Abstract

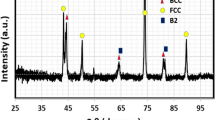

High entropy alloys (HEAs) have a wide spectrum of applications. Many researches investigate Fe-rich high entropy alloy (HEA). However, few authors deal with Cu-rich HEA. Therefore, this research discusses a novel non-equiatomic Cu40Mn25Al20Fe5Co5Ni5 HEA with a superior corrosion resistance, which is made by liquid metallurgy route. The alloy was prepared via casting in an electric resistance furnace under protective atmosphere. The as-cast alloy microstructure was experimentally characterized by optical microscopy, scanning electron microscopy (SEM), energy-dispersive spectroscopy (EDS), mapping of the elemental distribution, and x-ray diffraction (XRD). The corrosion behavior of Cu40Mn25Al20Fe5Co5Ni5 HEA was investigated using the weight-loss method and potentiodynamic polarization tests. The corrosion properties of the alloy were studied in different concentrations of 0.5, 1, 5 and 10% HNO3 acid solutions. The corroded Cu40Mn25Al20Fe5Co5Ni5 HEA samples were examined by SEM, EDS, and mapping of elements distribution. The results were concluded that the novel Cu40Mn25Al20Fe5Co5Ni5 HEA exhibits good corrosion performance when immersed in different concentrations of 0.5, 1, 5 and 10% nitric acid. Finally, alloy item selection and process parameter control are new research topics that hold the promise of future HEAs study.

Similar content being viewed by others

References

I. Florea, G. Buluc, R.M. Florea, V. Soare, and I. Carcea, Study on Corrosion Resistance of High – Entropy Alloy in Medium Acid Liquid and Chemical Properties, IOP Conf. Series: Mater. Sci. Eng., 2015, 95, p 012013

E.P. George, D. Raabe, and R.O. Ritchie, High-Entropy Alloys, Nat. Rev. Mater., 2019, 4(8), p 515–534

W. Cui, X. Zhang, F. Liou, Additive manufacturing of high-entropy alloys–a review. in Solid Freeform Fabrication 2017: Proceedings of the 28th Annual International (2017)

S. Kumar, S. Kumar, V. Singh, J. Kumar, High-Entropy alloys, A Review. Inter. Res. J. Eng. Technol. (IRJET), 2016, 3(9) p 1563–1566

V. Kukshal, A. Patnaik, and I.K. Bhat, Effect of Mn on Corrosion and Thermal Behaviour of AlCr1.5CuFeNi2Mnx High-Entropy Alloys, IOP Conf. Series: Mater. Sci. Eng, 2018, 377, p 012023

J. Li, Y. Huang, X. Meng, and Y. Xie, A Review on High Entropy Alloys Coatings: Fabrication Processes and Property Assessment, Adv. Eng. Mater., 2019, 21, p 1900343

Y. Zhang, T.T. Zuo, Z. Tang, M.C. Gao, K.A. Dahmen, P.K. Liaw, and Z.P. Lu, Microstructures and Properties of High-Entropy Alloys, Prog. Mater Sci., 2014, 61, p 1–93

J.W. Yeh, S.K. Chen, S.J. Lin, J.Y. Gan, T.S. Chin, T.T. Shun, C.H. Tsau, and S.Y. Chang, Nanostructured High-Entropy Alloys with Multiple Principal Elements: Novel Alloy Design Concepts and Outcomes, Adv. Eng. Mater., 2014, 6(5), p 299

J.B. Cheng, X.B. Liang, and B.S. Xu, Effect of Nb Addition on the Structure and Mechanical Behaviors of CoCrCuFeNi High-Entropy Alloy Coatings, Surf. Coat. Technol., 2014, 240, p 184

M.C. Gao and J. Qiao, High-Entropy Alloys (HEAs), Metals, 2018, 8, p 108

Y. Qiu, S. Thomas, M.A. Gibson, H.L. Fraser, and N. Birbilis, Corrosion of High Entropy Alloys, NPJ Mater. Degrad., 2017, 1, p 1–18

Q.-D. Qin, J.-B. Qu, Y. Hu, Y. Wu, and X. Su, Microstructural Characterization and Oxidation Resistance of Multicomponent Equiatomic CoCrCuFeNi–TiO High-Entropy Alloy, Inter. J. Miner. Metall. Mater., 2018, 25(11), p 1286

Y. Shi, B. Yang, and P.K. Liaw, Corrosion-Resistant High-Entropy Alloys: A Review, Metals, 2017, 7, p 43

H. Luo, Z. Li, A.M. Mingers, and D. Raable, Corrosion behavior of an equiatomic CoCrFeMnNi high-entropy alloy compared with 304 stainless steel in sulfuric acid solution, Corros. Sci., 2018, 134(15), p 131–139

X. Zhang, J. Guo, X. Zhang, Y. Song, Z. Li, X. Xing, and D. Kong, Influence of Remelting and Annealing Treatment on Corrosion Resistance of AlFeNiCoCuCr High Entropy Alloy in 3.5% NaCl Solution, J. Alloys Compd., 2019, 775, p 565–570

K.K. Alanemea, M.O. Bodunrina, and S.R. Okea, Processing, Alloy Composition and Phase Transition Effect on the Mechanical and Corrosion Properties of High Entropy Alloys: a Review, J. Mater. Res. Technol., 2016, 5(4), p 384–393

S.J. Mary, N. Rajan, S. Rajendran, and R. Epshipha, HEAs and Corrosion Resistance-a Bird’s Eye View, Eur. Chem. Bull, 2014, 3, p 1031–1035

Y.L. Chou, Y.C. Wang, J.W. Yeh, and H.C. Shih, Pitting corrosion of the high-entropy alloy Co1.5CrFeNi1.5Ti0.5Mo0.1 in chloride-containing sulphate solutions, Corris. Sci., 2010, 52, p 3481–3491

C.P. Lee, C.C. Chang, Y.Y. Chen, J.W. Yeh, and H.C. Shih, Effect of the Aluminium Content of AlxCrFe1.5MnNi0.5 High-Entropy Alloys on the Corrosion Behaviour in Aqueous Environments, Corros. Sci., 2008, 50(7), p 2053–2060

K.A. Abdelghafar, M.M. Ibrahim, M.A. Shoeib, and M.A. Waly, Evaluation of Microstructural and Corrosion Resistance of as-cast Cu45Mn25Al15Fe5Cr5Ni5 HEA, Mater. Res. Express, 2020, 7, p 016579

Xing-Wu Qiu and Chun-Ge Liu, Microstructure and Properties of Al2CrFeCoCuTiNix High-Entropy Alloys Prepared by Laser Cladding, J. Alloys Compd, 2013, 553, p 216–220

O.R.M. Khalifa, A.K. Kassab, H.A. Mohamed, and S.Y. Ahmed, Corrosion inhibition of copper and copper alloy in 3M nitric acid solution using organic inhibitors, J. Am. Sci., 2010, 6(8), p 487

R.H. Taha, G.H.A. Gaber, L.Z. Mohamed, and W.A. Ghanem, Corrosion inhibition of two Schiff base complexes on the mild steel in 1 M HCl in solution, Egypt. J. Chem., 2019, 62(Special Issue (Part 1)), p 367–381

G.H.A. Gaber, H.A. Aly, and L.Z. Mohamed, Effect of Sodium Tungstate on the Corrosion Behavior of Fe-Base Alloy in H2SO4 Solution, Int. J. Electrochem. Sci., 2020, 15(8), p 8229–8240

W.A. Ghanem, I.M. Ghayad, and G.H.A. Gaber, Corrosion Behavior of Reinforcing Steel in Cement Partially Replaced with Metakaolin in 3.5% NaCl and 5% MgSO4 Solution, Inter. J. Metall. Mater Sci. Eng. (IJMMSE), 2013, 3(5), p 1–8

W. Tu, Y. Cheng, T. Zhan, J. Han, and Ch Yingliang, Influence of Sodium Tungstate and Sealing Treatment on Corrosion Resistance of Coatings Formed on AZ31 Magnesium Alloy by Plasma Electrolytic Oxidation, Int. J. Electrochem. Sci., 2017, 12, p 10863–10881

B. Ren, Z.X. Liu, B. Cai, M.X. Wang, and L. Shi, Aging Behavior of a CuCr2Fe2NiMn High-Entropy Alloy, Mater. Des., 2012, 33, p 121–126

B. Ren, Z.X. Liu, D.M. Li, L. Shi, B. Cai, and M.X. Wang, Effect of Elemental Interaction on Microstructure of CuCrFeNiMn HEA System, J. Alloys Compd., 2010, 49, p 3148–3153

Y.K. Kim et al., Correlation Between Mechanical Properties and Thermodynamic Parameters of Dual-fcc-Phase CoCrFeCuxNi (x = 1, 1.71) and CoCu1. 71FeMnNi, Mater. Lett., 2020, 272, p 127866

A. Takeuchi and A. Inoue, Classification of Bulk Metallic Glasses by Atomic Size Difference, Heat of Mixing and Period of Constituent Elements and Its Application to Characterization of the Main Alloying Element, Mater. Trans., 2005, 46, p 2817–2829

S.G. Ma, J.W. Qiao, Z.H. Wang, H.J. Yang, and Y. Zhang, Microstructural Features and Tensile Behaviors of the Al0.5CrCuFeNi2 High-Entropy Alloys by Cold Rolling and Subsequent Annealing, Mater. Des., 2015, 88, p 1057–1062

O.H.S. Min and I.S. Hong, Microstructural Evolution and Mechanical Properties in a Mn1.05Fe1.05CoNiCu0.9 high entropy alloy, Key Eng. Mater., 2017, 737, p 44–49

A. Manzoni, H. Daoud, S. Mondal, S. van Smaalen, R. Völk, U. Glatze, and N. Wanderka, Investigation of Phases in Al23Co15Cr23Cu8Fe15Ni16 and Al8Co17Cr17Cu8Fe17Ni33 High Entropy Alloys and Comparison with Equilibrium Phases Predicted by Thermo-Calc, J. Alloys Compd, 2013, 552, p 430–436

A.D. Usman, A.F. Victoria, and L.N. Okoro, Weight Loss Corrosion Study of Some Metals in Acid Medium, J. Advan. Chemis., 2015, 11(2), p 3435–3440

W.A. Hussein, A.S.I. Ahmed, W.A. Ghanem, and GhA Gaber, Studies of Corrosion and Electrochemical Behavior of Cu-Zn Alloys in H2SO4 and HNO3 Acid Solutions, J. Metall. Eng. (ME), 2016, 5, p 27–37

M.M. Al-Abdallah, A.K. Maayta, M.A. Al-Qudah, and N.A.F. Al-Rawashdeh, Corrosion Behavior of Copper in Chloride Media, Open Corros. J., 2009, 2, p 71–76

M. Pourbaix, Atlas of Electrochemical Equilibria in Aqueous Solutions, NACE Int. Cebelcor, USA, 1974, p 384–392

J.C. Scully, The Fundamentals of Corrosion, 3rd ed., Pergamon Press, Oxford, 1990, p 75

M.B. Mahida, H.G. Chaudhari, and M.H. Metawal, Inhibitory Effect of Some Dyes on 60/40 Brass in Nitric Acid, Der Pharma Chem., 2013, 5(2), p 216–223

W.A. Ghanem, A.S.I. Ahmed, W.A. Hussein, and GhA Gaber, Electrochemical Behavior and Effect of Temperature on Dezincification of Cu-Zn Alloys in Brine Solution, Inter. J. Metall. Mater. Sci. Eng. (IJMMSE), 2016, 6(4), p 1–16

C.A. Loto and R.T. Loto, Corrosion Resistance Behaviour of Duplex (α β) Brass in Nitric Acid Concentrations, Int. J. Electrochem. Sci., 2012, 7, p 12021–12033

S. Yunzhu, B. Yang, and P.K. Liaw, Corrosion-Resistant High-Entropy Alloys: a Review, Metals, 2017, 7(2), p 43

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Aly, H.A., Abdelghafar, K.A., Gaber, G.A. et al. Fabrication, Characterization, and Corrosion Behavior of a New Cu40Mn25Al20Fe5Co5Ni5 High-Entropy Alloy in HNO3 Solution. J. of Materi Eng and Perform 30, 1430–1443 (2021). https://doi.org/10.1007/s11665-020-05390-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-020-05390-9