Abstract

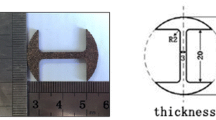

Diamond particles reinforced boron-alloyed Cu matrix (Cu-xB/diamond, x = 0.1, 0.2, 0.3, 0.4, 0.5, and 1.0 wt.%) composites were prepared by gas pressure infiltration. The size of the diamond particles was ~ 230 μm and the diamond volume fraction in the composites was ~ 66%. The interfacial carbide evolution plays an important role in improving the interfacial bonding and enhancing the mechanical properties of the Cu-B/diamond composites. The tensile, compressive and bending strengths firstly increase and then decrease with increasing boron content, giving a maximum tensile strength of 204 MPa, a maximum compressive strength of 608 MPa, and a maximum bending strength of 513 MPa at 0.5 wt.% B addition. The monotonic uniaxial tensile stress–strain curves of the Cu-B/diamond composites were predicted by using the Mori–Tanaka, generalized self-consistent, and Torquato identical hard spheres approximation models. The results suggest that alloying B to Cu matrix is an effective route to strengthening Cu/diamond composites.

Similar content being viewed by others

References

C. Zweben, Advances in Composite Materials for Thermal Management in Electronic Packaging, JOM, 1998, 50, p 47–51

K. Ueda, K. Kawamoto, and H. Asano, High-Temperature and High-Voltage Characteristics of Cu/Diamond Schottky Diodes, Diam. Relat. Mater., 2015, 57, p 28–31

H. Hu and J. Kong, Improved Thermal Performance of Diamond-Copper Composites with Boron Carbide Coating, J. Mater. Eng. Perform., 2014, 23, p 651–657

C. Zhao and J. Wang, Enhanced Mechanical Properties in Diamond/Cu Composites with Chromium Carbide Coating for Structural Applications, Mater. Sci. Eng., A, 2013, 588, p 221–227

T. Sadowski and P. Golewski, Heat Transfer in Composites Subjected to Temperature Variations, Solid State Phenom., 2014, 216, p 140–145

P. Sadowski, K. Kowalczyk-Gajewska, and S. Stupkiewicz, Classical Estimates of the Effective Thermoelastic Properties of Copper-Graphene Composites, Compos. Part B-Eng., 2015, 80, p 278–290

E. Linul, L. Marsavina, P.A. Linul, and J. Kovacik, Cryogenic and High Temperature Compressive Properties of Metal Foam Matrix Composites, Compos. Struct., 2019, 209, p 490–498

L. Marsavina, T. Sadowski, and N. Faur, Numerical Investigation of the Stress Field Near a Crack Normal to Ceramic-Metal Interface, J. Mech. Sci. Technol., 2011, 25, p 309–315

Y. Watanabe, T. Sugiura, H. Sato, and H. Tsuge, Fabrication of Al-Based Composites by Centrifugal Mixed-Powder Method and Their Application for Grinding Wheels, J. Mater. Eng. Perform., 2019, 28, p 3852–3863

H.L. Zhang, J.H. Wu, Y. Zhang, J.W. Li, and X.T. Wang, Effect of Metal Matrix Alloying on Mechanical Strength of Diamond Particle Reinforced Aluminum Composites, J. Mater. Eng. Perform., 2015, 24, p 2556–2562

D.J. Weidner, Y. Wang, and M.T. Vaughan, Strength of Diamond, Science, 1994, 266, p 419–422

V. Sinha and J.E. Spowart, Influence of Interfacial Carbide Layer Characteristics on Thermal Properties of Copper-Diamond Composites, J. Mater. Sci., 2013, 48, p 1330–1341

A.M. Abyzov, F.M. Shakhov, A.I. Averkin, and V.I. Nikolaev, Mechanical Properties of a Diamond-Copper Composite with High Thermal Conductivity, Mater. Des., 2015, 87, p 527–539

G.T. Hohensee, R.B. Wilson, and D.G. Cahill, Thermal Conductance of Metal-Diamond Interfaces at High Pressure, Nat. Commun., 2015, 6, p 6578

J.H. Wu, H.L. Zhang, Y. Zhang, J.W. Li, and X.T. Wang, Enhanced Mechanical Properties in Al/Diamond Composites by Si Addition, Rare Met., 2016, 35, p 701–704

K. Mizuuchi, K. Inoue, Y. Agari, M. Tanaka, T. Takeuchi, J. Tani, M. Kawahara, Y. Makino, and M. Ito, Effect of Boron Addition on the Thermal Properties of Diamond-Particle-Dispersed Cu-Matrix Composites Fabricated by SPS, J. Mater. Sci. Chem. Eng., 2016, 4, p 1–16

Y.H. Sun, L.K. He, C. Zhang, Q.N. Meng, B.C. Liu, K. Gao, M. Wen, and W.T. Zheng, Enhanced Tensile Strength and Thermal Conductivity in Copper Diamond Composites with B4C Coating, Sci. Rep., 2017, 7, p 10727

H.L. Zhang, Y.X. Qi, J.W. Li, J.G. Wang, and X.T. Wang, Effect of Zr Content on Mechanical Properties of Diamond/Cu-Zr Composites Produced by Gas Pressure Infiltration, J. Mater. Eng. Perform., 2018, 27, p 714–720

G.Z. Bai, L.H. Wang, Y.J. Zhang, X.T. Wang, J.G. Wang, M.J. Kim, and H.L. Zhang, Tailoring Interface Structure and Enhancing Thermal Conductivity of Cu/Diamond Composites by Alloying Boron to the Cu Matrix, Mater. Charact., 2019, 152, p 265–275

Z.P. Fang, The interfacial defects of Al/diamond composites produced by gas pressure infiltration, Master Thesis (University of Science and Technology Beijing, 2017)

X.Y. Tao, L.X. Dong, X.N. Wang, W.K. Zhang, B.J. Nelson, and X.D. Li, B4C-Nanowires/Carbon-Microfiber Hybrid Structures and Composites from Cotton T-Shirts, Adv. Mater., 2010, 22, p 2055–2059

K.A. Weidenmann, R. Tavangar, and L. Weber, Mechanical Behaviour of Diamond Reinforced Metals, Mater. Sci. Eng., A, 2009, 523, p 226–234

B.A. Mcwilliams, K.T. Ramesh, and C.F. Yen, Probabilistic Response of Heterogeneous Particle Reinforced Metal Matrix Composites with Particle Size Dependent Strengthening, Comput. Mater. Sci., 2013, 79, p 15–24

S. Panda, A study on deformation behavior of Cu-Al2O3 metal matrix composite with the variation of size and volume fraction of reinforcement particle, Master Thesis (National Institute of Technology, Rourkela, 2012)

H.O. Pierson, Handbook of Refractory Carbides and Nitrides: Properties, Characteristics, Processing and Applications, Noyes Publications, Westwood, 1996

T.S. Chow, Tensile Strength of Filled Polymers, J. Polym. Sci. Polym. Phys. Ed., 1982, 20, p 2103–2109

Q.Y. Wang, W.P. Shen, and M.L. Ma, Mean and Instantaneous Thermal Expansion of Uncoated and Ti Coated Diamond/Copper Composite Materials, Adv. Mater. Res., 2013, 702, p 202–206

W.H. Cubberly, Properties and Selection: Non-ferrous Alloys and Pure Metals, Metals Handbook, 9th ed., American Society for Metals, Metals Park, 1979

R. Mueller and A. Mortensen, Simplified Prediction of the Monotonic Uniaxial Stress-Strain Curve of Non-linear Particulate Composites, Acta Mater., 2006, 54, p 2145–2155

M. Kouzeli, L. Weber, C. San Marchi, and A. Mortensen, Quantification of Microdamage Phenomena During Tensile Straining of High Volume Fraction Particle Reinforced Aluminium, Acta Mater., 2001, 49, p 497–505

T. Mori and K. Tanaka, Average Stress in Matrix and Average Elastic Energy of Materials with Misfitting Inclusions, Acta Metall., 1973, 211, p 571–574

G.J. Weng, The Theoretical Connection Between Mori-Tanaka’s Theory and the Hashin-Shtrikman-Walpole Bounds, Int. J. Eng. Sci., 1990, 28, p 1111–1120

R.M. Christensen and K.H. Lo, Solutions for Effective Shear Properties in Three Phase Sphere and Cylinder Models, J. Mech. Phys. Solids, 1979, 27, p 315–330

R.M. Christensen, Erratum, J. Mech. Phys. Solids, 1986, 34, p 639

R.M. Christensen, A Critical Evaluation for a Class of Micro-mechanics Models, J. Mech. Phys. Solids, 1990, 38, p 379–404

S. Torquato, Effective Stiffness Tensor of Composite Media: II. Applications to Isotropic Dispersions, J. Mech. Phys. Solids, 1998, 46, p 1411–1440

S. Torquato, Random Heterogeneous Materials: Microstructure and Macroscopic Properties, Interdisciplinary Applied Mathematics, Springer, New York, 2005

J.R. Davis, Copper and Copper Alloys, ASM International, Cleveland, 2001

Acknowledgment

This work is financially supported by the National Key Research and Development Program of China (No. 2016YFB0402102), the National Natural Science Foundation of China (No. 51571015), and the Superior Discipline Talent Team Support Plan in Universities of Shandong Province, China.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Bai, G., Zhang, Y., Dai, J. et al. Mechanical Properties of Cu-B/Diamond Composites Prepared by Gas Pressure Infiltration. J. of Materi Eng and Perform 29, 3107–3119 (2020). https://doi.org/10.1007/s11665-020-04790-1

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-020-04790-1