Abstract

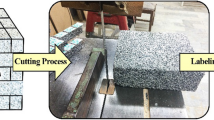

This work deals with the compression energy absorption aspects of an open-cell nickel foam–natural rubber hybrid material. A comprehensive numerical analysis and elaborate experiments were the main tools used in this investigation. Open-cell nickel foam was analyzed as tetrakaidecahedron geometry. Inputs to the geometric dimensions were obtained by subjecting the nickel foam samples to x-ray micro-computed tomography (µCT) technique. A Mooney–Rivlin 2 parameter-based material model was implemented for the rubber part. Analysis was carried out using finite element-based commercial software ANSYS® with explicit dynamics as the chosen analysis scheme. During analysis, symmetry boundary conditions were applied considering each unit cell to be a mirror image of the adjacent cells. Static compression experiments were conducted on fabricated samples for validation of analysis with regard to energy absorption behavior. Scanning electron microscopy examination was carried out on hybrid samples both pre- and post-compression test for better understanding of compression mechanism. The compression energy absorption value of hybrid sample is significantly better than open-cell nickel foam and natural rubber values. The study clearly demonstrates interfacial bonds failure coupled with progressive deformation of foam cell ligaments as the main reasons for enhanced energy absorption during compression loading and presents the results quantitatively as a novel feature. In the end, the paper thoroughly compares the analysis and results in a critical way.

Similar content being viewed by others

References

J.C. Viana, Polymeric Materials for Impact and Energy Dissipation, Plast., Rubber Compos., 2006, 35, p 260–267

L.J. Gibson and M.F. Ashby, Cellular Solids: Structures and Properties, 2nd ed., Cambridge University Press, Cambridge, 1997

T.I. Duarte, M. Vesenjak, L. Krstulović-Opara, and Z. Ren, Crush Performance of Multifunctional Hybrid Foams Based on an Aluminium Alloy Open-Cell Foam Skeleton, Polym. Test., 2018, 67, p 246–256

V. Raju, R. Johnson, and A.K. Khanra, Preparation and Comparative Evolution of Mechanical Behavior of Fe and Fe2O3 Foams and Their Polymer Composites, J. Alloys Compd., 2018, 750, p 71–76

S. Kishimoto and N. Shinya, Development of Metallic Closed Cellular Materials Containing Polymers, Mater. Des., 2000, 21, p 575–578

M. Reinfried, G. Stephani, F. Luthardt, J. Adler, M. John, and A. Krombholz, Hybrid Foams—A New Approach for Multifunctional Applications, Adv. Eng. Mater., 2011, 13(11), p 1031–1036

A. Kunmutta and A. Seksak, Structure and Mechanical Properties of ADC 12 Al Foam-Polymer Interpenetrating Phase Composites with Epoxy Resin or Silicone, Mater. Test., 2018, 60(11), p 1061–1065

S. Yin and N. Rayess, Characterization of Polymer-Metal Foam Hybrids for Use in Vibration Dampening and Isolation, in 8th International Conference on Porous Metals and Metallic Foams, 2014, in Procedia Materials Science, vol 4, p 295–300

N. Dukhan, N. Rayess, and J. Hadley, Characterization of Aluminum Foam–Polypropylene Interpenetrating Phase Composites: Flexural Test Results, Mech. Mater., 2010, 42(2), p 134–141

X.G. Yang, D.L. Duan, X. Zhang, S.L. Jiang, S. Li, and H.C. Zhang, Impact Behavior of Polyetheretherketone/Nickel Foam Co-continuous Composites, 2019, J. Mater. Eng. Perform., 2019, 28, p 6380–6390

A. Chaturvedi, Recent Developments in the Field of Metal Foam-Polymer Hybrid Materials: A Brief Overview, J. Met. Mater. Miner., 2018, 28(1), p 136–140

J.L. Yu, J.R. Li, and S.S. Hu, Strain-Rate Effect and Micro-structural Optimization of Cellular Metals, Mech. Mater., 2006, 38, p 160–170

H.F. Cheng and F.S. Han, Compressive Behavior and Energy Absorbing Characteristic of Open Cell Aluminum Foam Filled with Silicate Rubber, Scr. Mater., 2003, 49, p 583–586

M. Vesenjak, L. Krstulovic-Opara, Z. Ren, A. Ochsner, and Z. Domazet, Experimental Study of Open-Cell Cellular Structures with Elastic Filler Material, Exp. Mech., 2009, 49, p 501–509

Z. Yuan, N. Rayess, and N. Dukhan, Modelling of the Mechanical Properties of a Polymer-Metal Foam Hybrid, Proc. Mater. Sci., 2014, 4, p 215–219

F. Xie, L. Zixing, and Z. Yuan, Numerical Analysis of Elastic and Elastoplastic Behavior of Interpenetrating Phase Composites, Comput. Mater. Sci., 2015, 97, p 94–101

Y. Su, Z. Li, X. Gong, Q. Ouyang, Q. Guo, C. Guo, and J. Zhang, Structural Modeling and Mechanical Behavior of Metal-Porous-Polymer-Composites (MPPCs) with Different Polymer Volume Fractions, Compos. Struct., 2016, 153, p 673–681

A. Khodadadi, G. Liaghat, H. Ahmadi, A. Bahramian, Y. Anani, O. Razmkhah, and S. Asemeni, Numerical and Experimental Study of Impact on Hyperelastic Rubber Panels, Iran. Polym. J., 2019, 28, p 113–122

K. Angamnuaysiri and S. Asavavisithchai, Mechanical Properties of Interpenetrating Phase Composites Using Open-Cell Al Foams with Natural Rubber and Polyethylene, J. Met. Mater. Miner., 2015, 25(2), p 31–35

R. Tobajas, E. Ibartz, and L. Gracia, A Comparative Study of Hyperelastic Constitutive Models to Characterize the Behavior of a Polymer Used in Automotive Engines, in Proceedings of 2nd International Electronic Conference on Materials, MDPI, 2016, p A002

M. Shahzad, A. Kamran, M.Z. Siddiqui, and M. Farhan, Mechanical Characterization and FE Modelling of a Hyperelastic Material, Mater. Res., 2015, 18, p 918–924

W.-Y. Jang and S. Kyriakides, On the Crushing of Aluminum Open-Cell Foams: Part II, Analysis, Int. J. Solids Struct., 2009, 46, p 635–650

C. Perrot, R. Panneton, and X. Olny, Periodic Unit Cell Reconstruction of Porous Media: Application to Open-Cell Aluminum Foams, J. Appl. Phys. Am. Inst. Phys., 2007, 101(11), p 11–113538

J. Gao and N. Rayees, Modeling of the Mechanical Properties of a Polymer-Metal Foam Interpenetrating Phase Composite, in Proceedings of the ASME International Mechanical Engineering Congress and Exposition, Montreal, Canada, 2014

R. Jhaver and H. Tippur, Processing Compression Response and Finite Element Modeling of Syntactic Foam Based Interpenetrating Phase Composite (IPC), Mater. Sci. Eng., A, 2009, 499, p 507–517

S.J. Jerrams and J. Bowen, Modelling the Behaviour of Rubber-Like Materials to Obtain Correlation with Rigidity Modulus Tests, Trans. Model. Simul., 1995, 10, p 511–518

L.A. Wood, Stress–Strain Relation of Pure-Gum Rubber Vulcanizates in Compression and Tension, J. Res. Natl. Bur. Stand., 1958, 60(3), p 193–199

R.P. Merrett, G.S. Langdon, and M.D. Theobald, The Blast and Impact Loading of Aluminum Foam, Mats Des., 2013, 44, p 311–319

A.P.S. Selvadurai and M. Shi, Fluid Pressure Loading of a Hyperelastic Membrane, Int. J. Non-Linear Mech., 2012, 47(2), p 228–239

A. Eriksson and A. Nordmark, Non-unique Response of Mooney–Rivlin Model in Bi-axial Membrane Stress, Comput. Struct., 2014, 144, p 12–22

N. Kumar and V.V. Rao, Hyperelastic Mooney–Rivlin Model: Determination and Physical Interpretation of Material Constants, MIT Int J. Mech. Eng., 2016, 6(1), p 43–46

M.N. Hamza and H.M. Alwan, Hyperelastic Constitutive Modeling of Rubber and Rubber like Materials under Finite Strain, Eng. Technol. J., 2010, 28(13), p 2560–2575

C. Liu, C.M. Cady, M.L. Lovato, and E.B. Orler, Uniaxial Tension of Thin Rubber Liner Sheets and Hyperelastic Model Investigation, J. Mater. Sci., 2015, 50, p 1401–1411

Acknowledgments

Dr. Prabhat Ranjan is acknowledged for contributing toward thought-building process. Mr. Tarun Dewangan, Dr. P. S. Sarkar and Mr. Ashutosh Anand have provided crucial support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chaturvedi, A., Gupta, M.K. & Chaturvedi, S. Open-Cell Nickel Alloy Foam–Natural Rubber Hybrid: Compression Energy Absorption Behavior Analysis and Experiment. J. of Materi Eng and Perform 30, 885–893 (2021). https://doi.org/10.1007/s11665-020-05435-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-020-05435-z