conclusions, Metall. Mater. Trans. A, 1993, 24, p 1251–1256.

V.K. Vasudevan, S.J. Kim and C.M. Wayman, Precipitation Reactions and Strengthening Behavior in 18 wtPct Nickel Maraging Steels, Metall. Trans. A, 1990, 21, p 2655–2668.

J.B. Lecomte, C. Servant and G. Cizeron, A Comparison of the Structural Evolution Occurring During Anisothermal or Isothermal Treatments in the Case of Nickel and Manganese Type Maraging Alloys, J. Mater. Sci., 1985, 20, p 3339–3352.

C. Servant and N. Bouzid, Influence of the Increasing Content of Mo on the Precipitation Phenomena Occurring During Tempering in the Maraging Alloy Fe-12Mn-9Co-5Mo, Acta Metall., 1988, 36, p 2771–2778.

S.V.S. Narayana Murty, G.S. Rao, A. Venugopal, P.R. Narayanan, S.C. Sharma and K.M. George, Metallurgical Analysis of Defects in the Weld Joints of Large-Sized Maraging Steel Rocket Motor Casing, MetallogrMicrostruct Anal, 2014, 3, p 433–447.

S.V.S. Narayana Murty, S.K. Manwatkar and P.R. Narayanan, Metallurgical Analysis of a Failed Maraging Steel Shear Screw used in the Band Separation System of a Satellite Launch Vehicle, DefTechnol, 2016, 12, p 380–387.

S.K. Manwatkar, S.V.S. Narayana Murty, P. Ramesh Narayanan, S.C. Sharma and P.V. Venkitakrishnan, Stress Corrosion Cracking of a Maraging Steel Shear Bolt Used in the Interstage Structure of a Satellite Launch Vehicle, Metallogr. Microstruct. Anal., 2016, 5, p 411–420.

K.V.A. Chakravarthi, N.T.B.N. Koundinya, A. Sarkar, S.V.S. Narayana Murty and B.N. Rao, “Optimization of Hot Workability and Control of Microstructure in 18Ni (M250 Grade) Maraging Steel Using Processing Maps, Mater. Perform. Charact., 2018, 7, p 547–561.

K.V.A. Chakravarthi, N. Koundinya, S.V.S.N. Murty, D. Sivakumar and B.N. Rao, Optimization of Hot Workability and Control of Microstructure in CF250 Grade Cobalt-Free Maraging Steel: An Approach Using Processing Maps, Metallogr. Microstruct. Anal., 2018, 7, p 35–47.

K.V.A. Chakravarthi, N.T.B.N. Koundinya, S.V.S. Narayana Murty and B.N. Rao, Microstructure Properties and Hot Workability of M 300 Grade Maraging Steel, Def. Technol., 2017, 14, p 4–11.

K.V.A. Chakravarthi, N.T.B.N. Koundinya, S.V.S. Narayana Murty and B. Nageswara Rao, Microstructural Evolution and Constitutive Relationship of M350 Grade Maraging Steel During Hot Deformation, J. Mater. Eng. Perform., 2017, 26, p 1174–1185.

M.N. Rao and S.V.S. Narayana Murty, Hot Deformation of 18% Ni Maraging Steels: A Review, Mater. Perform. Charact., 2019, 8, p 742–765.

X.-M. Chen, Y.C. Lin, D.-X. Wen, J.-L. Zhang and M. He, Dynamic Recrystallization Behavior of a Typical Nickel-Based SuperalloyDuring Hot Deformation, Mater. Des., 2014, 57, p 568–577.

Y.C. Lin, Wu. Xian-Yang, X.M. Chen, J. Chen, D.X. Wen, J.L. Zhang and L.T. Li, EBSD Study of a Hot Deformed Nickel-Based Superalloy, J. Alloys Comp., 2015, 640, p 101–113.

Y.C. Yi-Wei Xiao, Y.Q.Y. Lin, X.Y. Zhang, G.D. Pang, D. Wang and K.C. Zhou, A Dislocation Density-Based Model and Processing Maps of Ti-55511 Alloy with Bimodal Microstructures During Hot Compression in α+β Region, Mater. Sci. Eng. A, 2020, 790, p 139692.

S.S. Ansari, K.V.A. Chakravarthi, S.V.S. Narayana Murty, B. Nageswara Rao and J. Mukhopadhyay, Hot Workability and Microstructure Control through the Analysis of Stress–Strain Curves During Hot Deformation of M350 Grade Maraging Steel, Mater. Perform. Charact., 2019, 8, p 969–984.

R.K.C. Nkhoma, C.W. Siyasiya and W.E. Stumpf, Hot Workability of AISI 321 and AISI 304 Austenitic Stainless Steels, J. Alloys Compd., 2014, 595, p 103–112.

H. Mirzadeh, Constitutive Modeling and Prediction of hot Deformation Flow Stress Under Dynamic Recrystallization Conditions, Mech. Mater., 2015, 85, p 66–79.

E.S. Puchi-Cabrera, J.D. Guérin, J.G. La Barbera-Sosa, M. Dubar and L. Dubar, Effect of Initial Grain Size on the Mechanical Behaviour of Austenite During Deformation Under Hot-Working Conditions, Mater. Sci. Eng A, 2021, 799, p 139553.

C. Li, L. Huang, M. Zhao, X. Zhang, J. Li and P. Li, Influence of Hot Deformation on Dynamic Recrystallization Behavior of 300M Steel Rules and Modelling, Mater. Sci. Eng., A, 2020, 797(21), p 139925.

Bo. Li, Du. Yong, Z. Chu, W. Zhou and X. Yang, Research on Dynamic Recrystallization Behavior of Ni-Fe-Cr Based Alloy, Mater. Charact., 2020, 169, p 110653.

R. Jarugula, S. Koppoju, R. Jeyaraam, S.G.S. Raman and G. Sundararajan, On the Understanding of Microstructural Evolution During Hot Deformation of n-ODS-18Cr Ferritic Steel Containing Heterogeneous Microstructure, Mater. Sci. Eng. A, 2021, 800(7), p 140343.

H. Abarghouee, H. Arabi, S.H. Seyedein and B. Mirzakhani, Modelling of Hot Flow Behavior of API-X70 Microalloyed Steel by Genetic Algorithm and Comparison with Experiments, Int. J. Press. Vessels Pip., 2021, 189, p 104261.

B. Aashranth, M. ArvinthDavinci, D. Samantaray, U. Borah and S.K. Albert, A New Critical Point on the Stress-Strain Curve Delineation of Dynamic Recrystallization from Grain Growth, Mater. Des., 2017, 116, p 495–503.

E.I. Poliakt and J.J. Jonas, A One-Parameter Approach to Determining the Critical Conditions for the Initiation of Dynamic Recrystallization, Acta Mater., 1996, 44, p 127–136.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ansari, S.S., Mukhopadhyay, J. & Murty, S.V.S.N. Analysis of Stress-Strain Curves to Predict Dynamic Recrystallization During Hot Deformation of M300 Grade Maraging Steel. J. of Materi Eng and Perform 30, 5557–5567 (2021). https://doi.org/10.1007/s11665-021-05780-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-05780-7