Abstract

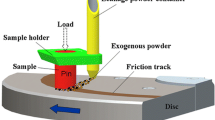

Niobium is a material widely used for particle accelerating facilities, such as cavities. These components are usually obtained through forming processes, and then to understand the friction behavior of niobium sheets during the forming process can be very useful. Therefore, in this work the friction behavior of niobium sheets under conditions similar to the ones faced in forming processes has been studied. Pin-on-disk tests have been carried out in both dry and lubricated conditions, and different values of contact force in the range of 2.5 and 20 N have been adopted to observe and understand the tribological behavior of niobium. The worn surfaces have been observed through a scanning electron microscope and EDX analyses to reveal the wear mechanisms. The experimental outcomes proved that niobium exhibits very high friction coefficient with a severe adhesive wear under dry condition, while a lower friction coefficient with a less severe wear mechanism has been observed when lubricant is adopted.

Similar content being viewed by others

References

J.H. Lim and J. Choi, Synthesis of Niobium Oxide Nanopowders by Field-Crystallization-Assisted Anodization, Curr. Appl. Phys. Curr. Appl. Phys., 2012, 12, p 155–159

S. Yang, H. Habazaki, T. Fujii, Y. Aoki, P. Skeldon, and G. Thompson, Control of Morphology and Surface Wettability of Anodic Niobium Oxide Microcones Formed in Hot Phosphate-Glycerol Electrolytes, Electrochim. Acta Electrochim. Acta, 2011, 56, p 7446–7453

T. Arunnellaiappan, S. Arun, S. Hariprasad, S. Gowtham, B. Ravisankar, and N. Rameshbabu, Fabrication of Corrosion Resistant Hydrophobic Ceramic Nanocomposite Coatings on PEO Treated AA7075, Ceram. Int., 2018, 44(1), p 874–884. https://doi.org/10.1016/j.ceramint.2017.10.014

D. Quintero, M.A. Gómez, W.S. Araujo, F. Echeverría, and J.A. Calderón, Influence of the Electrical Parameters of the Anodizing PEO Process on Wear and Corrosion Resistance of Niobium, Surf. Coat. Technol., 2019, 380, p 125067. https://doi.org/10.1016/j.surfcoat.2019.125067

T. Padamsee, H. Knobloch, and J. Hays, RF Superconductivity for Accelerators, 2nd ed., Wiley, New York, 2008

A. Chandra, M. Sumption, and G. Frankel, On the Mechanism of Niobium Electropolishing, J. Electrochem. Soc., 2012, 159, p C485–C491

K. Win, M. Sumption, and G. Frankel, Smoothening of Niobium by Electropolishing, J. Appl. Electrochem., 2013, 43, p 829

M. Olsson, H. Persson, V. Bushlya, and J.-E. Ståhl, Surface Roughness and Sub-Surface Deformation Measurements in Machining of Niobium, Proc. CIRP, 2018, 71, p 413–417

G. Myneni, Review of Ingot Niobium as a Material for Superconducting Radio Frequency Accelerating Cavities, Nucl. Instrum. Methods Phys. Res. A, 2015, 774, p 133–150

H.R.Z. Sandim, H.H. Bernardi, B. Verlinden, and D. Raabe, Equal Channel Angular Extrusion of Niobium Single Crystals, Mater. Sci. Eng. A, 2007, 467(1), p 44–52. https://doi.org/10.1016/j.msea.2007.02.086

L. Zhu, M. Seefeldt, and B. Verlinden, Three Nb Single Crystals Processed by Equal-Channel Angular Pressing—Part I: Dislocation Substructure, Acta Mater., 2013, 61(12), p 4490–4503. https://doi.org/10.1016/j.actamat.2013.04.018

L. Zhu, M. Seefeldt, and B. Verlinden, Three Nb Single Crystals Processed by Equal-Channel Angular Pressing—Part II: Mesoscopic Bands, Acta Mater., 2013, 61(12), p 4504–4511. https://doi.org/10.1016/j.actamat.2013.04.019

Z. Pan, F. Xu, S.N. Mathaudhu, L.J. Kecskes, W.H. Yin, X.Y. Zhang, K.T. Hartwig, and Q. Wei, Microstructural Evolution and Mechanical Properties of Niobium Processed by Equal Channel Angular Extrusion up to 24 Passes, Acta Mater., 2012, 60(5), p 2310–2323. https://doi.org/10.1016/j.actamat.2011.12.019

Q. Wei, T. Jiao, S.N. Mathaudhu, E. Ma, K.T. Hartwig, and K.T. Ramesh, Microstructure and Mechanical Properties of Tantalum after Equal Channel Angular Extrusion (ECAE), Mater. Sci. Eng. A, 2003, 358(1), p 266–272. https://doi.org/10.1016/S0921-5093(03)00305-8

Y. Wang, S. Goel, J.L. Sun, Y.M. Zhu, H. Yuan, and J.T. Wang, The Effect of Temperature on Activation Volume of Ultrafine Grained Tantalum, Int. J. Refract. Met. Hard Mater., 2017, 71, p 232–238

Y.R. Kolobov, B. Kieback, K.V. Ivanov, T. Weissgaerber, N.V. Girsova, Y.I. Pochivalov, G.P. Grabovetskaya, M.B. Ivanov, V.U. Kazyhanov, and I.V. Alexandrov, The Structure and Microhardness Evolution in Submicrocrystalline Molybdenum Processed by Severe Plastic Deformation Followed by Annealing, Int. J. Refract. Met. Hard Mater., 2003, 21(1), p 69–73. https://doi.org/10.1016/S0263-4368(03)00002-7

Kneisel P. et al., in AIP Conference Proceedings. Proceedings of the International Niobium Workshop on Single Crystal-Large Grain Niobium Technology (Araxá, Brazil, 2006), p. 84

A. Ermakov, I. Jelezov, X. Singer, W. Singer, G.B. Viswanathan, V. Levit, H.L. Fraser, H. Wen, and M. Spiwek, Physical Properties and Structure of Large Grain/Single Crystal Niobium for Superconducting RF Cavities, J. Phys. Conf. Ser., 2008, 97, p 1

N.W. Khun, G.S. Frankel, and M. Sumption, Effects of Normal Load, Sliding Speed, and Surface Roughness on Tribological Properties of Niobium under Dry and Wet Conditions, Tribol. Trans., 2014, 57(5), p 944–954. https://doi.org/10.1080/10402004.2014.927546

W. Singer, A. Brinkmann, D. Proch, and X. Singer, Quality Requirements and Control of High Purity Niobium for Superconducting RF Cavities, Phys. C Supercond., 2003, 386, p 379–384

F. Furuta, K. Saito, and T. Konomi, in IPAC 2010—1st International Part. Accelerator Conference. High Field Q-Slope Problem in End Group Cavities (2010), p. 3347–3349

T. Kubo, Y. Ajima, H. Inoue, K. Umemori, Y. Watanabe, and M. Yamanaka, in In-House Production of a Large-Grain Single-Cell Cavity at Cavity Fabrication Facility and Results of Performance Tests (2014), p. 2519–2521.

T.M. Wang, X.J. Wang, W.J. Wang, and J. Shi, Tribological Study of Nitrogen Implanted Niobium, Wear, 1996, 196(1), p 197–201. https://doi.org/10.1016/0043-1648(95)06905-4

S.F. Brunatto, A.N. Allenstein, C.L.M. Allenstein, and A.J.A. Buschinelli, Cavitation Erosion Behaviour of Niobium, Wear, 2012, 274–275, p 220–228. https://doi.org/10.1016/j.wear.2011.09.001

P.J. Blau, Friction Science and Technology, ed by Marcel Dekker (New York, 1996).

S.M. Mahdavian, Y.W. Mai, and B. Cotterel, Friction, Metallic Transfer and Debris Analysis of Sliding Surfaces, Wear, 1982, 82(2), p 221–232. https://doi.org/10.1016/0043-1648(82)90294-0

M. Clerico and V. Patierno, Sliding Wear of Polymeric Composites, Wear, 1979, 53(2), p 279–301. https://doi.org/10.1016/0043-1648(79)90083-8

A.A. Carvalho, S. Barrière, J. Brachet, B. Bulat, R. Calaga, E. Cano-Pleite, O. Capatina, T. Capelli, A. Dallocchio, M. Garlaschè, L. Giordanino, R. Leuxe, M. Narduzzi, and L. Prever-Loiri, Advanced Design of Tooling for Sheet-Metal Forming through Numerical Simulations in the Scope of SRF Crab Cavities at CERN (2019), p. 100008. https://doi.org/10.1063/1.5112641

V. Palmieri, F. Stivanello, S.Y. Stark, I. Lnl, L. Padua, C. Roncolato, and M. Valentino, in 10th Working RF Superconducors. Besides the Standard Niobium Bath Chemical Polishing (2001), p. 408–412

ISO 42871997-Geometrical Product Specifications (GPS)—Surface Texture Profile Method-Terms, Definitions and Surface Texture Parameters n.d.

M. Durante, L. Boccarusso, C. Velotti, A. Astarita, A. Squillace, and L. Carrino, Characterization of Ti-6Al-4V Tribopairs: Effect of Thermal Oxidation Treatment, J. Mater. Eng. Perform., 2017, 26(2), p 571–583. https://doi.org/10.1007/s11665-016-2477-6

T.R. Bieler, N.T. Wright, F. Pourboghrat, C. Compton, K.T. Hartwig, D. Baars, A. Zamiri, S. Chandrasekaran, P. Darbandi, H. Jiang, E. Skoug, S. Balachandran, G.E. Ice, and W. Liu, Physical and Mechanical Metallurgy of High Purity Nb for Accelerator Cavities, Phys. Rev. ST Accel. Beams, 2010, 13(3), p 31002. https://doi.org/10.1103/physrevstab.13.031002

E.K. Ampaw, E.K. Arthur, A.Y. Badmos, J.D. Obayemi, O.O. Adewoye, A.R. Adetunji, S.O.O. Olusunle, and W.O. Soboyejo, Sliding Wear Characteristics of Pack Cyanided Ductile Iron, J. Mater. Eng. Perform., 2019, 28(12), p 7227–7240. https://doi.org/10.1007/s11665-019-04471-8

N.W. Khun and E. Liu, Tribological Behavior of Polyurethane Immersed in Acidic Solution, Tribol. Trans., 2012, 55(4), p 401–408. https://doi.org/10.1080/10402004.2012.656881

N.W. Khun, H. Zhang, J.L. Yang, and E. Liu, Tribological Performance of Silicone Composite Coatings Filled with Wax-Containing Microcapsules, Wear, 2012, 296(1), p 575–582. https://doi.org/10.1016/j.wear.2012.07.029

N.W. Khun, H. Zhang, J. Yang, and E. Liu, Mechanical and Tribological Properties of Epoxy Matrix Composites Modified with Microencapsulated Mixture of Wax Lubricant and Multi-Walled Carbon Nanotubes, Friction, 2013, 1(4), p 341–349

F. Svahn, Å. Kassman-Rudolphi, and E. Wallén, The Influence of Surface Roughness on Friction and Wear of Machine Element Coatings, Wear, 2003, 254(11), p 1092–1098. https://doi.org/10.1016/S0043-1648(03)00341-7

P.L. Menezes, S. Kishore, and V. Kailas, Influence of Surface Texture and Roughness Parameters on Friction and Transfer Layer Formation during Sliding of Aluminium Pin on Steel Plate, Wear, 2009, 267(9), p 1534–1549. https://doi.org/10.1016/j.wear.2009.06.003

T.S. Barrett, G.W. Stachowiak, and A.W. Batchelor, Effect of Roughness and Sliding Speed on the Wear and Friction of Ultra-High Molecular Weight Polyethylene, Wear, 1992, 153(2), p 331–350. https://doi.org/10.1016/0043-1648(92)90174-7

E. Ceretti, A. Fiorentino, and C. Giardini, Process Parameters Influence on Friction Coefficient in Sheet Forming Operations, Int. J. Mater. Form., 2008, 1, p 1219–1222

T. Kasai, X.Y. Fu, D.A. Rigney, and A.L. Zharin, Applications of a Non-Contacting Kelvin Probe during Sliding, Wear, 1999, 225–229, p 1186–1204. https://doi.org/10.1016/S0043-1648(99)00057-5

L. Vitos, K. Larsson, B. Johansson, M. Hanson, and S. Hogmark, An Atomistic Approach to the Initiation Mechanism of Galling, Comput. Mater. Sci., 2006, 37, p 193–197

U. Wiklund and I.M. Hutchings, Investigation of Surface Treatments for Galling Protection of Titanium Alloys, Wear, 2001, 250, p 1034–1041

J.N. Anno, J.A. Walowit, and C.M. Allen, Microasperity Lubrication, J. Lubr. Technol., 1968, 90(2), p 351–355. https://doi.org/10.1115/1.3601568

Acknowledgments

The authors want to acknowledge the CERN HL-LHC Work Package 4, under which framework this experimental campaign has been enabled (https://hilumilhc.web.cern.ch/wp/wp4-crab-cavities-rf). The authors want also to acknowledge the Agreement KN3012/GEN between CERN and University of Naples “Federico II”.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Silvestri, A.T., Astarita, A., Boccarusso, L. et al. Understanding the Friction Behavior of Niobium Sheets during Forming Processes. J. of Materi Eng and Perform 29, 3055–3066 (2020). https://doi.org/10.1007/s11665-020-04868-w

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-020-04868-w